Lifting Magnet: Electro Magnet, Permanent Magnet & Scrap Magnet

Types of lifting magnets for cranes - magnetic overhead cranes & gantry cranes - Electro magnet, Permanent magnet, Battery Magnet & scrap magnet for sale.

Category: Magnetic Crane

Definition of lifting magnets

What is a lifting magnets? How does a lifting magnet work? What are the many types of lifting magnets? To respond to the aforementioned questions, we must first learn about and comprehend lifting magnets or crane magnets.

Lifting magnets are just what they sound like: magnets that use magnetic force to lift objects or steel or iron loads such as steel plates, sheets, coils, ballets, and other ferrous materials.

Working principles of crane magnets

What does the lifting magnetc work? Due to their magnetic clamping force, the lifting magnets for cranes are used in wide industrial applications to hold steel material or iron parts . Each type of lifting magnet type generates magnetic force in a different way.

Knowing the differences between electro-permanent type, electro type, and permanent type lifting magnets can help us better grasp their potential uses in industry.

Lifting Magnets - Custom Engineered Magnetic System to Fit Your Needs

Types of lifting magnets are designed and manufactured for a wide range of applications using permanent, electro-permanent, battery powered, and electromagnetic technologies. All of our industrial lifting magnets are custom-engineered to consistently and affordably pick up, transfer, or position ferrous items of any size, weight, or shape.

Steel mills, scrap yards, loading docks, warehouses, foundries, shipyards, coil and pipe distributors, and other users of applicable steel products commonly use these types of below-the-hook lifting magnets.

Types of lifting magnets based on magnet characteristics

Basically, in terms of magnet characteristics, the lifting magnets are classified into the permanent lifting magnets, electro lifting magnets, and electro-permanent lifting magnets.

Permanent-electro Lifting Magnet

Unaffected by power failure with zero power consumption during lift, suitable for thin/thick, vertical/horizontal plate lifting, loading & unloading plate and cut parts for cutting tables, and other steel material handling like billets, profiles, slabs, tubes, pipes, coils, etc.

Battery Powered Lifting Magnet

Provides the convenience of a lift magnet without cable and makes loading & unloading of ferrous parts simple and fast. Suitable for using in areas where electric power is not available.

Lifting Electromagnet

Featured with deep magnetic flux penetration, electric lifting magnet can be custom designed & manufactured for the handling of steel bundles like rebars, steel tubes, pipes, hot rolled steel wire rods, etc.

Permanent Lifting Magnet

This below-the-hook manually switched permanent magnetic lifter, for safe and reliable material handling of flat and round steel parts, allows steel handlers to quickly and simply maneuver steel plate, pipes and rods without the use of slings, chains and blocking.

Lifting electromagnet & lifting magnets for cranes

Lifting electromagnets for steel mill cranes -Round, oval & square magnet & magnetic beams- for lifting cold & hot steel scrap,slab, billet & ingot, coil, plate, pipe,beam, & rebar,etc.

Lifting electromagnets based on loads temperatures

- Lifting electromagnet with the shape of Circular, Square, and Rectangular are available with the diameters from 500 mm up to 3000 mm;

- Normal temperatures magnet & High temperature electromagnet: for normal loads handling & hot metal handling with surface temperature of up to 700°C;

- Lifting electromagnets for types of industrial cranes: indoor overhead crane & outdoor gantry cranes,used under any climatic condition.

Types of magnets based on shapes of crane magnets

Round/ Circle lifting magnet, Square magnet , Rectangular magnet & magnet beam

- Round electromagnet- Round /Circular lifting electromagnet is widely adopted for loading & unloading cast ingots, steel balls and various types of steel scraps and other metal scraps, etc.

- Rectangular magnet- Rectangular lifting electromagnets are for handling steel billet, l ingot, block, bloom & round, profiled steel, etc.

- Oval electromagnet - Oval lifting electromagnet helps the handling of steel scraps at narrow trunk-shaped container efficiently, etc.

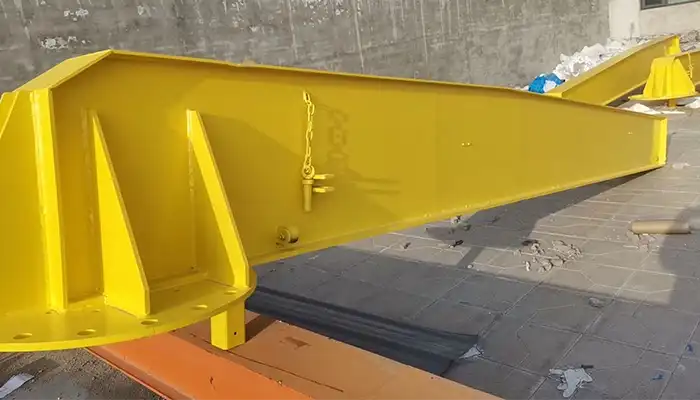

- Lifting magnet beam- Electromagnetic beam are mainly used for long and larger object handling such as un-bundled steel pipe, steel plate, steel bars,steel tubes, billets or bundled double-layer billets, steel pipe, large-sized ingots,steel plates and screw-thread steel, etc

Oval lifting electromagnet

Round type lifting magnet

Rectangular lifting electromagnet

Magnetic beam speader

Types of lifting magnets classied based on handling loads

Lifting magnets for types of loads handling including steel scrap, slab, billet & ingot, steel coil, plate, pipe, rebar, wire roll, etc.

Scrap Magnet

Electric lifting magnet used on excavator or crane, for sorting out steel scraps, is also referred as excavator magnet, or scrap magnet, scrap handling magnet, scrap yard magnet, junkyard magnet.

Single Steel Plate Lifting Magnets

- Electro permanent lifting magnets with spreader beam for lifting single steel sheet with min. thickness of 5mm

- Lifting a single steel plate/sheet each time, with plate size and weight varying, is a precision handling job that has strict requirement about the lifting magnets used. HVR MAG HM1 Series single plate lifting magnets are custom engineered for single steel plate/sheet handling.

Electro Permanent Lifting Magnets with Telescopic Beam

electro permanent lifting magnets with telescopic beams are specially developed for safe lifting and moving of steel sheets with different lengths.The electrically driven telescopic system makes it possible to use this traverse in limited spaces.

Thin Steel Plate Lifting Magnets

- Thin Steel Plate Lifting Magnets are designed for lifting thin steel plate with a minimum thickness of 3 mm.

- Thin steel plates/sheets usually come in long length with thin thickness. This makes the lifting of long and thin steel plates/sheets more tricky and challenging. In addition, long thin steel sheets are very flexible, which makes the handling job quite dangerous.

Vertical Plate Lifting Magnets

- HM4 Series Vertical Plate Lifting Magnet Clamps are ideal handling solutions for lifting steel plates/sheets in vertical or horizontal position, without compressing and / or deforming the steel plate/sheet.

- Due to the compact construction, the ultra-slim magnet modules fit perfectly between the vertical uprights of your steel sheet warehouse.

Lifting Magnets for Cutting Systems

- HM5 Series Lifting Magnets for Cutting Systems allow fast and efficient loading & unloading of plates on any type of cutting machines (plasma, oxyacetylene, laser), specially developed to remove cut pieces, including residual material, from the cutting table in one movement.

- Lowering labor costs while increasing productivity proportionately.

Lifting Magnets for Multiple Steel Plates

- Lifting multiple steel plates in one movement and releasing them plate by plate is feasible with HVR MAG custom engineered Lifting Magnets, widely applied in port companies,steel transhipment companies, logistics, etc. The electro permanent magnetic modules with deep magnetic field, ensure strong and stable gripping force of the load, presenting a competitive edge among other lifting magnets for fast and safe lifting of stacks of steel plates.

- With simple "tip-off" function to release plate by plate.

Lifting Magnets for Profiles

- Lifting magnets specifically manufactured for handling of steel profiles, h beam blanks and angle iron.

- Electro permanent magnet modules with slim pole shoes for lifting profiles from 80-600 mm in lengths up to 24,000 mm

- OPTIONAL: for profiles from 600 mm - 1000 mm, the modules are turnable over 90°.

- Electronic control unit on board with selection option of the magnetic modules, depending on the length of the profile to be lifted.

- Control via the built-in digital push buttons or via the standard supplied radio remote control.

Lifting Magnets for Slabs

- High-performance electro permanent magnet modules for large air gaps.

- Welded beam made of construction steel with electro permanent magnetic modules elastically suspended for perfect adaptation to the material.

- For loading and unloading ships, railway wagons, use in steel mills, etc.

Lifting Magnets for Steel Coils

- This complete range of electro permanent magnet modules is specially designed for quick and safe handling of coils, with horizontal or vertical eye.

- In addition, the coil material is not compressed and dammaged, which is the case when using traditional coil grippers.

- Since the coils can be stored side by side, up to 30% space can be saved.

Lifting Magnets for Steel Tubes

- For fast and safe manipulation of single, row and bundles of pipes with no risk of damage to the coating or paint layer.

- Space and cost saving solution as no wooden dividers are required.

- Electro permanent magnet modules with electronic control unit on board.

Customized Magnet Lifter for Steel

- These electrically switched permanent magnet lifters, are another type of hoist magnets, frequently used in industrial lifting and handling.

- For long loads like steel plates and beam blanks/profiles, we suggest magnetic lifting beams with groups of magnet lifters for safe and efficient handling.

- For use in places where power supply is unavailable, we recommend battery operated magnet lifter.

Lifting Electromagnet for Bundled Rebar

- Rebar Bundle Lifting Magnets: designed to handle bundles of steel rebars.

- With this bundle lifting magnet, each bundle can be carried from tie work area to storage yard or directly onto the truck platform safety and speedy, eliminating human job for wire roping or bundling. Strong magnetic power and deep penetration of magnetic flux, keeps bundles tightly not to collapse while handling.

Lifting Electromagnet for Steel Wire Rods

An electric lifting magnet is the use of electromagnetism to lift/handle ferrous magnetic materials. Unlike permanent lifting magnets, the lifting power/strength/force of an electromagnet can be increased by increasing the amount of electric current that flows through it, and vice versa.

Electro Permanent Lifting Magnet with Battery Supply for Flat and Round Steel Parts from 500-5000kg

- Thanks to the integrated rechargeable battery group, this revolutionary electro permanent lifting magnet functions completely autonomously.

- Battery Powered Lifting Magnets Loading Steel Plate for CNC Cutting Table

Electro Permanent Magnetic Lifting Beam with Battery Supply for Single Steel Plate

Thanks to the integrated rechargeable battery group, this revolutionary electro permanent magnetic beam functions completely autonomously.

Electro Permanent Magnetic Lifting Beam With Battery Supply for Profiles

Thanks to the integrated rechargeable battery group, this revolutionary electro permanent magnetic beam functions completely autonomously.

FAQ on magnetic lifters

In the following, the frequently asked questions on magnetic lifters are presented for your reference to have a better understanding and get your suitable lifting magnet for your needs.

What are the lifting capacity of magnetic lifter ?

If you need a magnet lifter with a lifting capacity of 100kg, 200kg, 300kg, 600kg, 1 ton, 2 ton, 5 ton, 10 ton, 16 ton, etc., you can get a customized solution from our factory, a professional lifting magnet manufacturer. All of our magnetic lifters including magnetic chucks and electromagnetic beam spreaders are custom-made to meet the needs of the clients. Since it is customized, the price of a magnetic lifter may vary depending on the requirements. If you need a magnetic lifting device, please feel free to contact us.

Meanwhile, we provide magnetic lifters for various industrial cranes and hoists to handle various industrial materials and loads such as steel plates, sheet metal, pipes, tubes, slabs, billets, and so on. If your material is ferrous-magnetic metals, steels or irons, a magnetic lifting device is a good choice for efficient, safe and easy lifting device.

What material can the electromagnet lift?

Lifting electromagnets are frequently working with various industrial overhead cranes to provide an ideal material handling solution for ferrous materials such as steel and iron of various weights, sizes, and temperatures in different industrial sectors, such as, ship manufacturing, heavy machinery, steel warehouses, ports, and railways field, etc. They are obviously usefully in metal processing industries and steel products distributing centers for handling cast ingot, steel ball, pig iron, machine chip,billet, ingot, steel coils, pipe, rebars, wires, tubes, and, others etc. What;s more, the lifting magnetic lifters also can be used to handle various types of steel scraps, return scraps, cropping, baling scraps, and so on in foundry factories and iron powder in coal washeries. At the beginning of the slag disposal process, it can remove considerable amounts of iron. It is suitable for usage in the waste steel recovery department and the steelmaking workshop.

What are the difference of Permanent lifting magnet vs. Electro lifting magnet vs.Electro-permanent lifting magnet

Difference in magnet working principles

Because of their magnetic gripping force or capacity, crane magnets are used in industrial lifting applications to attract steel material or parts. The generation of lifting magnetic force varies depending on the magnet type.

Permanent lifting magnet

It consists of a block with a main body and a rotor. It has two magnets in the main body and one in the rotor. When these two magnets are oriented in the same way, they generate magnetic flux that reaches the metallic objects to be handled.

Electro lifting magnet

Permanent magnets are unlike electromagnets. They are constructed of wire coils that have electricity running through them. An electromagnet's wire coils act like magnets when an electric current flows through them since moving charges produce magnetic fields.

Electro-permanent lifting magnet

It has two magnetic power sources. The first consists of a set of magnets with a high intrinsic coercive force (Hci), and the second consists of magnets with a low Hci. Electrical wire coils are wound around the low Hci magnets. Its magnetic orientation can be changed by reversing the direction of the current pulse in the coils. Permanent-electro lifting magnets gain more powerful griping force to ferromagnetic work pieces when both sets of magnets have the same magnetic orientation. No magnetic force for gripping would exist if the magnetic orientations were opposing and absorbed each other's energy.

Advantages of permanent lifting magnet

It can be utilized where electricity is not easily accessible because it doesn't need an electrical source when bearing the weight and there is no risk of dropping the material if there is a power outage.

Advantages of electric lifting magnet

As a device that generates a magnetic field with a continuous electrical supply, the strength may be increased by connecting it to a higher volt battery or charger, allowing for significantly greater lifting capacity. It may also generate a significantly deeper magnetic field than permanent magnets, allowing them to permeate through several plates in a stack, for example. Because of the higher depth of field, they are more forgiving of a small air gap.

Advantages of electro-permanent lifting magnet

Electro-permanent lifting magnets have the following features: energy efficiency (they only use power briefly when activated and deactivated); higher safety (they can continue holding the load even in the event of a power outage); availability of remote control; management of magnetic force for specific operations; and no need for maintenance.

Disadvantages of permanent lifting magnet

Because these magnets are composed of hard materials and are continuously magnetized, the magnetic field line strength is constant. As a result, permanent lifting magnets tend to deteriorate over time. As a result, the maximum magnetic field strength is reduced.The permanent magnet's poles cannot be changed.

After several operations, the permanent magnet would always lose some of its magnetic property, resulting in a malfunctioning system. Furthermore, we can only produce the magnetic field of a permanent magnet below a particular temperature. As a result, we can't use these magnets in hot-device applications.

Disadvantages of electric lifting magnet

Electromagnets tend to get heated due to current flow through the windings since they require a power source to be energized and a constant supply of current while working. That is to say, electric lifting magnets consume a lot of energy and heat up quickly. It could be dangerous if turned up too high. This may damage the magnets and their field at some point in time due to factors such as ohmic heating, inductive voltage spikes, core losses, coil coupling, and so on. There is also radiation caused by electromagnetic.

Disadvantages of electro-permanent lifting magnet

The magnetic flux of an electro-permanent lifting magnet penetrates relatively close to its poles as compared to lifting magnets that are electrically switched or controlled. Additionally, the air gap between the magnet and the load to be lifted is highly important. As the air gap grows, the lifting capacity rapidly diminishes. Therefore, loads with uneven or rough surfaces should not be lifted using an electro-permanent lifting magnet. Additionally, it is more expensive than permanent and electromagnets.

In conclusion,an electromagnet needs a power supply, and there are many potential safety risks. A permanent magnet, on the other hand, is always active and doesn't need a power supply. However, because the energy in electromagnets is driven by a power source, they are frequently stronger than permanent magnets. Electricity is only needed to activate and deactivate electro-permanent lifters. Additionally, they won't utilize electricity while using the lift. Therefore, compared to electro lifters, electro-permanent lifters are more energy-efficient. That's to say, each form of lifting magnet has advantages and disadvantages. We can select a more suitable magnetic lifter to suit the loads and working circumstances by being aware of their relative benefits and drawbacks.

What are the tests required for lifting magnet ?

All new, updated, or refurbished lifting devices shall undergo a rated load test and a functioning test performed by a trained examiner prior to beginning use. Make sure your lifting magnets are in good working order. Manufacturers are required to conduct this test and give written certification or video documentation of the results.

Visual examination

The following magnetic lifters must be visually inspected by the user before each use:

- The lifter must be free of any metal attachments and have no attracting force in the OFF position.

- The bottom should have a flat surface.

- The top hoist ring needs to be in good shape.

- Verify the safety latch and handle for smooth functioning.

- Confirm that the safety label that is attached can be read.

- Additionally, you should inspect each component for signs of wear, corrosion, or deformation.

Before its initial hoisting, it is required to adhere to the inspection guidelines to the letter. Make sure they are all functioning properly, especially if they have integrated emergency warning signs.

Breakaway test

When it comes to magnets, damage to the magnetic material inside the object is not visible from the outside. The breakaway test verifies the magnet's present lifting capacity. For a particular test plate, the test shows the force that the magnet released. The breakaway force is affected by a load's mass, composition, flatness, and smoothness. It enables the user to determine whether the magnet satisfies the manufacturer's specified rated capacity.

Operators must have a complete understanding of the loads before lifting.

Load tests are performed as a final step before the lifting magnet is approved for operation. The load test assures their safe operation, that the structure can withstand the loads it was planned for, and that your equipment is safe.

High-quality lifting magnet

These tests are critical to the safe operation of equipment, and our factory will not allow the lifting magnets to be used until they have been done on the equipment that we have installed.

What are the safety precaution attributes that needs to know?

The industrial lift magnet is used in a variety of industries, including metalworking, machinery, steel fabrication, shipbuilding, industrial automation, foundries, warehouses, etc. To insure your safety, the following safety tips are for your reference.

Safety precautions that industrial lift magnet features:

- A. Our electro-permanent magnet has a rated lifting force and a magnetic pull force. To ensure that the adsorbed object does not slip off during the lifting operation, the magnetic draw force is typically 2-4 times the lifting force. That means, our magnet has a safety factor of 3:1. If you have a 100KG ferrous workpiece to handle with our magnet, the lifting capacity of the magnet will be 100 kilogram. And you'll have to employ 300KG of force to get the workpiece off.

- B. Pre-magnetization is sufficient to lift the object, and full magnetization is required to transfer the object. Pre-magnetization is typically 80% of the magnetic force, with an additional 20% to ensure material handling safety.

- C. Some clients may have a question: if the operator accidentally clicks the "DEMAG" button during the handling procedure, will the raised object fall from the air? Our factory takes two precautions here: 1. Press two buttons at the same time to demagnetize the magnet. 2. Our lifting magnets feature a landing sensor (as seen in the above image) that detects whether or not the metal workpiece falls on the ground. Even if both buttons are pressed, demagnetizing will not work if no landing is detected.

- D. The final safety precaution is inherent in its properties: an electro-permanent magnet does not lose magnetism in the event of a power outage. So, even if the ferrous material is suspended in the air, the workpiece will not fall off and injure employees or equipment in the event of a power outage or voltage instability. Because magnetization takes only 2 seconds with a single pulse of electric current. It also requires no electricity when working.

How to operate lifting magnets effectively and safely?

Accidents can occur at any point in routine production. Operators must adhere to strict safety regulations when utilizing the electro-permanent magnet in order to eliminate safety hazards in the handling of heavy steel loads.

Operation rules or reminders for lifting magnets:

- Before each use, inspect the magnet visually. We must determine whether the magnet appears to be in good condition from the outside. Then we check to see if the controller parameters are properly adjusted, the wire is properly connected, and the magnetization and demagnetization are normal.

- Before using the magnet, the operator must read the instruction handbook. They should also be confident in their fundamental safety understanding. Any staff who is not authorized should not operate the magnet.

- Keep an eye on the load and avoid handling loads that exceed the lifting capacity of the lifting magnet. The capacity of the lifting magnet can be modified based on your load handling requirements.

- Keep an eye on the working temperature. Magnets can sometimes be custom-made to meet your precise temperature requirements. Use the magnet within the temperature range allowed, because the greater the temperature, the faster the magnetic force decays.

- Avoid any kind of collision or vibration during operation.

- Attempt to keep the load balanced and the weight equally distributed under the magnet.

- Ensure that the load and the magnet are fully in contact, and do not magnetize the magnet before this.

Lifting magnets are currently frequently used in automatic production lines for lifting and handling steel plates, pipes, coils, and ferromagnetic materials. Companies place a high value on safety in structural steel fabrication, construction machinery production, shipbuilding, and logistics. There are some additional instructions, reminders, and tips on how to use lifting magnets successfully. They are all aimed toward increasing your profits.

In the event of a power outage, how long can your lifting magnets continue to hold the load?

While magnetic lifting systems are regarded one of the safest means of lifting, there is always the possibility of a power failure during lifting. Is lifting magnets safe even if the electricity goes out? How long can your lifting magnets withstand a power outage?

There are three sorts of magnetic lifters, as we all know: electromagnets, permanent magnets, and electro-permanent magnets. What about their tenacity?

Permanent magnets:

As the name implies, permanent magnets do not require electricity and transport items using the magnetism of the poles, preventing unexpected accidents. The magnetic force steadily lessens as use increases, and unloading becomes slower.

Electromagnets:

In general, manufacturers will make extensive use of battery systems. When the power is unexpectedly cut when lifting workpieces, the electromagnetic system will instantly start the backup power supply to provide energy and keep the items in the absorption state.

Electromagnets can lose strength if coils burn out due to overheating (limit of 15 minutes) or rectifier sections fail. If an electromagnet abruptly ceases working, safety problems have most certainly arisen in that workplace.

Electro-permanent magnets:

Electro-permanent magnets consume less energy than typical magnetic lifers, have a strong and stable magnetic force, and are safe. The electro-permanent magnets are only energized when picked up and placed. There is no need for electricity during transportation, which drastically saves energy usage and eliminates the possibility of products failing.

Magnets simplify material handling operation. Lifting magnets improve efficiency in numerous situations. To ensure safety, proper attention must be paid to the backup power source. Ensure that everyone in the institution understands what to do in the event of an accident.

How to maintain your lifting magnet?

Electro-permanent lifting magnets have gained popularity among machinery makers, steel mills, foundries, metalworking factories, shipyards, and steel wholesalers. The maintenance process is not difficult, and the cost is quite inexpensive, which is a major factor. Your lifting magnets can have a longer lifespan and higher operational efficiency with routine maintenance.

Please make sure the following before any maintenance or repairs:

- The lifting magnet can only be maintained and repaired by qualified personnel.

- Before handling or removing components, turn off the circuit breaker located at the back of the magnet.

- Do not smoke in the area of the magnet.

- If the lifting magnet is battery-operated, make sure it is not charging.

1. Advice for maintaining your lifting magnet's mechanical components:

- A. Daily inspection before each use, including the housing and magnet surface look, cleanliness, and the condition of all welds, power wires, screws, chains, and rings, among other things.

- B. Inspect the appearance for any cracks or obvious stains. Verify the chains and rings to see if anything is hanging loose. On the magnet surface or the housing, are there any dings or signs of excessive wear?

2. Tips on maintaining electronic components of your lifting magnet:

- A. Proper storage is required. An anti-flammable, explosion-proof, dust-proof, and anti-strong magnetic field should surround the storage area. It is best to place the controller in a well-ventilated area without allowing liquid or metal particles to get inside.

- B. Avoid collisions or falling.

- C. Electrical equipment maintenance and repair must adhere to all applicable laws and technical guidelines.

- D. It is advised that the user perform routine checks of the magnet's buttons, indications, terminals, and power cords. If you use the magnet every day at work, check the resistance value and insulation value once every six months.

Will the hung heavy weight drop/fall off during the lift with lifting magnets?

No, it will not. Our lifting equipment's magnetic force is activated and deactivated by a brief electric pulse. Once magnetized, the lifting force is permanent unless the current is turned off again. That means, our lifting magnets need no power during the lift and can continue to retain the load even if the electricity goes off.

What should you know about steel object handling by lifting magnet?

What benefits do electro permanent magnet lifters have over permanent magnet lifters and electromagnetic lifters?

The magnetic flux penetration of EPM magnets can be adjusted according to the thickness of steel plates, ensuring that one plate is lifted each time without picking up the second. Energy efficiency, safety and durability, and ease of use are all advantages.

Can your lifting magnets lift multiple plates at once?

Yes, the number of plates to be lifted varies according to thickness, weight, and your individual operating conditions. We can design a magnetic lifting system specifically for your purpose.

Do you provide an electric hoist and a lifting beam?

We do provide electric hoists and overhead cranes, and below-the-hook overhead crane lifting magnets. In terms of the lifting beam, we can make it for you along with magnet lifters, or you can make it yourself to save money on transportation.

Is it possible for your magnetic lifting equipment to handle stainless steel materials or products?

No, our magnet lifting is not ideal for stainless steel parts; it is only suitable for ferrous objects with good magnetic conductivity.

What is the thinnest steel sheet your magnet lifting system can pick up?

Our lifting magnets can lift sheets as thin as 2mm, lifting one sheet at a time without picking up a second or multiple sheets. You can tell us about your handling needs, such as the thickness and number of sheets to be handled. We can design a magnetic lifting system specifically for your purpose.

How to select from Vacuum lifting systems to Magnet Lifting System for thin steel sheets handling?

Vacuum lifters are cheaper than our magnetic lifting method, but they are also more prone to damage, less safe than magnet lifters, and require more frequent maintenance. When using magnet lifters, there won't be any load slippage or drops because the magnetic force of these lifters can continue even if the power source is abruptly cut off.

How to choose or get a customized lifting magnet?

To cater to different needs, the tailored lifting magnet needs to be customized based on lifting needs and applications. And the following questions will help you to customized the lifting magnets for your application?

What and how much weight are you lifting?

The first thing we need to consider when deciding on a lifting magnet is: what and how much are you going to lift?

- The material you are lifting must first be familiar to you. Only ferrous materials can be raised by lifting magnets.

- The quantity and size of magnets required depend on the material types, sizes, and temperatures, etc.

- Safety is our top concern. To ensure that we can safely lift the handling material, we must use the magnet's maximum lifting capacity.

- Additionally, the material's weight indicates your working load. And the thickness will determine if your magnet can safely lift the fabric with a strong force.

What parameters required to provide to get custom magnet lifting?

- For handle plates, we need to know the length, width, thickness, and material type;

- for steel pipes and tubes, we need to know the diameter, wall thickness, length, and weight;

- and for particularly complex items, additional drawings or photographs will be necessary.

- For the customization of the magnet lifting system, other details such as whether the lifting process is handled automatically or manually, inside the home or outside, the types of crane, the maximum hoisting weight and height of the crane, etc., may also be required.

Contact us to get a custom lifting magnet for your industrial hoist and crane today!

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch