20 Ton Single Girder Goliath Cranes for Netherlands, Custom Design

20 ton goliath cranes for sale Netherlands. Custom single girder goliath crane, 20 ton capacity, box girder design, 400V electric crane for particular use.

Category: 20 Ton Overhead Crane

Your Trusted Goliath Gantry Crane Manufacturer & Supplier

20 Ton Single Girder Goliath Cranes for Netherlands, Custom Gantry Crane for Your Needs

20 ton goliath cranes for sale Netherlands. Custom single girder goliath crane, 20 ton capacity, box girder design, 400V electric crane for particular use.

20 Ton Single Girder Goliath Cranes for Netherlands

20-ton single girder goliath crane is tailored for the Netherlands' client. Designed to meet the rigorous demands of heavy lifting in diverse applications, our cranes offer unmatched efficiency, reliability, and versatility. With a focus on structural integrity, advanced technology, and adherence to safety standards, our single girder goliath cranes are poised to elevate material handling operations across the Netherlands.

Crane Specifications of 20 ton goliath crane for sale Netherlands

20 Ton Gantry Cranes for Sale Netherlands

Crane types: Single Girder goliath cranes, with European style box girder crane design

Crane capacity: 20 ton

Crane span: 7.5 ton

Crane lifting height: 5 m

Crane power: 400V/50HZ/3P

Detailes of 20 Ton Goliath Cranes

- Crane Capacity: At the heart of our design philosophy lies a commitment to strength and reliability. With a robust crane capacity of 20 tons, our single girder goliath crane stands ready to tackle the most demanding lifting tasks with ease. Whether it's heavy machinery or bulky materials, rest assured, our crane is up to the challenge.

- Crane Span: Efficiency is the name of the game, and our crane's 7.5-meter span ensures optimal coverage without sacrificing maneuverability. From navigating busy warehouse floors to reaching remote corners of industrial facilities, our crane's versatile span empowers operators to maximize productivity with minimal effort.

- Crane Lifting Height: Precision matters, especially when it comes to lifting operations. With a lifting height of 5 meters, our crane offers the perfect balance of reach and control. Whether it's loading cargo onto trucks or positioning materials for assembly, our crane's impressive lifting height ensures seamless operation in any setting.

- Crane Power Supply: Powering productivity is our top priority, which is why our crane comes equipped with a reliable 400V/50HZ/3P power supply. Designed to meet the rigorous demands of industrial applications, our crane ensures uninterrupted performance, even in the most challenging environments.

In summary, our crane specifications represent more than just numbers on a page - they're a testament to our unwavering commitment to excellence. From capacity to span, lifting height to power supply, every detail has been meticulously crafted to deliver unparalleled efficiency and performance in the Netherlands' industrial landscape. Stay tuned as we delve deeper into the intricacies of our single girder goliath crane, exploring its structural design, mechanical components, and the myriad ways it promises to revolutionize material handling operations across the country. Welcome to a new era of lifting solutions - welcome to the future of industry in the Netherlands.

20 ton single girder goliath crane for sale

20 ton gantry crane main girder assembly

20 ton goliath gantry crane assembly

single girder goliath crane assembly

Lowheadroom gantrty crane 20 ton for indoor use

Indoor goliath crane finished installation inside of workshop

Structural Design of 20 ton Single Girder Goliath Cranes

In material handling, structural integrity is paramount. Our 20-ton single girder goliath crane stands as a testament to precision engineering, with its structural design meticulously crafted to ensure unparalleled strength, stability, and reliability. Let's delve deeper into the intricate details of our crane's structural design, particularly focusing on the innovative European style box girder construction.

- European Style Box Girder Construction: At the heart of our crane's design lies the European style box girder—a hallmark of durability and resilience. Unlike traditional girder designs, the box girder offers superior torsional resistance and rigidity, ensuring optimal performance even under the heaviest loads. Its streamlined profile not only enhances structural integrity but also reduces weight, allowing for increased efficiency without compromising on strength.

- Materials and Fabrication: High-grade steel, renowned for its exceptional strength and durability, serves as the foundation of our crane's structural components. Each part is meticulously fabricated to exacting standards, employing advanced techniques and precision machining to ensure seamless integration and maximum performance. From the main girder to the end trucks, every element of our crane is engineered to withstand the rigors of daily operation, providing unmatched reliability in the most demanding industrial environments.

- Load-Bearing Capacity and Stress Analysis: Rigorous load-bearing capacity calculations and stress analyses are integral to our crane's design process. By simulating real-world operating conditions and accounting for factors such as material properties and dynamic loading, we ensure that our crane meets and exceeds industry standards for safety and performance. Through meticulous attention to detail and advanced engineering principles, we optimize our crane's design to deliver maximum efficiency and longevity, providing peace of mind to operators and stakeholders alike.

In essence, our crane's structural design isn't just about form—it's about function. It's a testament to our unwavering commitment to engineering excellence, ensuring that every aspect of our crane is meticulously crafted to deliver unmatched performance and reliability in the Netherlands' industrial landscape. Stay tuned as we delve deeper into the mechanical components, electrical systems, and operational considerations that make our single girder goliath crane a game-changer in material handling technology. Welcome to a new era of lifting solutions—welcome to the future of industry in the Netherlands.

Mechanical Components of 20 ton Goliath Gantry Cranes

Beyond its sturdy frame and robust construction, our 20-ton single girder goliath crane boasts a sophisticated array of mechanical components designed to deliver unparalleled efficiency and reliability. Join us as we delve into the inner workings of our crane, exploring the intricacies of its hoisting mechanism, trolley system, and gantry structure.

- Hoisting Mechanism: At the heart of our crane's lifting prowess lies its hoisting mechanism - a feat of engineering precision and power. Utilizing state-of-the-art motors and gear systems, our hoisting mechanism ensures smooth and controlled lifting of heavy loads with ease. Whether it's hoisting machinery onto factory floors or transporting materials across warehouse spaces, our crane's hoisting mechanism delivers unmatched performance, every time.

- Trolley Mechanism: Efficiency meets versatility with our crane's advanced trolley mechanism. Designed to traverse the length of the crane's span with precision and agility, the trolley mechanism enables seamless positioning of loads in any direction. Equipped with robust motors and precision bearings, our trolley system ensures swift and accurate movement, allowing operators to maximize productivity with minimal effort.

- Gantry Structure and Its Components: A solid foundation is essential for optimal performance, which is why our crane's gantry structure is engineered to perfection. Constructed from high-strength steel and reinforced with strategic bracing, the gantry structure provides unparalleled stability and support. From the main beams to the end trucks, every component is designed to withstand the rigors of daily operation, ensuring long-lasting reliability in the most demanding industrial environments.

In summary, our crane's mechanical components represent the pinnacle of engineering innovation - a seamless fusion of power, precision, and performance. Stay tuned as we explore the electrical systems, environmental considerations, and operational aspects that make our single girder goliath crane a game-changer in material handling technology. Welcome to a new era of lifting solutions - welcome to the future of industry in the Netherlands.

Electrical System of Single Beam Goliath Crane 20 Ton

Beyond its robust structure and mechanical prowess, our 20-ton single girder goliath crane is fortified by a sophisticated electrical system, engineered to ensure seamless operation, precise control, and utmost safety. Let's delve into the intricacies of our crane's electrical components, from power supply requirements to safety features and emergency stop mechanisms.

- Overview of Power Supply Requirements: Reliability begins with power, which is why our crane is designed to meet the stringent requirements of industrial applications. With a power supply of 400V/50HZ/3P, our crane ensures consistent and uninterrupted performance, even in the most demanding environments. Whether it's lifting heavy loads or traversing the length of the crane's span, operators can trust in the stability and reliability of our electrical system.

- Description of Control System: Precision control is the hallmark of our crane's operation, made possible by our advanced control system. Equipped with intuitive interfaces and ergonomic controls, our system allows operators to effortlessly maneuver the crane with pinpoint accuracy. From adjusting lifting heights to controlling trolley movement, our control system puts power and precision at the operator's fingertips, ensuring smooth and efficient operation in any setting.

- Explanation of Safety Features and Emergency Stop Mechanisms: Safety is non-negotiable, which is why our crane is equipped with a comprehensive array of safety features and emergency stop mechanisms. From overload protection to anti-collision sensors, our crane is designed to prioritize the safety of operators and assets alike. In the event of an emergency, our emergency stop mechanisms provide instant shutdown capabilities, minimizing the risk of accidents and ensuring peace of mind for all stakeholders.

In essence, our crane's electrical system isn't just about power - it's about precision, control, and safety. From power supply requirements to control systems and safety features, every aspect is meticulously engineered to deliver unmatched performance and reliability in the Netherlands' industrial landscape. Stay tuned as we explore the environmental considerations, operational aspects, and real-world applications that make our single girder goliath crane a game-changer in material handling technology. Welcome to a new era of lifting solutions - welcome to the future of industry in the Netherlands.

Environmental Consideration for Indoor Goliath Crane and Oudoor Goliath Cranes

When it comes to deploying goliath cranes, whether indoors or outdoors, environmental factors play a pivotal role in ensuring optimal performance and longevity. Let's explore the unique considerations for both indoor and outdoor goliath cranes, highlighting the measures taken to enhance efficiency and durability in varying environments.

- Weatherproofing and Corrosion Resistance: While indoor environments may seem sheltered, factors like humidity and temperature variations can still impact crane performance. Our indoor goliath cranes are equipped with robust weatherproofing measures and corrosion-resistant coatings to withstand these conditions, ensuring uninterrupted operation and minimizing maintenance requirements.

- Space Optimization: In indoor settings with limited space, our goliath cranes are designed to maximize efficiency without compromising on functionality. Compact yet powerful, these cranes offer precise maneuverability and high lifting capacities, enabling operators to navigate tight spaces with ease and handle heavy loads with precision.

- Noise Reduction: Noise pollution can be a concern in indoor environments, especially in manufacturing facilities or warehouses. Our goliath cranes are engineered with noise-reducing features to minimize disruptions to workers and neighboring areas, ensuring a quieter and more conducive working environment.

- Weather Resistance: Outdoor goliath cranes face a host of environmental challenges, including exposure to harsh weather conditions such as rain, wind, and extreme temperatures. Our cranes are built to withstand these elements, with weatherproofing measures and durable coatings that protect against corrosion and degradation over time.

- UV Protection: Prolonged exposure to sunlight can degrade crane components and affect performance. Our outdoor goliath cranes are equipped with UV-resistant materials and coatings to mitigate the effects of sun exposure, ensuring long-term reliability and functionality even in the harshest outdoor environments.

- Structural Stability: Outdoor goliath cranes must withstand dynamic forces such as wind loads and temperature fluctuations. Our cranes feature robust structural designs and reinforced components to ensure stability and safety in outdoor settings, minimizing the risk of structural damage or failure.

In summary, whether deployed indoors or outdoors, our goliath cranes are engineered to excel in diverse environments, delivering reliable performance, efficiency, and durability. By addressing specific environmental considerations and implementing targeted solutions, we ensure that our cranes meet the unique requirements of each application, providing maximum value to our customers across industries.

Operational Considerations: Ensuring Efficiency and Safety

Efficiency in industrial operations isn't just about the equipment—it's also about how well it's maintained, operated, and utilized safely. Here's how our 20-ton single girder goliath crane addresses key operational considerations to ensure seamless performance and safety in the Netherlands.

- Explanation of Maintenance Procedures: Like any sophisticated machinery, regular maintenance is crucial for optimal performance and longevity. Our crane comes with comprehensive maintenance procedures designed to keep it running smoothly. From routine inspections to lubrication schedules, our maintenance guidelines ensure that every component of the crane is in top condition, minimizing the risk of unexpected downtime and costly repairs.

- Training Requirements for Operators: Operating heavy machinery requires specialized skills and knowledge. That's why we offer comprehensive training programs for crane operators. Our training covers everything from basic operation and safety protocols to advanced troubleshooting techniques. By ensuring that operators are well-trained and certified, we prioritize safety and efficiency in every operation.

- Safety Protocols and Guidelines for Usage: Safety is our top priority, which is why our crane comes with stringent safety protocols and usage guidelines. From pre-operation checks to emergency response procedures, our safety guidelines cover every aspect of crane operation. Additionally, we provide clear signage, safety barriers, and personal protective equipment to further mitigate risks and ensure a safe working environment for all.

In essence, operational considerations are integral to the success of our crane in the Netherlands. By emphasizing maintenance, training, and safety, we empower operators to maximize the crane's potential while minimizing risks and ensuring efficient and safe operations. Stay tuned as we explore cost estimation, market analysis, and real-world applications that demonstrate the value of our single girder goliath crane in the Dutch industrial landscape. Welcome to a new era of lifting solutions—welcome to the future of industry in the Netherlands.

Cost Estimation: Maximizing Value, Minimizing Expenses

Investing in a 20-ton single girder goliath crane is not just about the upfront cost—it's about maximizing value over the long term. Here's a comprehensive breakdown of the estimated costs associated with our crane, along with comparisons to market prices for similar models and consideration of additional expenses.

Breakdown of Estimated Costs:

Design: Our meticulous design process involves engineering expertise and innovative technology, accounting for a significant portion of the crane's overall cost.

Materials: High-grade steel and quality components ensure the durability and reliability of our crane, representing a substantial investment in materials.

Labor: Skilled labor is essential for the fabrication, assembly, and installation of our crane, contributing to the overall cost of the project.

Installation: Proper installation is critical for the crane's performance and safety, requiring skilled technicians and specialized equipment.

Comparison with Market Prices:

Our crane's pricing is competitive with similar models on the market, reflecting its advanced features, superior performance, and exceptional durability.

While initial costs may vary, our crane offers long-term value through reduced maintenance requirements, increased efficiency, and extended lifespan.

Consideration of Additional Costs:

Transportation: Shipping the crane to its destination incurs additional costs, depending on the distance and logistics involved.

Taxes: VAT and other taxes may apply, adding to the overall expense of purchasing and installing the crane.

Maintenance: While our crane is designed for reliability, ongoing maintenance is necessary to ensure optimal performance and longevity.

In summary, while our 20-ton single girder goliath crane represents a significant investment, its value extends far beyond the initial price tag. By providing superior performance, reliability, and efficiency, our crane offers a compelling return on investment for businesses in the Netherlands. Stay tuned as we explore market analysis, customer testimonials, and real-world applications that showcase the tangible benefits of our single girder goliath crane in the Dutch industrial landscape. Welcome to a new era of lifting solutions—welcome to the future of industry in the Netherlands.

Application in the Netherlands

Embarking on the journey of introducing our 20-ton single girder goliath crane into the Dutch market isn't just about selling a product—it's about understanding the unique needs and demands of the local industry landscape. Let's delve into a comprehensive case study that analyzes the demand for 20-ton goliath cranes, conducts market research on potential clients and industries, and discusses the advantages of offering single girder goliath cranes in the Dutch market.

- Analysis of Demand: The Netherlands boasts a thriving industrial sector characterized by manufacturing, logistics, and warehousing operations.

With the need for efficient material handling solutions on the rise, there's a growing demand for heavy-duty cranes capable of lifting large loads with precision and reliability.

The versatility and strength of our 20-ton single girder goliath crane position it as an ideal solution for a wide range of applications, from manufacturing facilities to ports and shipyards. - Market : Our market research identifies potential clients across various industries, including automotive, aerospace, construction, and renewable energy.

Key clients may include manufacturing plants requiring heavy lifting capabilities, logistics companies handling oversized cargo, and construction firms in need of versatile material handling solutions. - Advantages of Offering Single Girder Goliath Cranes: Single girder goliath cranes offer several advantages over traditional double girder cranes, including lower cost, reduced weight, and easier installation. The European style box girder design enhances structural integrity and stability, making our crane an attractive option for businesses seeking reliable and efficient lifting solutions. By offering single girder goliath cranes in the Dutch market, we provide businesses with a cost-effective yet high-performance alternative, enabling them to enhance productivity and streamline operations without breaking the bank.

In summary, our case study highlights the significant potential for our 20-ton single girder goliath crane in the Netherlands. By analyzing demand, conducting market research, and emphasizing the advantages of our crane, we position ourselves as a trusted partner in the Dutch industrial landscape. Stay tuned as we explore customer testimonials, success stories, and real-world applications that demonstrate the transformative impact of our single girder goliath crane in the Netherlands. Welcome to a new era of lifting solutions—welcome to the future of industry in the Netherlands.

Conclusion: Shaping the Future of Industry in the Netherlands

In conclusion, our journey through the design, specifications, and application of 20-ton single girder goliath cranes in the Netherlands has illuminated the immense potential of these cutting-edge lifting solutions. Let's summarize the key points discussed and highlight the suitability and benefits of our crane for the Dutch market.

Throughout our exploration, we've uncovered the meticulous engineering behind our crane's structural design, mechanical components, electrical systems, and operational considerations. From its European style box girder construction to its advanced control systems and safety features, every aspect of our crane is designed to deliver unmatched performance, efficiency, and reliability.

We've delved into the practical applications of our crane in the Dutch industrial landscape, analyzing the demand for heavy-duty lifting solutions and identifying potential clients and industries. With its versatility, strength, and cost-effectiveness, our crane offers a compelling value proposition for businesses seeking to enhance productivity and streamline operations.

The advantages of offering 20-ton single girder goliath cranes in the Netherlands are clear: improved efficiency, increased safety, and reduced costs. By investing in our crane, businesses can elevate their material handling capabilities, optimize workflow processes, and stay ahead of the competition in today's dynamic market.

As we conclude our discussion, we invite further exploration and inquiry into our 20-ton single girder goliath cranes. Whether you're a manufacturing plant, logistics company, or construction firm, we're here to collaborate with you to find the perfect lifting solution for your needs.

Welcome to a new era of lifting solutions—welcome to the future of industry in the Netherlands. Let's shape it together.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

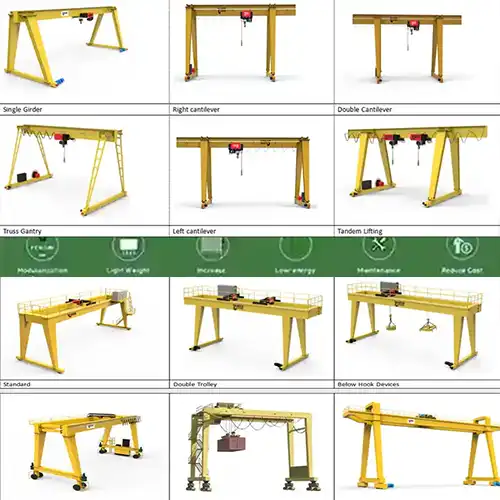

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch