Underhung Bridge Crane Kit 5 Ton for Sale Canada, No Girder Crane

Underhung Bridge Crane Kit 5 Ton for Sale Canada, No Girder Crane Kit, Cost-effective Solution, Customized power suply 575V50HZ3P. Get your crane kit.

Category: Canada Overhead Crane

Your Trusted Underhung Crane Manufacturer & Supplier

Case Study: 5 Ton Underhung Bridge Crane Kit wiht No Main Girder

Cost-Effective 5 Ton Underhung Overhead Crane Kit with Customized Power Supply for Canadian Operations

A tailored 5-ton underhung crane system with customized 575V, 50Hz, 3-Ph power supply, maximizing space, cost savings, and operational efficiency for Canadian businesses.

Cost-Effective 5 Ton Underhung Bridge Crane Kit with Customized Power Supply for Canadian Operations

Overview of the Project

Customer Overview and Crane Requirements

The customer is a Canadian manufacturer specializing in heavy-duty machinery components. They were seeking a reliable crane system to handle 5-ton loads within their production facility. The primary challenge was to fit a crane system into a limited space without compromising on lifting capacity or efficiency. After evaluating their options, the customer chose a 5-ton underhung bridge crane to meet their operational needs.

Why the No-Girder Solution Was Chosen

The decision to select a no-girder crane system was driven by the customer’s specific space limitations and need for a compact design. Key reasons for choosing the no-girder solution include:

- Space Efficiency: Traditional overhead cranes with girders require significant headroom, which would reduce available space in the facility.

- Compact Design: The underhung system is mounted beneath the ceiling, saving vertical space and maintaining maximum clearance for other operations.

- Reduced Structural Modifications: Without the need for a large, bulky support structure, the crane system minimized installation costs and time.

Cost-Effective and Customized Solutions for Canadian Operations

The customer needed a cost-effective lifting solution that could be customized to suit their specific operational requirements. The underhung bridge crane kit was selected for the following reasons:

- Cost Savings: The no-girder design offered a more affordable option compared to traditional overhead cranes.

- Tailored Power Supply: The crane system was customized with a 575V, 50Hz, 3-phase power supply, perfectly suited for Canadian electrical standards.

- Energy Efficiency: The customized power configuration ensures efficient crane operation, reducing long-term energy costs.

By choosing this customized 5-ton crane system, the customer was able to achieve both cost savings and operational efficiency while meeting the specific demands of their Canadian workshop.

underhung bridge crane with no main girder for sale Canada

Project Requirements

Crane Specifications

The project required a crane system that could handle a 5-ton load, with the following key specifications:

- Capacity: 5 tons, suitable for handling the customer’s typical load sizes within their production environment.

- Span: 9.7 meters, providing ample coverage for lifting and transporting materials across the workshop.

- Lifting Height: 6.1 meters, ensuring the crane could reach the required elevation to safely lift components within the customer’s workspace.

These specifications were tailored to meet the customer’s operational needs, offering both the lifting capacity and spatial flexibility required for efficient operations.

Power Supply Customization

To ensure the crane system would operate optimally within the Canadian facility, a customized power supply was provided:

- Customized Power Supply: 575V, 50Hz, 3-phase power configuration, which aligns with Canadian electrical standards.

- Power Compatibility: This customization ensured that the crane could be integrated smoothly with the existing electrical infrastructure in the facility.

- Enhanced Efficiency: The customized power setup also contributed to the crane’s energy efficiency, supporting both performance and long-term operational savings.

The power supply customization was a key component in ensuring the crane’s seamless operation within the specific environment of the customer’s Canadian facility.

Solution Provided: Underhung Bridge Crane Kit

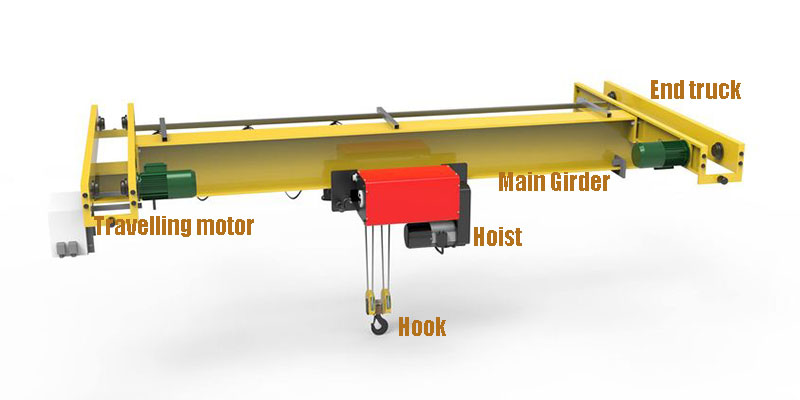

Design and Features: Explanation of the Underhung Bridge Crane System

The solution provided to the customer was a 5-ton underhung bridge crane kit, a highly efficient and space-saving system designed for industrial applications. In an underhung system, the crane’s runway beams are mounted below the supporting structure, rather than above as in traditional overhead cranes. This design allows the crane to operate beneath the ceiling beams, leaving the overhead space free for other activities.

Key features of the system include:

- Compact Design: The underhung design minimizes the space required for installation and operation.

- Efficient Lifting Mechanism: The crane uses a trolley and hoist system mounted on the bridge, designed to maximize lifting height and coverage.

- Smooth Operation: The crane runs smoothly along the rails mounted below the ceiling, offering precise control over load movements.

electric under running overhead crane hoist

electric under running overhead crane hoist

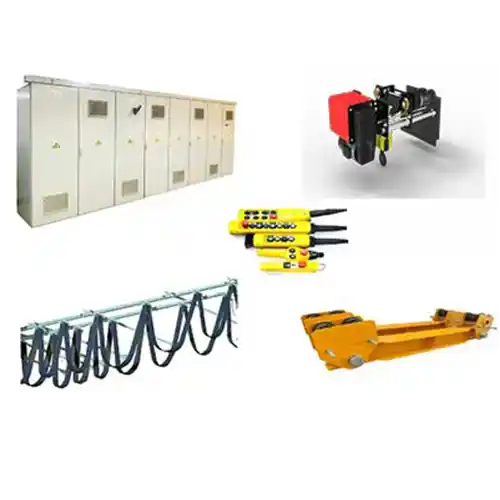

end carriages and other parts and components of underhung crane kit

end carriages and other parts and components of underhung crane kit

Advantages of a No-Girder Solution for Space Efficiency and Cost Savings

One of the standout features of the solution is the no-girder design, which offers several key advantages over traditional bridge cranes:

- Maximized Space Usage: Traditional cranes with girders require significant headroom, which can reduce vertical space. The no-girder system allows for greater use of available space, leaving more room for other operations.

- Cost Savings on Structural Modifications: Since the crane runs beneath the ceiling beams, there’s no need for additional structural support or costly modifications to the building’s infrastructure.

- Lower Installation Costs: With fewer components and simpler installation requirements, the no-girder solution cuts down on both installation time and labor costs.

By eliminating the need for large supporting girders, the underhung system provides an economical solution that increases space utilization and reduces costs across the board.

How the Crane Design Minimizes Installation Costs and Maximizes Operational Efficiency

The underhung bridge crane kit is designed with simplicity in mind, which directly impacts both installation and operational efficiency:

- Quick Installation: The kit comes with pre-engineered components that are easy to assemble, minimizing the time required for installation.

- Reduced Downtime: The crane system is designed for minimal maintenance and maximum uptime, ensuring continuous operation with fewer disruptions.

- Optimized Performance: With an efficient lifting system, the crane offers smooth operation and precise load control, improving overall productivity and reducing operational bottlenecks.

This straightforward design not only saves money but also helps the customer maximize the return on investment by improving overall operational efficiency.

Power Supply Customization: Tailoring the Power Supply for Optimal Performance and Safety in Canada

The crane system was customized with a 575V, 50Hz, 3-phase power supply, tailored specifically for Canadian electrical standards. This customization ensures the crane operates smoothly and safely in the local environment.

- Compatibility with Canadian Electrical Infrastructure: The 575V power supply aligns with Canada’s industrial electrical standards, ensuring that the crane works efficiently with the existing infrastructure.

- Safety and Compliance: By using a power configuration suited to Canadian conditions, the crane system adheres to local safety regulations and minimizes electrical risks.

- Energy Efficiency: The 575V system optimizes the crane’s energy consumption, making it both cost-effective and environmentally friendly.

This tailored power solution ensures the crane operates at peak efficiency while meeting the specific requirements of Canadian manufacturing environments.

Why the Underhung Bridge Crane Kit with No Main Girder is the Economical Solution for Clients in Canada

The 5-ton underhung bridge crane kit with no main girder is the ideal solution for Canadian clients due to its combination of cost-efficiency, space-saving design, and customization options.

- Space-Saving Design: The no-girder setup ensures the crane uses minimal vertical space, offering maximum clearance for other operations while still providing powerful lifting capabilities.

- Lower Installation and Operational Costs: The crane requires fewer structural modifications, reducing installation costs. Additionally, the simplified design and fewer components mean less maintenance and downtime over the long term.

- Tailored Power Supply: The 575V, 50Hz, 3-phase power supply is specifically chosen to meet Canadian electrical standards, optimizing performance and energy consumption.

Overall, the underhung bridge crane kit provides a cost-effective, space-efficient, and highly functional solution for industrial operations in Canada, making it an excellent choice for companies looking to enhance productivity while keeping costs under control.

Conclusion: Why This Solution Works for Canadian Customers

Summary of Benefits

The 5-ton underhung bridge crane kit offers a range of benefits that make it an ideal solution for Canadian businesses, particularly those looking for space-efficient, cost-effective, and reliable lifting systems.

- Cost Savings: The no-girder design minimizes both installation and operational costs. By eliminating the need for bulky overhead girders and reducing structural modifications, the crane system offers significant savings in the long run.

- Customized Power Supply: The 575V, 50Hz, 3-phase power configuration ensures that the crane operates efficiently and safely within Canadian electrical standards. This customization makes the crane compatible with local infrastructure, reducing potential electrical issues and enhancing overall performance.

- Ease of Installation: With a straightforward design and pre-engineered components, the crane system is easy to install. This reduces downtime and minimizes the need for complex setup procedures, allowing businesses to start using the crane quickly.

These key features ensure that the crane system delivers both immediate and long-term value for businesses in Canada.

Long-Term Value

This underhung bridge crane kit isn’t just a short-term solution; it’s designed with long-term reliability and future adaptability in mind.

- Reliability: Built with high-quality materials and a simple yet robust design, the crane system is highly reliable. Its low-maintenance features ensure that businesses can count on it for years to come, reducing the risk of costly downtime and repairs.

- Efficiency: The crane’s compact design and smooth operation translate into consistent performance, boosting productivity and minimizing disruptions in daily operations. The efficient power supply also contributes to lower energy costs, helping businesses save money over time.

- Future Adaptability: As businesses grow and evolve, so too does their need for flexible equipment. The underhung crane system is customizable and scalable, meaning it can be easily adapted to meet changing operational demands or upgraded with new features as technology evolves.

In conclusion, this crane system offers a perfect blend of cost-effectiveness, performance, and future-proofing. It meets the specific needs of Canadian businesses, providing a reliable and efficient solution that will continue to deliver value for years to come.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch