How to Confirm Your Underhung Bridge Cranes Specifications & Design?

A detailed guide to accurately determine and specify underhung bridge crane requirements, ensuring optimal performance and compliance for your operations.

Category: Underhung Bridge Crane

Your Trusted Underhung/ Under Running Overhead Crane Manufacturer & Supplier

How to Confirm Your Underhung Bridge Cranes Specifications & Design?

Hot Sale Underslung Crane 1 Ton, 2 Ton, 3 Ton, 5 Ton

A detailed guide to accurately determine and specify underhung bridge crane requirements, ensuring optimal performance and compliance for your operations.

Confirm Your Underhung Bridge Cranes Specifications to Get Your Design

Underhung bridge cranes might not be a household term, but they play a crucial role in various industries, from manufacturing to logistics. In simple terms, these cranes are the unsung heroes of efficient material handling, offering versatility and precision in moving heavy loads within a workspace.

So, what exactly are underhung bridge cranes? Picture a crane system with a bridge-like structure spanning the width of your workspace. Unlike traditional overhead cranes, underhung cranes have their hoist mechanism attached to the bottom of the bridge girder, allowing them to travel along the length of the runway beams beneath. This design maximizes floor space utilization and offers smoother load movement.

In the design and production of underhung bridge cranes, one size certainly does not fit all. The specifications of these cranes must align precisely with the unique needs of your operations. Overlooking this crucial step can lead to inefficiencies, safety hazards, and unnecessary expenses down the line. Accurate specifications ensure that your crane system operates seamlessly, optimizing productivity while minimizing downtime.

Ceiling Mounted Underhung Bridge Crane Parameters:

- Load capacity: 0.5-10t

- Span: 3-22.5m

- Lifting height: 6-30m

- Lifting speed: 0.7-8m/min

- Hoist running speed: 20m/min

- Crane running speed: 20m/min

- Work duty: A3, A4

Technical Parameter:

| Technical Parameter of -LX Single Girder Underhung Bridge Crane | |||||||

| Capacity | t | 0.5 | 1 | 2 | 3 | 5 | 10 |

| Span | S(m) | 3~22.5 | 3~22.5 | 3~22.5 | 3~22.5 | 3~22.5 | 3~22.5 |

| Lifting height | m | 6~30 | 6~30 | 6~30 | 6~30 | 6~30 | 9~30 |

| Lifting speed | m/min | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 8(0.8/8) | 7(0.7/7) |

| Trolley speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) |

| Crane speed | m/min | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) | 20(30) |

| Work duty | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | A3~A4 | |

Understanding Your Needs

Before you dive headfirst into the world of underhung bridge cranes, it's essential to take a step back and evaluate your specific requirements. Understanding your needs is the cornerstone of selecting the right crane system that will seamlessly integrate into your operations.

Assessing Work Environment

Take a stroll around your workspace and observe the layout, obstacles, and any potential hazards. Consider factors such as ceiling height, floor layout, and existing equipment. Are there any structural limitations or obstructions that could impact crane installation or operation? By thoroughly assessing your work environment, you'll gain valuable insights into the challenges and opportunities that lie ahead.

A thorough assessment of your work environment is the foundational step in determining the appropriate underhung bridge crane specifications for your needs. By taking a detailed look at your workspace, you can identify key factors that will influence the design, installation, and operation of the crane. Here are the steps and considerations involved in this crucial phase:

Layout and Spatial Configuration:

Ceiling Height: Measure the ceiling height to determine the maximum allowable height for the crane and its components. Ensure there is sufficient clearance for the crane to operate without obstruction.

Floor Layout: Examine the overall floor plan, noting the positions of walls, columns, machinery, and other fixed equipment. Understand the flow of materials and personnel to ensure the crane can navigate effectively within the space.

Structural Limitations:

Building Structure: Assess the structural integrity of the building, including the strength and condition of the ceiling and floor. Determine if the existing structure can support the weight and dynamic loads of the crane or if reinforcement is necessary.

Obstructions: Identify any physical obstructions that could interfere with crane installation or operation, such as beams, ducts, pipes, or lighting fixtures. Plan to either relocate these obstructions or design the crane to accommodate them.

Operational Environment:

Work Area Conditions: Consider the environmental conditions of the work area, including temperature, humidity, dust, and exposure to corrosive substances. These factors can influence the choice of materials and protective coatings for the crane.

Hazards: Identify potential hazards within the work environment that could impact crane safety and performance. These might include overhead power lines, combustible materials, or restricted visibility areas. Implement measures to mitigate these risks.

Existing Equipment:

Integration with Existing Systems: Evaluate how the new crane will integrate with existing equipment and processes. Ensure that the crane's path does not interfere with the operation of other machinery or equipment.

Compatibility: Check for compatibility with current material handling systems, such as conveyors, forklifts, or other cranes. Plan for seamless interaction between different systems to enhance efficiency and safety.

Usage Patterns:

Operational Flow: Observe the workflow and movement patterns within the workspace. Understand how materials are transported and processed to design the crane system for optimal efficiency.

Frequency and Duration of Use: Consider how often and for how long the crane will be used each day. High-frequency, long-duration operations may require more robust components and advanced features to ensure reliability and longevity.

Accessibility and Maintenance:

Access for Installation: Ensure there is adequate access for transporting and installing the crane components. This includes entry points for trucks, sufficient space for assembly, and appropriate lifting equipment.

Maintenance Access: Plan for easy access to the crane for routine inspections, maintenance, and repairs. Ensure that maintenance personnel can safely reach all critical components without excessive effort or risk.

Future Expansion:

Scalability: Consider potential future expansions or modifications to the workspace. Design the crane system to be flexible and scalable to accommodate future growth or changes in operational needs.

Technological Upgrades: Factor in the possibility of incorporating advanced technologies, such as automation, remote monitoring, or integration with other digital systems, as part of future upgrades.

By taking a comprehensive stroll around your workspace and carefully assessing these factors, you will gain valuable insights into the unique challenges and opportunities that lie ahead. This thorough understanding of your work environment is essential for designing and selecting an underhung bridge crane that meets your specific requirements and enhances your operational efficiency and safety.

Determining Load Capacity Requirements

Next up, it's time to crunch some numbers and determine your load capacity requirements. Take stock of the heaviest loads you'll be lifting on a regular basis. Factor in not only the weight of the load but also any potential dynamic forces or impact loads. It's better to err on the side of caution and overspecify load capacity to ensure safety and reliability.

- Assessing Heaviest Loads: Identify the heaviest loads that your crane will need to lift as part of your daily operations. This could include raw materials, equipment, finished products, or machinery components. Consult with relevant personnel or departments to gather accurate information about the weight of these loads. Consider historical data, production schedules, and future projections to ensure comprehensive coverage.

- Considering Dynamic Forces: Recognize that the actual force exerted on the crane and its components may exceed the static weight of the load due to dynamic factors such as acceleration, deceleration, and sudden stops. Factor in dynamic forces that may occur during lifting, lowering, traversing, or sudden changes in load direction. These forces can significantly impact crane performance and safety.

- Accounting for Impact Loads: Anticipate impact loads that may occur when the load is initially lifted, lowered, or maneuvered. Impact loads can result from sudden starts, stops, or collisions and can impose additional stress on crane components. Incorporate a safety margin to accommodate potential impact loads and prevent overloading of the crane. It's essential to err on the side of caution to ensure the crane's structural integrity and longevity.

- Determining Load Capacity: Calculate the total load capacity required for the crane based on the weight of the heaviest loads, dynamic forces, and impact loads. Consider both the vertical (lifting) capacity and the horizontal (traverse) capacity of the crane. Consult crane manufacturers' specifications and load capacity charts to determine the appropriate crane model and configuration that can safely accommodate your load requirements.

- Overspecifying for Safety: Err on the side of caution when determining load capacity requirements. It's better to overspecify the crane's capacity than to risk overloading, which can lead to equipment damage, accidents, or injuries. Take into account potential future growth or changes in your operation that may require lifting heavier loads. Design the crane system with scalability in mind to accommodate evolving needs over time.

By diligently assessing your heaviest loads, considering dynamic forces and impact loads, and prioritizing safety by overspecifying load capacity, you can ensure that your underhung bridge crane is capable of safely and efficiently handling the demands of your operation. This proactive approach mitigates risks, enhances reliability, and contributes to the overall success of your material handling processes.

Analyzing Space Constraints

Space is often a precious commodity in industrial settings, and optimizing floor space is key to maximizing efficiency. Consider the available space for crane installation, maneuvering, and load positioning. Will a traditional overhead crane be too bulky, or is an underhung bridge crane the perfect space-saving solution? Analyze space constraints to determine the most suitable crane configuration for your needs.

In industrial environments, space optimization is crucial for maximizing efficiency and productivity. When analyzing space constraints for crane installation, maneuvering, and load positioning, careful consideration is required to ensure optimal utilization of available space. Let's explore how to approach this analysis effectively:

- Evaluate Available Space: Measure the available floor space where the crane will be installed, considering both the footprint of the crane system and the clearance required for safe operation. Assess vertical space constraints, including ceiling height and any overhead obstacles, to determine the maximum height at which the crane can operate without obstruction.

- Consider Traditional Overhead Cranes: Traditional overhead cranes are a common choice for material handling applications, offering high lifting capacities and extensive coverage. However, they require sufficient overhead clearance for the crane bridge and hoist to traverse without interference. Evaluate whether the available space and structural constraints can accommodate the installation of a traditional overhead crane, considering factors such as runway beam length, hook height, and clearance requirements.

- Explore Underhung Bridge Cranes: Underhung bridge cranes offer a space-saving alternative to traditional overhead cranes, as they utilize existing support structures or runways mounted beneath the ceiling. Assess whether an underhung bridge crane configuration is better suited to your space constraints, as it eliminates the need for overhead clearance and may require less floor space for installation and maneuvering.

- Compare Crane Configurations: Compare the spatial requirements of traditional overhead cranes and underhung bridge cranes to determine which configuration best aligns with your available space and operational needs. Consider the advantages and limitations of each crane type in relation to space constraints, such as maneuverability, coverage area, and compatibility with existing infrastructure.

- Optimize Layout and Positioning: Optimize the layout and positioning of the crane within the workspace to maximize efficiency and minimize interference with other operations or equipment. Explore different installation configurations, such as parallel or perpendicular to existing work areas, to achieve optimal utilization of space and streamline material flow.

- Plan for Future Expansion: Anticipate future growth or changes in your operation that may impact space requirements for crane installation and operation. Design the crane system with scalability in mind, allowing for future expansion or modifications to accommodate evolving needs without compromising efficiency or safety.

By carefully analyzing space constraints and considering the suitability of traditional overhead cranes versus underhung bridge cranes, you can make informed decisions that optimize space utilization and enhance operational efficiency in your industrial facility. This proactive approach ensures that your crane configuration aligns seamlessly with your space constraints and contributes to the overall success of your material handling processes.

Considering Operational Frequency and Duration

How often will your crane be in operation, and for how long? Will it be used for occasional heavy lifts or continuous material handling tasks? Understanding the operational frequency and duration helps in selecting the appropriate duty cycle for your crane. A crane that operates intermittently may have different specifications than one used in a high-volume production environment. Whether your crane will be used occasionally for heavy lifts or continuously for material handling tasks, tailoring its design to match the operational requirements is crucial. Here's how to consider operational frequency and duration effectively:

- Assess Operational Frequency: Determine how often your crane will be in operation, whether it's sporadic use for occasional tasks or continuous operation throughout the day. Evaluate the frequency of lifting operations, including the number of lifts per hour, shift, or day, to gauge the crane's workload and duty cycle requirements.

- Evaluate Operational Duration: Consider the duration of each lifting operation, including the time spent lifting, traversing, and positioning loads. Determine whether the crane will be used for short-duration tasks with frequent starts and stops or long-duration tasks with continuous operation over extended periods.

- Understand Duty Cycle Requirements: Duty cycle refers to the ratio of operating time to total time and is a critical factor in selecting crane specifications. Choose a duty cycle rating that matches the crane's expected workload and operational profile. Duty cycle classifications typically range from light-duty for intermittent use to heavy-duty for continuous operation.

- Select Appropriate Crane Components: Based on the assessed operational frequency and duration, select crane components such as motors, brakes, and gearboxes with suitable duty ratings. Ensure that the selected components can withstand the expected workload and provide reliable performance over the crane's operational lifespan.

- Consider Heat Dissipation: Continuous operation or high-frequency use can lead to heat buildup in crane components, potentially affecting performance and reliability.

Choose components with adequate heat dissipation capabilities to prevent overheating and ensure consistent operation under demanding conditions. - Factor in Maintenance Requirements: The operational frequency and duration of the crane can impact its maintenance requirements, including inspection intervals, lubrication schedules, and component replacements. Develop a proactive maintenance plan tailored to the crane's operational profile to minimize downtime, prolong equipment life, and ensure safe and reliable operation.

- Plan for Future Workload Changes: Anticipate changes in operational requirements or production volumes that may impact the crane's workload and duty cycle in the future. Design the crane system with flexibility and scalability to accommodate evolving needs and workload fluctuations without compromising performance or safety.

By carefully considering the operational frequency and duration of your underhung bridge crane, you can select the appropriate specifications and duty cycle to optimize performance, reliability, and efficiency in your material handling operations. This proactive approach ensures that your crane system is well-suited to meet the demands of your specific application, both now and in the future.

By thoroughly assessing your work environment, load requirements, space constraints, and operational parameters, you'll lay the groundwork for choosing the perfect underhung bridge crane. Stay tuned for the next section, where we'll explore the key parameters to consider when specifying your crane system. Until then, keep evaluating and refining your needs to ensure a seamless integration of your new crane into your operations.

Exploring Key Parameters

Now that you have a clear understanding of your operational needs, it's time to delve into the key parameters that will define the specifications of your underhung bridge crane. Each parameter plays a crucial role in ensuring the efficiency, safety, and effectiveness of your crane system. Let's explore these parameters in detail:

- Span and Length Requirements: The span and length of your crane system determine its coverage area and reach within your workspace. Measure the distance between the runways or support structures to determine the required span. Consider the maximum distance the crane needs to travel to access all areas of your facility. Balancing span and length requirements ensures optimal coverage without unnecessary overreach.

- Height Clearance : Height clearance is critical to prevent collisions with ceiling structures, equipment, or personnel. Measure the distance from the floor to the lowest obstruction in your workspace, accounting for the height of the crane and the loads it will be lifting. Ensure adequate clearance for safe crane operation and load movement.

- Hoist Speed and Control Options : The hoist speed and control options determine the efficiency and precision of load handling. Consider the required speed for lifting, lowering, and horizontal travel based on your operational needs. Choose control options that offer ease of use and flexibility, such as pendant controls, radio remote controls, or automated systems.

- Duty Cycle and Load Handling Capacity : The duty cycle and load handling capacity define the crane's ability to withstand continuous use and handle heavy loads. Determine the frequency and duration of crane operation to select the appropriate duty cycle rating. Ensure that the crane's load handling capacity exceeds the heaviest loads you'll be lifting to maintain safety and reliability.

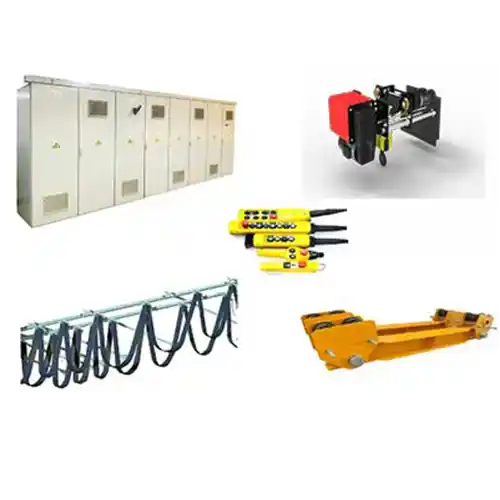

- Electrical Specifications : Electrical specifications encompass various components, including power supply, voltage, and wiring requirements. Ensure compatibility with your facility's electrical infrastructure and voltage standards. Consider options for power distribution, backup systems, and energy-efficient features to optimize crane performance and minimize downtime.

- Safety Features and Compliance : Safety should always be a top priority when selecting a crane system. Look for safety features such as overload protection, emergency stop controls, and collision avoidance systems. Ensure compliance with industry standards and regulations to mitigate risks and maintain a safe working environment for your personnel.

By exploring these key parameters and considering their implications on your operations, you'll be well-equipped to specify the perfect underhung bridge crane for your needs. Stay tuned for the next section, where we'll discuss the differences between ceiling-mounted and free-standing underhung bridge cranes to help you make an informed decision.

Types of Underhung Bridge Cranes

When it comes to underhung bridge cranes, there are primarily two main types: ceiling-mounted and free-standing. Each type offers unique advantages and limitations, making it essential to understand their differences to choose the right fit for your application.

Ceiling-Mounted Underhung Bridge Cranes

Ceiling-mounted underhung bridge cranes are precisely what their name suggests: they are installed directly onto the ceiling structure of your facility.

Ceiling-mounted underhung bridge cranes feature a bridge that runs along the length of the runway beams attached to the ceiling. The hoist mechanism is suspended from the bottom of the bridge girder, allowing for smooth horizontal movement along the runway beams.

Advantages:

Maximized Floor Space: By mounting the crane on the ceiling, you free up valuable floor space that would otherwise be occupied by support columns or other structural components.

Enhanced Maneuverability: Ceiling-mounted cranes offer greater flexibility in navigating around obstacles and accessing tight spaces within your facility.

Improved Safety: With the crane suspended from the ceiling, there are fewer obstructions on the floor, reducing the risk of accidents and collisions with personnel or equipment.

Limitations:

Structural Requirements: Installing a ceiling-mounted crane requires a robust ceiling structure capable of supporting the weight of the crane, runway beams, and loads. Structural modifications may be necessary to ensure proper installation and safety.

Ceiling Height Constraints: Ceiling-mounted cranes require sufficient overhead clearance for safe operation. Low ceiling heights or existing equipment may limit the feasibility of installation.

Limited Load Capacity: Depending on the ceiling structure and installation method, ceiling-mounted cranes may have lower load capacities compared to free-standing cranes.

Ideal Applications and Environments:

Manufacturing Facilities: Ceiling-mounted cranes are well-suited for manufacturing environments where floor space optimization is critical, such as assembly lines or production areas.

Warehouses: In warehouse settings with high ceilings, ceiling-mounted cranes offer efficient material handling and storage solutions.

Clean Rooms: In clean room environments where floor space must be kept clear for sanitation purposes, ceiling-mounted cranes provide an ideal overhead lifting solution.

The advantages, limitations, and ideal applications of ceiling-mounted underhung bridge cranes is essential for making informed decisions about your material handling needs. In the next section, we'll explore the characteristics of free-standing underhung bridge cranes to provide a comprehensive comparison.

Main Parameterers Required for The Quotation of Ceiling Moutned Underhung Bridge Cranes

When requesting a quotation for ceiling-mounted underhung bridge cranes, several key parameters are essential to provide accurate pricing and specifications. Here are the main parameters typically required:

- Load Capacity: The maximum weight that the crane will need to lift regularly. This includes both the dead weight of the load and any potential dynamic forces or impact loads.

- Span Length: The distance between the runway beams or support structures where the crane will operate. This determines the coverage area of the crane and influences the crane's structural design.

- Ceiling Height: The vertical distance from the floor to the ceiling where the crane will be mounted. This affects the clearance required for the crane's movement and determines the available lifting height.

- Duty Cycle: The frequency and duration of crane operation, ranging from light-duty for intermittent use to heavy-duty for continuous operation.

- Hoist Speed: The speed at which the hoist can raise and lower loads, typically specified in feet per minute (FPM) or meters per minute (MPM).

- Control System: The type of control system required for the crane, such as pendant control, radio remote control, or automated systems.

- Electrical Specifications: Voltage, phase, and frequency requirements for the crane's electrical system, ensuring compatibility with the facility's power supply.

- Safety Features: Any additional safety features or accessories required, such as overload protection devices, anti-collision systems, or emergency stop controls.

- Ceiling Structure: Information about the ceiling structure, including its load-bearing capacity and suitability for mounting the crane. This ensures proper installation and safe operation of the crane.

- Installation Environment: Details about the installation environment, including floor conditions, existing infrastructure, and any potential obstructions or obstacles.

- Certifications and Compliance: Any specific certifications or regulatory compliance requirements, such as CE marking, OSHA compliance, or local building codes.

- Additional Accessories: Optional accessories or features that may enhance crane performance or functionality, such as festoon systems, conductor bars, or lighting kits.

By providing detailed information on these parameters, crane suppliers can accurately assess your requirements and provide a tailored quotation that meets your needs. Additionally, consulting with a qualified crane manufacturer or supplier can help ensure that all essential parameters are considered and addressed in the quotation process.

Free-Standing Underhung Bridge Cranes

Free-standing underhung bridge cranes offer an alternative solution to ceiling-mounted cranes, providing versatility and reliability in various industrial applications.

Free-standing underhung bridge cranes are supported by their own independent support structures, typically comprised of columns or posts anchored to the floor. The bridge of the crane travels along the length of the runway beams, similar to ceiling-mounted cranes.

Design features may include adjustable heights, bolted connections for easy assembly and disassembly, and customizable configurations to suit specific space requirements.

Advantages:

Flexibility in Installation: Free-standing cranes do not rely on existing ceiling structures for support, allowing for installation in facilities with low ceiling heights or inadequate structural support for ceiling-mounted cranes.

Portability and Reusability: The modular design of free-standing cranes enables easy relocation and reinstallation in different areas of the facility or even across multiple sites, offering long-term flexibility and cost-effectiveness.

High Load Capacities: Free-standing cranes can often support heavier loads compared to ceiling-mounted cranes, as they are not constrained by the limitations of the ceiling structure.

Limitations:

Floor Space Utilization: Unlike ceiling-mounted cranes, free-standing cranes occupy floor space for their support structures, potentially reducing available workspace and maneuverability for other operations or equipment.

Obstruction of Floor Traffic: The support columns or posts of free-standing cranes may obstruct the movement of vehicles, personnel, or material handling equipment within the facility, requiring careful planning of layout and traffic flow.

Installation Complexity: Setting up free-standing cranes may involve more extensive planning and construction compared to ceiling-mounted cranes, particularly in facilities with challenging floor conditions or space constraints.

Ideal Applications and Environments:

Workshops and Maintenance Areas: Free-standing cranes are commonly used in workshops and maintenance facilities where flexibility and portability are essential for servicing various equipment and machinery.

Outdoor Environments: In outdoor settings such as construction sites or shipping yards, free-standing cranes offer a reliable lifting solution without relying on existing structures.

Temporary Projects: For temporary projects or short-term operations where mobility and versatility are paramount, free-standing cranes provide a practical solution that can be easily installed and removed as needed.

By understanding the definition, advantages, limitations, and ideal applications of free-standing underhung bridge cranes, you can make informed decisions when selecting the right crane system for your specific requirements. In the next section, we'll compare the characteristics of ceiling-mounted and free-standing cranes to help you determine the most suitable option for your facility.

Main Parameterers Required for The Quotation of Freestanding Underhung Bridge Cranes

When requesting a quotation for freestanding underhung bridge cranes, several key parameters are essential to provide accurate pricing and specifications. Here are the main parameters typically required:

- Load Capacity: The maximum weight that the crane will need to lift regularly. This includes both the dead weight of the load and any potential dynamic forces or impact loads.

- Span Length: The distance between the runway beams or support structures where the crane will operate. This determines the coverage area of the crane and influences the crane's structural design.

- Height of Lift: The vertical distance that the crane will need to lift loads. This includes the hook height and any additional clearance required for safe operation.

- Duty Cycle: The frequency and duration of crane operation, ranging from light-duty for intermittent use to heavy-duty for continuous operation.

- Hoist Speed: The speed at which the hoist can raise and lower loads, typically specified in feet per minute (FPM) or meters per minute (MPM).

- Control System: The type of control system required for the crane, such as pendant control, radio remote control, or automated systems.

- Electrical Specifications: Voltage, phase, and frequency requirements for the crane's electrical system, ensuring compatibility with the facility's power supply.

- Safety Features: Any additional safety features or accessories required, such as overload protection devices, anti-collision systems, or emergency stop controls.

- Installation Environment: Information about the installation environment, including floor conditions, ceiling height, and any potential obstructions or obstacles.

- Certifications and Compliance: Any specific certifications or regulatory compliance requirements, such as CE marking, OSHA compliance, or local building codes.

- Additional Accessories: Optional accessories or features that may enhance crane performance or functionality, such as festoon systems, conductor bars, or lighting kits.

- Budgetary Constraints: Any budgetary considerations or limitations that may impact the selection of crane components or configurations.

By providing detailed information on these parameters, crane suppliers can accurately assess your requirements and provide a tailored quotation that meets your needs. Additionally, consulting with a qualified crane manufacturer or supplier can help ensure that all essential parameters are considered and addressed in the quotation process.

Consultation and Collaboration

Effective consultation and collaboration are essential steps in the process of determining underhung bridge crane specifications. Engaging with various stakeholders and experts can provide valuable insights, ensure feasibility, and ultimately lead to the selection of the most suitable crane system for your needs.

Engaging with Crane Manufacturers or Suppliers

- Initial Contact: Reach out to reputable crane manufacturers or suppliers to initiate discussions about your project requirements. Provide detailed information about your facility, operational needs, and desired crane specifications.

- Technical Assessment: Work closely with crane experts to conduct a thorough technical assessment of your facility. This may involve site visits, measurements, and evaluations to determine feasibility and identify any potential challenges or constraints.

- Customization Options: Explore customization options offered by manufacturers to tailor the crane system to your specific needs. Discuss features such as span, capacity, control options, and safety enhancements to ensure alignment with your requirements.

- Budget and Timeline: Collaborate with manufacturers to establish a budget and timeline for the project. Discuss pricing, financing options, and delivery schedules to ensure that the project stays within budget and meets your deadlines.

Seeking Professional Engineering Input

- Engineering Evaluation: Enlist the expertise of professional engineers to evaluate the structural integrity and feasibility of crane installation within your facility. Engineers can assess factors such as load-bearing capacity, structural modifications, and adherence to building codes and regulations.

- Design Optimization: Work with engineers to optimize the design of the crane system for maximum efficiency and safety. They can provide valuable input on structural considerations, electrical requirements, and integration with existing infrastructure.

- Risk Assessment: Collaborate with engineers to conduct a comprehensive risk assessment to identify and mitigate potential hazards associated with crane operation. This may involve evaluating factors such as load dynamics, collision risks, and emergency procedures.

Collaborating with Operations and Maintenance Teams

- Operational Input: Engage with operations teams to gather insights into day-to-day workflows, material handling processes, and production schedules. Their input can help refine crane specifications to align with operational requirements and optimize workflow efficiency.

- Training and Support Needs: Collaborate with maintenance teams to assess training and support needs for crane operation and maintenance. Identify requirements for operator training, preventive maintenance programs, and spare parts inventory management to ensure smooth crane operation and minimize downtime.

- Feedback Loop: Establish a feedback loop with operations and maintenance teams throughout the project lifecycle. Encourage open communication and solicitation of feedback to address any issues or concerns promptly and optimize crane performance post-installation.

By engaging in consultation and collaboration with crane manufacturers, engineers, and operations and maintenance teams, you can leverage collective expertise and ensure that your underhung bridge crane specifications align with your operational needs and facility requirements. This collaborative approach fosters transparency, innovation, and ultimately, the successful implementation of your crane project.

Budgeting and Cost Considerations

Budgeting and cost considerations are crucial aspects of selecting an underhung bridge crane that meets your operational needs while staying within your financial constraints. By carefully evaluating initial investments, long-term costs, financing options, and potential cost-saving measures, you can make informed decisions that balance efficiency and affordability.

Initial Investment vs. Long-term Cost Analysis

- Initial Investment: Consider the upfront costs associated with purchasing and installing an underhung bridge crane, including crane components, structural modifications, installation labor, and any additional equipment or accessories. Obtain detailed quotes from crane manufacturers or suppliers to assess initial investment requirements accurately.

- Long-term Cost Analysis: Conduct a comprehensive analysis of long-term costs associated with crane ownership and operation. Factor in ongoing expenses such as maintenance, repairs, energy consumption, and potential downtime. Consider the expected lifespan of the crane and calculate the total cost of ownership over its lifetime to evaluate the overall cost-effectiveness.

Exploring Financing Options

- Cash vs. Financing: Evaluate your financing options to determine the most suitable approach for acquiring the crane system. Assess whether purchasing the crane outright with cash or financing it through loans, leasing, or other financing arrangements aligns with your financial goals and cash flow requirements.

- Vendor Financing Programs: Inquire about financing programs offered by crane manufacturers or suppliers. Some vendors may provide financing options with favorable terms, such as low-interest rates, flexible repayment schedules, or deferred payment plans, to facilitate the acquisition of the crane system.

Identifying Potential Cost-saving Measures

- Efficiency Improvements: Explore opportunities to improve efficiency and productivity through the use of advanced crane technologies, automation, or process optimizations. Investing in energy-efficient components, predictive maintenance systems, or workflow enhancements can result in long-term cost savings by reducing energy consumption, downtime, and operational inefficiencies.

- Maintenance Strategies: Implement proactive maintenance strategies to prolong the lifespan of the crane system and minimize repair costs. Develop a preventive maintenance program that includes regular inspections, lubrication, and component replacements to address potential issues before they escalate into costly repairs or downtime.

- Training and Operator Efficiency: Invest in comprehensive training programs for crane operators and maintenance personnel to enhance their skills, efficiency, and safety awareness. Well-trained operators can maximize crane performance, minimize errors, and prevent accidents, leading to improved productivity and reduced operational costs over time.

By conducting a thorough analysis of budgeting and cost considerations, you can make informed decisions that optimize the financial viability and long-term sustainability of your underhung bridge crane investment. Balancing initial investments with long-term cost savings, exploring financing options, and identifying potential cost-saving measures empower you to maximize the value of your crane system while staying within budgetary constraints.

Regulatory Compliance and Standards

Ensuring regulatory compliance and adherence to industry standards is paramount when selecting and operating an underhung bridge crane. Failure to comply with applicable regulations can result in safety hazards, legal liabilities, and costly penalties. Let's explore the key aspects of regulatory compliance and standards:

Understanding Local and International Regulations

- Local Regulations: Familiarize yourself with local regulations and building codes governing the installation, operation, and maintenance of crane systems. These regulations may vary by region and may include requirements related to structural design, electrical safety, noise emissions, and zoning restrictions.

- International Standards: Stay informed about international standards and guidelines that govern crane design, manufacturing, and operation. Standards such as ISO (International Organization for Standardization) and ANSI (American National Standards Institute) provide globally recognized criteria for crane performance, safety, and quality assurance.

Ensuring Compliance with Industry Standards

- OSHA Standards: In the United States, the Occupational Safety and Health Administration (OSHA) sets regulations and standards for workplace safety, including crane safety. Ensure compliance with OSHA's crane and derrick standards (29 CFR 19179) to protect workers from hazards associated with crane operations.

- CE Marking: In Europe, underhung bridge cranes must comply with CE marking requirements, indicating conformity with essential health, safety, and environmental protection standards. CE marking ensures that the crane meets European Union regulations and can be legally sold and operated within the EU market.

Importance of Certification and Inspection

- Certification: Prioritize underhung bridge cranes that are certified by reputable certification bodies or agencies. Certification verifies that the crane meets specified performance, safety, and quality standards, providing assurance of compliance with regulatory requirements and industry best practices.

- Routine Inspection: Implement a regular inspection and maintenance program to ensure ongoing compliance and safe operation of the crane system. Conduct routine inspections of crane components, structural integrity, electrical systems, and safety features to identify and address potential issues proactively.

- Third-Party Inspection: Consider engaging third-party inspection services to conduct independent assessments of the crane's compliance and safety. Third-party inspectors can provide unbiased evaluations and recommendations to ensure regulatory compliance and mitigate risks associated with crane operation.

By understanding and adhering to local and international regulations, ensuring compliance with industry standards, and prioritizing certification and inspection protocols, you can mitigate safety risks, maintain legal compliance, and uphold operational integrity when selecting and operating an underhung bridge crane. Compliance with regulatory requirements is not only a legal obligation but also a fundamental aspect of responsible and ethical crane management.

Customization and Special Requirements

Customization plays a pivotal role in ensuring that your underhung bridge crane meets the unique demands of your application and environment. By tailoring the crane design, integrating additional features or accessories, and addressing unique challenges or constraints, you can optimize crane performance and enhance operational efficiency. Let's explore each aspect in detail:

Tailoring Crane Design to Specific Applications

- Assessment of Application Needs: Begin by conducting a comprehensive assessment of your application requirements, including load characteristics, operating environment, workflow processes, and space constraints.

- Customized Design Solutions: Work closely with crane manufacturers or suppliers to develop customized design solutions that align with your specific application needs. This may involve modifications to crane dimensions, structural components, lifting mechanisms, or control systems to optimize performance and functionality.

- Specialized Configurations: Explore specialized configurations such as double-girder cranes, gantry cranes, or monorail systems to accommodate unique application requirements. These configurations offer increased load capacities, extended reach, or enhanced maneuverability to address specific operational challenges.

Integrating Additional Features or Accessories

- Enhanced Safety Features: Consider integrating additional safety features and accessories to enhance crane safety and operator protection. This may include anti-collision systems, overload protection devices, emergency stop controls, and warning lights or alarms to mitigate risks and prevent accidents.

- Productivity Enhancements: Explore features or accessories that improve productivity and efficiency in material handling operations. Examples include variable speed controls, automation technologies, remote monitoring systems, and ergonomic operator interfaces to streamline workflow processes and reduce cycle times.

- Environmental Considerations: Incorporate environmental considerations into crane design by selecting eco-friendly components, energy-efficient motors, and noise reduction measures. Minimizing environmental impact not only promotes sustainability but also enhances workplace comfort and compliance with regulatory requirements.

Addressing Unique Challenges or Constraints

- Site-Specific Challenges: Identify and address site-specific challenges or constraints that may impact crane installation or operation. This may include limited space, overhead clearance restrictions, floor conditions, seismic considerations, or corrosive environments that require specialized design solutions.

- Collaborative Problem-Solving: Engage in collaborative problem-solving with crane experts, engineers, and stakeholders to develop innovative solutions for unique challenges. By leveraging collective expertise and creativity, you can overcome obstacles and achieve optimal crane performance in challenging environments.

- Adaptability and Future-Proofing: Design the crane system with adaptability and future-proofing in mind to accommodate evolving operational needs and technological advancements. Incorporate modular components, scalable configurations, and upgradeable features to facilitate easy modifications or expansions as your business grows.

By embracing customization and addressing special requirements, you can tailor your underhung bridge crane to suit your specific application needs, enhance safety and productivity, and overcome unique challenges or constraints. Collaboration with crane experts and stakeholders throughout the customization process ensures that the final solution meets your expectations and delivers long-term value to your operations.

Documentation and Finalizing Specifications

The documentation and finalization of specifications are critical steps in the process of acquiring an underhung bridge crane. Thorough documentation ensures clarity, consistency, and compliance with regulatory requirements, while careful review and refinement of specifications help to optimize crane performance and functionality. Let's explore each aspect in more detail:

Compiling Technical Data and Documentation

- Gathering Technical Data: Begin by compiling comprehensive technical data related to the underhung bridge crane, including specifications provided by crane manufacturers or suppliers, engineering drawings, structural calculations, electrical schematics, and safety manuals.

- Documenting Design Requirements: Document specific design requirements and performance criteria for the crane system, including load capacities, span lengths, hoist speeds, control options, safety features, and any customized configurations or special considerations.

- Recording Compliance Documentation: Ensure that all documentation aligns with regulatory requirements and industry standards. Include copies of certifications, test reports, compliance statements, and other documentation demonstrating adherence to applicable regulations and standards.

Reviewing and Refining Specifications

- Internal Review Process: Conduct a thorough internal review of the compiled specifications to identify any discrepancies, inconsistencies, or areas for improvement. Engage relevant stakeholders, including engineering, operations, maintenance, and safety personnel, to provide input and feedback on the proposed specifications.

- Refining Performance Criteria: Refine performance criteria based on feedback from stakeholders and any new insights or considerations that may have emerged during the review process. Ensure that specifications are realistic, achievable, and aligned with operational needs and budgetary constraints.

- Optimizing Design Solutions: Collaborate with crane manufacturers or suppliers to explore optimization opportunities and refine design solutions. Incorporate feedback from the review process to fine-tune crane specifications and maximize performance, safety, and reliability.

Securing Approvals and Sign-offs

- Internal Approvals: Obtain internal approvals from key decision-makers within your organization, including management, finance, and operations departments. Ensure that all stakeholders are in agreement with the finalized crane specifications and that any concerns or objections have been addressed satisfactorily.

- External Approvals: If required, seek external approvals from regulatory authorities, building inspectors, or other relevant agencies responsible for overseeing crane installations. Provide them with the necessary documentation and evidence of compliance to secure official approvals and permits for crane operation.

- Sign-offs and Contracts: Obtain sign-offs from all parties involved in the procurement process, including crane manufacturers or suppliers, contractors, and subcontractors. Finalize contracts and agreements detailing the scope of work, delivery schedules, payment terms, warranties, and any other contractual obligations.

By meticulously compiling technical data and documentation, reviewing and refining specifications, and securing approvals and sign-offs, you can ensure that your underhung bridge crane project progresses smoothly from concept to implementation. Clear and comprehensive documentation facilitates effective communication, minimizes misunderstandings, and lays the foundation for a successful crane installation that meets your operational needs and regulatory requirements.

Send Your Main Parameters to get Your Underhung Bridge Crane Quotation

How to confir your underhung bridge crane specification? Crane capacity, crane span, and lifting height,

Request for Bridge Crane Quotation

Crane Types:_________?

- Ceiling-Mounted Underhung Bridge Crane

- Free-Standing Underhung Bridge Crane

Main Parameters:

- Load Capacity: _________?

Key Terms: Rated capacity, lifting capacity, maximum load, safe working load (SWL) - Span Length: _________?

Key Terms: Bridge span, runway length, distance between runway beams, coverage area - Lifting Height: : _________?

Key Terms: Maximum lift height, hook height, vertical clearance, lifting range - Ceiling Height (for ceiling-mounted):: _________?

Key Terms: Ceiling clearance, lift height, vertical space, mounting height - Support Structure (for freestanding):: _________?

Key Terms: Support columns, foundation requirements, structural integrity, base plate dimensions - Duty Cycle:: _________? ( If you are not sure about it, please feel free to contact us. )

Key Terms: Operational frequency, duty rating, cycle time, intermittent duty, continuous duty. - Hoist Speed:: _________?

Key Terms: Lifting speed, travel speed, FPM (Feet Per Minute), MPM (Meters Per Minute) - Control System:: _________?

Key Terms: Control type (pendant, radio remote, automated), control voltage, control method - Electrical Specifications:: _________? ( 380v 50hz 3phase, or others )

Key Terms: Voltage, phase, frequency, power supply requirements, electrical components - Installation Environment:: _________?

Key Terms: Floor conditions, ceiling structure, obstructions, environmental factors, general use workshops or hazarous environment. - Special Requirements: _________?

Conclusion

As we wrap up our journey through the process of determining underhung bridge crane specifications, let's reflect on the key points discussed and the importance of thorough planning and evaluation in this endeavor.

Throughout this guide, we've covered a wide range of topics essential to selecting the right underhung bridge crane for your needs. From understanding your operational requirements to exploring key parameters, types of cranes, consultation and collaboration, budgeting, regulatory compliance, customization, documentation, and finalizing specifications, we've delved into every aspect to ensure a comprehensive understanding.

Thorough planning and evaluation are the cornerstones of success when it comes to selecting an underhung bridge crane. By taking the time to assess your operational needs, analyze space constraints, evaluate regulatory requirements, and collaborate with stakeholders and experts, you lay the groundwork for informed decision-making and optimal crane performance.

By following the guidelines outlined in this guide, decision-makers are empowered with the confidence to make informed choices regarding underhung bridge crane specifications. Armed with a clear understanding of their needs, regulatory obligations, budgetary constraints, and available options, decision-makers can navigate the procurement process with confidence, knowing that they've considered all relevant factors and made choices that align with their organizational goals.

In conclusion, selecting an underhung bridge crane is a multifaceted process that requires careful consideration, collaboration, and attention to detail. By following the steps outlined in this guide and leveraging the expertise of crane manufacturers, engineers, and stakeholders, you can ensure that your crane system meets your operational needs, complies with regulatory requirements, and delivers long-term value to your organization.

Main Projects

Related Products

22/5 Ton Overhead Crane Double Hook System: Robust double girder crane with 22-ton main and 5-ton auxiliary hooks for heavy lifting. Get double hook crane!

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch