Portable Electric Hoist with Remote Control / Pendant Control

Portable electric hoists for sale 0.3 ton to 50 ton. Custom portable electric chain hoists with remote control or pendant control for your needs, 3 t, 5 t, 10t, 20 t, 30 t, up to 50 ton.

Category: Light Crane & Portable Crane

Your Trusted Portable Crane and Hoist Manufacturer & Supplier

Portable Electric Chain Hoists & Portable Electric Hoist for Sale

Portable Electric Hoists with Remote Control or Pendant Control for Your Needs

Portable electric hoists for sale 0.3 ton to 50 ton. Custom portable electric chain hoists with remote control or pendant control for your needs, 3 t, 5 t, 10t, 20 t, 30 t, up to 50 ton.

Unveiling the Power and Versatility of Portable Electric Hoists: A Comprehensive Guide

In the world of lifting and material handling, portable electric hoists stand as versatile and indispensable tools. These devices, powered by electricity, exhibit a remarkable blend of power, precision, and adaptability, transforming lifting operations across various industries.

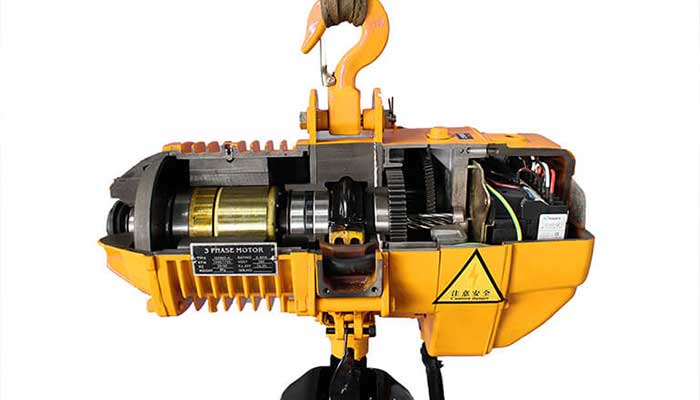

Portable electric hoists, ingeniously engineered lifting devices, operate through the sheer power of electricity. Employing electric motors, these hoists enable seamless vertical lifting and lowering of heavy loads. Their functionality revolves around a straightforward yet sophisticated design, incorporating mechanisms for controlled lifting operations. Equipped with hooks or suspension points, these hoists easily attach to overhead support structures, offering a secure and stable lifting solution.

The marriage of electric power and portability in these hoists presents a multitude of advantages. The electric motor-driven mechanism ensures consistent and controlled lifting, allowing for precise positioning of loads with minimal effort. Additionally, the portability factor grants the freedom to transport and set up these hoists swiftly, providing flexible solutions for lifting operations in various locations. This feature proves invaluable in scenarios where mobility and adaptability are essential.

The ability to swiftly and securely attach these hoists to diverse support structures further underscores their versatility. From steel beams to trolleys or other mounting points, the adaptability of portable electric hoists facilitates seamless integration into different work environments.

Portable electric hoists serve as reliable companions across numerous industries, offering not only the power of electricity for lifting but also the freedom of mobility. Their functionality, precision, and adaptability make them indispensable assets in streamlining lifting operations and optimizing efficiency in diverse work settings.

Types of Portable Electric Hoists

Portable electric hoists come in various types based on different criteria. Some main types include:

Mounting Configuration-based Types:

Hook Mount Portable Electric Hoists:

Features:

Hook Mounting: Equipped with a hook suspension system for easy attachment to various support structures, such as beams, frames, or other overhead fixtures.

Versatile Attachment: The hook mount design offers flexibility in installation and allows for quick setup and use in different locations.

Adjustable Hook Position: Some models may come with adjustable hook positions, allowing users to set the hook at different heights for lifting.

Benefits:

Ease of Installation: Quick and straightforward attachment to existing support structures without the need for specialized mounting or installation.

Versatility: Can be easily moved and used in different areas or workstations that have compatible support structures.

Adaptability: Suitable for lifting tasks where the hoist needs to be positioned at variable heights or where mobility is essential.

Typical Applications:

Construction Sites: Used for lifting materials, equipment, or tools in construction projects.

Warehouses: Suitable for loading/unloading goods or moving materials within warehouse spaces.

Maintenance Work: Ideal for workshops or maintenance areas where lifting tasks occur at different locations.

Lug Mounted Portable Electric Hoists:

Features:

Lug Mounting System: Designed with lugs or brackets for secure and specific attachment to compatible structures or equipment.

Fixed Attachment: The lug mount offers a secure and stable connection once installed, providing a fixed lifting point.

Rigid Mounting: Offers increased stability and load distribution compared to hook-mounted hoists.

Benefits:

Stability and Security: Provides a secure and stable attachment point, minimizing movement during lifting operations.

Specific Lifting Points: Offers a fixed lifting position, beneficial for tasks requiring precise positioning of loads.

Enhanced Load Distribution: Provides better weight distribution compared to hook mounts, suitable for heavier loads.

Typical Applications:

Manufacturing Settings: Used for specific lifting tasks along assembly lines or with machinery.

Heavy Industrial Use: Ideal for lifting heavy machinery or equipment in industrial environments.

Rigging and Overhead Cranes: Can be used in conjunction with cranes or fixed structures for specialized lifting operations.

Both Hook Mount and Lug Mounted Portable Electric Hoists offer distinct advantages in various applications. Hook-mounted hoists provide flexibility and versatility in attachment, allowing them to be easily moved between locations. On the other hand, lug-mounted hoists offer stability and secure fixed points for specific and precise lifting tasks. The choice between these types often depends on the nature of the lifting task, the available support structures, and the need for mobility or fixed positioning.

Operation-based Types:

Pendant-Controlled Portable Electric Hoists:

Features:

Controlled via a pendant or control pendant connected to the hoist unit via a cable.

Offers direct control over lifting operations from a close distance.

Allows precise and immediate control over lifting, lowering, and directional movements.

Benefits:

Provides precise control for operators working in close proximity to the load.

Enables real-time adjustments and safe handling of loads.

Typical Applications:

Work areas where operators need close control and visibility over lifting tasks.

Tasks requiring frequent adjustments during lifting operations.

Remote-Controlled Portable Electric Hoists:

Features:

Controlled remotely using a wireless transmitter.

Allows operators to control the hoist from a distance.

Offers flexibility and improved safety by allowing operators to maintain a safe distance from the load.

Benefits:

Enhances safety by allowing operators to control lifting operations from a safe distance.

Provides flexibility in positioning and operating the hoist without physical constraints.

Typical Applications:

Construction sites where operators need to maintain a safe distance from heavy loads.

Hazardous or inaccessible areas where manual control is challenging.

Design-based Types:

Standard Portable Electric Chain Hoists:

Features:

Equipped with a chain mechanism driven by an electric motor.

Offers versatility in lifting operations across various industries.

Available in different load capacities and configurations.

Benefits:

Versatile and adaptable to a wide range of lifting tasks and industries.

Reliable and widely used for general lifting purposes.

Typical Applications:

Warehousing, manufacturing, and construction industries for general lifting tasks.

Workshops or assembly lines requiring standard lifting operations.

European-Style Portable Electric Chain Hoists:

Features:

Known for superior build quality, often utilizing high-quality materials.

Compliance with strict European safety standards and norms.

Advanced safety features and durability.

Benefits:

Ensures higher safety standards and reliability in industrial environments.

Offers advanced safety features and compliance with European regulations.

Typical Applications:

Industrial settings requiring stringent safety standards and durability.

Specialized manufacturing environments demanding reliability and safety compliance.

These various types of portable electric hoists cater to different lifting needs, environments, and operational requirements, providing a range of features and functionalities to suit diverse applications in various industries.

Capacity-based Types:

Light-Duty Portable Electric Hoists:

Features:

Typically designed for lifting lighter loads, ranging from a few hundred pounds to a ton.

Compact and lightweight design for easy transportation.

Suitable for smaller-scale applications, workshops, and tasks requiring less lifting capacity.

Benefits:

Easy to maneuver and transport due to their lighter weight.

Ideal for tasks that don't require heavy lifting, enhancing efficiency in smaller work environments.

Cost-effective and suitable for occasional or intermittent use.

Typical Applications:

Automotive workshops for lifting engines or parts.

Small manufacturing or repair units for handling lighter materials.

Heavy-Duty Portable Electric Hoists with Explosion Proof Design

Features:

Engineered to handle heavier loads, ranging from several tons to higher capacities.

Robust construction and design for durability and strength.

Suitable for industrial and construction applications requiring substantial lifting capacities.

Benefits:

Capable of lifting and handling heavier materials or equipment efficiently.

Offers reliability and strength for heavy-duty operations.

Ideal for continuous use and demanding lifting tasks in industrial settings.

Typical Applications:

Construction sites for lifting steel beams, concrete, or heavy machinery.

Manufacturing plants for handling larger industrial components or materials.

Based on Speed of Portable Electric Hoists

Variable Speed Portable Electric Hoist:

Features:

Offers a range of speed settings, allowing operators to adjust the speed continuously within a specific range.

Provides precise control over lifting operations with multiple speed options.

Often equipped with user-friendly controls for adjusting speed as required.

Benefits:

Customizable lifting speeds to match specific load requirements or operational needs.

Enables gradual and precise positioning of loads at different heights or distances.

Enhanced adaptability and versatility in handling various lifting scenarios.

Typical Applications:

Rigging tasks where precise and variable speed control is crucial for safety and accuracy.

Construction projects requiring varied speeds for different lifting tasks or materials.

Tasks demanding gradual acceleration or deceleration during lifting operations.

Single Speed Portable Electric Hoist:

Features:

Operates at a constant speed, offering a single speed setting for lifting and lowering operations.

Typically has straightforward controls for basic up and down movements without speed adjustment options.

Simple design, suitable for straightforward lifting tasks requiring consistent speeds.

Benefits:

Easy to operate due to its uncomplicated controls.

Cost-effective and suitable for applications where variable speeds are not required.

Reliability in lifting tasks that do not demand speed adjustments.

Typical Applications:

Loading/unloading tasks in warehouses requiring consistent lifting speeds.

Basic lifting operations in workshops or assembly lines where speed variation is unnecessary.

Double Speed Portable Electric Hoist:

Features:

Offers two different speed settings for lifting and lowering operations.

Typically includes a high-speed setting for faster movements and a low-speed setting for precision and controlled movements.

Allows operators to switch between speeds for different lifting requirements.

Benefits:

Versatility in handling different types of loads or tasks that require varying speeds.

High-speed setting for faster lifting and low-speed setting for more controlled and precise positioning.

Enhanced flexibility compared to single-speed hoists.

Typical Applications:

Manufacturing or assembly tasks requiring both rapid lifting and precise positioning of loads.

Work environments where tasks involve lifting various loads that demand different speeds.

Choosing between single speed, double speed, or variable speed portable electric hoists depends on the specific lifting requirements, the need for precise speed control, and the nature of the tasks at hand. Each type offers distinct advantages in addressing different speed-related lifting demands across various industries and applications.

Typical Industrial Applications of Portable Electric Hoists

Portable electric hoists stand as indispensable assets across a myriad of industries, revolutionizing lifting operations and enhancing efficiency in various work environments.

Construction Sites: Efficient Material Handling

In the dynamic realm of construction, where time and precision are paramount, portable electric hoists play a pivotal role. These hoists efficiently handle material lifting tasks, ranging from maneuvering heavy building materials to positioning essential construction components. Their adaptability and ability to swiftly navigate diverse construction sites make them invaluable in streamlining material handling operations.

Warehouses: Streamlined Inventory Management

Warehouses bustling with inventory movement require efficient material handling solutions. Portable electric hoists aid in the seamless movement of goods, pallets, and equipment within warehouses. These hoists facilitate the swift and safe transfer of goods to different storage levels, optimizing space utilization and enhancing inventory management processes.

Manufacturing: Precision Assembly Operations

Precision is the cornerstone of manufacturing operations, and portable electric hoists significantly contribute to assembly tasks. Whether lifting heavy machinery components or aiding in intricate assembly operations, these hoists ensure precise positioning and controlled movements. Their adaptability to different support structures within manufacturing facilities ensures streamlined assembly processes.

Maintenance: Reliable and Accessible Lifting Solutions

Maintenance tasks in industrial facilities often necessitate reliable lifting solutions. Portable electric hoists provide accessibility and reliability, enabling maintenance crews to maneuver heavy equipment for repairs or servicing. Their versatility allows for lifting in confined spaces or areas with restricted access, ensuring that maintenance operations run smoothly and safely.

From construction sites requiring efficient material handling to warehouses seeking streamlined inventory management, and from manufacturing facilities demanding precision assembly to maintenance operations needing reliability – portable electric hoists stand as versatile and essential tools across a spectrum of industrial applications.

Addressing User Concerns with Portable Electric Hoists

Safety, maintenance, and proper training are crucial aspects when using portable electric hoists. Addressing user concerns ensures safe and efficient operations in diverse work environments.

Safety Features and Compliance Standards

Portable electric hoists are equipped with a multitude of safety features, including overload protection, emergency stop functions, and limit switches. These features ensure the hoist operates within its designated capacity and adheres to stringent compliance standards. Regular inspections and adherence to manufacturer recommendations for usage and maintenance further contribute to safe hoist operation.

Maintenance Practices for Longevity

Adhering to recommended maintenance practices is vital for the longevity and performance of portable electric hoists. Routine inspections, lubrication of moving parts, and prompt replacement of worn components are essential to ensure optimal functionality. Manufacturers often provide detailed maintenance guidelines, and adherence to these protocols enhances the hoists' longevity, reliability, and safety during operations.

Operator Training and Safety Guidelines

Proper training and adherence to safety guidelines are imperative for safe and efficient hoist operations. Operators should undergo comprehensive training programs focusing on hoist operation, safety protocols, load capacity understanding, and emergency procedures. Promoting a culture of following manufacturer instructions and safe practices ensures a secure and efficient work environment.

Providing ongoing training and periodic refresher courses ensures that operators remain updated with the latest safety protocols and operational best practices. Regular skill assessments and evaluations further reinforce safe usage habits among operators, minimizing risks and ensuring optimal performance of the hoists.

By addressing safety concerns through compliance standards, emphasizing maintenance protocols for longevity, and prioritizing comprehensive operator training, the usage of portable electric hoists becomes not only efficient but also significantly safer in diverse industrial settings.

FAQs about Portable Electric Hoists

How do I determine the suitable hoist for my lifting needs?

Determining the appropriate hoist involves assessing factors like load weight, frequency of use, available space, lifting height, and the environment of operation. Considering the hoist's load capacity, power source, control options, and adherence to safety standards aids in choosing the most suitable hoist for specific lifting requirements. Consultation with hoist specialists or manufacturers can provide valuable guidance in selecting the ideal hoist for tailored applications.

What are the load capacities of different electric hoists?

Portable electric hoists come in various load capacities catering to diverse lifting needs. Capacities typically range from a few hundred pounds to several tons, varying depending on the type and model of the hoist. It's crucial to verify the specific load capacity of the hoist model to ensure alignment with intended lifting tasks and compliance with safety standards.

Can portable electric hoists be used outdoors?

While some portable electric hoists are designed for indoor use in controlled environments, specific models are engineered to withstand outdoor conditions. Weather-resistant hoists equipped with protective coatings, sealed components, and corrosion-resistant materials can be utilized in outdoor settings. Manufacturers' specifications and recommendations must be reviewed to determine a hoist's suitability for outdoor use and compliance with environmental conditions.

What are the top safety considerations during operation?

Safety during hoist operation is paramount. Operators should conduct pre-operation inspections, checking for any signs of wear or damage, and ensure that loads don't exceed the hoist's rated capacity. Properly securing the load using suitable rigging equipment and following manufacturer instructions and safety guidelines during operation are critical. Emphasis on operator training regarding emergency procedures and adherence to safety protocols further enhances safe hoist operations.

Addressing these frequently asked questions provides valuable insights into selecting, using, and ensuring safety when operating portable electric hoists. Prioritizing safety considerations, understanding load capacities, and assessing environmental suitability contribute to maximizing the efficiency and safety of hoist operations in various industrial settings.

Empowering Your Lifting Solutions with Portable Electric Hoists

Portable electric hoists stand as powerful assets, transforming lifting operations across various industries and enhancing efficiency in diverse work environments.

In summary, portable electric hoists offer a multitude of benefits, including precise lifting capabilities, adaptability to diverse settings, and enhanced operational control. Their design and functionalities cater to a spectrum of lifting needs, from heavy-duty operations to delicate tasks, ensuring efficiency and safety in lifting operations.

As you aim to optimize your lifting solutions, we encourage exploring the array of tailored options available for specific needs. Assessing the lifting requirements, environmental conditions, and load capacities will aid in selecting the ideal portable electric hoist that aligns with your unique lifting challenges.

Our comprehensive range of hoists provides solutions for various industries and lifting demands. Whether it's for construction, warehousing, manufacturing, or maintenance, our hoists are designed to meet diverse lifting needs with efficiency and precision.

For expert assistance in selecting the right portable electric hoist for your lifting requirements or guidance in purchasing, our team of experts is ready to assist you. Contact us at [Insert Contact Information - Phone Number, Email, Website], and our knowledgeable staff will provide personalized support, ensuring you find the perfect lifting solution tailored to your applications.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch