Wire Rope Electric Hoist 20 Ton 9M Lifting Height for Sale Vietnam

20 ton electric hoist for sale Vietnam. European-style Style Wire Rope Electric Hoist for Double Girder Crane , Low headrom crab hoist and trolley 20 ton.

Category: Vietnam

Your Trusted Overhead Crane Manufacturer & Supplier

Wire Rope Electric Hoist 20 Ton 9M Lifting Height for Sale Vietnam

20 ton electric hoist for sale Vietnam. European-style Style Wire Rope Electric Hoist for Double Girder Crane , Low headrom crab hoist and trolley 20 ton.

Project Background: Addressing the Need for a Versatile and Powerful Lifting Solution

Need for the 20-Ton Wire Rope Electric Hoist

The decision to implement a 20-ton wire rope electric hoist in this project was driven by the growing demand for a more efficient and reliable material handling system within the client's manufacturing facility. The existing overhead crane infrastructure was struggling to keep up with the increasing production volumes and heavier load requirements, leading to bottlenecks and reduced operational efficiency.

To address these challenges, the organization recognized the need for a robust and versatile lifting solution that could seamlessly integrate with their double girder crane setup. The goal was to enhance the crane's load-handling capabilities, improve productivity, and ensure the safe movement of heavy materials throughout the facility.

Specifications of the Required Hoist

The key specifications for the 20-ton wire rope electric hoist were as follows:

- European Style: The hoist was designed to adhere to the rigorous European standards for quality, safety, and performance, ensuring a high level of engineering excellence.

- Double Girder Crane: The hoist was required to be compatible with the existing double girder crane infrastructure, allowing for seamless integration and improved load-handling capabilities.

- Low Headroom Crab Hoist and Trolley: The compact and low-profile design of the hoist and trolley was crucial to maintain the necessary headroom clearance within the facility's crane system.

- 20-Ton Capacity: The hoist was specified to have a lifting capacity of 20 tons, enabling the safe and efficient handling of the heaviest loads within the production environment.

- 9-Meter Lifting Height: The required lifting height of 9 meters was determined based on the facility's layout and the operational needs for material movement.

- 380V, 50Hz, 3-Phase Power: The hoist was designed to operate on a 380V, 50Hz, 3-phase electrical power supply, ensuring compatibility with the existing electrical infrastructure.

20 ton electric hoist with 9 meters lifting height

Wire rope electric hoist for sale Vietnam

Electric wire rope hoist 20 ton for sale Vietnam

Procurement and Installation Process

The procurement and installation of the 20-ton wire rope electric hoist involved a collaborative effort between the client, the hoist manufacturer, and the installation team. The process included:

- Thorough market research and vendor evaluation to identify the most suitable hoist solution that met the project's specific requirements.

- Detailed planning and coordination to ensure a seamless integration of the hoist with the existing double girder crane system, minimizing disruptions to ongoing operations.

- Careful installation and commissioning of the hoist, including the setup of the control systems, safety features, and operator training.

- Comprehensive testing and performance validation to verify the hoist's capabilities and ensure compliance with all relevant standards and regulations.

The successful integration of the 20-ton wire rope electric hoist into the client's material handling ecosystem laid the foundation for enhanced productivity, improved safety, and increased operational efficiency within the manufacturing facility.

Technical Evaluation: Ensuring Optimal Performance and Safety

Hoist Selection and Features

The selection of the 20-ton wire rope electric hoist was a critical step in ensuring the success of this project. After a comprehensive evaluation of the available options, the client chose a hoist featuring the following key technical specifications:

- SEW Motor: The hoist was equipped with a high-efficiency SEW motor, renowned for its reliability, durability, and energy-saving performance. This motor selection was crucial in providing the necessary power and torque to handle the 20-ton load capacity.

- Variable Speed Control: The hoist was designed with a variable speed control system, allowing operators to precisely regulate the lifting and lowering speeds. This feature enabled more controlled and precise material handling, enhancing both safety and efficiency.

Compatibility with the Existing Crane System

Ensuring the seamless integration of the 20-ton wire rope electric hoist with the client's existing double girder crane system was a critical aspect of the technical evaluation. The hoist's design and dimensions were carefully assessed to ensure a perfect fit within the crane's infrastructure, without compromising the overall system's functionality or load-bearing capacity.

The hoist's low-headroom crab design was particularly important in this regard, as it allowed for the installation without the need for significant structural modifications to the crane. This helped to minimize the disruption to the client's operations and streamline the implementation process.

Safety and Reliability Considerations

Safety and reliability were paramount priorities throughout the technical evaluation process. The 20-ton wire rope electric hoist was thoroughly tested and certified to meet the rigorous European safety standards, ensuring the protection of both personnel and the handled materials.

Key safety features incorporated into the hoist design included:

- Overload protection mechanisms to prevent exceeding the rated capacity

- Automatic braking systems to ensure controlled and secure load movements

- Emergency stop functions for immediate halt in case of any unexpected events

- Comprehensive safety monitoring and diagnostic systems

Furthermore, the hoist's robust construction and high-quality components were carefully assessed to guarantee long-term reliability and minimal downtime, enabling the client to maintain a consistent and efficient material handling operation.

By meticulously evaluating the technical aspects of the 20-ton wire rope electric hoist, the project team ensured that the selected solution not only met the client's specific requirements but also delivered superior performance, safety, and reliability throughout its lifetime.

Implementation and Commissioning: Seamless Integration and Operational Readiness

Delivery and Installation

The successful implementation of the 20-ton wire rope electric hoist began with the seamless delivery and installation process. The hoist and its associated components were carefully transported to the client's facility, ensuring that the delicate equipment was not compromised during the journey.

The installation team, comprising experienced technicians, worked closely with the client's operations team to develop a detailed plan for the hoist's integration with the existing double girder crane system. This planning phase addressed key logistical considerations, such as crane downtime, workspace management, and safety protocols, to minimize disruptions to the ongoing production activities.

The installation process itself was carried out with the utmost precision, with the hoist being carefully positioned and secured within the crane infrastructure. The team ensured that all mechanical, electrical, and control connections were properly established, adhering to the manufacturer's specifications and industry best practices.

Testing and Commissioning

Following the successful installation, the project team initiated a comprehensive testing and commissioning phase to validate the hoist's performance and ensure its readiness for operational use. This included:

- Load testing: The hoist was subjected to rigorous load tests, gradually increasing the weight up to 125% of its rated capacity to verify its load-handling capabilities and safety mechanisms.

- Functional testing: The team meticulously tested all the hoist's features, including the variable speed control, braking systems, and emergency stop functions, to ensure seamless and reliable operation.

- Safety checks: Detailed inspections were conducted to validate the proper implementation of all safety features, such as overload protection, limit switches, and fault detection systems.

- Integration testing: The hoist's integration with the double girder crane was thoroughly verified, ensuring smooth and coordinated movements between the two components.

Upon successful completion of the testing and commissioning phase, the project team documented the results and obtained the necessary certifications and approvals, paving the way for the hoist's entry into full-scale operational use.

Operator Training

To ensure the safe and efficient utilization of the 20-ton wire rope electric hoist, the project team provided comprehensive operator training sessions. These sessions covered:

- Hoist operation: Detailed instructions on the proper use of the hoist's controls, including the variable speed function and emergency stop procedures.

- Maintenance and inspections: Guidance on the routine maintenance tasks and regular inspections required to keep the hoist in optimal condition.

- Safety protocols: Comprehensive training on the safety features and best practices for handling heavy loads, ensuring the protection of both personnel and equipment.

- Troubleshooting and reporting: Instruction on how to identify and address any operational issues, as well as the appropriate channels for reporting and resolving problems.

By equipping the operators with the necessary knowledge and skills, the project team ensured that the 20-ton wire rope electric hoist would be utilized to its full potential, maximizing productivity, safety, and efficiency within the client's material handling operations.

Performance Evaluation: Measuring the Impact of the 20-Ton Wire Rope Electric Hoist

Operational Efficiency

The implementation of the 20-ton wire rope electric hoist had a profound impact on the client's operational efficiency within the manufacturing facility. Key performance indicators showcased the significant improvements:

- Increased load-handling capacity: The hoist's 20-ton lifting capacity allowed for the safe and efficient movement of heavier materials, eliminating the need for multiple handling steps and reducing the overall processing time.

- Enhanced productivity: The hoist's variable speed control and precise maneuvering capabilities enabled faster load movements, resulting in reduced cycle times and increased throughput for the crane system.

- Improved material flow: The seamless integration of the hoist with the double girder crane facilitated a more streamlined and organized material flow throughout the production area, minimizing bottlenecks and optimizing the overall workflow.

Maintenance and Downtime

The technical evaluation and rigorous testing during the implementation phase ensured that the 20-ton wire rope electric hoist was built to withstand the demands of the client's operations. This translated to:

- Reduced maintenance requirements: The hoist's robust construction and high-quality components required fewer interventions, leading to a decrease in scheduled maintenance downtime.

- Minimal unplanned downtime: The comprehensive safety features and fault detection systems built into the hoist helped to prevent unexpected failures, minimizing the impact of unplanned outages on the client's production schedule.

- Streamlined maintenance processes: The hoist's user-friendly design and the operator training program enabled efficient troubleshooting and faster resolution of any maintenance issues that did arise.

Cost Savings and Productivity Improvements

The enhanced operational efficiency and reduced maintenance requirements of the 20-ton wire rope electric hoist directly contributed to significant cost savings and productivity improvements for the client:

- Energy savings: The high-efficiency SEW motor and variable speed control system resulted in lower energy consumption, leading to reduced operational costs.

- Labor cost optimization: The improved material handling capabilities and reduced downtime allowed the client to reallocate labor resources more effectively, improving overall productivity and reducing labor-related expenses.

- Increased revenue: The combined benefits of faster throughput, reduced bottlenecks, and more reliable material handling enabled the client to fulfill more orders and capitalize on new business opportunities, ultimately driving revenue growth.

The comprehensive performance evaluation demonstrated the transformative impact of the 20-ton wire rope electric hoist on the client's material handling operations, positioning the organization for greater efficiency, cost savings, and competitive advantage within the industry.

Lessons Learned: Insights for Future Hoist Implementation Projects

Challenges Faced During Implementation

While the implementation of the 20-ton wire rope electric hoist was largely successful, the project team encountered a few challenges along the way that provided valuable lessons for future initiatives:

- Coordination and communication: Ensuring seamless coordination between the client, the hoist manufacturer, and the installation team required constant communication and proactive problem-solving to address any logistical or technical issues that arose.

- Facility layout considerations: The tight confines of the existing crane infrastructure presented some spatial challenges during the installation process, highlighting the importance of thorough planning and adaptability to overcome site-specific constraints.

- Operator training engagement: Securing full engagement from the equipment operators during the training sessions was crucial to ensure the successful and safe utilization of the hoist's advanced features, requiring a tailored approach to address any initial resistance to change.

Recommendations for Future Projects

Based on the lessons learned from this implementation, the project team has identified the following recommendations for organizations considering the integration of a 20-ton wire rope electric hoist in their material handling operations:

- Engage stakeholders early: Involve all relevant stakeholders, including operations, maintenance, and safety personnel, from the very beginning of the project to foster a collaborative environment and ensure buy-in.

- Conduct comprehensive site assessments: Thoroughly evaluate the existing crane infrastructure, layout, and operational requirements to identify potential integration challenges and develop appropriate mitigation strategies.

- Prioritize operator training and change management: Invest significant time and resources in comprehensive operator training programs, coupled with effective change management strategies, to ensure the smooth adoption of the new hoist technology.

- Establish robust maintenance protocols: Develop detailed maintenance schedules and procedures, along with a comprehensive spare parts inventory, to maximize the hoist's uptime and reliability.

- Continuously monitor and optimize performance: Implement a structured performance evaluation framework to track key metrics, identify areas for improvement, and continuously optimize the hoist's integration within the overall material handling ecosystem.

By applying these lessons learned and recommendations, organizations can ensure a more seamless and successful implementation of a 20-ton wire rope electric hoist, maximizing the benefits and positioning their operations for long-term efficiency and productivity gains.

Conclusion: Unlocking the Potential of a 20-Ton Wire Rope Electric Hoist

Summary of the Case Study

This case study has explored the implementation of a 20-ton European-style wire rope electric hoist for a double girder overhead crane system within a manufacturing facility. The project was driven by the need to enhance the organization's material handling capabilities, improve operational efficiency, and ensure the safe movement of heavy loads.

The case study delved into the specific requirements and features of the hoist, its seamless integration with the existing crane infrastructure, and the comprehensive testing and commissioning processes that ensured its readiness for full-scale operational use. The performance evaluation highlighted the significant improvements in operational efficiency, reduced maintenance requirements, and the resulting cost savings and productivity gains realized by the client.

Throughout the implementation journey, the project team encountered and overcame various challenges, providing valuable lessons that were captured to inform recommendations for future hoist integration projects.

Key Takeaways and Future Considerations

The successful implementation of the 20-ton wire rope electric hoist has yielded several key takeaways and considerations for organizations seeking to enhance their material handling capabilities:

- Importance of technical compatibility: Ensuring the hoist's seamless integration with the existing crane system is crucial for maximizing efficiency and minimizing disruptions to ongoing operations.

- Emphasis on safety and reliability: Prioritizing safety features and robust construction can lead to increased operator confidence, reduced maintenance, and higher uptime, delivering long-term benefits.

- Comprehensive operator training: Investing in thorough operator training and change management strategies is essential for unlocking the full potential of the hoist's advanced features and ensuring safe and efficient utilization.

- Continuous performance monitoring: Establishing a structured framework for evaluating and optimizing the hoist's performance can help organizations adapt to evolving operational needs and capitalize on emerging technological advancements.

As organizations continue to navigate the challenges of increasing production demands and the need for more efficient material handling, the insights gained from this case study can serve as a valuable roadmap for the successful implementation of a 20-ton wire rope electric hoist, ultimately driving greater operational excellence and competitive advantage within the industry.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

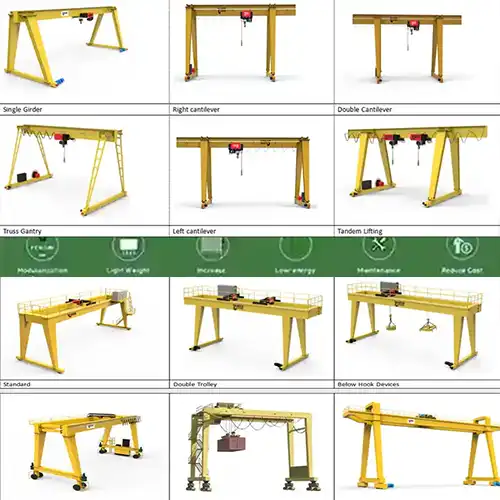

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch