Variable Speed Hoists 5 Ton for Sale in Singapore, Advanched Hoist

5 ton variable speed hoist for sale. Check a case on variable Speed Hoists 5 Ton for Sale in Singapore with Advanced Safety Features.

Category: Wire Rope Hoist Crane

Your Trusted Wire Rope Hoist Crane Manufacturer & Supplier

Variable Speed Hoists 5 Ton for Sale in Singapore, Advanched Hoist

5 ton variable speed hoist for sale. Check a case on variable Speed Hoists 5 Ton for Sale in Singapore with Advanced Safety Features.

Background Information

Overview of the Hoisting Industry in Singapore

Singapore is a major industrial hub with key sectors such as construction, manufacturing, and logistics driving the need for effective lifting solutions. Hoists play an essential role in these industries, helping businesses lift and move heavy loads safely and efficiently.

Industries That Use Hoists

- Construction: Wire Rope Hoists are used to lift building materials like steel, concrete, and equipment on construction sites.

- Manufacturing: Factories use hoists to move raw materials, parts, and finished products within their production lines.

- Logistics & Ports: Hoists are crucial in port operations to handle cargo, containers, and heavy goods.

Demand for Modern Hoisting Solutions

- As industries grow, there is increasing demand for hoists that are more efficient and reliable. Businesses need equipment that can handle heavy loads safely and precisely.

- The focus has shifted toward hoists with variable speed control and advanced safety features to improve performance and reduce risks.

Importance of Safety Features in Hoist Systems

In any industry where heavy lifting is involved, safety is crucial. Hoists must be designed with safety features to protect both the operator and the equipment.

Why Safety Features Matter

- Variable Speed Control: Allows the operator to adjust the speed of the hoist, reducing the risk of sudden movements that could cause accidents or damage.

- Limit Switches: Prevent the hoist from moving too far, which helps prevent damage to the hoist and surrounding equipment.

- Audible and Visual Alarms: Warn the operator and other workers if there's a potential problem, helping to avoid accidents before they happen.

Benefits of Safety Features

- These features help reduce downtime, improve productivity, and keep operations running smoothly.

- In environments like construction sites or factories, safety features ensure that lifting tasks are carried out without incidents, protecting both the people and the equipment.

Variable speed hoist 5 ton for sale

5 ton electric variable speed hoist for sale Singapore

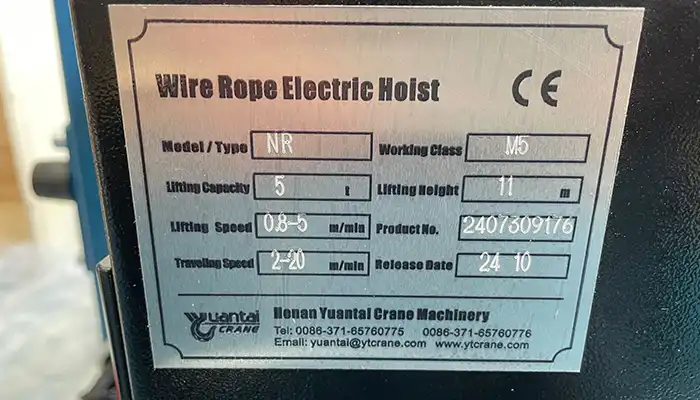

Customized Hoist Specification for 5T Capacity with Variable Speed

1. General Overview

- Type of Hoist: Variable Speed Electric Hoist

- Capacity: 5 Tons (5,000 kg)

- Lifting Height: 11 meters

- Power Supply: 415V, 50Hz, 3-Phase

- Speed Control: Variable Speed Control (ensures smooth and precise lifting operations)

2. Motor and Power Supply

- Motor Type: High-efficiency electric motor with variable speed capability, ensuring optimal performance and energy savings.

- Power Supply: Operates on a 415V, 50Hz, 3-phase electric power supply, providing consistent and reliable performance suitable for industrial environments.

- Voltage Compatibility: Fully compatible with standard industrial voltage, offering easy integration into existing infrastructure.

3. Safety Features

- Huichuan Inverter: Provides precise control over lifting speed for smooth operation, minimizing mechanical stress and reducing wear and tear.

- Schneider Cross Limit Switch: Limits hoist movement to predefined maximum and minimum points, preventing over-travel and potential damage to the hoist and load.

- Audible and Visual Alarms: Alerts operators to malfunctions or safety breaches, ensuring quick intervention and enhancing overall operational safety.

4. Design and Structure

- Frame Construction: Built with a robust steel frame designed for durability, ensuring reliable operation in demanding industrial environments.

- Lifting Mechanism: Uses high-strength steel rope or chain (depending on hoist design), optimized for smooth lifting and lowering of loads with minimal friction and wear.

5. Control System

- Control Method: Equipped with remote control featuring variable speed adjustment for precise control over lifting and lowering speeds, tailored to the operator's needs.

- Controls: Available with either an ergonomic pendant control or wireless remote, offering flexibility and ease of use.

- Safety Interlocks: Integrated interlocks ensure the hoist operates only within safe parameters, preventing dangerous operations.

6. Performance

- Lifting Speed: Variable lifting speed that can be adjusted according to specific operational needs, optimizing speed for load handling.

- Lowering Speed: Variable lowering speed ensures that heavy loads are lowered smoothly, preventing sudden movements or damage.

7. Environmental Compatibility

- Temperature Range: Designed to operate effectively within a wide temperature range, making it ideal for both hot and cold industrial environments.

- Corrosion Resistance: Optional protective coatings or corrosion-resistant materials are available, making it suitable for humid, chemically aggressive, or coastal environments.

8. Maintenance and Serviceability

- Easy Maintenance: Featuring modular components for easy repair and replacement, reducing downtime.

- Inspection Points: Clearly marked maintenance points ensure quick access for routine inspections and servicing, minimizing maintenance time and ensuring optimal hoist performance.

9. Optional Features

- Overload Protection: Optional overload protection prevents hoist damage by cutting off power if the load exceeds safe limits.

- Emergency Stop Function: A manual emergency stop function is available to immediately halt the hoist in case of an emergency, ensuring quick safety responses.

This 5-ton variable speed hoist is a highly customizable and efficient lifting solution, designed with advanced safety features, durable construction, and adaptable performance. It ensures precise lifting and lowering operations, maximizes operational safety, and offers long-term reliability and cost-effectiveness for industries in need of heavy-duty lifting solutions.

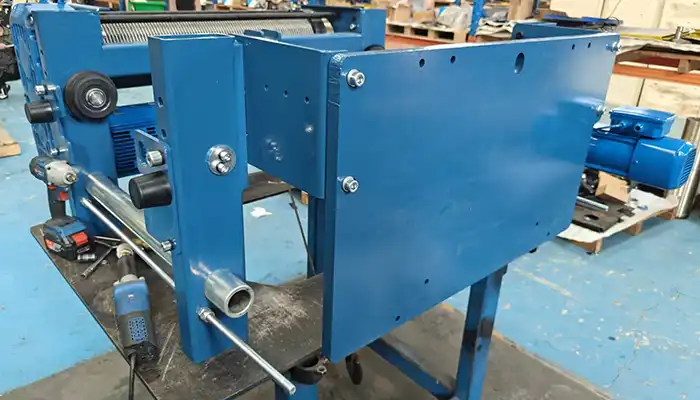

Testing of variable speed hoist before leaving the factory

Advanced Safety Features

Huichuan Inverter for Variable Speed Control

The Huichuan inverter provides critical functionality by allowing smooth, precise control over the hoist's speed. This is particularly important for handling varying loads and ensuring safe, efficient lifting.

Smooth Speed Adjustments: The inverter modulates the power supplied to the motor, enabling variable speeds for lifting. This ensures that the hoist can start and stop gradually, avoiding sudden jerks or abrupt movements that could cause damage.

Key Benefits:

- Enhanced Efficiency: Operators can adjust the hoist's speed based on the load and task requirements, reducing energy consumption while improving operational performance.

- Longer Equipment Lifespan: By controlling acceleration and deceleration, the inverter minimizes wear and tear on the hoist's mechanical components, leading to fewer maintenance needs and extending the hoist's lifespan.

- Precise Handling: Variable speed allows for greater precision in load handling, especially in delicate operations where accuracy is critical.

Schneider Cross Limit Switch

The Schneider cross limit switch plays a vital role in preventing the hoist from exceeding its operational boundaries, ensuring that it remains within safe operational limits.

Functionality: The limit switch is installed at critical points along the hoist's travel path. When the hoist reaches its preset limit (either upper or lower), the switch automatically halts further movement, preventing over-travel.

Benefits for Safety:

- Prevents Over-Travel: By halting the hoist when it reaches its travel limits, the switch protects both the hoist and the load from potential damage caused by exceeding safe operating ranges.

- Protects Load Stability: Over-travel can destabilize the load, causing dangerous shifts or even drops. The limit switch ensures the hoist operates safely within its defined range.

- Reduces Maintenance Costs: Preventing over-travel not only protects the hoist from mechanical failure but also reduces the frequency of costly repairs or part replacements.

Audible and Visual Alarms

The audible and visual alarms are critical safety features that alert operators to potential risks and irregularities in the hoist's operation.

Functionality: These alarms are triggered by abnormal conditions such as overload, malfunction, or exceeding safety limits. The audible alarm emits a sound, while visual signals (typically flashing lights) provide a visual alert.

Safety Enhancements:

- Increased Awareness: Both audible and visual alarms ensure that operators are immediately aware of safety concerns, even in noisy or busy environments.

- Accident Prevention: These alarms act as early warnings to prevent accidents by alerting operators to unsafe conditions, such as lifting beyond the rated capacity or operating at unsafe speeds.

- Vital in High-Risk Environments: In environments where hoist operations are critical—such as in manufacturing, construction, or heavy-duty material handling—the combination of sound and light alerts ensures that operators can respond promptly to potential hazards.

- Emergency Response: The alarms signal nearby personnel about the potential risk, giving them a chance to act before an accident occurs. This collective awareness helps mitigate injury or equipment damage.

The combination of the Huichuan inverter, Schneider cross limit switch, and audible/visual alarms creates a robust safety framework for the hoist. These features work together to ensure smooth operation, protect against over-travel, and enhance operator safety, minimizing the risk of accidents and damage in demanding industrial environments.

croess travelling limit

sound and alarm safety device

Aviation plugiin

Namplate of 5 ton variable speed hoist

Benefits of Customization

Tailored to Customer Needs

The 5-ton variable speed hoist offers a high degree of customization to meet the specific operational requirements of different industries, ensuring maximum efficiency, safety, and performance. Here's how it can be tailored:

- Capacity: The hoist can be customized to handle different load capacities, making it suitable for a range of applications—from light-duty lifting to heavy-duty operations. In this case, with a 5-ton capacity, the hoist is ideal for medium-to-heavy lifting tasks, but it can be adapted for higher or lower capacities depending on the customer's needs.

- Lifting Height: The lifting height of the hoist can be adjusted to suit specific building or operational constraints. For example, a lifting height of 11 meters is commonly required in industries like construction and manufacturing where large vertical movement is necessary, but this height can be customized for taller or shorter facilities.

- Power Supply: The hoist system can be customized to accommodate different power supply specifications, such as the standard 415V, 50Hz, 3-phase power or other configurations depending on the customer's existing electrical infrastructure. This flexibility ensures compatibility with both industrial-grade and commercial facilities.

- System Flexibility: The hoist is adaptable to various operational environments, whether indoors or outdoors. It can be integrated into existing crane systems, assembly lines, or material handling processes. Custom features, such as specialized hook attachments or lifting mechanisms, can be incorporated to handle specific loads or applications. Whether lifting heavy machinery in a factory, cargo in a port, or construction materials on a building site, the hoist is engineered to seamlessly meet the unique challenges of each environment.

Conclusion

The 5-ton variable speed hoist is a robust and versatile solution for a wide range of industrial applications. With a capacity of 5 tons, it is well-suited for handling medium-to-heavy loads in manufacturing, logistics, construction, and port operations. The hoist offers an impressive 11-meter lifting height, ideal for applications where vertical movement is essential, and it operates on a 415V, 50Hz, 3-phase power supply, making it compatible with most industrial power systems.

Key benefits include:

- Variable speed control for smooth, precise lifting, reducing mechanical stress and enhancing operational efficiency.

- Advanced safety features like the Huichuan inverter, Schneider cross limit switch, and audible and visual alarms, which ensure smooth, safe operations and protect both the hoist and load from potential damage.

These features work together to maximize uptime, improve productivity, and reduce maintenance costs, making the hoist a valuable asset in any industrial setting.

The Importance of Advanced Safety Features

The hoist's advanced safety features are integral to its performance:

- Huichuan Inverter: This allows for smooth variable speed control, preventing sudden jerks or abrupt stops, which not only improves efficiency but also reduces wear and tear on hoist components.

- Schneider Cross Limit Switch: This feature prevents over-travel of the hoist, ensuring it operates within safe parameters and reducing the risk of damaging both the hoist and the load.

- Audible and Visual Alarms: These alarms provide instant feedback, alerting operators to unsafe conditions such as overloads or malfunctions, thereby improving safety in busy environments and preventing accidents.

Together, these safety systems ensure that the hoist operates efficiently and safely, creating a more reliable lifting solution for businesses.

Why Singapore Businesses Should Consider This Hoist

For businesses in Singapore, this customized 5-ton variable speed hoist presents an ideal lifting solution. Singapore's industries—spanning manufacturing, logistics, construction, and ports—require equipment that can handle demanding tasks with precision, reliability, and safety. This hoist offers all of that and more:

- Efficiency: With its customizable specifications, it can meet specific operational requirements such as lifting heights, load capacities, and power supply, ensuring it works seamlessly within each business's unique setup.

- Safety: The hoist's advanced safety features are crucial for reducing accidents and enhancing worker safety, particularly in high-risk environments like ports or construction sites.

- Cost-effectiveness: The long-term savings from reduced downtime, lower maintenance costs, and fewer accidents make this hoist a smart investment, providing excellent return on investment (ROI).

For companies looking to improve their lifting operations, reduce maintenance costs, and ensure safer, more efficient performance, this hoist is the ideal choice. By investing in this customized solution, Singapore businesses can benefit from enhanced operational capabilities while ensuring the safety and well-being of their workforce.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch