Jib Crane Pricing: Guide to Essential Terms and Jargon

Learn vital terms and jargon for jib crane pricing, covering capacity, reach, mounting types, rotation & installation specifics, to ensure accurate cost estimates.

Category: Ask for Hoist And Crane Price

Your Trusted Jib Crane Manufacturer & Supplier

Jib Crane Pricing: A Comprehensive Guide to Essential Terms and Jargon

Jib cranes, often hailed as the workhorses of material handling, play a vital role in various industries worldwide. These versatile lifting devices are designed to facilitate the movement of heavy loads within a confined space, offering efficiency, flexibility, and safety in operations.

Why Understanding Jib Crane Pricing and Terminology Matters

In the material handling equipment, knowing the ins and outs of jib crane pricing and terminology can make all the difference. Whether you're a seasoned procurement professional or a business owner looking to invest in efficient lifting solutions, understanding the nuances of jib crane terminology is crucial.

Jib crane pricing is influenced by various factors, including load capacity, design features, material quality, and manufacturer reputation. Without a solid grasp of these terms and jargon, navigating the procurement process can be daunting and potentially costly.

By demystifying jib crane pricing and terminology, you gain the confidence to make informed decisions, negotiate effectively with suppliers, and ultimately, invest in the right lifting solution for your needs. So, let's dive in and unravel the complexities of jib crane terminology together.

Types of Jib Cranes

Jib cranes come in various configurations, each tailored to specific applications and operational requirements. In this section, we'll explore the first type: Floor Mounted Jib Cranes.

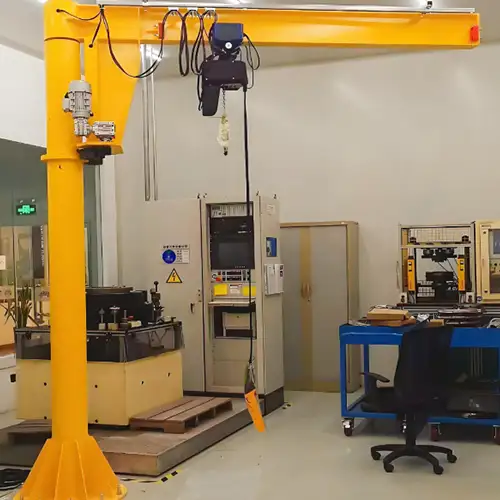

Floor Mounted Pillar Jib Cranes

Floor mounted jib cranes are freestanding lifting devices that are securely anchored to the floor, providing a stable and reliable solution for material handling tasks. These cranes feature a vertical mast, which is bolted directly to a concrete foundation, ensuring robust support for lifting heavy loads.

Common Applications of Floor Mounted Jib Cranes

Floor mounted jib cranes find widespread use across a range of industries and applications, thanks to their versatility and accessibility. Some common applications include:

- Loading and Unloading: Floor mounted jib cranes are ideal for loading and unloading materials onto trucks, trailers, or workstations, streamlining logistics operations in warehouses and distribution centers.

- Workstation Lifting: In manufacturing and assembly environments, floor mounted jib cranes provide efficient lifting solutions for moving components between workstations, improving productivity and ergonomics.

- Maintenance and Repair: Floor mounted jib cranes are invaluable for maintenance and repair tasks, allowing technicians to safely lift and position heavy equipment or machinery for servicing.

Key Features and Components

Floor mounted jib cranes typically consist of the following key features and components:

- Vertical Mast: The central support structure of the crane, securely anchored to the floor using anchor bolts embedded in a concrete foundation.

- Boom Arm: The horizontal boom arm extends from the mast and supports the lifting mechanism, providing a reach for lifting and maneuvering loads within the crane's coverage area.

- Hoist or Lifting Mechanism: Depending on the application, floor mounted jib cranes may be equipped with manual chain hoists, electric wire rope hoists, or other lifting mechanisms to raise and lower loads.

- Rotation Mechanism: Many floor mounted jib cranes feature a swivel mount or slew bearing that allows the boom arm to rotate, providing flexibility in positioning loads.

- Control System: Floor mounted jib cranes may be operated manually using hand-operated controls or equipped with motorized systems for precise and efficient lifting operations.

By understanding the definition, common applications, and key features of floor mounted jib cranes, you can better assess whether this type of crane is suitable for your lifting needs. In the next section, we'll explore another type of jib crane: Pillar Jib Cranes.

Wall Jib Cranes:

Wall jib cranes are specialized lifting devices that are mounted to a vertical surface, such as a wall or column, rather than being freestanding like floor or pillar-mounted cranes. These cranes are designed to provide efficient material handling solutions in areas where floor space is limited or where a freestanding crane is impractical.

Common Applications of Wall Jib Cranes

Wall jib cranes are utilized in a variety of industries and applications where overhead lifting is required. Some common applications include:

- Workstation Lifting: Wall jib cranes are often installed above workstations or assembly areas to facilitate lifting and maneuvering of components or materials during manufacturing processes.

- Loading Docks: Wall jib cranes are commonly used in loading dock areas to assist in loading and unloading trucks or trailers, improving efficiency and safety in logistics operations.

- Warehouse Storage: Wall jib cranes can be installed in warehouse environments to lift and position heavy items onto shelves or storage racks, maximizing storage space and organization.

Types of Wall Jib Cranes

There are two main types of wall jib cranes:

- Wall-Mounted Jib Cranes: These cranes are securely attached to a vertical wall or structure using mounting brackets or anchor bolts. They provide a fixed lifting solution for specific areas and are ideal for applications where a permanent lifting solution is required.

- Wall-Traveling Jib Cranes: Also known as wall-traveling gantry cranes, these cranes are mounted on tracks or rails that run along a wall or column. They can move horizontally along the length of the wall, providing greater coverage and flexibility in material handling operations.

Key Features and Components

Wall jib cranes typically consist of the following key features and components:

- Mounting Bracket: Wall-mounted jib cranes are attached to a vertical surface using a sturdy mounting bracket or anchor bolts. Wall-traveling jib cranes are mounted on tracks or rails that allow them to move horizontally along the wall.

- Boom Arm: The horizontal boom arm extends from the mounting bracket or rail system and supports the lifting mechanism, providing a reach for lifting and positioning loads.

- Lifting Mechanism: Wall jib cranes are equipped with various lifting mechanisms, such as electric chain hoists, wire rope hoists, or manual chain hoists, depending on the load requirements and application.

- Rotation Mechanism: Many wall jib cranes feature a swivel mount or slew bearing that allows the boom arm to rotate 180 degrees or more, providing flexibility in positioning loads.

- Control System: Wall jib cranes may be operated manually using hand-operated controls or equipped with motorized systems for precise and efficient lifting operations.

By understanding the definition, common applications, types, and key features of wall jib cranes, you can determine whether this type of crane is suitable for your material handling needs. In the next section, we'll delve into the factors influencing jib crane prices.

Essential Terms and Jargon

To navigate the world of jib cranes effectively, it's crucial to understand the key terminology used in the industry.

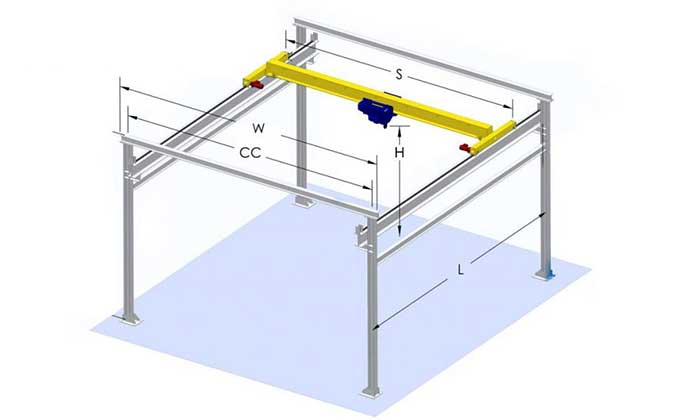

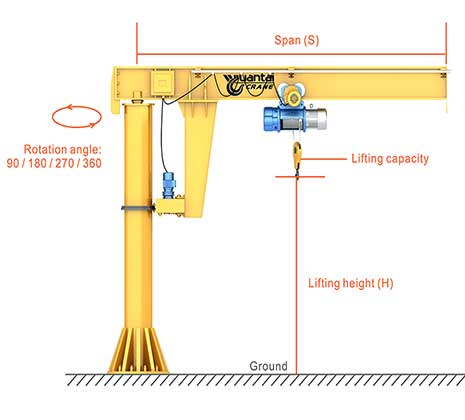

pillar jib crane drawing to confirm the main parameters of your required floor jib cranes

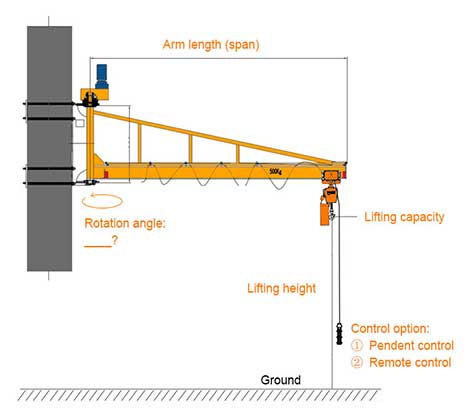

Wall jib crane drawing to confirm the main specifications of your required wall jib crane

Let's break down some essential terms and jargon you'll encounter when discussing jib crane specifications:

- Load Capacity:The maximum weight that a jib crane can lift safely. Expressed in tons or kilograms, this is a critical factor in determining the suitability of a crane for a particular application.

- Boom Length:The horizontal distance from the central pivot point of the crane (usually the mast or column) to the tip of the boom arm. Longer boom lengths allow for greater reach and coverage.

- Rotation Degree:The degree of rotation that the crane's boom arm can achieve. Common options include 180°, 270°, and 360° rotation, providing varying degrees of coverage.

- Mounting Type:Refers to how the jib crane is mounted or anchored. Common mounting types include floor-mounted, pillar-mounted, wall-mounted, and ceiling-mounted configurations.

- Foundation Requirements:The specifications and construction requirements for the foundation or base on which the crane will be installed. This may include concrete footings, anchor bolts, and reinforcement.

- Hoist Type and Capacity:The type of lifting mechanism used on the crane (e.g., electric chain hoist, wire rope hoist) and its maximum lifting capacity. Hoist capacity should match or exceed the load capacity of the crane.

- Cantilever Length:The horizontal distance from the central pivot point of the crane to the outer end of the boom arm. This term is commonly used in reference to wall-mounted jib cranes.

- Reach:Similar to boom length, reach refers to the horizontal distance that the crane's boom arm can extend from its pivot point. It indicates the maximum distance a load can be moved laterally.

- Swing Radius:The radius of the circular area that the crane's boom arm can cover when rotated. It's essential to consider swing radius to ensure that the crane has sufficient clearance to operate safely.

- Cantilever Offset:The horizontal distance between the central pivot point of the crane and the mounting surface (e.g., wall) for wall-mounted jib cranes. It determines the amount of clearance required for installation.

- Foundation Anchor Bolts:Bolts used to secure the base or foundation of the crane to a concrete surface. Properly installed anchor bolts are crucial for the stability and safety of the crane.

- Arm Profile:The shape or configuration of the crane's boom arm. Common profiles include I-beam, enclosed track, and profiled steel.

- Slewing Lock:A safety feature that locks the rotation of the crane's boom arm in place, preventing unintended movement during lifting operations.

- Installation Clearance:The minimum clearance required around the crane's installation site to ensure safe operation and maintenance access.

- Control Options (Manual vs. Motorized):Refers to the method of controlling the crane's movements. Manual control involves hand-operated controls, while motorized control utilizes electric or hydraulic systems for automated operation.

By familiarizing yourself with these essential terms and jargon, you'll be better equipped to discuss jib crane specifications, understand quotes and proposals, and make informed decisions when selecting the right crane for your application. In the next section, we'll explore the factors that influence jib crane pricing.

Factors Affecting Pricing

When it comes to purchasing a jib crane, several factors influence the overall cost. Understanding these factors can help you make informed decisions and ensure you get the best value for your investment. Let's explore the key factors affecting jib crane pricing:

- Capacity and Load:The lifting capacity of the crane, measured in tons or kilograms, significantly impacts its price. Cranes with higher load capacities typically cost more due to the robust construction and components required to handle heavier loads.

- Crane Design and Features:The design and features of the crane, such as boom length, rotation degree, and mounting type, play a significant role in determining its price. Cranes with longer booms, greater rotation capabilities, and specialized mounting configurations may command a higher price.

- Material and Build Quality:The quality of materials used in the construction of the crane, as well as the level of craftsmanship and engineering expertise, can affect its price. High-quality materials and superior build quality contribute to a more durable and reliable crane but may come at a higher cost.

- Brand and Manufacturer:The reputation and brand recognition of the manufacturer can influence the price of a jib crane. Established brands known for producing high-quality, reliable equipment may command a premium price compared to lesser-known manufacturers.

- Additional Features and Customizations:Optional features and customizations, such as motorized rotation, variable speed controls, and specialized attachments, can add to the cost of the crane. While these features enhance functionality and performance, they may also increase the overall price of the crane.

By considering these factors when evaluating jib crane pricing, you can better understand the value proposition offered by different suppliers and select a crane that meets your requirements and budget. In the next section, we'll explore how to interpret and compare quotes from jib crane suppliers effectively.

Quotes and Estimates

When exploring quotes and estimates for jib cranes, it's essential to delve beyond the surface and understand the finer details. Here's what you need to know to make informed decisions:

- Itemized Costs Breakdown:A transparent breakdown of costs is crucial for understanding what you're paying for. Look for itemized lists that detail the price of the crane itself, any additional features or customizations, shipping fees, taxes, and installation charges.

- Hidden Costs and Fees:Be vigilant for hidden costs or fees that may not be immediately apparent. These could include charges for special packaging, handling, or expedited production. Ask suppliers to clarify any ambiguities to avoid unexpected expenses later on.

- Total Cost of Ownership:Consider the total cost of ownership over the lifespan of the crane. This includes not only the upfront purchase cost but also ongoing maintenance, repairs, spare parts, and operational expenses. Investing in a higher-quality crane upfront may result in lower long-term costs.

- Warranty and After-Sales Support:Assess the warranty coverage provided by the supplier, including the duration and what is included. Inquire about after-sales support services such as maintenance, repairs, and technical assistance. A comprehensive warranty and reliable after-sales support can provide peace of mind and minimize downtime.

By scrutinizing quotes and estimates with these factors in mind, you can ensure that you're making a well-informed decision and getting the best value for your investment in a jib crane. In the next section, we'll discuss tips for effective communication when requesting quotes and negotiating with suppliers.

Tips for Effective Communication

Clear and effective communication with jib crane suppliers is essential for ensuring that your needs are met and that you receive accurate quotes. Here are some tips to help you communicate effectively:

- Asking the Right Questions:Prepare a list of questions to ask potential suppliers to gain a comprehensive understanding of their products and services. Ask about load capacities, crane features, installation requirements, lead times, and warranty coverage.

- Providing Detailed Project Specifications:Clearly outline your project requirements and specifications to suppliers. Provide information about your application, such as load weights, lifting heights, operational environment, and any special considerations. The more detailed your specifications, the more accurately suppliers can tailor their proposals to meet your needs.

- Clarifying Terms and Expectations:Don't hesitate to ask for clarification on any terms or technical aspects you don't understand. Make sure both parties have a clear understanding of expectations regarding pricing, delivery timelines, installation, and after-sales support. Misunderstandings can lead to delays and dissatisfaction down the line.

By following these tips for effective communication, you can streamline the quoting process, ensure that you receive accurate proposals, and ultimately select the best jib crane supplier for your project needs. In the next section, we'll conclude our comprehensive guide with a summary of key takeaways.

Conclusion

As we conclude our comprehensive guide to understanding jib crane pricing and terminology, let's recap the key points and takeaways:

Recap of Key Terms and Concepts:

We've covered essential terms and jargon related to jib cranes, including load capacity, boom length, mounting type, and more. Understanding these terms is crucial for navigating the procurement process effectively.

- Importance of Terminology in Pricing Negotiations:Terminology plays a vital role in pricing negotiations with jib crane suppliers. By speaking the same language and clearly articulating your requirements, you can ensure that you receive accurate quotes and proposals that meet your needs.

- Encouragement to Seek Clarification and Guidance:Effective communication is key to success when procuring jib cranes. Don't hesitate to seek clarification from suppliers or industry experts if you're unsure about any terms or technical aspects. Seeking guidance can help you make informed decisions and avoid costly mistakes.

The terminology used in jib crane pricing and effectively communicating your requirements to suppliers, you can streamline the procurement process and select the best crane for your needs. Remember to ask the right questions, provide detailed project specifications, and clarify any terms or expectations to ensure a successful outcome.

Thank you for joining us on this journey through the world of jib crane pricing and terminology. We hope you found this guide valuable and informative. If you have any further questions or need assistance with your jib crane procurement process, don't hesitate to reach out to trusted suppliers or industry professionals. Click to learn more on jib crane price range for your reference and customized jib crane price is provided based on your lifting requirement and specifications. Happy lifting!

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch