0.5 to 80 Ton Sluice Gate Electric Hoist,Customized Double Hook

0.5 to 80 ton Sluice Gate Electric Hoist for sale. Tailored double hook hoist for synchronized sluice gate operation, for efficient, balanced,safe lifting.

| Hoist type | Sluice Gate Electric Hoist |

| Capacity | 0.5 ton to 80 ton |

| Lifting height | 6m to 200 meters |

Category: Hoist

Your Trusted Overhead Crane Manufacturer & Supplier

0.5 Ton- 80 Ton Sluice Gate Electric Hoist

Customized Double Hook Electric Hoist for Synchronous Sluice Gate Operation

Overview of Sluice Gate Electric Hoist

The Sluice Gate Electric Hoist is a specially designed lifting solution for the controlled opening and closing of sluice gates, commonly used in hydroelectric power plants, dams, and water management systems. This hoist is built for heavy-duty operations, ensuring precise control of large gates with minimal effort.

Key Features:

- Double Hook Design: Ensures synchronized lifting and lowering of gates.

- Heavy-Duty Performance: Capable of lifting large, heavy gates with ease.

- Precision Operation: Provides smooth and reliable gate movements.

The hoist's design offers a balance between power and precision, making it essential for controlling water flow and maintaining safety in critical infrastructure like flood control systems and reservoirs.

Importance of Synchronized Operation:

Synchronized operation is vital for the smooth movement of sluice gates, especially in large-scale systems such as hydroelectric plants. If one side of the gate moves faster or slower than the other, it can cause misalignment, increasing the risk of damage or failure.

Key Benefits:

- Even Gate Movement: Both hooks lift or lower the gate at the same time, ensuring even movement.

- Reduced Risk of Damage: Prevents misalignment that can lead to mechanical issues.

- Increased Safety: Maintains structural integrity of the gate and hoist during operation.

By ensuring that both hooks operate in unison, the hoist protects the gate and surrounding structures from unnecessary strain, improving the lifespan of the equipment and reducing the need for frequent maintenance.

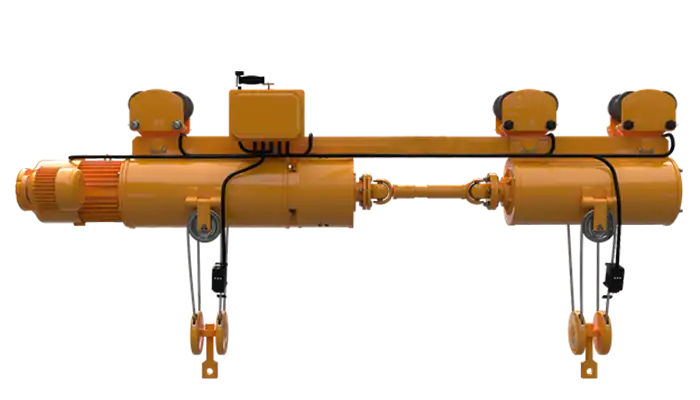

Sluice Gate Electric Hoist

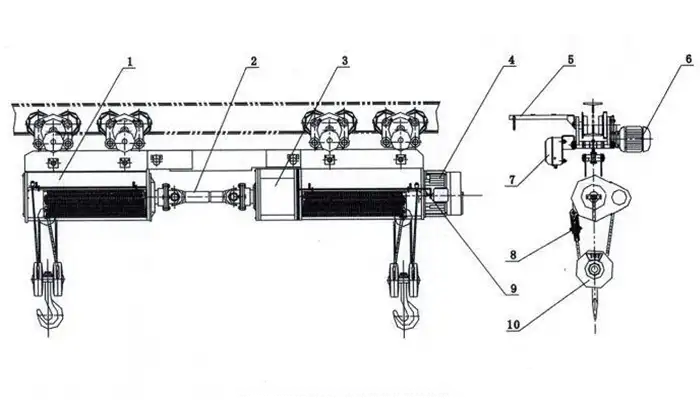

Sluice Gate Electric Hoist Drawing

Benefits of a Double Hook Design:

The double hook design is one of the most important features of the sluice gate electric hoist. It ensures that the weight of the gate is distributed evenly across both hooks, preventing the gate from becoming unbalanced during operation.

Advantages:

- Balanced Lifting: Distributes the weight evenly to avoid misalignment.

- Smooth Operation: Reduces friction and wear on the equipment.

- Longer Lifespan: Minimizes strain on both the hoist and the gate, extending their service life.

The double hook system not only enhances the performance of the hoist but also contributes to safer and more reliable lifting, especially when handling large and heavy gates.

Specifications of Sluice Gate Electric Hoist

Sluice Gate Electric Hoist (Simultaneous Lifting of Sluice Gates) |

|||

| Lifting Capacity (t) | 2x5 |

2x10 |

2x16 |

| Lifting Height (m) | 6-30 |

6-30 |

9-24 |

| Hook Point Span | 3-12 |

3-12 |

3-12 |

| Rope Reeving Method | 2/4+2/4 |

2/4+2/4 |

1/4+1/4 |

| Lifting Speed (m/min) | 7(0.7/7) |

4.5(0.45/4.5) |

2.3(0.23/2.3) |

| Lifting Power (kW) | 13(1.5/13) |

6-pole 18.5 (6-pole 2.2/18.5) |

6-pole 18.5 (6-pole 2.2/18.5) |

| Traveling Speed (m/min) | 20 |

20 |

20 |

| Traveling Power (kW) | 0.8*2 |

0.8*4 |

1.5*4 |

| Protection Class | IP44/54/55 |

IP44/54/55 |

IP44/54/55 |

| Insulation Class | F Class | F Class | F Class |

| Release Method | Electric + Manual | Electric + Manual | Electric + Manual |

| Steel-Body Reducer | FM | FM | FM |

| Lifting Attachment Type | Gate Lifting Lugs | Gate Lifting Lugs | Gate Lifting Lugs |

| Operation Mode | Handle / Remote Control | Handle / Remote Control | Handle / Remote Control |

| Duty Classification | M3 |

M3 |

M3 |

| Power Supply | 3P 380V 50HZ |

3P 380V 50HZ |

3P 380V 50HZ |

Key Features:

Dual Hook Design for Synchronized Operation:

The dual hook design is the heart of the sluice gate electric hoist. This system uses two hooks that are connected and operate together, ensuring that both sides of the sluice gate move in perfect unison. The dual hooks are driven by a single motor and synchronized using a common drive shaft, which eliminates any imbalance between the two sides of the gate during operation.

- Synchronized Lifting and Lowering: Both hooks lift or lower the gate simultaneously, preventing misalignment and uneven weight distribution.

- Maintaining Balance: This balance is crucial to avoid placing excessive stress on one side of the gate, which could lead to mechanical failure or damage to both the hoist and the gate.

- Prevention of Mechanical Stress: The synchronized operation reduces strain on the hoist system, minimizing wear and tear on moving parts, which extends the life of the equipment and reduces maintenance costs.

Customization Options:

The sluice gate electric hoist can be tailored to meet specific operational needs and conditions. Customization ensures that the hoist system is perfectly suited to the size and design of the sluice gate, providing optimal performance for each unique application.

- Tailored Design for Gate Sizes: The hoist can be custom-built to match the exact dimensions and weight of any sluice gate, ensuring the best fit and performance.

- Adjustable Hook Distances: The distance between the hooks can be adjusted to suit different gate sizes or installation environments, providing flexibility for varied applications.

- Custom Lifting Capacities: The lifting capacity can be configured based on the gate's weight and the required operational load, ranging from smaller, lighter gates to massive, heavy-duty installations.

This level of customization ensures that the hoist meets the exact needs of each customer, providing reliable and efficient lifting in all conditions.

High Power and Efficiency:

The hoist is designed to offer both high power and energy efficiency, making it ideal for continuous and heavy-duty use in demanding environments.

- Powerful Motor: The hoist features a motor that delivers ample power to lift and lower large sluice gates with ease, ensuring quick and smooth operation, even under heavy loads.

- Energy-Efficient Operation: Despite its power, the hoist is designed to operate efficiently, reducing energy consumption during operation. This is particularly important for large-scale installations that require long hours of use, making the hoist an environmentally and cost-effective choice.

- Continuous Duty Rating: The hoist is capable of running continuously without overheating, making it perfect for the demanding cycles of sluice gate operations, where the gate must be moved frequently or for long periods.

These features ensure that the hoist is not only powerful but also economical to run, making it an ideal solution for both large and small-scale water control systems.

Safety and Reliability:

The sluice gate electric hoist is built with a range of safety features to ensure both the safety of operators and the long-term reliability of the system.

- Overload Protection: The hoist is equipped with overload protection to prevent damage in case the weight exceeds the hoist's capacity. This helps prevent accidents and ensures that the hoist operates within its safe limits.

- Emergency Stop Functions: In case of an emergency, the hoist includes an emergency stop button that immediately halts all movement, providing a quick response to potential hazards.

- Limit Switches: Limit switches are installed to stop the hoist at the desired positions, ensuring that the gate does not overrun and causing potential mechanical damage.

- High-Quality Materials: Built with durable, corrosion-resistant materials, the hoist is designed to withstand harsh environments, including exposure to moisture, dust, and extreme temperatures.

- Anti-Corrosion Design: The hoist's components are specially treated to prevent corrosion, especially in environments like hydroelectric plants where water and humidity are constant factors.

These safety features and the robust design of the hoist ensure reliable operation and minimize the risks associated with gate movements.

Remote Operation and Monitoring:

The sluice gate electric hoist can be equipped with advanced remote operation and monitoring capabilities for increased convenience, control, and performance tracking.

- Remote Control: The hoist can be operated from a distance using a remote control, which allows operators to control the lifting and lowering of the gate without being in close proximity to the equipment. This feature increases operator safety, especially in environments where the gate is located in difficult-to-reach or hazardous areas.

- Real-Time Monitoring: The hoist can be integrated with a monitoring system to track performance data in real time. This system can provide valuable insights into operational efficiency, load handling, and wear and tear, allowing for proactive maintenance and performance optimization.

- Diagnostic Integration: The hoist can send diagnostic alerts to operators if any potential issues arise, allowing for immediate troubleshooting and minimizing downtime.

These features enhance the operational control, ease of use, and efficiency of the hoist system, making it ideal for modern, high-tech water control facilities.

Applications

Hydroelectric Power Plants:

The sluice gate electric hoist plays a critical role in hydroelectric power plants by controlling the opening and closing of gates that regulate water flow through the plant. These gates, including floodgates and penstocks, are essential for managing the water level and flow needed to generate electricity efficiently.

- Water Flow Control: The hoist is responsible for managing the flow of water through turbines, ensuring optimal conditions for electricity generation.

- Safe Operation of Floodgates and Penstocks: By allowing precise control over gate movements, the hoist ensures that floodgates, penstocks, and other hydraulic structures open and close safely, avoiding damage to the infrastructure or flooding risks.

- Efficient Power Generation: The synchronized operation of the hoist ensures consistent and reliable gate movement, which is vital for maintaining the efficiency of power production processes, especially during changes in water levels.

In hydroelectric power plants, the sluice gate electric hoist ensures that water management operations are conducted safely, reliably, and efficiently, supporting the long-term functionality of the plant.

Small Electric Gates:

The sluice gate electric hoist is also highly effective in smaller-scale water control applications, such as electric gates used in industrial, agricultural, or municipal water management systems.

- Industrial Water Control: In industrial settings, sluice gates are often used to manage water flow in cooling systems, drainage, or wastewater management. The electric hoist provides precise control over the gates, ensuring smooth operations in these critical processes.

- Agricultural Water Management: For irrigation systems, sluice gates control the flow of water into fields. The hoist's reliable lifting and lowering of these smaller gates allow for better resource management in agricultural settings.

- Municipal Water Management: In municipal systems, sluice gates control water flow in canals, dams, or wastewater facilities. The hoist ensures that these gates operate smoothly to manage local water resources effectively.

For these smaller-scale applications, the sluice gate electric hoist ensures that gates are operated with precision and reliability, enhancing overall water management efficiency.

Other Relevant Industries:

In addition to hydroelectric plants and small electric gates, the sluice gate electric hoist is versatile and can be used in various other industries that rely on water control systems.

- Dams and Reservoirs: The hoist ensures smooth and synchronized operation of sluice gates in dams and reservoirs, controlling the release of water to prevent overflow or ensure consistent water levels for downstream use.

- Water Treatment Facilities: In water treatment plants, sluice gates are used to control the flow of water through filtration and treatment processes. The hoist's precision and reliability help maintain smooth operations in these critical environments.

- Flood Control: Sluice gate hoists are also integral in flood control systems, where they regulate water levels to prevent flooding in sensitive areas. The ability to synchronize multiple gates provides greater control over floodgate systems.

In these industries, the sluice gate electric hoist enhances the operational efficiency, safety, and reliability of water management systems, making it an essential tool in a wide range of water control applications.

Technical Specifications

Lifting Capacity:

The sluice gate electric hoist is available in a wide range of lifting capacities to suit various gate sizes and operational requirements. The hoist can be customized to meet specific lifting demands for both large and small gates.

- Standard Capacity Range: Options include 5 tons, 10 tons, 20 tons, and higher, depending on the size and weight of the gate being operated.

- Custom Capacities: Custom lifting capacities can be designed to meet specific gate weights, ensuring optimal performance and safety.

This flexibility ensures that the hoist can handle a variety of gate sizes and weights, from smaller gates in municipal systems to large, heavy gates in hydroelectric plants.

Lifting Height:

The lifting height of the hoist is customizable to meet the unique requirements of each installation. The height depends on the gate design, clearance requirements, and specific application needs.

- Customizable Lifting Heights: The hoist can be designed to lift gates from a few meters to significantly higher elevations, depending on the height of the gate and the operational setup.

- Gate-Specific Designs: Each hoist system is built with the precise lifting height needed to ensure smooth and efficient gate operations without compromise.

This customization ensures that the hoist is perfectly suited to the gate's dimensions, whether it's for smaller, low-clearance applications or taller, high-lift gates in dams and power plants.

Lifting Speed:

The hoist provides a range of lifting speeds that are ideal for efficient and precise operation of sluice gates. The lifting speed is adjustable, allowing for both quick and controlled movements as required by the application.

- Typical Lifting Speed Options: Common lifting speeds range from 8 m/min to 3.5 m/min, depending on the gate size and operational needs.

- Adjustable Speed Control: The hoist can be fitted with variable speed options for better control, particularly when precise gate positioning is required in sensitive operations like floodgate control.

This range of lifting speeds ensures that the gate can be moved at the optimal speed, balancing between rapid operations and precise control as needed.

Power Supply and Motor Details:

The hoist is powered by a high-performance motor that ensures it meets the demanding requirements of sluice gate operations. The motor and power supply are designed for both power and energy efficiency.

- Power Supply: Typically, the hoist operates on a three-phase power supply (380V, 50Hz), but can be customized for different voltage and frequency standards based on geographical or customer requirements.

- Motor Type: The hoist uses a robust asynchronous motor with sufficient torque to lift heavy gates efficiently. The motor is designed for continuous duty, ensuring reliable operation under demanding conditions.

- Energy Efficiency: The motor is designed for optimal energy consumption, making it suitable for long-duration use in large-scale operations without excessive energy costs.

These power specifications ensure the hoist is capable of handling high loads with minimal energy consumption, ensuring both performance and cost-efficiency.

Control System:

The sluice gate electric hoist is equipped with an advanced electrical control system that allows for both remote and manual operation.

- Electrical Control System: The hoist features an electrical control panel that offers easy operation and monitoring of all functions. The system ensures precise control of the lifting and lowering of the gate.

- Remote Control: An optional remote control system allows operators to control the hoist from a safe distance, which is particularly useful in hazardous or hard-to-reach locations. Remote operation enhances safety by allowing operators to remain clear of moving parts and heavy loads.

- Manual Backup: In case of power failure or system malfunction, a manual backup system is included to allow for manual operation of the hoist, ensuring continued functionality and safety.

- Safety Features: The control system is designed with overload protection, emergency stop functions, and limit switches to ensure safe operation at all times.

This comprehensive control system makes the sluice gate electric hoist highly versatile and easy to operate, whether remotely or manually, enhancing overall safety and control during gate operations.

Benefits of Customized Solutions

Tailored to Your Needs:

Customizing the sluice gate electric hoist to fit specific operational requirements provides several significant advantages. By tailoring the hoist system to your exact needs, you can ensure that it performs optimally and meets the safety and efficiency demands of your unique operation.

- Enhanced Operational Efficiency: Custom solutions are designed to match the exact size, weight, and lifting capacity of the sluice gates, ensuring smooth and efficient operation. With a customized hoist, you reduce the chances of overloading, underperformance, or unnecessary wear and tear on components.

- Improved Safety: A hoist that is tailored to the specific dimensions and operational parameters of your gate ensures safer lifting and lowering actions. Customization can include the addition of safety features such as overload protection, limit switches, and backup controls, all of which enhance the overall safety of both operators and the equipment.

- Optimized Performance: A hoist built specifically for your application ensures it operates under ideal conditions, reducing downtime and minimizing the need for adjustments during operation. The system will always be ready to meet peak performance demands.

By customizing the hoist to suit your precise lifting requirements, you can create a system that maximizes efficiency and safety throughout its service life.

Design Flexibility:

The design flexibility of the sluice gate electric hoist makes it a versatile solution for a wide range of applications, regardless of gate size, installation constraints, or environmental conditions. Customizing the hoist allows it to fit seamlessly into your existing infrastructure, while also adapting to specific requirements of the gate and its environment.

- Adaptable to Specific Gate Requirements: Whether you are working with large floodgates or smaller industrial gates, the hoist can be designed with the right lifting capacity, height, and speed to handle the task. Customizing the hoist for your gate's exact dimensions and weight ensures that the lifting operation is both effective and reliable.

- Installation Space Compatibility: In cases where space constraints are a factor, the hoist system can be adjusted to fit within the available installation area. This might include modifications to the mounting structure, hook distances, or the configuration of the hoist itself to ensure it integrates well with the gate and surrounding environment.

- Environmental Adaptability: If the hoist is going to be used in harsh or specialized environments (e.g., coastal, high-humidity, or chemical-rich areas), customization can include anti-corrosion coatings, weather-resistant components, or explosion-proof options to enhance the hoist's durability and reliability.

The design flexibility of the sluice gate electric hoist means it can be adapted to meet both the functional and environmental demands of each project, providing an effective, durable, and space-efficient solution.

Why Choose Our Sluice Gate Electric Hoist

Quality Assurance:

We are committed to delivering only the highest quality sluice gate electric hoists that meet the most stringent manufacturing standards. Our rigorous quality control processes ensure that every hoist is built to perform reliably, with minimal maintenance and maximum uptime.

- Manufacturing Standards: Each hoist is constructed with precision and care, adhering to international quality certifications and standards to ensure that they operate safely and efficiently.

- Comprehensive Testing: Before leaving the factory, our hoists undergo a series of thorough tests, including load testing, safety checks, and operational assessments, to guarantee that they meet or exceed performance expectations.

By choosing our hoists, you can be confident that you're investing in a product that is built to last and performs reliably under the toughest conditions.

Durability and Longevity:

Our sluice gate electric hoists are designed for heavy-duty use, with enhanced features that increase their durability and longevity, even in challenging environments.

- Corrosion Resistance: Special anti-corrosion treatments, including high-quality coatings and materials, protect the hoist from damage caused by harsh environmental conditions such as humidity, saltwater, or industrial chemicals. This ensures a longer service life, even in coastal or water-rich areas.

- Heavy-Duty Performance: Built with robust components, our hoists are designed to withstand the stress of continuous use, making them ideal for demanding applications like hydroelectric power plants and floodgate control.

- Low Maintenance: The durable design reduces the need for frequent repairs or replacements, saving on long-term maintenance costs and improving operational efficiency.

With features that prevent wear and tear, our hoists offer exceptional longevity and reliability, making them a wise investment for long-term operations.

Expert Consultation and Support:

We offer personalized consultation and ongoing support to ensure that you select the sluice gate electric hoist best suited for your needs and that it operates smoothly throughout its service life.

- Tailored Product Selection: Our team of experts works closely with you to understand the unique requirements of your sluice gate operations. We assist in choosing the hoist that meets your lifting capacity, speed, and environmental specifications.

- Installation and Setup Guidance: Our support doesn't end with the purchase. We provide expert advice and guidance during the installation process, helping you set up the hoist for optimal performance and safety.

- Ongoing Maintenance Support: We also offer ongoing maintenance support to ensure your hoist operates at peak efficiency. Should you encounter any issues, our knowledgeable team is available to provide troubleshooting, repairs, and parts replacements.

By partnering with us, you gain access to valuable expertise that ensures your sluice gate hoist meets your operational needs and runs efficiently throughout its life.

Case Studies or Testimonials

Success Stories:

Our sluice gate electric hoists have been successfully installed in various critical applications, from large hydroelectric power plants to municipal water management systems. Here are some notable success stories:

- Hydroelectric Power Plant – Water Flow Management: In a major hydroelectric power plant, our customized sluice gate electric hoist was installed to control the opening and closing of multiple floodgates. The hoist ensured synchronized lifting and lowering, which improved the efficiency of the plant's water management system. The hoist's heavy-duty design handled the demanding operational conditions, contributing to a significant reduction in downtime and maintenance costs. The plant now operates smoothly, with better control over water flow to the turbines, optimizing power generation.

- Municipal Water Treatment Facility: At a large municipal water treatment facility, our hoist was used to manage the opening and closing of sluice gates in the facility's wastewater treatment process. The hoist's corrosion-resistant features were key in this environment, as the system had to deal with harsh, chemical-laden water. The customized solution ensured safe, reliable gate movements, contributing to the facility's efficiency and compliance with environmental regulations.

- Agricultural Irrigation System: A large agricultural irrigation project required a hoist capable of managing small-scale sluice gates for water distribution across several fields. The double hook design ensured precise, synchronized gate operation, while the hoist's energy-efficient motor helped the farm reduce operational costs. The customized hoist also improved safety by allowing remote control, preventing workers from needing to be in proximity to heavy lifting operations.

These case studies demonstrate the versatility and reliability of our sluice gate electric hoists in a variety of settings, offering tailored solutions that improve operational efficiency and safety.

Pricing and Order Information

Get a Quote:

To receive a personalized quote for a sluice gate electric hoist, please follow these steps:

- Provide Lifting Requirements: Share your specific lifting capacity needs (e.g., 5 tons, 10 tons, 20 tons, etc.), lifting height, and the type of gate or application for which the hoist will be used.

- Customization Specifications: Let us know about any specific customization requirements, such as hook distance, lifting speed, and special features like remote control or corrosion-resistant coatings.

- Site and Environmental Conditions: Inform us about the environment where the hoist will be operating, such as the presence of chemicals, saltwater, or extreme temperatures, to ensure we recommend the most suitable materials and design.

- Request a Quote: Submit your details through our website, or contact our sales team directly. We will evaluate your needs and send a detailed, competitive quote that includes all costs, including customization options.

We pride ourselves on offering tailored solutions at competitive prices, ensuring you get the best value for your investment.

Ordering Process:

Follow this simple, step-by-step guide to place your order for a sluice gate electric hoist:

- Initial Consultation: Once you've requested a quote, our expert team will reach out to discuss your specific needs and confirm your hoist's specifications.

- Review and Approval: We will provide a detailed proposal, including the technical specifications, customization options, and final pricing. After reviewing the quote, you can request any final adjustments to the design or features before approval.

- Order Confirmation: Once you've approved the proposal, we'll send you an official order confirmation and invoice. At this stage, we'll finalize the lead time and delivery details.

- Payment Options: We offer flexible payment options, including bank transfers and major credit cards. For large orders, installment payments may be available.

- Manufacturing and Quality Control: Upon receiving your payment, we will begin manufacturing the hoist. During production, we maintain rigorous quality control to ensure your hoist meets all specifications and safety standards.

- Lead Time and Delivery: The typical lead time for manufacturing a customized sluice gate electric hoist is between 4-6 weeks, depending on the complexity and level of customization. We will provide an estimated delivery timeline based on your location and any special requirements.

- Shipping and Installation: Once the hoist is ready, it will be shipped to your location. We offer international shipping and will ensure the hoist is properly packaged to prevent damage during transit. Additionally, we can arrange for installation assistance if needed.

- After-Sales Support: After installation, our team will provide ongoing support, including training for operators, maintenance guidelines, and troubleshooting assistance.

Contact Us

For any inquiries, technical support, or after-sales service, our dedicated customer support team is here to assist you. We are committed to providing you with timely and effective solutions for all your sluice gate electric hoist needs.

Our team is ready to assist with product inquiries, troubleshooting, and guidance on maintenance or repairs. If you need parts replacement, troubleshooting, or have any questions regarding product performance, don't hesitate to reach out.

Request a Consultation:

Need help determining the best sluice gate electric hoist for your project? Schedule a consultation or site visit with one of our experts to get personalized recommendations based on your specific requirements.

How to Request:

- Fill out the consultation form on our website, including details about your sluice gate specifications and operational needs.

- Or, call or email us to schedule an appointment with a technician or consultant who will visit your site and assess the best hoist solution for your application.

Consultation Services Include:

- On-site assessment of gate size, weight, and operational conditions.

- Custom recommendations based on lifting capacity, design, and environmental conditions.

- Discussion of customization options (e.g., hook distance, lifting speed, safety features).

Scheduling a consultation ensures that you receive the most accurate and tailored solution for your needs, ensuring seamless integration and optimal performance of the sluice gate electric hoist.

Let us help you find the right solution for your project! Leave us a message or contact us by WhatsApp; + 86 151 3871 1597.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch