Telescopic Magnetic Beam Overhead Crane for Steel Plate Handling

Overhead cranes & gantry cranes with telescopic electromagnetic beam for steel plate & plates handling in steel mill & outdoor use. Design steel plate crane for you.

Category: Magnetic Crane

Your Trusted Steel Plates Handling Crane Manufacturer & Supplier

Telescopic Magnetic Beam Overhead Cranes and Gantry Cranes for

Single Steel Plate &Plates Handling

Overhead cranes & gantry cranes with telescopic electromagnetic beam for steel plate & plates handling in steel mill & outdoor use. Design steel plate crane for you.

Steel plate overhead crane & gantry crane with Telescopic electromagnetic beam

Overhead cranes and gantry cranes are widely used to meet the lifting and transportation requirements of different specifications of steel plates. Typically, the bridge cranes are equipped with telescopic electromagnetic beam to improve steel plate and steel plates handling efficiency and safety and at same time they are used rationally to save the workshop space, improve productivity, and reduce production costs as much as possible. As for outdoor steel plates handling, the outdoor gantry cranes are used, which are designed with free standing legs to travelling on ground tracks. For heavy and long steel plates and thick steel plate handling, the processed cranes are typically designed with double girder crane configurations with capacity up to 550 ton.

Telescopic magnetic beam overhead cranes for steel mills

The double girder overhead crane with open winch trolley is designed and manufactured for heavy duty application. There are QD series 3t~320t overhead crane and QDX series 3 -80 Ton bridge cranes are available. It travels on a supporting structure of a building. The open winch trolley runs on the double girder for material handling.

Overhead double girder cranes can be used in a variety of material handling environments, including a factory, warehouse, workshop, workstation, store, machine assembly shop, metallurgy plant for ladle handling, steel plant for steel pipe/plate/coil handling, and so on.

Steel plates or sheet steel are frequently moved from one location to another in a steel mill or a steel manufacturing plant by an industrial overhead crane equipped with lifting magnets.

Applications: Handling one thick steel plate for each lift; or picking up several short pieces of steel plate at once.

16 ton overhead crane with telescopic beam magnetic spreader for steel mill - double girder overhead crane series

Double girder gantry crane with mangetic beam spreader for steel plate handling

The double girder gantry crane is with a double main beam/girder structure. The open winch hoist runs on the girders for lifting operation. The double girder gantry crane travels on rail tracks to different positions for steel plates handling. At the two ends of the main beam, there can be outstretched cantilevers for a larger working range. The truss girder & bix gurder double girder gantry cranes are available for outdoor steel plates handling. The double-girder gantry cranes are all made in accordance with national standards and regulations. Standard lifting capacity of steel plate gantry cranes are from 10 ton – 550 ton.

Telescopic magnetic beam gantry cranes for steel mills - double girder gantry crane series

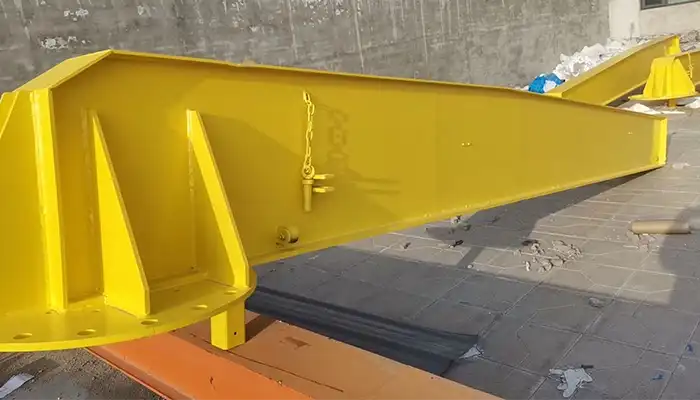

Telescopic magnetic beam

A new kind of telescopic electromagnetic spreader beam is developed in order to meet the lifting and transport needs of various steel plate specifications, utilize the workshop space sensibly, increase productivity, and lower production costs as much as possible. The hanging beam can be freely stretched in the length direction by adjusting the spacing of some of the spreader beam's electromagnets, making it easier to lift steel plates of various lengths and specifications. The hanging beam made of telescopic electromagnets perfectly satisfies the requirements of real-world engineering applications.

The main parameters of the telescopic electromagnetic spreader beam:

- Spreader beam dead weight up to 21t

- Spreader beam length 12~16m or 14~18m

- Extending time: Extend 30s, retract 30s

- Rated lifting capacity up to 24t

- Lifting steel plate specifications:

- Length 3000~20000mm

- Width 900~4900mm

Structural Composition of crane telescopic electromagnetic spreader beam

The main components of the telescopic electromagnetic spreader beam are the hanger, the fixed beam, the telescopic beam, the telescopic drive mechanism, the limit device, the electromagnets and magnets adjustment device, and other components.

The telescopic electromagnetic spreader beam is constructed as a box-type double-beam, with two "three-in-one" reducers acting as the driving force, vertical roller guidance, driving the telescopic beam to move in the fixed beam, and realizing the distance between the electromagnets automatically adjusted, as well as additional safety measures like limit devices and buffer devices.

How does magnetic telescopic beam

Reducer of the telescopic drive mechanism by operating the control switch to rotate the gear, causing the gear and the pin and rack to mesh with each other, allowing the pin and rack to reciprocate linearly and pass through. To drive the magnetic telescopic beam, the long axis is connected to the support on the telescopic beam, allowing the telescopic beam to be extended or retracted in the fixed beam. The reducer is turned off, and the magnetic telescopic beam is placed on the slab to be lifted through the overhead crane hook. The electromagnets are then activated, and the hanging beam begins to lift the slab, and the slab is hoisted to a suitable location. Following the position, the electromagnets are turned off, completing the slab lifting operation.

For different sizes of steel plates handling

In the telescopic electromagnetic hanging beam, the changing and adjustment of the electromagnets spacing mainly relies on the telescopic sliding of the motor-driven telescopic beam.

- The longest steel plate could be lifted when the telescopic beam extends out of the fixed beam and reaches its maximum limit.

- The shortest steel plate could be handled when the telescopic beam retracts into the fixed beam and reaches its minimum limit.

When the steel plate does not need to be lifted and transported, the lifting crane telescopic beam is retracted into the fixed beam, and the hanging beam takes up little space.

Features of steel plate handling overhead cranes and gantry cranes

With telescopic electro-magnets hanging beam, the overhead cranes and gantry cranes has the following advantages:

Wide range of applications -The main performance parameters section of the text shows the specifications of the steel plates that can be lifted and transported by telescopic electromagnetic spreader beam overhead cranes, which have a wide range of applications.

- High operational flexibility and productivity efficiency -High production efficiency and operational flexibility -The design of the magnetic overhead crane should fully consider the driving force required to overcome the self-weight of the telescopic beam, the self-weight of the single electromagnets, and the frictional resistance of the mechanism itself when the telescopic beam is extended and retracted. The telescopic beam can freely expand and contract, and the electromagnetic spreader beam moves smoothly, making it ideal for lifting and transporting steel plates of various lengths. The variable-distance telescopic electromagnets spreader beam offers the advantages of convenient length adjustment, strong versatility, and high productivity when hoisting long steel plates, especially ultra-long thin plates.

- Safe and reliable material handling performance -The fixed beam's and telescopic beam's strength and stiffness are calculated in accordance with the harsh working conditions. The calculation takes into account the dynamic load coefficient as well as the partial load coefficient, which means that the steel plate is in the most unfavorable partial load lifting position based on the electromagnetic spreader beam rated load.If the strength and stiffness are calculated using this working condition, the electromagnetic spreader beam can lift the slab safely and reliably. In addition, the telescopic spreader beam's operation reliability and travel reliability are guaranteed, the safety of the mechanism operation is improved, and it more than satisfies the development requirements of contemporary industry thanks to the double protection design of mechanical limit and electrical limit.

- High degree of automation- In order to meet the operational needs of automation and semi-automation of lifting operations, as well as adapt to the development needs of contemporary industrial enterprises, special personnel on the ground are not required; one driver is sufficient. This saves both manpower and material resources.

- Low price - The cost is only about half to a third of what European-made products cost.

- Easy control - the overhead crane and the telescopic beam can stretch or retract by itself via pushing a button on controller, to adapt to the varying lengths of the plates to be handled.

- Superior safety - These industrial lifting magnets can continue to hold even in the event of a sudden power outage, preventing the lifted plate from falling off.

- Reduced labor intensity - When compared to plate lifting clamps, a radio remote controller only requires one worker to operate, saving the trouble of manual plate separation.

The telescopic electromagnets beam overhead cranes and gantry cranes can be widely used in steel mills, warehouses and wharfs and other places.The flexible lifting solution satisfies the demands of contemporary business. Practical engineering applications can fully rely on it due to its reliability, rapid development, and security.

Upon request from the client, the processed industrial overhead crane and ganry cranes with lifting magnets can also be used to handle coils, billets, profiled steel, etc. in addition to plates.For a magnetic overhead crane solution for your steel material handling, get in touch with us.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch