Crane and Hoist Buying: Tips to Avoid Mistakes for a Wise Investment

Crane and hoist purchases require careful consideration to avoid critical mistakes, ensuring a smart investment for efficient, safe, and cost-effective material handling

Category: Ask for Hoist And Crane Price

Your Trusted Overhead Crane Manufacturer & Supplier

Crane and Hoist Buying: Tips to Avoid Mistakes for a Wise Investment

Crane and hoist purchases require careful consideration to avoid critical mistakes, ensuring a smart investment for efficient, safe, and cost-effective material handling

In industries and construction, where efficiency and safety are important, the significance of investing in high-quality cranes and hoists cannot be overstated. These essential pieces of equipment form the backbone of various operations, from lifting heavy loads to streamlining production processes.

At the heart of any successful investment in cranes and hoists lies a commitment to maintenance and regular inspections. While the initial purchase may seem like a significant outlay, it's crucial to view it as an investment in the long-term productivity and profitability of your operations.

Maintenance and inspections play a pivotal role in maximizing return on investment (ROI) for crane and hoist purchases. By ensuring these equipment are well-maintained and regularly inspected, businesses can prevent costly breakdowns, minimize downtime, and extend the lifespan of their assets.

Understanding Your Needs

Assessing Operational Requirements and Budget Constraints

Before diving into the marketplace, it's essential to take a step back and evaluate your operational requirements. Consider the nature of your business, the types of loads you'll be handling, and the frequency of crane usage. Understanding these operational nuances will guide you towards selecting the right crane or hoist that aligns with your workflow and enhances efficiency.

At the same time, it's crucial to acknowledge your budget constraints. While it may be tempting to opt for the latest and most advanced models, it's essential to strike a balance between functionality and affordability. By setting a realistic budget upfront, you can narrow down your options and focus on solutions that offer the best value for your investment.

Design Pitfalls and Specification Mistakes

In the pursuit of acquiring the perfect crane or hoist, it's easy to fall into the trap of design pitfalls and specification mistakes. This section sheds light on some common pitfalls to avoid during the procurement process.

Over-Designing and Its Impact on Functionality

One of the most prevalent mistakes buyers make is succumbing to the allure of over-designing. While it may seem appealing to opt for a crane or hoist with all the bells and whistles, excessive design can actually hinder functionality. Over-designed equipment often comes with unnecessary features or complexities that can complicate operations and increase maintenance requirements. Instead of focusing on flashy designs, prioritize functionality and choose a crane or hoist that meets your specific operational needs without unnecessary embellishments.

Common Errors in Load Capacity Determination

Another critical aspect to consider is load capacity determination. Underestimating or overestimating the load capacity of a crane or hoist can lead to disastrous consequences. A crane that is under capacity risks overloading, compromising safety and efficiency. Conversely, a crane with excessive capacity incurs unnecessary costs and may be less efficient in handling lighter loads. To avoid this pitfall, conduct a thorough assessment of your lifting requirements and consult with experts if needed to ensure accurate load capacity determination.

Overlooking Essential Specifications like Span and Lift Height

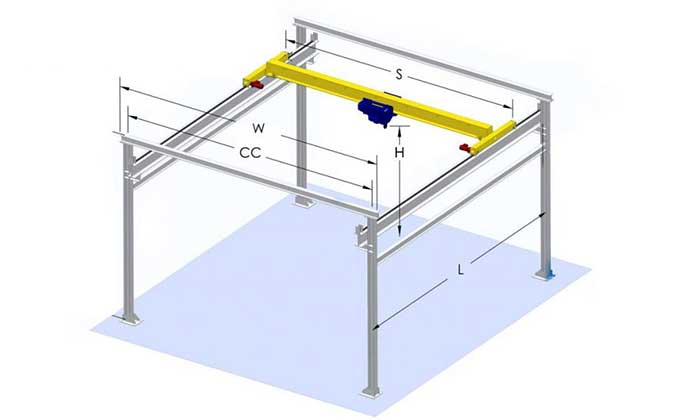

When it comes to crane and hoist specifications, overlooking essential details like crane span and lift height can be a costly mistake. The span refers to the distance between the runways or rails on which the crane operates, while lift height denotes the maximum height the crane can lift a load. Failure to consider these specifications can result in equipment that is ill-suited for your workspace or unable to handle your lifting requirements effectively. Before making a purchase, carefully assess your workspace dimensions and lifting needs to ensure the crane or hoist specifications align with your operational requirements.

By steering clear of design pitfalls and specification mistakes, you can make a more informed decision when selecting a crane or hoist for your operations.

Neglecting Safety Considerations

In the industrial operations, safety should always be the top priority. Neglecting safety considerations when procuring cranes and hoists can have serious consequences. This section highlights the critical importance of prioritizing safety throughout the procurement process.

Importance of Compliance with Safety Standards

Safety standards exist for a reason – to protect workers and assets from harm. When purchasing cranes and hoists, it's essential to ensure compliance with relevant safety standards such as those set forth by OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute). These standards outline specific requirements and guidelines for equipment design, installation, operation, and maintenance to mitigate risks and ensure a safe working environment. By adhering to safety standards, businesses can minimize the likelihood of accidents, injuries, and costly penalties.

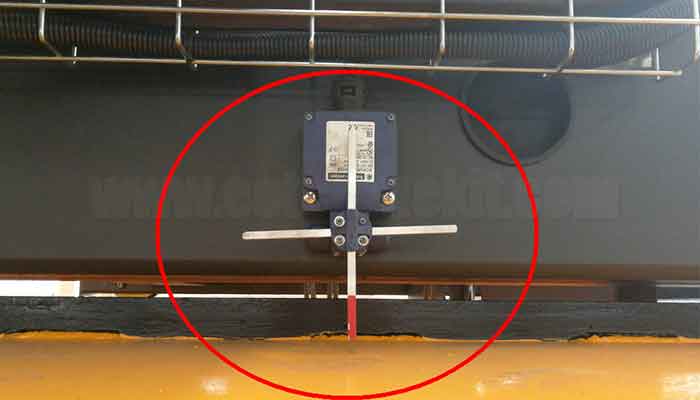

Understanding Safety Factor Requirements and Duty Class

Beyond basic safety standards, it's crucial to consider safety factor requirements and required safety devices and duty class when selecting cranes and hoists. Safety factor refers to the ratio of the ultimate load capacity to the rated load capacity, providing a margin of safety against overloading and potential failure. Duty class, on the other hand, categorizes cranes and hoists based on their intended usage and workload, ranging from light-duty to heavy-duty applications.

Understanding safety factor requirements and duty class ensures that the selected equipment is appropriately rated for the intended workload and operating conditions. Neglecting these considerations can result in equipment failure, accidents, and injuries. Therefore, it's imperative to consult with safety experts and equipment manufacturers to determine the appropriate safety factors and duty class for your specific needs.

By prioritizing safety considerations and ensuring compliance with safety standards, businesses can create a safer work environment, protect personnel and assets, and mitigate potential liabilities.

Ignoring Installation and Maintenance Factors

When it comes to procuring overhead cranes and hoists, overlooking installation and maintenance factors can lead to significant challenges down the line. This section emphasizes the importance of considering these factors from the outset of the procurement process.

Budgeting for Installation Costs and Setup

An often underestimated aspect of crane and hoist procurement is the cost of installation and setup. Proper installation is crucial for ensuring the safe and effective operation of these equipment. It involves tasks such as assembly, wiring, and testing, all of which require skilled labor and specialized tools. By budgeting adequately for installation costs upfront, businesses can avoid delays, ensure compliance with safety standards, and minimize the risk of installation errors that could compromise equipment performance.

Long-Term Maintenance Planning and Budget Allocation

Equally critical is long-term maintenance planning and budget allocation. Regular maintenance is essential for extending the lifespan of cranes and hoists, maximizing uptime, and preventing costly breakdowns. However, maintenance costs can vary depending on factors such as equipment type, usage intensity, and environmental conditions. Therefore, it's essential to develop a comprehensive maintenance plan that outlines routine inspections, servicing schedules, and budget allocations for spare parts and repairs.

By incorporating maintenance planning into the procurement process, businesses can ensure they have the necessary resources in place to sustainably maintain their equipment over its lifespan. This proactive approach not only minimizes the risk of unexpected downtime but also enhances safety and operational efficiency.

Myth Debunking

Dispelling the Myth of "More is Always Better" in Crane Selection

One prevalent misconception among buyers is the belief that "more is always better" when it comes to crane selection. While it may seem intuitive to opt for the largest or most powerful crane available, this approach can often lead to inefficiencies and unnecessary costs. In reality, selecting a crane with excessive capacity or features beyond your operational needs can result in higher initial costs, increased energy consumption, and reduced overall efficiency. Instead, focus on selecting a crane that is appropriately sized and equipped to handle your specific workload and operational requirements.

Importance of Optimal Weight and Design for Safety and Performance

By debunking these myths and emphasizing the importance of optimal weight and design for safety and performance, buyers can make more informed decisions when selecting cranes.

Cost vs. Quality

Balancing budget constraints with quality standards is a pivotal aspect of crane procurement. This section delves into the delicate balance between cost and quality, emphasizing the importance of making informed decisions while ensuring clarity in scope and budget.

Balancing Budget Constraints with Quality Standards

When it comes to crane procurement, cost considerations often loom large. However, prioritizing cost savings over quality can have long-term implications on safety, reliability, and operational efficiency. While it may be tempting to opt for the cheapest option available, it's essential to assess the quality standards of the equipment thoroughly. Investing in high-quality cranes and hoists that meet industry standards and regulations may entail a higher initial investment but can yield significant returns in terms of durability, performance, and overall value over time.

Additional Charges and Ensuring Scope Clarity

In addition to the upfront cost of the equipment, buyers must also consider additional charges and ensure clarity in scope when evaluating proposals. These additional charges may include installation fees, transportation costs, taxes, and ongoing maintenance expenses. By carefully reviewing proposals and seeking clarification on any ambiguous terms or charges, buyers can avoid unpleasant surprises and ensure that they have a comprehensive understanding of the total cost of ownership. Moreover, establishing clear scope parameters and expectations upfront can help prevent misunderstandings and disputes down the line, fostering a more transparent and productive vendor-client relationship.

By striking a balance between budget constraints and quality standards and ensuring clarity in scope and budget, buyers can make more informed decisions that optimize both cost-effectiveness and equipment performance.

Failing to Research Suppliers

Choosing the right supplier is paramount when procuring cranes and hoists. This section emphasizes the significance of conducting thorough research on suppliers and provides guidance on asking critical questions to ensure reliability and suitability.

Importance of Supplier Reputation, Experience, and Reliability

One of the most common pitfalls in crane procurement is failing to research suppliers adequately. The reputation, experience, and reliability of a supplier can significantly impact the quality of the equipment and the overall success of the project. Before engaging with a supplier, it's essential to assess their track record, reputation in the industry, and experience in providing solutions that meet your specific needs. A supplier with a proven track record of delivering high-quality, reliable equipment and excellent customer service is more likely to provide a positive experience and ensure the success of your project.

Critical Questions to Ask Potential Suppliers

When evaluating potential suppliers, asking the right questions is crucial to gaining insight into their capabilities, expertise, and suitability for your project. Some critical questions to ask include:

1. Can you provide references or case studies from similar projects?

2. What certifications and qualifications do your products and personnel possess?

3. What is your approach to customer service and support?

4. How do you ensure the quality and reliability of your equipment?

5. What is your process for handling warranty claims and addressing issues after installation?

By asking these questions and thoroughly evaluating the responses, buyers can gain a better understanding of a supplier's capabilities, reliability, and suitability for their project. Additionally, reaching out to references or conducting site visits can provide valuable insights into the supplier's performance and customer satisfaction levels.

By prioritizing supplier research and asking critical questions, buyers can mitigate risks, ensure quality and reliability, and ultimately, make more informed decisions when procuring cranes and hoists. In the next section, we'll explore the importance of user training and support in maximizing the value of your equipment investment. Stay tuned for valuable insights!

Lack of User Training and Support

Inadequate user training and support can undermine the effectiveness and safety of crane and hoist operations. This section emphasizes the importance of investing in operator training and evaluating post-purchase support options to ensure the efficient and safe operation of equipment.

Ensuring Adequate Operator Training and Knowledge Transfer

One of the most critical factors in ensuring the safe and efficient operation of cranes and hoists is adequate operator training. Proper training equips operators with the skills and knowledge necessary to operate equipment safely, identify potential hazards, and respond appropriately to various operating conditions. It's essential to invest in comprehensive operator training programs conducted by qualified instructors who can provide hands-on instruction and practical experience. Additionally, ongoing refresher training should be provided to ensure that operators remain proficient and up-to-date with best practices and safety procedures.

Evaluating Post-Purchase Support Options for Effective Crane Operation

Beyond operator training, evaluating post-purchase support options is crucial for maintaining the effectiveness and longevity of crane and hoist operations. A reputable supplier should offer comprehensive support services to assist with installation, commissioning, and ongoing maintenance. This includes access to technical support personnel who can provide guidance on troubleshooting issues, as well as readily available spare parts and repair services to minimize downtime. Additionally, suppliers should offer warranty coverage and service agreements to provide peace of mind and ensure timely resolution of any issues that may arise.

By prioritizing operator training and evaluating post-purchase support options, buyers can ensure the safe and effective operation of their cranes and hoists throughout their lifespan. Investing in training and support not only enhances safety and efficiency but also maximizes the return on investment and prolongs the lifespan of equipment.

After-Sales Services

After-sales services play a crucial role in ensuring the smooth and uninterrupted operation of cranes and hoists. This section dives deeper into the importance of after-sales services in minimizing downtime and maximizing uptime, as well as how to assess manufacturer support for efficient issue resolution.

Importance of After-Sales Services in Minimizing Downtime and Maximizing Uptime

After-sales services encompass a range of support activities provided by manufacturers or suppliers to address issues that may arise after the purchase of cranes and hoists. These services are instrumental in minimizing downtime, which can be costly and disruptive to operations. Timely maintenance, repairs, and technical support ensure that equipment remains in optimal working condition, reducing the risk of unexpected breakdowns and production delays. Moreover, after-sales services can help maximize uptime by proactively identifying and addressing potential issues before they escalate into major problems.

Assessing Manufacturer Support and Response Time for Efficient Issue Resolution

When evaluating after-sales services, it's essential to assess the level of manufacturer support and response time for issue resolution. A reputable manufacturer should offer prompt and efficient support to address any technical issues or concerns that may arise. This includes access to knowledgeable technical support staff who can provide timely assistance and guidance, as well as a streamlined process for resolving issues and scheduling repairs or maintenance activities. Additionally, manufacturers should offer comprehensive warranty coverage and service agreements to provide customers with peace of mind and ensure that their equipment investment is protected.

By prioritizing after-sales services and assessing manufacturer support and response time, buyers can minimize downtime, maximize uptime, and ensure the continued reliability and performance of their cranes and hoists. Investing in comprehensive after-sales support not only enhances operational efficiency but also strengthens the long-term partnership between buyers and manufacturers.

Appendices

In the following, you'll find additional resources to supplement your understanding of crane and hoist procurement and enhance your decision-making process.

Glossary of Terms for Reference

This glossary provides definitions for key terms and jargon commonly used in the crane and hoist industry. Whether you're new to the field or seeking clarification on specific terminology, this reference guide will help you navigate technical discussions and make more informed decisions.

Additional Resources for Further Reading and Research

Expand your knowledge and expertise with these additional resources, including articles, books, industry standards, and guidelines. Whether you're interested in delving deeper into specific topics or staying updated on the latest trends and developments in crane and hoist technology, these resources offer valuable insights and practical guidance to support your decision-making process.

By leveraging these appendices, you can enhance your understanding of crane and hoist procurement and equip yourself with the knowledge and tools needed to make informed decisions that optimize safety, efficiency, and value.

Congratulations on completing our comprehensive guide on mastering crane and hoist purchases! We hope you found the information valuable and insightful. If you have any further questions or require assistance, don't hesitate to reach out to industry experts or suppliers for personalized guidance.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

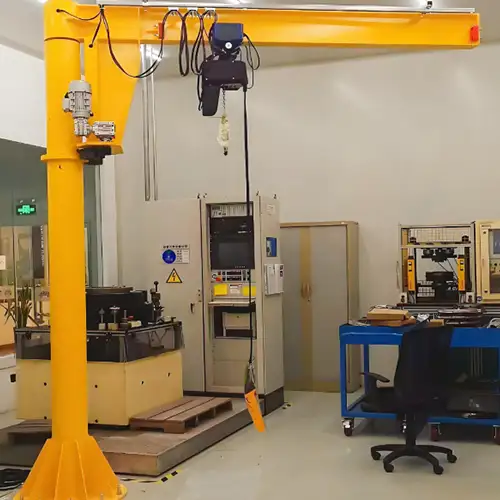

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch