Steel Mill Crane Case: 25/5 Ton Overhead Cranes for Sale

25 ton overhead crane for sale. Customized steel mill crane specification: 25 ton /5 ton bridge crane, 17.7m span, 24m lift height. Get 25 ton eot crane.

Category: 20 Ton Overhead Crane

Your Trusted Overhead Steel Mill Crane Manufacturer & Supplier

Steel Mill Crane Case: 25/5 Ton Overhead Cranes for Sale

Customized Eot Crane Specification: 25 Ton /5 Ton Bridge Crane, 17.7m Span, 24m Lift Height

Steel Mill Crane Case: 25/5 Ton Overhead Cranes for Sale. 25 ton overhead crane for sale. Customized steel mill crane specification: 25 ton /5 ton bridge crane, 17.7m span, 24m lift height. Get 25 ton eot crane.

Steel Mill Crane Customized for Industrial Success, 25/5 Ton Overhead Cranes Case

When it comes to steel mill design and material handling, one size certainly doesn't fit all. That's where our specialized expertise comes into play. With years of experience under our belt, we've honed our craft to understand the intricate nuances of steel mill operations like no other.

From the moment raw materials enter the mill to the final stages of production, every step demands precision and efficiency. Our team excels at crafting tailored solutions that seamlessly integrate into the workflow, optimizing every aspect of material handling.

Streamlining Steel Mill Operations: The Role of Overhead Crane Efficiency

In steel mills, where precision and efficiency reign supreme, the seamless operation of overhead cranes is paramount. Join us as we delve into the intricate dance between steel mill processes and the pivotal role played by overhead cranes in optimizing material handling efficiency.

Comprehending Steel Mill Processes

Steel mill operations are a symphony of intricate processes, each step crucial to the overall production cycle. From the smelting of raw materials to the shaping and finishing of steel products, every stage demands precision and seamless coordination.

At the core of our expertise lies a deep understanding of these processes. We've spent years immersing ourselves in the intricacies of steel mill operations, dissecting each step to identify opportunities for optimization. From the moment raw materials are introduced to the final product's completion, every step in the steelmaking process is meticulously choreographed to ensure efficiency and quality.

- Raw Material Processing: The journey begins with the processing of raw materials, including iron ore, coal, and limestone. These materials undergo a series of transformations, including crushing, mixing, and heating in blast furnaces, to produce molten iron.

- Steelmaking: Once molten iron is obtained, it undergoes further refinement in steelmaking processes such as basic oxygen furnaces (BOF) or electric arc furnaces (EAF). During this stage, various alloying elements are added to achieve the desired chemical composition and properties of the steel.

- Casting and Forming: The molten steel is then cast into semi-finished products such as slabs, blooms, or billets, which serve as the raw material for subsequent processing. These semi-finished products are then shaped and formed through processes like rolling, forging, or extrusion to produce finished steel products.

- Finishing Operations: Finally, the finished steel products undergo additional finishing operations such as heat treatment, surface treatment, and quality inspection to meet customer specifications and industry standards.

Our Expertise in Steel Mill Operations

At the core of our expertise lies a deep understanding of these intricate processes. We've dedicated years to immersing ourselves in the nuances of steel mill operations, dissecting each step to uncover opportunities for optimization and improvement.

By comprehending the unique challenges and requirements of steel mills, we're able to tailor our crane solutions to seamlessly integrate into the workflow. Whether it's optimizing material flow during raw material handling, facilitating precise positioning during steelmaking processes, or supporting efficient product handling during finishing operations, our crane solutions are designed to enhance every stage of the steelmaking process.

Through close collaboration with steel mills and a keen focus on understanding their specific needs, we're able to develop crane solutions that not only meet but exceed expectations. From increasing productivity and efficiency to enhancing safety and reliability, our crane solutions are instrumental in driving success in steel mill operations.

In essence, our expertise in comprehending steel mill processes forms the foundation of our ability to deliver crane solutions that are perfectly tailored to meet the unique challenges and requirements of the steel industry.

QD Double Girder Overhead Crane for Sale

The QD Double Girder Overhead Crane for sale offers high load capacity and robust construction, ideal for heavy-duty lifting in industrial applications, ensuring reliability and efficiency in material handling. The double girder overhead crane is customized designed with open winch trolley whihc is widely used for heavy duty material handling with capacity from 5 ton to 550 ton.

Technical Parameter of QD Overhead Crane | |||||||

Capacity | t | 5 | 10 | 16 | 20 | 32 | 50 |

Span | S(m) | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 | 10.5~31.5 |

Lifting height | m | 6~16 | 6~16 | 6~16 | 6~16 | 6~18 | 6~16 |

Lifting speed | m/min | 11.5 | 8.5 | 7.9 | 7.2 | 6 | 6 |

Trolley speed | m/min | 37.2 | 37.4 | 40.1 | 40 | 37 | 31.3 |

Crane speed | m/min | 70.6 | 70.6 | 74.3 | 75.1 | 64.9 | 58.5 |

Work duty |

| A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 |

Track type |

| P38 | P38 P43 | P43 | P43 | QU70 | QU80 |

|

|

|

|

|

|

|

|

Capacity | t | 75 | 100 | 125 | 160 | 200 | 250 |

Span | S(m) | 10.5~31.5 | 13~31 | 13~31 | 13~31 | 13~31 | 13~31 |

Lifting height | m | 6~20 | 6~20 | 6~20 | 6~22 | 6~20 | 6~20 |

Lifting speed | m/min | 3.9 | 3.1 | 3.9 | 3.5 | 2.6 | 2.2 |

Trolley speed | m/min | 31.3 | 33.6 | 33 | 40 | 32 | 32 |

Crane speed | m/min | 61 | 61.8 | 62.3 | 68 | 48 | 50 |

Work duty |

| A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 | A3~A7 |

Track type |

| QU100 | QU100 | QU100 | QU120 | QU120 | QU120 |

|

|

|

|

|

|

|

|

Capacity | t | 300 | 350 | 400 | 450 |

|

|

Span | S(m) | 13~31 | 13~31 | 13~31 | 13~31 |

|

|

Lifting height | m | 6~24 | 6~24 | 6~24 | 6~24 |

|

|

Lifting speed | m/min | 2.4 | 2.2 | 2.6 | 2.1 |

|

|

Trolley speed | m/min | 28 | 28 | 31 | 27 |

|

|

Crane speed | m/min | 42 | 42 | 45 | 42 |

|

|

Work duty |

| A3~A7 | A3~A7 | A3~A7 | A3~A7 |

|

|

Track type |

| QU120 | QU120 | QU120 | QU120 |

|

|

Tailoring Crane Solutions for Optimal Efficiency

The efficiency of steel mill operations hinges on the smooth flow of materials throughout the facility. This is where overhead cranes come into play as the unsung heroes of material handling. Our team excels at designing crane solutions that not only meet but exceed the demands of steel mill environments.

From heavy-duty lifting to precise maneuvering, our overhead cranes are engineered to tackle the toughest challenges with ease. But it's not just about raw power; it's about finesse. By fine-tuning crane specifications to match the unique requirements of each steel mill, we ensure optimal efficiency and productivity.

Role of Overhead Cranes:

Overhead cranes are the backbone of material handling in steel mills, facilitating the movement of heavy loads with precision and reliability. They are essential for tasks such as transferring raw materials to furnaces, moving semi-finished products between processing stages, and transporting finished steel products to storage or shipping areas.

Backbone of Material Handling:

- Overhead cranes serve as the backbone of material handling operations in steel mills, providing the muscle and finesse necessary to transport heavy loads with precision and reliability. Their robust construction and versatile design make them indispensable assets in the industrial landscape.

Facilitating Critical Tasks:

From the moment raw materials enter the mill to the final stages of product finishing, overhead cranes are involved in every step of the process. They play a vital role in:

- Raw Material Handling: Overhead cranes are responsible for transferring raw materials such as iron ore, coal, and scrap metal to the furnaces for processing. This initial stage sets the foundation for the entire production cycle.

- Intermediate Material Movement: As materials undergo various processing stages, overhead cranes are instrumental in moving semi-finished products between different areas of the mill. Whether it's transferring hot metal from the furnace to the rolling mill or transporting slabs between production lines, overhead cranes ensure seamless workflow continuity.

- Product Handling and Storage: Once steel products are finished, overhead cranes step in to transport them to designated storage areas or shipping docks. Their precision and reliability are crucial in ensuring that finished products are handled with care and delivered to the right location on time.

Precision and Reliability:

The demanding nature of steel mill operations requires equipment that can perform with precision and reliability. Overhead cranes are engineered to meet these stringent requirements, offering:

- High Load Capacities: Overhead cranes are capable of lifting and moving heavy loads ranging from several tons to hundreds of tons, depending on the specific application.

- Accurate Positioning: Advanced control systems and ergonomic features enable overhead cranes to maneuver with precision, allowing for accurate positioning of materials and products throughout the mill.

- Continuous Operation: With robust construction and dependable components, overhead cranes are designed for continuous operation, ensuring minimal downtime and maximum productivity.

In essence, overhead cranes are the unsung heroes of steel mill material handling, enabling seamless operations from raw material intake to finished product delivery. Their reliability, precision, and versatility make them indispensable assets in the quest for operational excellence in the steel industry.

Engineering for Challenges:

Our team specializes in designing overhead crane solutions that go beyond mere functionality. Each crane is meticulously engineered to excel in the demanding environment of steel mills, where robustness and precision are non-negotiable.

Heavy-Duty Lifting Capability:

Steel mill operations often involve handling heavy loads, from raw materials to semi-finished products and finished goods. Our overhead cranes are meticulously engineered to handle these loads with ease, ensuring efficient material flow without compromising safety or performance. Key features include:

- Robust Structural Design: Our cranes are built with high-strength materials and robust structural components to withstand the rigors of heavy lifting in steel mill environments.

- Powerful Lifting Mechanisms: Equipped with powerful hoists and trolleys, our cranes are capable of lifting heavy loads ranging from several tons to hundreds of tons, depending on the specific requirements of the application.

Precise Maneuverability:

Precision is paramount in steel mill operations, where materials and products need to be accurately positioned and maneuvered throughout the facility. Our cranes are designed with advanced control systems and ergonomic features to facilitate smooth and accurate movements, minimizing downtime and maximizing productivity. This includes:

- Advanced Control Systems: Our cranes are equipped with state-of-the-art control systems that provide operators with intuitive interfaces for precise control and monitoring of crane movements.

- Ergonomic Features: Ergonomically designed cabs and control interfaces ensure operator comfort and efficiency, allowing for extended periods of operation without fatigue.

Adaptability and Flexibility:

No two steel mills are alike, and each facility presents its own unique set of challenges and operational requirements. We excel in customizing crane specifications to match the specific needs of each steel mill, ensuring seamless integration into existing workflows. This adaptability and flexibility are achieved through:

- Customization Options: Our cranes can be customized in terms of load capacities, lifting heights, span widths, and other parameters to suit the precise requirements of each application.

- Specialized Attachments: We offer a range of specialized attachments and accessories that can be integrated into our crane designs to accommodate unique handling tasks and operational challenges.

By engineering our cranes with a focus on heavy-duty lifting capability, precise maneuverability, and adaptability, we ensure that they meet the exacting demands of steel mill environments, driving efficiency, productivity, and safety in every operation.

Customization Options

- Load Capacities: We understand that steel mills handle a wide range of loads, from small components to large machinery. That's why our cranes offer customizable load capacities to accommodate varying weight requirements. Whether you're lifting lightweight materials or heavy machinery, our cranes are tailored to meet your specific needs.

- Lifting Heights: Steel mill facilities often have unique layouts and spatial constraints. Our cranes can be customized with adjustable lifting heights to ensure optimal reach and coverage within your facility. Whether you're working in tight spaces or navigating obstacles, our cranes are designed to adapt to your environment.

- Span Widths: Every steel mill has its own layout and configuration. Our cranes are available in a range of span widths, allowing for seamless integration into existing workflows. Whether you're operating in a narrow aisle or a wide-open space, our cranes can be tailored to fit your facility's dimensions.

Specialized Attachments

- Coil Handling Attachments: Steel mills often deal with large coils of metal that require specialized handling. Our cranes can be equipped with coil handling attachments, including C-hooks and coil grabs, to safely and efficiently lift and transport coils throughout the facility.

- Magnet Lifters: For handling ferrous materials such as steel sheets and plates, our cranes can be outfitted with magnet lifters. These powerful attachments provide secure grip and precise control, ensuring smooth and efficient material handling.

- Ladle Handling Devices: In steelmaking operations, ladles are used to transport molten metal from the furnace to the casting area. Our cranes can be fitted with ladle handling devices, such as ladle hooks and ladle tilters, to safely maneuver and pour molten metal with precision and accuracy.

By offering a wide range of customization options and specialized attachments, we empower steel mills to optimize their material handling processes according to their unique requirements. Whether it's adapting to varying load capacities, lifting heights, or specialized handling tasks, our cranes are engineered to excel in any environment, driving efficiency, productivity, and safety in every operation.

Optimizing Efficiency and Productivity:

In the fast-paced and demanding environment of steel mills, every minute counts. That's why we go beyond simply providing cranes with raw lifting power. Our focus is on fine-tuning crane specifications to address the specific needs and challenges of steel mill operations, ultimately driving efficiency and productivity to new heights. Here's how we achieve this:

Reduced Downtime:

- Downtime can be costly for steel mills, disrupting production schedules and impacting overall efficiency. Our cranes are engineered for reliability, with robust construction and dependable components that minimize the risk of breakdowns. Additionally, we provide comprehensive maintenance support to ensure that cranes operate at peak performance levels, reducing the likelihood of unexpected downtime and maximizing uptime.

Enhanced Safety:

Safety is paramount in steel mill operations, where heavy loads and complex machinery pose inherent risks to personnel and equipment. We prioritize safety by implementing a range of features and protocols designed to safeguard both workers and machinery during material handling operations. This includes:

- Safety Sensors and Alarms: Our cranes are equipped with sensors and alarms that detect potential hazards, such as overloads or collisions, and alert operators to take corrective action.

- Operator Training and Certification: We provide comprehensive training programs to ensure that crane operators are well-equipped to safely and efficiently operate the equipment, minimizing the risk of accidents or injuries.

Improved Throughput:

Maximizing throughput is essential for meeting production targets and staying competitive in the steel industry. Our cranes are designed to streamline material flow processes, accelerating production cycles and enabling steel mills to meet demanding schedules. This includes:

- Optimized Workflow Integration: We work closely with steel mills to analyze their material handling workflows and identify areas for improvement. By optimizing crane placement and movement patterns, we minimize bottlenecks and optimize material flow, improving overall throughput.

- Advanced Automation and Control Systems: Our cranes are equipped with advanced automation and control systems that enhance operational efficiency and precision. Automated features such as load positioning and collision avoidance help streamline operations and minimize delays, further improving throughput.

Our commitment to optimizing crane solutions for steel mills is rooted in our deep understanding of the intricacies of material handling within these environments. By partnering closely with steel mills and continuously seeking feedback, we not only address current challenges but also anticipate future needs, driving continuous improvement and operational excellence. Together, we're shaping the future of material handling in the steel industry, one optimized crane solution at a time.

Tailerd 25 /5 Ton Bridge Crane Solutions for Industrial Excellence

In industrial operations, one size rarely fits all. That's why we're proud to showcase our expertise in customized crane design—a testament to our commitment to meeting the unique needs of diverse industrial settings. Join us as we explore the versatility and flexibility of our crane solutions, designed to elevate efficiency and productivity across industries.

Versatility in Crane Design

At the heart of our offerings lie our 25/5 Ton Overhead Cranes—powerful yet versatile workhorses engineered to excel in a myriad of industrial environments. From manufacturing floors to warehousing facilities, our cranes seamlessly adapt to the demands of each setting, ensuring optimal performance every step of the way.

What sets our cranes apart is their adaptability. Whether it's navigating tight spaces with precision or lifting heavy loads with ease, our crane solutions rise to the occasion, delivering unmatched versatility that empowers businesses to tackle any challenge head-on.

Highlighting Customization for Unique Requirements

We understand that every industrial operation is unique, with its own set of challenges and requirements. That's why we take pride in our ability to customize crane specifications to meet the specific needs of each client.

From load capacity to speed and control, we work closely with our clients to tailor every aspect of our crane designs, ensuring they align perfectly with their operational requirements. Whether it's a specialized lifting application or a unique space constraint, our team of experts is dedicated to delivering crane solutions that exceed expectations.

By highlighting the flexibility to customize crane specifications, we're not just providing tools; we're empowering businesses to optimize their operations like never before. With tailored crane solutions that are as unique as the industries they serve, we're redefining the standards of industrial excellence.

25 /5 Ton Overhead Crane with Open Winch Trolley for Steel Mill Project Showcase

Main Specifications of 25 /5 Ton Overhead Cranes

- Crane Type: QD type Top Running Double Girder Overhead Crane with Hooks

- Crane Capacity: 25 /5 ton

- Crane Span 17.7 m

- Crane lifting height: 24 m

- Crane Application: Steel Mill

Main Beam of 25/5 Ton Overhead Crane: Box Girder Design

The main beam of a 25/5 ton overhead crane serves as the backbone of the crane structure, providing support and stability for the lifting mechanism and load. When it comes to the design of the main beam, one popular option is the box girder design, known for its strength, rigidity, and versatility. Let's delve into the specifics:

Box Girder Design: In the box girder design, the main beam is constructed as a hollow box-shaped structure, with top and bottom flanges connected by vertical webs. This design offers several advantages:

- Strength and Rigidity: The closed-box configuration of the girder enhances its strength and rigidity, allowing it to withstand heavy loads and dynamic forces encountered during crane operation.

- Lightweight Construction: Despite its robustness, the box girder design is relatively lightweight compared to other types of crane girders. This results in reduced dead weight, allowing for greater lifting capacities and operational efficiency.

- Resistance to Deflection: The box girder's closed-section geometry provides excellent resistance to bending and deflection, ensuring precise load handling and minimal sway during crane operation.

- Streamlined Maintenance: The enclosed nature of the box girder protects internal components from environmental factors such as dust, debris, and moisture, reducing the risk of corrosion and simplifying maintenance requirements.

Advantages of QD Type Double Girder Cranes in China:

In China, the QD type double girder crane has gained widespread popularity in various industries due to its numerous advantages:

- High Lifting Capacity: QD type double girder cranes are capable of handling heavy loads with ease, making them ideal for industries such as steel manufacturing, shipbuilding, and automotive production.

- Long Span Capability: These cranes can be designed with long spans, allowing for efficient material handling across large work areas or warehouses.

- Smooth Operation: QD type double girder cranes are equipped with advanced control systems and precision mechanisms, ensuring smooth and precise load handling.

- Customization Options: Manufacturers in China offer a wide range of customization options for QD type double girder cranes, allowing customers to tailor the crane specifications to their specific requirements.

- Cost-Effectiveness: Despite their high lifting capacities and advanced features, QD type double girder cranes are competitively priced, making them a cost-effective solution for many industrial applications.

- Reliability and Durability: Built to withstand the rigors of heavy-duty operations, QD type double girder cranes are known for their reliability and durability, ensuring long-term performance and minimal downtime.

In summary, the main beam of a 25/5 ton overhead crane with a box girder design offers superior strength, rigidity, and efficiency. Paired with the advantages of QD type double girder cranes in China, such as high lifting capacity, long span capability, and cost-effectiveness, these cranes become indispensable assets in a wide range of industrial applications.

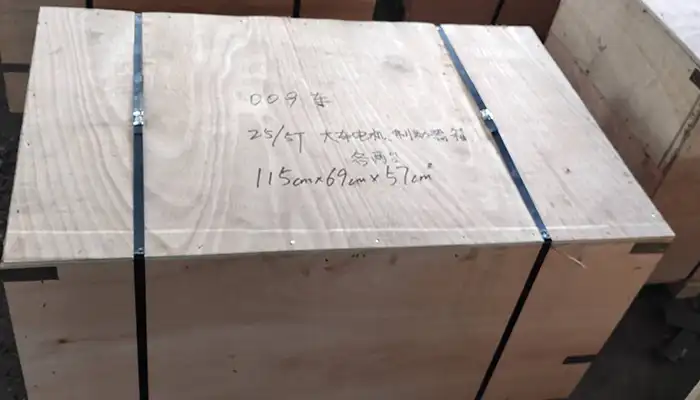

Main girder of 25 /5 ton overhead crane

Double girder of the overhead crane packed for delivery

End Beam of 25/5 Ton Overhead Crane: QD Type

The end beam of a 25/5 ton overhead crane, especially in the QD type configuration, plays a critical role in ensuring the structural integrity and operational efficiency of the crane. Let's explore the key aspects and advantages of the end beam in a QD type overhead crane:

Structural Design and Functionality:

- Load Distribution: The end beam is responsible for distributing the load from the main beam to the runway beams and ultimately to the supporting structure of the building. It must withstand the weight of the crane and the loads being lifted while maintaining stability and balance.

- Connection Points: The end beam serves as the connection point between the main beam and the runway beams, providing support and alignment for the entire crane system. It must be securely attached to the main beam to ensure proper load transfer and distribution.

- Attachment for Hoisting Mechanism: The end beam typically houses the hoisting mechanism, including the trolley and hoist, which are responsible for lifting and lowering loads. It must be designed to accommodate the weight and movement of these components while maintaining structural integrity.

Advantages of QD Type End Beams:

- High Load Capacity: QD type overhead cranes are renowned for their high lifting capacities, and the end beams are engineered to support these heavy loads with ease. They are designed to withstand the stresses and forces associated with lifting and moving large and heavy objects.

- Durability and Longevity: End beams in QD type overhead cranes are constructed from high-quality materials and undergo rigorous testing to ensure durability and longevity. They are built to withstand the harsh conditions of industrial environments, including exposure to temperature fluctuations, dust, and debris.

- Precision Engineering: QD type end beams are precision-engineered to provide smooth and precise movement of the hoisting mechanism along the runway beams. This ensures efficient and accurate positioning of loads, minimizing downtime and maximizing productivity.

- Customization Options: Manufacturers offer a range of customization options for QD type end beams, allowing customers to tailor the design to their specific requirements. This includes options for different lifting heights, spans, and attachment configurations to accommodate various applications and operational needs.

- Compatibility with Automation: QD type end beams are designed to seamlessly integrate with automation and control systems, allowing for advanced features such as remote operation, load monitoring, and automated positioning. This enhances operational efficiency and safety while reducing the need for manual intervention.

In conclusion, the end beam of a 25/5 ton overhead crane in the QD type configuration is a critical component that ensures the structural integrity, load-bearing capacity, and operational efficiency of the crane system. With its robust design, precision engineering, and customizable options, the end beam plays a pivotal role in facilitating safe, reliable, and productive material handling operations in a variety of industrial settings.

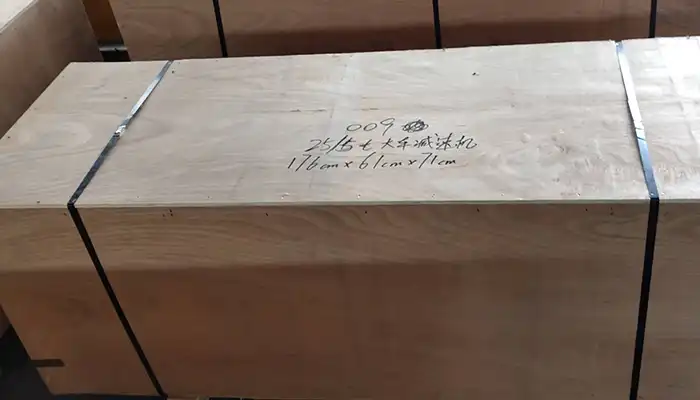

End carriage - main parts and components of 25 ton /5 ton electric overhead travelling crane

End carriages and trucks are packed for delivery

Open Winch Trolley of 25/5 Ton Overhead Crane: QD Type

The open winch trolley is a fundamental component of a 25/5 ton overhead crane, particularly in the QD type configuration. It's a crucial mechanism responsible for the precise movement and positioning of loads within the working area. Let's delve into the specifics of the open winch trolley in a QD type overhead crane:

Functionality and Design Features:

- Load Handling: The open winch trolley is equipped with a hoisting mechanism that comprises a motor, gearbox, drum, and wire rope. This mechanism is responsible for lifting, lowering, and traversing the load with precision and control.

- Versatility: The design of the open winch trolley allows for versatility in load handling. It can accommodate a wide range of load sizes, shapes, and weights, making it suitable for various applications across different industries.

- Adjustable Speeds: The motor-driven winch allows for adjustable lifting and traversing speeds, providing flexibility to match the specific requirements of each lifting task. This ensures efficient and safe operation while minimizing cycle times.

- Safety Features: Open winch trolleys are equipped with safety features such as overload protection, emergency stop mechanisms, and limit switches to prevent accidents and ensure operator safety during crane operation.

Advantages of QD Type Open Winch Trolleys:

- High Lifting Capacity: QD type overhead cranes are known for their high lifting capacities, and the open winch trolleys are designed to match these capabilities. They can efficiently handle heavy loads up to 25/5 tons, making them suitable for demanding industrial applications.

- Smooth Operation: The precision-engineered design of QD type open winch trolleys ensures smooth and precise movement of loads, minimizing sway and oscillation during lifting and traversing operations. This enhances safety and productivity in material handling tasks.

- Durable Construction: Open winch trolleys in QD type overhead cranes are built to withstand the rigors of industrial environments. They are constructed from high-quality materials and undergo stringent quality control measures to ensure durability and reliability in operation.

- Customizable Options: Manufacturers offer a range of customizable options for QD type open winch trolleys, including different hoisting speeds, lifting heights, and control systems. This allows customers to tailor the trolley specifications to their specific application requirements.

- Compatibility with Automation: QD type open winch trolleys are compatible with automation and control systems, enabling advanced features such as remote operation, load monitoring, and automated positioning. This enhances operational efficiency and enables seamless integration with modern industrial processes.

In summary, the open winch trolley of a 25/5 ton overhead crane in the QD type configuration is a versatile and reliable mechanism that plays a crucial role in material handling operations. With its high lifting capacity, smooth operation, durability, and customizable options, the open winch trolley enhances efficiency, productivity, and safety in a wide range of industrial applications.

Open winch trolley assembled

Open winch trolley assembled

Motor of 25/5 Ton Overhead Crane: YZR Bridge Crane Motor

The motor is the powerhouse of a 25/5 ton overhead crane, providing the necessary drive and torque to lift, lower, and traverse heavy loads with precision and efficiency. In the case of QD type overhead cranes, the YZR bridge crane motor is a commonly used motor type known for its robust performance and reliability. Let's explore the key features and advantages of the YZR bridge crane motor:

Functionality and Operation:

- Hoisting Power: The YZR bridge crane motor is specifically designed for hoisting applications in overhead cranes. It delivers high torque and power output to lift heavy loads vertically with ease.

- Smooth Operation: These motors are engineered for smooth and precise operation, providing consistent performance even under heavy loads. This ensures stable and controlled lifting and lowering of loads, minimizing the risk of sway or oscillation.

- Traversing Capability: In addition to hoisting, the YZR bridge crane motor can also be used for traversing movements along the crane runway. It provides the necessary drive and control for horizontal movements, allowing for efficient positioning of loads within the working area.

- Variable Speed Control: Some YZR bridge crane motors offer variable speed control options, allowing operators to adjust the lifting and traversing speeds according to the specific requirements of each lifting task. This provides flexibility and versatility in crane operation.

Advantages of YZR Bridge Crane Motors:

- High Torque: YZR motors are known for their high torque output, making them suitable for lifting heavy loads with ease. This ensures efficient and reliable performance in demanding industrial applications.

- Robust Construction: These motors are built to withstand the rigors of industrial environments, with robust construction and durable components that ensure long-term reliability and durability.

- Low Maintenance Requirements: YZR motors are designed for minimal maintenance, with sealed enclosures and rugged construction that protect internal components from dust, debris, and moisture. This reduces the need for frequent servicing and prolongs the lifespan of the motor.

- Energy Efficiency: Despite their high power output, YZR motors are engineered for energy efficiency, with optimized designs and advanced control systems that minimize energy consumption during operation. This helps reduce operating costs and environmental impact.

- Compatibility with Crane Control Systems: YZR bridge crane motors are compatible with a wide range of crane control systems, allowing for seamless integration and interoperability with modern crane automation technologies. This enables advanced features such as remote operation, load monitoring, and automated positioning.

In summary, the YZR bridge crane motor is a reliable and efficient power source for 25/5 ton overhead cranes in the QD type configuration. With its high torque output, smooth operation, robust construction, and energy efficiency, this motor type ensures optimal performance and reliability in material handling operations across various industrial applications.

Motor and brakes , main parts of open winch trolley

Crane motors and brakes packed for delivery

Reducer of 25/5 Ton Overhead Crane: QD Type

The reducer is a crucial component of a 25/5 ton overhead crane in the QD type configuration, serving to reduce the speed of the motor while increasing the torque output to efficiently lift and move heavy loads. Let's explore the functions, features, and advantages of the reducer in this context:

Functionality and Operation:

- Speed Reduction: The primary function of the reducer is to decrease the speed of the motor output shaft while increasing the torque output. This reduction in speed allows the crane to lift heavy loads with greater control and precision.

- Torque Amplification: By increasing the torque output of the motor, the reducer enables the crane to exert greater force on the load, facilitating smooth and efficient lifting and traversing movements.

- Gear Mechanism: Reducers typically employ gear mechanisms to achieve speed reduction and torque amplification. Common types of gears used in reducers include helical gears, spur gears, and planetary gears, each offering specific advantages in terms of efficiency, smoothness, and compactness.

- Precision Engineering: Reducers are precision-engineered components designed to withstand the high forces and stresses encountered during crane operation. They are constructed with high-quality materials and undergo stringent quality control measures to ensure reliable performance and longevity.

Advantages of Reducers in QD Type Overhead Cranes:

- High Efficiency: Reducers in QD type overhead cranes are designed for optimal efficiency, minimizing energy losses and maximizing power transmission. This ensures that the crane operates with maximum efficiency, reducing energy consumption and operating costs.

- Smooth Operation: The gear mechanisms used in reducers provide smooth and precise movement, allowing for accurate positioning of loads without jarring or jerky motions. This enhances safety and reduces wear and tear on crane components.

- Compact Design: QD type overhead cranes require reducers with compact designs to fit within the limited space available in the crane structure. Reducers are engineered to be compact and lightweight while still delivering high torque output, ensuring efficient use of space and resources.

- Durability and Reliability: Reducers are critical components of overhead cranes and are built to withstand the demanding conditions of industrial environments. They are constructed from robust materials and undergo rigorous testing to ensure durability, reliability, and long service life.

- Customization Options: Manufacturers offer a range of customization options for reducers in QD type overhead cranes, allowing customers to tailor the specifications to their specific requirements. This includes options for different gear ratios, input and output shaft configurations, and mounting arrangements.

In summary, the reducer is a vital component of a 25/5 ton overhead crane in the QD type configuration, providing the necessary speed reduction and torque amplification to lift and move heavy loads with precision and efficiency. With their high efficiency, smooth operation, compact design, durability, and customization options, reducers play a key role in ensuring the reliable performance and longevity of overhead crane systems in various industrial applications.

Crane reducer, main parts of double girder overhead crane 25 ton /5 ton

Reducer packed in wooden case for delivery

Trolley Conduction I Beam and Trolley Conduction Frame in Overhead Cranes

In overhead crane systems, the trolley conduction I beam and trolley conduction frame are essential components that enable the smooth and efficient movement of the trolley along the crane runway. Let's explore the functions, features, and importance of these components:

Trolley Conduction I Beam:

- Functionality: The trolley conduction I beam serves as the track or runway along which the trolley moves horizontally. It is typically mounted parallel to the main crane runway beams and provides support and guidance for the trolley wheels.

- Construction: Trolley conduction I beams are usually constructed from high-strength steel, ensuring durability and reliability in supporting the weight of the trolley and the loads being lifted. They are designed to withstand the dynamic forces and stresses encountered during crane operation.

- Precision Machining: The surface of the trolley conduction I beam is machined to precise tolerances to ensure smooth and accurate movement of the trolley wheels. This minimizes friction and wear on the wheels, prolonging their lifespan and reducing maintenance requirements.

- Alignment: Proper alignment of the trolley conduction I beam is critical for smooth and efficient trolley movement. It must be installed level and parallel to the main crane runway beams to prevent binding or uneven wear on the trolley wheels.

Trolley Conduction Frame:

- Functionality: The trolley conduction frame provides structural support and rigidity for the trolley mechanism. It typically consists of a welded steel frame that houses the trolley drive mechanism, including the motor, gearbox, and other components.

- Integration: The trolley conduction frame is mounted on the trolley conduction I beam and provides a secure mounting point for the trolley drive mechanism. It ensures proper alignment and positioning of the drive components, allowing for smooth and efficient trolley movement.

- Protection: The trolley conduction frame also serves to protect the trolley drive mechanism from environmental factors such as dust, debris, and moisture. It provides a sealed enclosure that helps prevent contamination and extends the lifespan of the drive components.

- Accessibility: While the trolley conduction frame provides protection for the drive mechanism, it is also designed to allow for easy access and maintenance when necessary. Removable panels or access doors facilitate inspection, lubrication, and repair of the drive components.

In summary, the trolley conduction I beam and trolley conduction frame are integral components of overhead crane systems, working together to facilitate the smooth and efficient movement of the trolley along the crane runway. With their robust construction, precision machining, and protective features, these components ensure reliable performance and longevity in material handling operations across various industrial applications.

Trolley conduction I beam

Trolley conduction frame

Walking Platform

A walking platform, also known as a maintenance platform or catwalk, is a raised structure typically installed along the length of an overhead crane runway or bridge. It provides a safe and accessible pathway for maintenance personnel to inspect, repair, and maintain the crane and its associated components.

Features and Functions:

- Safety: The primary function of a walking platform is to enhance safety by providing a designated area for maintenance personnel to perform tasks without the need for harnesses or ladders. It reduces the risk of falls and injuries associated with working at height.

- Accessibility: Walking platforms offer easy access to various components of the overhead crane, including the trolley, hoist, end trucks, and runway beams. This facilitates routine inspections, lubrication, and repairs, ensuring the crane remains in optimal working condition.

- Support Structure: Walking platforms are typically constructed from durable materials such as steel or aluminum and are designed to support the weight of maintenance personnel and equipment. They may feature handrails, guardrails, and toeboards for additional safety.

- Modularity: Walking platforms can be modular in design, allowing for easy installation, customization, and expansion. They can be adapted to fit the specific layout and requirements of the crane runway, accommodating curves, bends, and obstacles as needed.

- Accessibility: Walking platforms can be equipped with access ladders or stairs at various intervals along the crane runway, providing convenient entry and exit points for maintenance personnel. This ensures accessibility to all areas of the crane for inspection and servicing.

- Integration: Walking platforms can be integrated with other crane safety features, such as fall protection systems, signage, and lighting. This enhances overall safety and visibility for maintenance personnel working on or near the crane.

Benefits:

- Enhanced Safety: By providing a stable and secure working platform, walking platforms reduce the risk of accidents and injuries during crane maintenance activities.

- Improved Efficiency: Maintenance personnel can perform tasks more efficiently and effectively with easy access to all areas of the crane, reducing downtime and optimizing crane performance.

- Cost Savings: Regular maintenance and inspections conducted from a walking platform can help identify issues early, preventing costly breakdowns and repairs in the long run.

- Compliance: Walking platforms help ensure compliance with safety regulations and standards governing crane maintenance and operation, minimizing liability and risk for crane owners and operators.

In summary, a walking platform is a critical safety feature of overhead crane systems, providing a secure and accessible workspace for maintenance personnel to inspect, repair, and maintain crane components. With their focus on safety, accessibility, and efficiency, walking platforms contribute to the smooth and reliable operation of overhead cranes in various industrial settings.

cable

Electric cabinet

Crane hook

Crane Cable, Cabinet and Hook of 25/5 Ton Overhead Cranes for Steel Mill

Crane Cable:

- Functionality: The crane cable, also known as wire rope or lifting cable, serves as the primary means of lifting and lowering loads attached to the crane hook. It is typically made of high-strength steel wires wound together to form a flexible yet durable rope.

- Load Capacity: The crane cable is designed to withstand the weight of the maximum rated load of the crane, ensuring safe and reliable lifting operations. The diameter, construction, and material composition of the cable are selected based on the specific requirements of the crane and its intended application.

- Durability and Strength: Crane cables are engineered to withstand high loads, abrasion, bending, and fatigue, ensuring long-term durability and reliability in demanding industrial environments such as steel mills. They undergo rigorous testing to meet industry standards for safety and performance.

- Maintenance: Regular inspection and maintenance of the crane cable are essential to ensure its integrity and reliability. This includes visual inspections for signs of wear, damage, or corrosion, as well as lubrication and tension adjustments as needed to prolong the lifespan of the cable.

Cabinet:

- Functionality: The cabinet, also referred to as the control panel or electrical enclosure, houses the electrical and control components of the overhead crane system. It serves as the central hub for controlling and monitoring crane operations, including hoisting, traversing, and trolley movement.

- Electrical Components: The cabinet contains various electrical components such as contactors, relays, circuit breakers, and controllers, which regulate the power supply to the crane motors and other devices. It may also house safety features such as limit switches, emergency stop buttons, and overload protection devices.

- Protection: The cabinet is designed to protect electrical components from environmental factors such as dust, moisture, and temperature fluctuations. It may feature sealed enclosures, ventilation systems, and insulation to ensure reliable operation in harsh industrial environments.

- Accessibility: The cabinet is typically located in a central or easily accessible location near the crane runway, allowing maintenance personnel to inspect, troubleshoot, and repair electrical components as needed. Removable panels or doors provide access to internal components for servicing.

Hook:

- Functionality: The crane hook is the device used to attach and lift loads during crane operations. It is typically attached to the end of the crane cable and may feature various configurations such as single, double, or triple hooks depending on the application.

- Load Capacity: The crane hook is designed to safely lift and support the maximum rated load of the crane. It undergoes rigorous testing to ensure strength, reliability, and compliance with industry standards for safety.

- Construction: Crane hooks are typically made of forged or cast steel, with a robust design capable of withstanding high loads and dynamic forces during lifting operations. They may feature latch mechanisms or safety catches to secure the load during lifting and prevent accidental release.

- Maintenance: Regular inspection and maintenance of the crane hook are essential to ensure its integrity and reliability. This includes visual inspections for signs of wear, deformation, or damage, as well as load testing and certification to verify compliance with safety standards.

In summary, the crane cable, cabinet, and hook are critical components of 25/5 ton overhead cranes designed for steel mill applications. With their focus on strength, durability, reliability, and safety, these components play essential roles in ensuring smooth and efficient material handling operations in the demanding environment of a steel mill. Regular inspection, maintenance, and compliance with safety standards are essential to maximize the lifespan and performance of these components.

Custom Overhead Crane Solutions Across Industries

In industrial innovation, versatility is the key to staying ahead of the curve. Join us as we journey beyond the confines of steel mills to explore the boundless applications of our crane solutions across a spectrum of industries. From manufacturing floors to construction sites, our crane designs transcend boundaries, revolutionizing material handling with unmatched adaptability and efficiency.

Cross-Industry Adaptability

While our roots may lie in steel mill design, our crane solutions are not bound by industry borders. We take pride in showcasing how our crane designs transcend traditional applications, seamlessly integrating into a diverse array of industrial sectors.

From the precision engineering of manufacturing facilities to the logistical challenges of warehouse operations, our crane solutions are engineered to excel in any environment. What sets us apart is our commitment to understanding the unique requirements of each industry and tailoring our crane solutions accordingly.

- Versatility Unleashed:Our pride lies in showcasing the transformative power of our crane designs, which defy traditional boundaries and adapt effortlessly to diverse industrial applications. Whether it's the precise demands of manufacturing facilities or the intricate logistical maneuvers of warehouse operations, our crane solutions rise to the challenge, setting new standards of excellence.

- Precision Engineering for Manufacturing Excellence:In the realm of manufacturing, precision is not just a goal but a necessity. Our crane solutions are engineered with meticulous attention to detail, optimizing every aspect of material handling processes. From streamlining assembly line operations to facilitating seamless material flow, our cranes elevate manufacturing efficiency to unprecedented levels.

- Navigating the Complexity of Logistics:Logistical challenges are a constant in today's industrial landscape, yet our crane solutions thrive amidst this complexity. From bustling distribution centers to sprawling warehouses, our cranes are the backbone of efficient material handling operations. With advanced technology and precision controls, we navigate the intricacies of logistics with finesse and agility.

- Tailored Solutions for Every Industry Need:What truly sets us apart is our unwavering commitment to understanding the unique nuances of each industry we serve. We recognize that no two industries are alike, and our approach reflects this understanding. Whether it's customizing crane specifications to handle specialized loads or integrating cutting-edge features to meet industry regulations, our solutions are tailored to address the distinct requirements of every sector.

In essence, our cross-industry adaptability is not just a testament to our engineering prowess but a reflection of our dedication to innovation and customer-centricity. By transcending traditional applications and embracing the challenges of diverse industrial sectors, we continue to redefine the boundaries of crane design and elevate material handling to new heights of efficiency and excellence.

Showcasing Success Across Industries: Impact of Our Crane Solutions

Our commitment to cross-industry adaptability isn't just a lofty claim – it's a reality borne out by the tangible impact of our crane solutions across diverse industrial sectors. From optimizing production lines in manufacturing plants to revolutionizing warehouse logistics and facilitating large-scale construction projects, our cranes have become indispensable tools driving efficiency and productivity in every industry they serve.

Case Studies: From Concept to Reality

Through a series of compelling case studies and real-world examples, we offer a glimpse into the transformative power of our crane designs. These stories highlight how our solutions have reshaped material handling operations, delivering tangible results that go beyond mere promises. Whether it's reducing downtime on the factory floor, streamlining inventory management in warehouses, or accelerating project timelines in construction sites, our cranes have consistently proven their worth.

Proven Track Record: Trust Earned, Partnerships Forged

Our success isn't measured solely by the number of cranes we've deployed but by the trust we've earned from businesses around the world. From small enterprises to multinational corporations, our crane solutions have become synonymous with reliability, efficiency, and innovation. We've forged lasting partnerships with clients who have witnessed firsthand the transformative impact of our crane solutions on their operations.

Opening Doors to New Possibilities

By showcasing our successful implementations across industries, we're not just demonstrating the versatility of our crane solutions – we're inspiring new possibilities. With each success story, we're opening doors to innovation, collaboration, and progress. Whether it's finding innovative ways to handle unique materials, optimizing workflows for maximum efficiency, or pushing the boundaries of crane technology, we're committed to driving continuous improvement and pushing the limits of what's possible in material handling.

In conclusion, our track record of success speaks volumes about the real-world impact of our crane solutions. Through practical examples and tangible results, we're not just revolutionizing material handling – we're shaping the future of industry. With our expertise and innovation, the opportunities for reimagining material handling in the modern industrial landscape are endless.

The Impact of Tailored Crane Solutions

In the realm of industrial innovation, the impact of tailored crane solutions extends far beyond the confines of steel mills or construction sites. It permeates every aspect of material handling, driving efficiency, productivity, and safety across diverse industries.

- Precision Engineering, Tangible Results: Tailored crane solutions are not just a concept; they are a catalyst for real-world transformation. By meticulously customizing crane specifications to align with the unique requirements of each industry and application, we unlock a world of possibilities. Whether it's optimizing workflow in manufacturing facilities, navigating logistical challenges in warehouses, or facilitating complex construction projects, the impact of tailored crane solutions is undeniable.

- Empowering Industries to Reach New Heights: The true measure of success lies in the tangible outcomes delivered by tailored crane solutions. From increased throughput and reduced downtime to enhanced safety and operational excellence, the impact reverberates throughout the entire value chain. With every successful implementation, we empower industries to reach new heights of efficiency, productivity, and profitability.

- Driving Innovation, Shaping the Future: Tailored crane solutions are not just about meeting current needs; they're about anticipating future challenges and opportunities. By pushing the boundaries of crane technology, embracing emerging trends, and collaborating closely with our clients, we're driving innovation and shaping the future of material handling. Whether it's integrating cutting-edge automation, harnessing the power of data analytics, or pioneering sustainable solutions, the impact of tailored crane solutions extends far beyond the present moment.

In conclusion, the impact of tailored crane solutions is profound and far-reaching. It's about more than just lifting heavy loads; it's about unlocking the full potential of industries, driving progress, and shaping a brighter future for generations to come. With our commitment to innovation, expertise, and customer-centric approach, we're not just providing crane solutions – we're delivering lasting impact.

Success Stories in Steel Mills: Revolutionizing Industrial Production

Steel mills stand as the pulsating heart of industrial production, where every movement directly impacts the bottom line. In our first case study, we shine a spotlight on how our customized crane solutions have redefined steel mill operations from start to finish – from the smelting of raw materials to the precision shaping and finishing of steel products.

Through meticulous customization of crane specifications to match the unique demands of each steel mill, we've been able to orchestrate a symphony of efficiency. By streamlining material handling processes, minimizing downtime, and enhancing overall productivity, we've transformed challenges into opportunities for success. Our tailored approach not only optimizes performance but also empowers steel mills to reach unprecedented levels of productivity and profitability.

In each success story, we witness the tangible impact of our crane solutions as they turn industry norms on their heads, setting new benchmarks for excellence. With innovation as our compass and customization as our guiding principle, we're not just redefining steel mill operations – we're shaping the future of industrial production, one tailored solution at a time.

Cross-Industry Applications

But our journey doesn't stop at steel mills. In our second case study, we venture into diverse industrial environments to showcase the versatility of our crane designs. From manufacturing floors to warehouse facilities, our crane solutions have left an indelible mark on every industry they touch.

- Manufacturing Floors: In the fast-paced world of manufacturing, efficiency is paramount. Our crane solutions have revolutionized manufacturing processes by providing precise and reliable material handling capabilities. Whether it's the seamless movement of components along assembly lines or the efficient transfer of goods between workstations, our cranes optimize workflow and drive productivity to new heights.

- Warehouse Facilities: Logistical challenges are a constant in warehouse operations, but our crane solutions rise to the occasion. In warehouse facilities, our cranes serve as the backbone of efficient material handling, facilitating the smooth movement of goods from storage shelves to loading docks. With advanced technology and precision controls, we navigate the intricacies of warehouse logistics with ease, minimizing downtime and maximizing throughput.

The impact of our crane solutions reverberates across every industry they touch. From automotive manufacturing plants to pharmaceutical distribution centers, our cranes have become indispensable tools for driving efficiency, productivity, and profitability. With each successful implementation, we reinforce our commitment to innovation and customer satisfaction, setting new standards of excellence in material handling.

In essence, our cross-industry applications showcase the versatility and adaptability of our crane designs. By transcending traditional boundaries and embracing the unique challenges of diverse industrial environments, we continue to redefine the possibilities of material handling, one industry at a time.

Forging Partnerships: Collaborating for Crane Solutions Excellence

Designing Tailored Solutions, Together

Our partnership is built on a foundation of shared vision and mutual commitment to success. From the outset, we embark on a collaborative journey, engaging in in-depth consultations and interactive workshops to gain a deep understanding of your operation's unique requirements, challenges, and aspirations. Together, we'll delve into the intricacies of your workflow, exploring every facet of your operation to uncover opportunities for improvement and innovation.

Through open dialogue and transparent communication, we'll work hand in hand to co-create crane solutions that are perfectly aligned with your specific needs and objectives. Whether it's enhancing efficiency, increasing productivity, or improving safety standards, our goal is to deliver tailored solutions that not only address your immediate concerns but also lay the groundwork for long-term growth and prosperity.

With your insights guiding our design process, we'll leverage our expertise and industry-leading technologies to develop crane solutions that are truly tailored to your operation. From selecting the optimal crane configurations to integrating advanced features and functionalities, every aspect of the solution will be meticulously crafted to meet your exact specifications.

But our collaboration doesn't end there. We'll continue to engage with you throughout the design process, seeking your feedback and input every step of the way. By fostering a culture of openness and collaboration, we ensure that the final crane solution reflects your vision and exceeds your expectations.

In essence, our partnership is more than just a business transaction – it's a collaborative effort to drive innovation, maximize efficiency, and achieve shared success. Together, we'll forge a path forward that propels your operation to new heights of excellence and sets the stage for a brighter future.

Expert Consultation and Support Every Step of the Way

But our partnership doesn't end with the design phase. We're committed to providing expert consultation and support at every stage of the project lifecycle. From initial concept development to final implementation and beyond, our team will be by your side, offering guidance, insights, and solutions to ensure the success of your project.

Our commitment to your success extends far beyond the design phase. We understand that implementing crane solutions is a multifaceted process, and we're dedicated to providing expert consultation and support at every stage of the project lifecycle.

- Initial Concept Development:At the outset of our partnership, we'll collaborate closely with your team to understand your unique requirements, challenges, and goals. Through in-depth discussions and thorough analysis, we'll help you conceptualize crane solutions that are tailored to your specific needs and objectives.

- Detailed Design and Planning:Once the concept is established, our team of experts will dive into the nitty-gritty details of design and planning. We'll work tirelessly to ensure that every aspect of the crane solution aligns seamlessly with your operational requirements and industry standards. From load capacities to structural integrity, no detail will be overlooked.

- Implementation and Installation:As the project moves into the implementation phase, our dedicated team will be there to oversee every aspect of the installation process. We'll work closely with your team to ensure that the crane solution is installed safely, efficiently, and with minimal disruption to your ongoing operations.

- Training and Optimization:Once the crane solution is up and running, our support doesn't end there. We'll provide comprehensive training for your staff to ensure that they are fully equipped to operate and maintain the equipment effectively. Additionally, we'll continue to monitor and optimize the performance of the crane solution to maximize efficiency and productivity.

- Ongoing Maintenance and Support:Even after the project is complete, our commitment to your success remains unwavering. Our team will be on hand to provide ongoing maintenance, support, and troubleshooting services to ensure the continued smooth operation of your crane solution. Whether it's routine inspections, repairs, or upgrades, we've got you covered every step of the way.

In essence, our dedication to providing expert consultation and support at every stage of the project lifecycle is a testament to our commitment to your success. With our experienced team by your side, you can rest assured that your crane solution will not only meet but exceed your expectations, delivering unparalleled performance and reliability for years to come.

Expert Consultation and Support: Guiding You Every Step of the Way

At the core of our partnership approach lies a steadfast commitment to providing unparalleled expert consultation and support throughout the entirety of the project lifecycle. We recognize that navigating the intricacies of crane design and implementation can be a daunting task, which is why we're here to serve as your trusted advisors, offering unwavering guidance and support at every turn.

- Harnessing Years of Experience and Industry KnowledgeOur team of experts brings a wealth of experience and industry knowledge to the table, garnered from years of navigating the complexities of crane design and implementation. Drawing upon this wealth of expertise, we provide invaluable insights and recommendations tailored to your unique needs and challenges. Whether you're grappling with determining the optimal crane specifications for your operations or seeking solutions to unforeseen challenges that arise during implementation, our team is dedicated to ensuring that your project is a resounding success.

- Empowering Informed Decision-Making:We understand that informed decision-making is paramount to the success of any project. That's why we're committed to equipping you with the knowledge and insights you need to make sound choices every step of the way. Through detailed consultations and collaborative discussions, we'll work closely with you to analyze your specific requirements, explore potential solutions, and develop a tailored strategy that aligns with your goals and objectives.

- A Partner You Can Rely On:When you partner with us, you're not just gaining access to cutting-edge crane solutions – you're gaining a trusted ally dedicated to your success. From the initial planning stages to the final implementation and beyond, our team will be by your side, providing unwavering support and guidance to ensure that your project is executed seamlessly and efficiently.

In essence, our commitment to providing expert consultation and support is a testament to our dedication to your success. With our experienced team at your disposal, you can rest assured that you'll have the guidance and expertise you need to navigate the complexities of crane design and implementation with confidence and ease.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch