Material Handling Bridge Cranes & Gantry Cranes for Auto Sector

Discover how custom-designed material handling overhead bridge crane, jib crane gantry cranes can enhance efficiency & productivity in the auto sector.

Category: Auto

Your Trusted Overhead Crane Manufacturer & Supplier

Overhead Crane Types, Uses & Selection in the Automotive Industry

Explore various overhead crane types, their specific automotive uses, and key selection criteria to optimize efficiency, safety, and productivity in automotive manufacturing.Also, check how to the custom-designed material handling overhead bridge crane, jib crane gantry cranes to enhance efficiency & productivity in the auto sector.

Overhead cranes are industrial lifting devices designed to move heavy loads within a workspace. These cranes consist of a horizontal bridge that travels along a pair of tracks or rails mounted to the building's walls or ceiling. The bridge supports a hoist, which can raise and lower loads. Overhead cranes are essential tools in various industries due to their ability to handle substantial weights and perform precise movements.

Importance in Industrial Settings

In industrial environments, overhead cranes play a crucial role in streamlining material handling. They reduce the need for manual lifting and transporting of heavy items, thereby enhancing workplace safety and efficiency. By providing reliable and efficient load handling, these cranes help improve productivity, minimize downtime, and ensure smooth operation of manufacturing processes.

Relevance to the Automotive Industry

Role of Overhead Cranes in Automotive Manufacturing and Assembly

In the automotive industry, overhead cranes are indispensable for several key tasks. They are used to move large automotive parts such as engines, chassis, and body panels along the assembly line. These cranes support the assembly process by accurately positioning components and managing the heavy lifting required for vehicle construction. Additionally, they assist in moving parts between different stages of production, which helps maintain a steady workflow and reduces production bottlenecks.

Benefits of Using Overhead Cranes in Automotive Applications

The use of overhead cranes in automotive manufacturing offers numerous advantages:

- Efficiency: By automating the handling of heavy and bulky components, overhead cranes speed up the assembly process and reduce the need for manual labor.

- Safety: These cranes minimize the risk of injury associated with manual lifting and handling, providing a safer working environment for employees.

- Precision: Overhead cranes can position parts with high accuracy, ensuring that components are aligned correctly and reducing errors during assembly.

- Flexibility: They can be adapted to handle various types of loads and tasks, making them versatile tools in automotive production facilities.

Overall, overhead cranes are vital in the automotive industry, helping to optimize production processes, enhance safety, and improve operational efficiency.

Overhead Bridge Cranes in the Automobile Industry

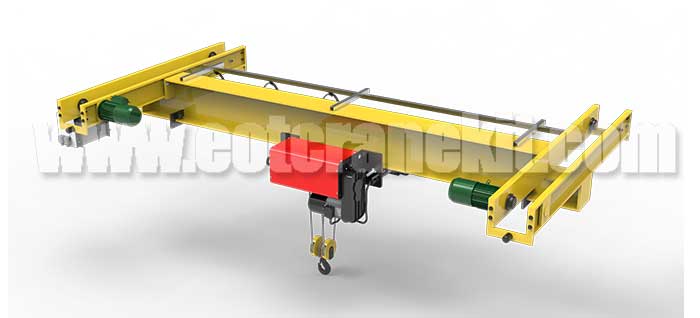

Overhead bridge cranes, also known as bridge cranes, consist of a horizontal bridge that spans the width of a workspace, supported by two end trucks that travel along parallel tracks. These cranes are commonly used for lifting and moving heavy loads across large areas. In the automotive industry, Overhead bridge cranes are essential for handling large components, assemblies, and materials in production, assembly, and maintenance operations.

Applications in the Automobile Industry

Assembly Lines:

- Environment: Utilized in assembly lines where large and heavy components need to be moved efficiently across different stages of production.

- Role of Cranes: Lifts and positions components such as engine blocks, body panels, and chassis frames during the assembly process.

Manufacturing and Fabrication:

- Environment: In manufacturing facilities where heavy and bulky materials need to be handled and processed.

- Role of Cranes: Moves large metal sheets, subassemblies, and fabricated components throughout the manufacturing process.

Maintenance and Repair:

- Environment: In maintenance areas where heavy equipment or automotive parts need to be lifted and repositioned.

- Role of Cranes: Assists in handling and moving engines, transmissions, and other heavy parts during repair or maintenance activities.

Storage and Warehousing:

- Environment: In parts warehouses or storage areas where efficient handling of large quantities of automotive parts is required.

- Role of Cranes: Facilitates the retrieval and storage of large or heavy items, improving organization and access.

Typical Objects Handled

Automotive Components:

- Engine Blocks: Moves engine blocks between different stages of production or assembly.

- Chassis and Frames: Lifts and positions chassis frames and other large structural components.

Assemblies and Subassemblies:

- Body Panels: Handles large body panels during assembly and painting processes.

- Transmission Units: Moves heavy transmission units and other subassemblies within the manufacturing or repair area.

Bulk Materials:

- Metal Sheets and Coils: Transfers large quantities of metal sheets or coils used in production.

- Parts and Tools: Manages the movement of automotive parts and tools within storage or production facilities.

Special Features of Overhead bridge Cranes

Wide Span and High Capacity:

- Design: Features a bridge that spans the width of the workspace, allowing for wide coverage and high lifting capacities.

- Performance: Capable of handling very heavy loads, making them suitable for large components and assemblies.

Adjustable and Flexible Operation:

- Traveling Mechanism: The bridge can travel along the length of the tracks, providing flexibility in moving loads across the entire span of the crane.

- Customizable: Available in various sizes and configurations to meet specific operational requirements.

Precision and Control:

- Advanced Controls: Equipped with sophisticated control systems for precise positioning and movement of loads.

- Load Handling: Includes features for accurate load handling, minimizing the risk of swinging or swaying.

Safety and Reliability:

- Safety Features: Designed with safety features such as limit switches, emergency stops, and load sensors to ensure safe operation.

- Durability: Built for durability and reliability, with robust construction to handle heavy loads and frequent use.

Detailed Breakdown of Features

Wide Span and High Capacity:

- Bridge Design: The horizontal bridge spans the entire width of the workspace, allowing for extensive coverage and handling of large loads.

- High Capacity: Capable of lifting very heavy components, including complete engine assemblies and large structural parts.

Adjustable and Flexible Operation:

- Travel Mechanism: The crane's bridge moves along parallel tracks, providing flexibility in load movement across a large area.

- Customization Options: Available in different sizes and lifting capacities to fit various industrial needs and workspace dimensions.

Precision and Control:

- Control Systems: Features advanced control systems for precise movement and positioning of loads, improving operational efficiency.

- Load Stability: Includes systems to manage load stability, reducing the risk of accidents and improving safety.

Safety and Reliability:

- Integrated Safety Features: Equipped with safety mechanisms such as limit switches and emergency stop functions to ensure safe operation.

- Robust Construction: Built with high-strength materials and components to ensure long-term reliability and performance.

Overhead bridge cranes play a crucial role in the automotive industry by providing wide coverage, high lifting capacities, and flexible operation. They are used in assembly lines, manufacturing and fabrication processes, maintenance and repair activities, and storage and warehousing. With features such as wide spans, high capacities, adjustable operation, precision control, and robust safety measures, Overhead bridge cranes offer effective solutions for handling heavy and large automotive components and materials, contributing to improved efficiency and productivity in the automotive sector.

Under-Hung Overhead Cranes in the Automobile Industry

Under-hung overhead cranes, also known as under-running cranes, are designed with their rails mounted below the crane's bridge. This design is particularly advantageous in environments with limited headroom or where the crane needs to operate in tight spaces. In the automotive industry, these cranes are valued for their ability to provide effective material handling in areas with height constraints.

Applications in the Automobile Industry

Assembly Lines:

- Environment: Used in production lines where space is limited and efficient material handling is required.

- Role of Cranes: Facilitates the movement of components and subassemblies along the assembly line, particularly in areas where traditional overhead cranes might be impractical due to height limitations.

Maintenance and Repair Areas:

- Environment: In service and repair bays where overhead space is used efficiently.

- Role of Cranes: Provides localized lifting capabilities to handle tools, parts, and equipment needed for vehicle maintenance and repair.

Warehouse and Storage Areas:

- Environment: In parts warehouses and storage areas where vertical space is at a premium.

- Role of Cranes: Moves parts and materials efficiently in confined or cramped spaces, optimizing the use of available vertical space.

Typical Objects Handled

Small to Medium-Sized Components:

- Parts Handling: Moves smaller components like engine parts, transmission assemblies, and interior parts.

- Tool and Equipment Handling: Handles tools, equipment, and accessories used in the assembly and maintenance of vehicles.

Workstations:

- Localized Tasks: Provides lifting capabilities for tasks at individual workstations, such as installing or assembling specific components.

Special Features of Under-Hung Overhead Cranes

Space Efficiency:

- Design: Rails are mounted below the bridge, allowing for maximum use of the available headroom and reducing the overall crane height.

- Headroom Utilization: Ideal for environments where vertical space is limited but horizontal space is available.

Flexibility and Maneuverability:

- Operation: Provides flexibility in positioning and maneuvering within tight spaces.

- Adjustability: Can be adjusted to fit various workspace configurations and operational needs.

Reduced Building Load:

- Structural Impact: The under-hung design typically results in reduced load on building structures compared to traditional overhead cranes.

- Installation: Easier to install in facilities with existing structural constraints or where additional support is not feasible.

Detailed Breakdown of Features

Space Efficiency:

- Compact Design: The crane's compact design allows for efficient use of overhead space, making it suitable for low-ceiling environments.

- Headroom Advantage: Enhances accessibility and operational efficiency in environments where maximum headroom is needed for other equipment or processes.

Flexibility and Maneuverability:

- Precision Movement: Offers precise control over crane movement, allowing for accurate placement of components and materials.

- Adaptability: Can be adapted to various types of workstations and production setups, providing versatile handling solutions.

Reduced Building Load:

- Load Distribution: Distributes weight more evenly across the building structure, reducing the need for additional structural reinforcement.

- Installation Benefits: Facilitates installation in existing facilities without significant modifications to the building structure.

Under-hung overhead cranes are particularly beneficial in the automotive industry for their space-efficient design and adaptability. They excel in applications where vertical space is limited, such as assembly lines, maintenance areas, and warehouses. With features like space efficiency, flexibility, and reduced building load, under-hung cranes provide effective and versatile material handling solutions in constrained environments, enhancing operational efficiency and productivity in automotive manufacturing and related sectors.

Single Girder Overhead Cranes in the Automobile Industry

Single girder overhead cranes are a type of bridge crane designed with a single main girder supported by end trucks that run on elevated rails. They are known for their simplicity, cost-effectiveness, and suitability for lighter to medium-duty lifting tasks. In the automotive industry, single girder overhead cranes are widely used for various applications due to their ability to provide efficient lifting solutions in constrained spaces.

Applications in the Automobile Industry

Production Lines:

- Environment: In automotive manufacturing lines where space is limited and precise, frequent lifting is required.

- Role of Cranes: Moves smaller components such as engine parts, body panels, and subassemblies between different stages of production.

Assembly Areas:

- Environment: In assembly areas where handling and positioning of medium-sized components and parts are necessary.

- Role of Cranes: Assists in lifting and positioning parts like chassis frames, transmissions, and other subassemblies during the assembly process.

Maintenance and Repair Facilities:

- Environment: In maintenance and repair facilities where lifting of heavy automotive parts is needed in a confined space.

- Role of Cranes: Provides the capability to lift and maneuver large components such as engines, gearboxes, and axle assemblies during repair or replacement.

Warehousing and Storage:

- Environment: In warehouses where automotive parts and materials are stored and retrieved.

- Role of Cranes: Facilitates the efficient handling of stored items, including large parts and materials, improving inventory management and retrieval.

Typical Objects Handled

Automotive Components:

- Engine Parts: Moves engine blocks and components within the production or repair areas.

- Chassis Frames: Handles and positions chassis frames and structural components during assembly or maintenance.

Subassemblies and Parts:

- Body Panels: Lifts and positions body panels and other subassemblies during the manufacturing or repair processes.

- Transmission Units: Assists in moving and positioning transmission units and other heavy subassemblies.

Raw Materials:

- Metal Sheets and Coils: Transports raw materials such as metal sheets and coils used in the fabrication of automotive parts.

Special Features of Single Girder Overhead Cranes

Simple and Cost-Effective Design:

- Construction: Features a single girder supported by end trucks, offering a more straightforward design compared to double girder cranes.

- Cost: Generally more affordable than double girder cranes, making them suitable for budget-conscious projects.

Compact Footprint:

- Space Efficiency: Requires less vertical clearance and overall space compared to double girder cranes, making them ideal for environments with limited headroom.

- Installation: Easier and quicker to install due to its simpler design and lower weight.

Lightweight and Maneuverable:

- Load Capacity: Typically designed for lighter to medium-duty applications, making them suitable for handling moderate loads efficiently.

- Flexibility: Can be customized with different hoist options and control systems to meet specific operational needs.

Enhanced Visibility and Access:

- Design: Provides unobstructed overhead space, allowing for better visibility and access to the area being worked on.

- Accessibility: Improves operator access to various parts and components, facilitating easier and safer handling.

Single girder overhead cranes are an effective and cost-efficient solution for lifting and moving automotive components and materials in the automobile industry. Their simple design, compact footprint, and versatility make them suitable for a range of applications, including production lines, assembly areas, maintenance facilities, and warehousing. By offering a combination of affordability, space efficiency, and functional capability, single girder overhead cranes enhance material handling processes and contribute to improved operational efficiency in automotive manufacturing and repair environments.

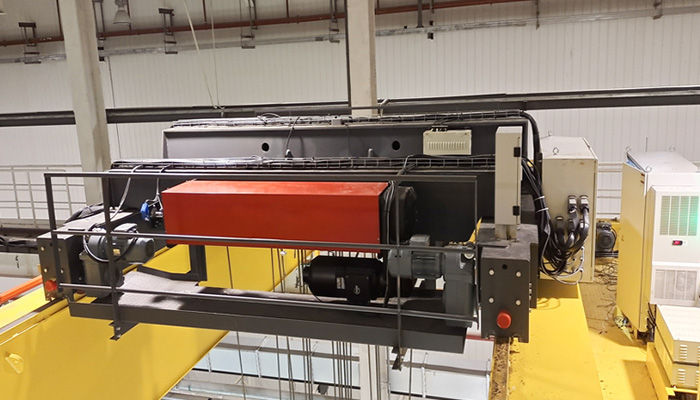

Double-Girder Overhead Cranes in the Automobile Industry

Double-girder overhead cranes feature two parallel girders that support the crane bridge and are designed to handle heavy and bulky loads. They are widely used in the automotive industry for their robustness, high load capacity, and versatility. These cranes are ideal for lifting and moving large components and materials throughout manufacturing and assembly processes.

Applications in the Automobile Industry

Heavy Component Handling:

- Environment: Used in areas where large and heavy automotive components are handled, such as engine assembly and frame manufacturing.

- Role of Cranes: Efficiently lifts and moves large parts like engine blocks, chassis, and transmission assemblies with precision and safety.

Assembly and Production Lines:

- Environment: In production lines where high load capacity and stability are required.

- Role of Cranes: Supports the movement of heavy assemblies along the production line, ensuring smooth and efficient workflow.

Maintenance and Service Areas:

- Environment: In maintenance bays where heavy equipment and parts need to be handled for repairs and servicing.

- Role of Cranes: Provides the necessary lifting power to handle large and heavy vehicle components during maintenance activities.

Storage and Warehousing:

- Environment: In warehouses and storage areas for handling large quantities of automotive parts and materials.

- Role of Cranes: Moves heavy and bulky items, facilitating efficient storage and retrieval processes.

Typical Objects Handled

Heavy Automotive Components:

- Engine Blocks: Lifts and positions large engine blocks during assembly and maintenance.

- Chassis Frames: Handles chassis frames, which are often large and heavy.

Large Assemblies:

- Transmission Systems: Moves transmission systems, which require significant lifting capacity.

- Body Panels: Handles large body panels and other sizeable parts during assembly and manufacturing.

Bulk Materials:

- Metal Sheets and Coils: Manages large metal sheets or coils used in stamping and body fabrication.

- Parts and Accessories: Moves bulk quantities of automotive parts and accessories in storage and production areas.

Special Features of Double-Girder Overhead Cranes

High Load Capacity:

- Design: Equipped with two girders that provide increased strength and support, enabling the crane to handle heavier loads.

- Capacity: Typically used for lifting capacities ranging from 10 tons to over 500 tons, depending on the specific application.

Enhanced Stability and Precision:

- Structural Integrity: The double-girder design offers enhanced stability, reducing load sway and increasing operational precision.

- Precision Controls: Includes advanced control systems for precise movement and positioning of heavy loads.

Wide Span Capabilities:

- Coverage: Can cover large areas with wide spans, making them suitable for extensive production lines and large workspaces.

- Versatility: Provides flexibility in handling large and heavy items across broad production or storage areas.

Customizable Options:

- Design Flexibility: Available in various configurations and sizes to meet specific operational requirements.

- Integration: Can be customized with additional features such as specialized hoists, sensors, and automation systems.

Detailed Breakdown of Features

High Load Capacity:

- Girders and Supports: Dual girders distribute the load evenly and provide the strength necessary for handling very heavy loads.

- Capacity Range: Can accommodate a wide range of capacities, from moderate to very high, depending on the specific needs of the facility.

Enhanced Stability and Precision:

- Load Control: Advanced load control mechanisms ensure that loads are handled with minimal sway and maximum accuracy.

- Operational Safety: Reduces the risk of accidents and improves safety during the handling of heavy and large components.

Wide Span Capabilities:

- Span Length: Capable of covering large distances, making them ideal for large production areas and expansive workspaces.

- Coverage Flexibility: Can be adapted to various facility layouts and requirements, providing effective coverage for different operational needs.

Customizable Options:

- Modular Design: Offers modular and customizable design options to fit specific industrial needs and preferences.

- Integration with Automation: Can be integrated with automated systems for enhanced efficiency and productivity.

Double-girder overhead cranes are essential in the automotive industry for their ability to handle heavy and bulky loads with high precision and stability. They are used in various applications, including heavy component handling, assembly lines, maintenance areas, and storage. With their high load capacity, enhanced stability, wide span capabilities, and customizable options, double-girder cranes provide robust and versatile solutions for efficient material handling and production processes in the automotive sector.

In addition to standard overhead cranes, several specialized types of overhead cranes are used in the automobile industry and related sectors. These cranes are designed to handle specific tasks and environments, offering features tailored to unique needs. Here are some examples of specialized overhead cranes and their characteristics:

Explosion-Proof Overhead Cranes in the Automobile Industry

Explosion-proof overhead cranes are designed to operate safely in environments where there is a risk of explosive gases, vapors, or dust. These specialized cranes are crucial in specific areas of automotive manufacturing where hazardous conditions exist. Here's a detailed look at their applications, the objects they handle, and their special features:

Applications in the Automobile Industry

- Environment: Paint shops involve the use of volatile chemicals and paints that can create explosive atmospheres.

- Role of Cranes: Explosion-proof overhead cranes are used to lift and move vehicle bodies or components through various stages of the painting process, ensuring safety and preventing ignition sources that could lead to accidents.

Battery and Fuel System Assembly:

- Environment: Areas where fuel systems and batteries are assembled are prone to explosive atmospheres due to the presence of flammable materials.

- Role of Cranes: These cranes handle sensitive components such as fuel tanks, batteries, and associated parts. They ensure safe lifting and positioning of these components without risking ignition.

Typical Objects Handled

Components in Hazardous Environments:

- Fuel Systems: Handling fuel tanks and associated components which are highly sensitive to explosions.

- Battery Packs: Moving and positioning large battery packs used in electric vehicles, which contain flammable materials.

Materials in Paint Shops:

- Vehicle Bodies: Handling painted and pre-painted vehicle bodies as they move through different stages of the paint process.

- Paint Components: Moving large containers or equipment used for mixing and applying paint.

Special Features of Explosion-Proof Overhead Cranes

Explosion-Proof Design:

- Construction: The crane is designed to operate safely in environments where explosive conditions are present. This includes using materials and design features that minimize the risk of sparks or heat.

- Compliance: Meets standards and regulations for explosion-proof equipment, such as those outlined by ATEX (European standards) or NEC (National Electrical Code in the U.S.).

Sealed Electrical Components:

- Protection: Electrical components are sealed to prevent any ignition sources from coming into contact with explosive gases or dust.

- Durability: Ensures that the crane's electrical systems remain functional and safe in harsh environments.

Anti-Spark Features:

- Material Selection: Uses materials and coatings that prevent the generation of sparks during operation.

- Design Considerations: Includes features such as spark-resistant motors and components to further reduce the risk of ignition.

Detailed Breakdown of Features

Explosion-Proof Design:

- Safety Enclosures: Components are housed in protective enclosures that prevent the escape of sparks or heat.

- Intrinsic Safety Measures: Implements intrinsic safety principles to ensure that any electrical faults do not lead to explosions.

Sealed Electrical Components:

- Enclosures: Electrical controls and circuits are enclosed in explosion-proof housings that prevent entry of hazardous substances.

- Sealing Techniques: Uses gaskets, seals, and other techniques to ensure no gaps or openings that could allow hazardous substances inside.

Anti-Spark Features:

- Material Selection: Components are made from non-sparking materials such as bronze or aluminum bronze.

- Maintenance Protocols: Regular maintenance is performed to ensure anti-spark features remain effective over time.

Explosion-proof overhead cranes in the automotive industry are essential for safely handling components in hazardous environments. They are specially designed with explosion-proof features to manage the risks associated with volatile chemicals and flammable materials. Their specialized design includes sealed electrical components and anti-spark features to ensure the safety and efficiency of operations in potentially explosive atmospheres, such as paint shops and battery assembly areas.

Magnetic Overhead Cranes in the Automobile Industry

Magnetic overhead cranes are equipped with electromagnets to lift and move ferrous materials. In the automotive industry, they play a crucial role in handling metal components efficiently and effectively. These cranes are particularly valuable in environments where heavy and bulky metal parts need to be managed.

Overhead bridge crane for horizontal steel coils handling

magnetic overhead crane for vertical coil handling

Applications in the Automobile Industry

Metal Processing Areas:

- Environment: In areas where metal parts are processed, such as stamping or cutting stations, magnetic overhead cranes are used to handle large metal sheets and components.

- Role of Cranes: They facilitate the movement of heavy metal parts with minimal physical contact, reducing the risk of damage and improving handling efficiency.

Assembly and Manufacturing:

- Environment: During assembly and manufacturing processes, magnetic cranes are used to lift and position metal components like chassis parts, engine blocks, and structural elements.

- Role of Cranes: They ensure smooth and precise handling of large metal parts, which are essential for vehicle assembly and production.

Typical Objects Handled

Metal Sheets and Panels:

- Handling Large Sheets: Magnetic cranes are used to move large metal sheets that are used in body stamping and fabrication.

- Sheet Metal Handling: Facilitates the transport of sheets between processing stations, such as from the cutting area to the stamping area.

Steel Parts:

- Heavy Steel Components: Used for lifting and moving heavy steel parts like engine blocks, chassis frames, and other structural components.

- Bulk Metal Handling: Efficiently manages large quantities of metal scrap or parts in recycling or storage areas.

Special Features of Magnetic Overhead Cranes

Electromagnetic Lifting Mechanism:

- Lifting Power: Utilizes powerful electromagnets to lift and hold ferrous materials securely.

- Adjustable Magnet Strength: Allows for adjustment of the magnet's strength to handle different sizes and weights of metal objects.

Quick Release Mechanism:

- Efficiency: Provides a quick-release feature that allows for rapid unloading and repositioning of metal parts.

- Automation: Often integrated with automated systems for seamless operation and efficiency.

Precision Control:

- Accuracy: Features precise control systems that ensure accurate positioning and handling of metal parts.

- Ease of Use: Includes user-friendly controls for adjusting magnet strength and crane movement.

Detailed Breakdown of Features

Electromagnetic Lifting Mechanism:

- Magnet Types: Includes electro-permanent magnets and electromagnetic lifts, each suited to different applications and load requirements.

- Safety Features: Equipped with safety features to prevent accidental release of the load, ensuring secure handling.

Quick Release Mechanism:

- Release System: Features an automated or manual system that allows for rapid detachment of the load from the magnet.

- Operational Speed: Enhances operational speed by reducing the time required for loading and unloading metal parts.

Precision Control:

- Control Systems: Advanced control systems allow operators to fine-tune the magnet's strength and crane movements for precise handling.

- Integration with Automation: Can be integrated with automated production lines for synchronized operation with other equipment.

Magnetic overhead cranes in the automotive industry are essential for efficiently handling large and heavy ferrous materials. They are used extensively in metal processing areas and assembly lines to lift and move metal sheets, panels, and parts. Their special features, including electromagnetic lifting mechanisms, quick-release systems, and precision controls, enable efficient, safe, and accurate handling of metal components, contributing to streamlined production and assembly processes

Free-Standing Gantry Cranes

Special Features:

- Self-Supporting Structure: Does not require attachment to existing building structures, providing flexibility in placement.

- Portability: Can be moved within the facility as needed.

Typical Objects Handled:

- Vehicle Assembly and Maintenance: Lifting and positioning vehicles or large components in areas where permanent cranes are not feasible.

- Workshop Equipment: Moving equipment or tools in automotive maintenance and repair workshops.

Clean Room Overhead Cranes

Special Features:

- Clean Room Compatibility: Designed to operate in clean rooms or environments with strict cleanliness standards.

- Special Coatings and Materials: Use materials and coatings that minimize particle generation and are easy to clean.

Typical Objects Handled:

- Sensitive Components: Handling delicate or high-precision parts such as electronic components or sensors.

- Clean Parts: Moving parts that must be kept free of contamination during assembly or testing.

High-Speed Overhead Cranes in the Automobile Industry

High-speed overhead cranes are designed to operate at faster speeds compared to standard cranes, enhancing productivity and efficiency in various industrial settings. These cranes are specifically engineered for applications where quick and precise movement of materials is critical. In the automotive industry, high-speed overhead cranes are utilized to streamline production processes and improve handling efficiency.

Applications in the Automobile Industry

High-Speed Production Lines:

- Environment: Used in fast-paced production environments where rapid movement of components is essential.

- Role of Cranes: Facilitates quick transfer of parts between different stages of the assembly line, minimizing production downtime and improving throughput.

Just-In-Time Manufacturing:

- Environment: In just-in-time (JIT) manufacturing setups where timely delivery of parts and components is crucial.

- Role of Cranes: Ensures fast and reliable movement of parts to meet strict production schedules and reduce inventory holding times.

Automated Assembly Systems:

- Environment: Integrated into automated systems where speed and precision are necessary for efficient operation.

- Role of Cranes: Works alongside automated machinery to quickly move and position components during automated assembly processes.

High-Volume Material Handling:

- Environment: In warehouses or distribution centers where large volumes of automotive parts need to be handled rapidly.

- Role of Cranes: Handles high volumes of parts and materials efficiently, improving overall material flow and warehouse operations.

Typical Objects Handled

Automotive Components:

- Engine Parts: Moves engine components such as cylinder heads, blocks, and crankshafts quickly between assembly stages.

- Chassis and Frames: Transfers chassis frames and other large parts efficiently in production and assembly areas.

Assemblies:

- Subassemblies: Handles subassemblies like transmission units and suspension systems, facilitating rapid assembly and integration.

- Body Panels: Moves large body panels and exterior components through various stages of assembly and finishing.

Bulk Materials:

- Metal Parts: Moves bulk metal parts, such as brackets and fittings, efficiently in manufacturing or storage areas.

- Components and Accessories: Handles large quantities of automotive components and accessories in warehousing and distribution.

Special Features of High-Speed Overhead Cranes

High-Speed Operation:

- Design: Engineered for high-speed lifting and movement to meet the demands of fast-paced production environments.

- Performance: Capable of operating at speeds significantly higher than standard cranes, enhancing productivity.

Precision and Control:

- Advanced Controls: Equipped with advanced control systems for precise movement and positioning of loads at high speeds.

- Load Handling: Includes features to ensure stable and accurate handling of loads during high-speed operation.

Enhanced Safety Features:

- Safety Mechanisms: Includes safety features such as speed limiters, load sensors, and emergency stop functions to prevent accidents during high-speed operation.

- Operator Protection: Designed with safety measures to protect operators and equipment from high-speed impacts.

Robust Construction:

- Structural Integrity: Built with reinforced materials and components to withstand the stresses of high-speed operation.

- Durability: Designed for durability and long-term performance in demanding industrial environments.

Detailed Breakdown of Features

High-Speed Operation:

- Engineering: Utilizes advanced engineering techniques to achieve high-speed operation while maintaining stability and load control.

- Operational Efficiency: Increases efficiency by reducing the time required for material handling and transfer.

Precision and Control:

- Control Systems: Features sophisticated control systems that allow for precise adjustments and movements, ensuring accuracy even at high speeds.

- Load Management: Equipped with systems to manage load stability and prevent swinging or swaying during fast movement.

Enhanced Safety Features:

- Speed Limiters: Includes limiters to control maximum operating speeds and prevent overloading or accidents.

- Emergency Systems: Provides emergency stop functions and safety interlocks to protect operators and equipment during high-speed operations.

Robust Construction:

- Reinforced Design: Constructed with high-strength materials and robust design to handle the demands of high-speed operation without compromising structural integrity.

- Long-Term Durability: Engineered for durability and reliability, ensuring consistent performance in high-speed applications.

High-speed overhead cranes are essential in the automotive industry for their ability to enhance productivity and efficiency in fast-paced environments. They are used in high-speed production lines, just-in-time manufacturing, automated assembly systems, and high-volume material handling. With features such as high-speed operation, precision control, enhanced safety, and robust construction, high-speed overhead cranes provide critical support for rapid and efficient material handling, contributing to improved production processes and overall operational effectiveness in the automotive sector.

Semi-Gantry Cranes in the Automobile Industry

Semi-gantry cranes are a type of gantry crane where only one side of the crane runs on rails or tracks, while the other side is supported by legs or wheels that run on the ground. This design combines features of both overhead and gantry cranes, providing versatility and flexibility in various lifting applications. In the automobile industry, semi-gantry cranes are used for handling and moving heavy components and materials in production, assembly, and maintenance operations.

Single girder semi gantry crane

Double girder semi gantry crane

Applications in the Automobile Industry

Production Lines:

- Environment: In automotive production lines where space constraints or specific configurations make traditional overhead cranes impractical.

- Role of Cranes: Facilitates the movement of heavy components like engine blocks, chassis frames, and body panels between different stages of production.

Maintenance and Repair Facilities:

- Environment: In maintenance areas where large or heavy automotive parts need to be lifted and moved for repair or servicing.

- Role of Cranes: Assists in handling and positioning components such as engines, transmissions, and other major assemblies during maintenance tasks.

Fabrication and Assembly Areas:

- Environment: In fabrication shops and assembly areas where precise and flexible handling of materials is required.

- Role of Cranes: Moves large fabricated parts, subassemblies, and materials used in the manufacturing of automotive components.

Warehousing and Storage:

- Environment: In warehouses where heavy parts and materials need to be stored and retrieved efficiently.

- Role of Cranes: Helps in the storage and retrieval of large items, improving inventory management and access to stored components.

Typical Objects Handled

Automotive Components:

- Engine Assemblies: Lifts and positions engine assemblies during production and maintenance.

- Chassis and Frames: Handles chassis frames and other large structural components during assembly or repair.

Subassemblies and Parts:

- Body Panels: Moves large body panels and subassemblies through various stages of production or repair.

- Transmission Units: Assists in the handling of heavy transmission units and other significant subassemblies.

Fabrication Materials:

- Metal Sheets and Coils: Transfers metal sheets, coils, and other raw materials used in fabrication.

- Fabricated Parts: Handles large fabricated components during the manufacturing process.

Special Features of Semi-Gantry Cranes

Versatile Design:

- Structure: Combines features of overhead and gantry cranes, with one side running on rails and the other side supported by legs or wheels.

- Flexibility: Provides flexibility in design and application, allowing it to fit into various workspace configurations.

Space Efficiency:

- Footprint: Requires less floor space compared to full gantry cranes, making it suitable for areas with space constraints.

- Operation: Offers efficient use of available space by providing lifting capabilities in areas where traditional cranes may not be practical.

Adjustable and Mobile:

- Mobility: The crane can be equipped with wheels or casters on the non-rail side, allowing it to be moved easily within the workspace.

- Adjustability: The height and span of the crane can be adjusted to suit different lifting requirements and operational needs.

Robust Construction:

- Durability: Built with high-strength materials and components to handle heavy loads and frequent use.

- Safety Features: Equipped with safety features such as limit switches, emergency stops, and load sensors to ensure safe operation.

Detailed Breakdown of Features

Versatile Design:

- Combination Structure: Features a combination of rail-mounted and ground-supported elements, providing flexibility for various lifting tasks.

- Adaptability: Can be customized to fit different workspace configurations and operational requirements.

Space Efficiency:

- Compact Footprint: Designed to fit in tighter spaces where full gantry cranes might be too large or impractical.

- Efficient Use of Space: Provides effective lifting capabilities while minimizing the impact on available floor space.

Adjustable and Mobile:

- Mobility Options: Can be equipped with wheels or casters on the ground-supported side, allowing for easy movement within the workspace.

- Height and Span Adjustments: Features adjustable height and span to accommodate different lifting needs and operational requirements.

Robust Construction:

- High-Strength Materials: Constructed from durable materials to handle heavy loads and withstand the stresses of frequent use.

- Safety Mechanisms: Includes safety features such as limit switches, load sensors, and emergency stop functions to ensure safe operation.

Semi-gantry cranes are valuable in the automotive industry for their versatility, space efficiency, and flexibility. They are used in production lines, maintenance facilities, fabrication and assembly areas, and warehousing. With features such as a versatile design, space efficiency, adjustable and mobile operation, and robust construction, semi-gantry cranes provide effective solutions for handling large and heavy automotive components and materials, contributing to improved efficiency and productivity in various automotive operations.

Rail-Mounted and Rubber-Tyred Gantry Cranes in the Automobile Industry

Rail-mounted and rubber-tyred gantry cranes are two distinct types of gantry cranes used for lifting and transporting heavy loads across different industrial applications. In the automotive industry, these cranes are utilized for handling large and heavy components in manufacturing, assembly, maintenance, and warehousing operations. Each type of crane has unique features and benefits suited to specific operational needs and environments.

Rail-Mounted Gantry Cranes (RMG)

Rail-mounted gantry cranes (RMG) operate on fixed tracks or rails, providing stable and precise lifting capabilities for heavy loads. They are commonly used in environments where high load capacities and precise positioning are required.

RMG Container Cranes for your reference, Custom designed are available.

Applications in the Automobile Industry

Production Lines:

- Environment: In automotive production lines where precise and stable handling of large components is needed.

- Role of Cranes: Moves large engine blocks, chassis frames, and body panels between different production stages.

Assembly Areas:

- Environment: In assembly areas where large and heavy automotive parts need to be lifted and positioned accurately.

- Role of Cranes: Handles and positions assembled components and subassemblies during the assembly process.

Warehousing and Storage:

- Environment: In parts warehouses where large and heavy items are stored and retrieved.

- Role of Cranes: Facilitates the efficient handling of stored automotive parts and materials.

Typical Objects Handled

Automotive Components:

- Engine Assemblies: Moves complete engine assemblies within the production or maintenance area.

- Chassis and Frames: Handles large chassis and frame components during production or repair.

Subassemblies and Parts:

- Body Panels: Lifts and positions large body panels during manufacturing or painting.

- Transmission Units: Assists in moving heavy transmission units and other significant subassemblies.

Fabrication Materials:

- Metal Sheets and Coils: Transfers raw materials such as metal sheets and coils used in fabrication processes.

Special Features of Rail-Mounted Gantry Cranes

Precision and Stability:

- Track System: Operates on fixed rails, providing precise and stable movement of heavy loads.

- Accuracy: Offers high accuracy in load positioning and handling.

High Load Capacity:

- Design: Capable of handling very heavy loads, making it suitable for large automotive components.

- Strength: Built with robust materials to support high load capacities.

Fixed Positioning:

- Operational Area: Limited to the tracks on which they run, providing stable but less flexible operation compared to mobile cranes.

Rubber-Tyred Gantry Cranes (RTG)

Rubber-tyred gantry cranes (RTG) are equipped with rubber tires instead of running on fixed rails. This mobility allows them to be used in environments where flexibility and maneuverability are required.

Applications in the Automobile Industry

Production Facilities:

- Environment: In production facilities where flexibility and the ability to move between different areas are needed.

- Role of Cranes: Handles and moves heavy automotive components, such as engines and body panels, throughout the production process.

Assembly and Maintenance:

- Environment: In assembly and maintenance areas where maneuverability is crucial for accessing various parts and components.

- Role of Cranes: Assists in lifting and positioning large parts and subassemblies during assembly or repair.

Warehousing and Logistics:

- Environment: In warehouses and logistics centers where flexibility in moving and handling large items is required.

- Role of Cranes: Facilitates the storage and retrieval of automotive parts and materials, providing efficient inventory management.

Typical Objects Handled

Automotive Components:

- Engine Blocks: Moves engine blocks to different locations within the production or maintenance area.

- Chassis and Frames: Handles large chassis frames and other structural components.

Subassemblies and Parts:

- Body Panels: Lifts and transports body panels during manufacturing or assembly.

- Transmission Units: Moves transmission units and other significant subassemblies.

Fabrication Materials:

- Raw Materials: Transfers raw materials such as metal sheets and coils used in the fabrication process.

Special Features of Rubber-Tyred Gantry Cranes

Mobility and Flexibility:

- Tire System: Equipped with rubber tires, allowing for movement across various surfaces and greater flexibility in operation.

- Versatility: Can navigate different areas and adjust positioning as needed.

Adaptability:

- Operational Area: Capable of operating in various environments, including uneven or non-structured surfaces.

- Customizable: Available in different sizes and configurations to meet specific operational needs.

High Efficiency:

- Handling: Efficient in moving and handling heavy loads with ease.

- Operational Speed: Provides fast and effective handling of materials and components.

Rail-mounted and rubber-tyred gantry cranes each play a crucial role in the automotive industry, offering distinct advantages based on their design and operational characteristics. Rail-mounted gantry cranes (RMG) provide stability, precision, and high load capacities, making them suitable for production lines, assembly areas, and warehousing where precise handling is required. Rubber-tyred gantry cranes (RTG) offer mobility and flexibility, allowing them to navigate various environments and handle heavy loads in production, assembly, and logistics settings. Both types of cranes contribute to improved efficiency and productivity in the automotive sector by facilitating the effective handling of large and heavy components and materials.

Jib Cranes in the Automobile Industry

Jib cranes are versatile lifting devices with a horizontal arm (or jib) that extends from a vertical column. They are designed for localized lifting and maneuvering of materials, offering flexibility in handling tasks in confined or specific areas. In the automotive industry, jib cranes are valued for their ability to provide precise, localized lifting capabilities where larger overhead cranes may not be practical.

Applications in the Automobile Industry

Assembly Stations:

- Environment: Used in assembly stations where components need to be positioned accurately and efficiently.

- Role of Cranes: Provides localized lifting for placing and adjusting parts like engine components, body panels, and small assemblies during the assembly process.

Maintenance and Repair:

- Environment: In maintenance areas where heavy or awkward components need to be lifted and repositioned.

- Role of Cranes: Assists with lifting and moving components such as engines, transmissions, and other parts during maintenance or repair tasks.

Storage and Retrieval:

- Environment: In parts storage areas where components need to be picked and placed from shelves or racks.

- Role of Cranes: Facilitates the retrieval and storage of automotive parts, improving efficiency in inventory management.

Fabrication and Manufacturing:

- Environment: In manufacturing areas where precise placement of parts and materials is required.

- Role of Cranes: Aids in the handling of metal sheets, brackets, and other fabrication materials during the production process.

Typical Objects Handled

Automotive Components:

- Engine Parts: Lifts and positions engine blocks, cylinder heads, and other engine components.

- Transmission Units: Handles heavy transmission systems and subassemblies.

Large Assemblies:

- Body Panels: Moves and positions large body panels during assembly or repair.

- Chassis Frames: Assists in handling and positioning chassis frames and other structural components.

Tools and Equipment:

- Work Tools: Lifts and places tools and equipment used in maintenance or assembly tasks.

- Accessories: Moves automotive accessories and components in storage or production areas.

Special Features of Jib Cranes

Flexible Reach:

- Design: Features a horizontal arm (jib) that can extend and retract to provide adjustable reach and flexibility.

- Operation: Allows for precise and controlled lifting and placement of materials in specific locations.

Space Efficiency:

- Compact Design: Designed for use in confined spaces where larger cranes might be impractical.

- Footprint: Occupies a smaller footprint compared to overhead cranes, making it suitable for tight or congested areas.

Versatility:

- Applications: Can be used for a wide range of tasks, from assembly and maintenance to storage and fabrication.

- Customization: Available in various configurations, including wall-mounted, floor-mounted, and mobile designs, to suit different operational needs.

Ease of Operation:

- User-Friendly Controls: Equipped with simple controls for easy operation and precise handling of loads.

- Manual and Powered Options: Available in manual, electric, or pneumatic versions to match different lifting requirements.

Detailed Breakdown of Features

Flexible Reach:

- Adjustable Arm: The jib arm can be adjusted to different lengths and angles, providing flexibility for handling materials in various positions.

- Pivoting Capability: The arm typically rotates around the column, allowing for a wide range of motion and access to different areas.

Space Efficiency:

- Compact Footprint: The vertical column and horizontal arm design minimizes space requirements, making it ideal for use in areas with limited space.

- Space Optimization: Maximizes the use of available floor space by providing effective lifting capabilities in tight or crowded environments.

Versatility:

- Adaptable Configurations: Can be configured to fit different types of workspaces, including wall-mounted, floor-mounted, or mobile setups.

- Various Lifting Capacities: Available in different sizes and lifting capacities to handle a range of materials and components.

Ease of Operation:

- Simple Controls: Features intuitive controls for smooth and accurate operation, reducing operator fatigue and increasing productivity.

- Manual and Powered Options: Offers flexibility in operation with manual or powered options, depending on the lifting requirements and preferences.

Jib cranes are essential in the automotive industry for their localized lifting capabilities, flexibility, and space efficiency. They are used in various applications, including assembly stations, maintenance and repair areas, storage and retrieval, and fabrication. With features such as flexible reach, space efficiency, versatility, and ease of operation, jib cranes provide valuable support for handling automotive components and materials in specific and confined spaces, contributing to improved efficiency and productivity in the automotive sector.

Freestanding Jib Cranes and Wall-Mounted Jib Cranes in the Automobile Industry

Jib cranes are versatile lifting solutions used for localized material handling in various industrial settings. They are designed to provide precise, flexible lifting capabilities within a specific area. There are two primary types of jib cranes: freestanding and wall-mounted. Each type has unique features and applications suited to different operational needs in the automobile industry.

Freestanding Jib Cranes

Freestanding jib cranes are mounted on a column that is anchored to the floor, allowing the crane to operate independently of any supporting structure. They are highly flexible and can be placed anywhere in the workspace, providing a dedicated lifting point for various tasks.

Applications in the Automobile Industry

Production Lines:

- Environment: In automotive production lines where localized, flexible lifting is required.

- Role of Cranes: Handles components such as engine blocks, body panels, and smaller parts during assembly and production tasks.

Assembly and Maintenance Areas:

- Environment: In assembly areas where heavy or bulky components need to be lifted and positioned.

- Role of Cranes: Facilitates the lifting and maneuvering of components like transmissions, chassis parts, and assemblies during maintenance or repair.

Workshop and Repair Facilities:

- Environment: In workshops and repair facilities where frequent and precise lifting of automotive parts is needed.

- Role of Cranes: Provides localized lifting for tasks such as removing or installing engines, moving large parts, or repositioning subassemblies.

Typical Objects Handled

Automotive Components:

- Engine Assemblies: Moves engine assemblies into place for assembly or repair.

- Chassis Frames: Handles large chassis frames and structural components during production or maintenance.

Subassemblies and Parts:

- Body Panels: Lifts and positions body panels and subassemblies during manufacturing.

- Transmission Units: Assists in moving and positioning heavy transmission units.

Tools and Equipment:

- Workshop Tools: Lifts and maneuvers heavy tools or equipment within the workshop.

Special Features of Freestanding Jib Cranes

Flexibility and Mobility:

- Rotation Range: Typically allows 360-degree rotation, providing extensive coverage within the operational area.

- Adjustable Reach: Can be customized with various reach and height options to suit different tasks.

Versatility:

- Standalone Design: Does not require support from existing structures, allowing for placement in various locations.

- Adaptability: Suitable for a wide range of applications in production, maintenance, and repair.

Load Capacity:

- Strength: Capable of handling a range of load capacities depending on the design and configuration.

- Customization: Available in different sizes and capacities to meet specific needs.

Wall-Mounted Jib Cranes

Wall-mounted jib cranes are attached to a wall or structural column, using it as the support for the crane's arm. This design is ideal for areas with limited floor space or where the crane needs to be integrated into existing structures.

Applications in the Automobile Industry

Production and Assembly Areas:

- Environment: In production and assembly areas where space is limited, and precise lifting is needed.

- Role of Cranes: Handles components and subassemblies in tight spaces or areas adjacent to walls or columns.

Maintenance and Repair:

- Environment: In maintenance and repair facilities where wall space is available for crane installation.

- Role of Cranes: Facilitates localized lifting of heavy or awkward components during maintenance tasks.

Storage and Warehousing:

- Environment: In storage areas where efficient use of floor space is crucial.

- Role of Cranes: Assists in retrieving and repositioning parts or materials stored against walls.

Typical Objects Handled

Automotive Components:

- Engine Parts: Moves engine parts and assemblies for assembly or maintenance.

- Body Panels: Handles body panels and other large components during production or storage.

Subassemblies and Parts:

- Chassis Components: Assists in positioning chassis and frame components.

- Transmission Parts: Lifts and maneuvers transmission parts and other subassemblies.

Workshop Tools:

- Heavy Equipment: Moves heavy tools or equipment within a confined space.

Special Features of Wall-Mounted Jib Cranes

Space Efficiency:

- Compact Design: Mounted on walls, freeing up floor space for other uses.

- Optimal Use of Vertical Space: Provides lifting capabilities without occupying valuable floor area.

Fixed Position:

- Stability: Provides stable and fixed lifting points based on wall or column support.

- Limited Reach: Typically has a fixed reach and height depending on wall installation.

Cost-Effective:

- Installation: Often less expensive to install compared to freestanding cranes, especially if wall structures are already available.

- Maintenance: Lower maintenance costs due to simpler design and integration.

Freestanding and wall-mounted jib cranes each offer distinct advantages in the automotive industry. Freestanding jib cranes provide flexibility, mobility, and versatility, making them suitable for various production, maintenance, and workshop applications. Wall-mounted jib cranes offer space efficiency, fixed positioning, and cost-effectiveness, ideal for environments with limited floor space or where integration with existing structures is needed. Both types of jib cranes enhance material handling capabilities, contributing to improved efficiency and productivity in automotive manufacturing, assembly, and repair operations.

Uses of Overhead Cranes in the Automotive Industry

Assembly Line Support

Handling and Positioning Components

In automotive manufacturing, overhead cranes are crucial for handling and positioning heavy and intricate components along the assembly line. These cranes enable workers to lift and place parts like engines, transmission systems, and body panels with precision. By moving components directly to the assembly stations, overhead cranes streamline the process of integrating various parts into the vehicle. This capability is particularly important for large or awkwardly shaped items that would be difficult or unsafe to handle manually.

Enhancing Assembly Efficiency

The use of overhead cranes significantly enhances assembly line efficiency in several ways:

- Reduced Downtime: By quickly and efficiently moving parts between different workstations, overhead cranes minimize idle time and keep the production line running smoothly.

- Increased Throughput: The ability to handle multiple components simultaneously allows for a faster assembly process, increasing the overall output of the manufacturing facility.

- Optimized Workflow: Overhead cranes can be integrated with automated systems and conveyors to create a seamless workflow. This integration helps maintain a steady pace and reduces the likelihood of production delays caused by manual handling.

Overall, overhead cranes contribute to a more organized and efficient assembly line, supporting the smooth operation of automotive manufacturing processes and helping to meet production targets effectively.

Material Handling

Moving Large Automotive Parts (e.g., Engines, Chassis)

Overhead cranes are essential for moving large and heavy automotive parts, such as engines and chassis, throughout the manufacturing plant. These components are typically too bulky and heavy for manual handling or smaller lifting equipment. Overhead cranes can lift and transport these parts with ease, positioning them accurately where they are needed on the production line. This capability not only speeds up the assembly process but also ensures that parts are moved safely and efficiently, reducing the risk of damage or injury.

Handling Raw Materials and Subassemblies

In addition to moving finished automotive parts, overhead cranes are also used to handle raw materials and subassemblies within the plant. Raw materials like metal sheets, engine blocks, and other heavy materials are often delivered in bulk and need to be moved to various storage areas or directly to the production line. Overhead cranes can handle these materials efficiently, streamlining the supply chain and ensuring that materials are readily available for production.

For subassemblies—pre-assembled components that are integrated into the final product—overhead cranes provide a convenient way to transport them to different parts of the assembly line. This includes moving subassemblies between various workstations, or from storage areas to assembly points. By facilitating the efficient movement of these elements, overhead cranes help maintain the flow of the manufacturing process and support the overall productivity of the facility.

Maintenance and Repair

Supporting Heavy Maintenance Tasks

Overhead cranes play a vital role in supporting heavy maintenance tasks within automotive manufacturing facilities. Large and complex machinery, such as engine assembly lines or heavy production equipment, often requires regular maintenance and repair to ensure optimal performance. Overhead cranes assist in these tasks by lifting and positioning heavy components, such as motors, pumps, or large mechanical assemblies, so that technicians can access and service them effectively. This ability to handle substantial weights safely reduces manual labor and enhances the efficiency of maintenance operations.

Role in Equipment Servicing

In addition to supporting routine maintenance, overhead cranes are also crucial for servicing large equipment. For instance, when major repairs or replacements are needed, such as changing out heavy parts or replacing damaged components, overhead cranes facilitate the removal and installation of these elements. They provide the necessary reach and lifting power to maneuver equipment into and out of service areas, ensuring that repairs are performed quickly and with minimal disruption to the production process.

By assisting with both regular maintenance and major repairs, overhead cranes help maintain the reliability and longevity of automotive manufacturing equipment. This, in turn, helps prevent unexpected breakdowns, reduces downtime, and keeps production running smoothly.

Storage and Inventory Management

Managing and Accessing Parts Storage

Overhead cranes are instrumental in managing and accessing parts storage within automotive manufacturing and warehouse facilities. These cranes facilitate the handling of heavy automotive parts and components that are stored in high shelves or bulky stacks. By using overhead cranes to move these parts to and from storage areas, facilities can efficiently organize inventory and ensure that components are readily accessible when needed.

For instance, overhead cranes can retrieve large parts from high racks or deep storage areas, placing them onto pallets or directly onto assembly lines. This capability allows for better organization of parts, reducing the time spent searching for items and minimizing the risk of inventory being misplaced or damaged.

Optimizing Warehouse Operations

Overhead cranes also play a crucial role in optimizing warehouse operations. They streamline the process of receiving, sorting, and dispatching automotive parts and materials, helping to maintain a smooth flow of goods throughout the warehouse. By automating the movement of large and heavy items, overhead cranes reduce the need for manual handling and improve overall warehouse efficiency.

Furthermore, the use of overhead cranes in warehousing enables better space utilization. Cranes can efficiently handle high-density storage systems, allowing for the vertical stacking of inventory and freeing up valuable floor space. This optimization helps in maximizing storage capacity and improving the overall layout of the warehouse, contributing to more effective inventory management and faster order fulfillment.

Selection Criteria for Overhead Cranes in Automotive Applications

Load Capacity

Determining Required Capacity Based on Automotive Components

When selecting an overhead crane for automotive applications, determining the appropriate load capacity is crucial. The crane must be capable of handling the heaviest components encountered in the manufacturing process. Key factors to consider include:

- Weight of Automotive Parts: Identify the maximum weight of the heaviest components, such as engines, chassis, and large subassemblies. This ensures that the crane can safely lift and move these parts without risk of overloading or equipment failure.

- Load Distribution: Consider how loads are distributed across the crane. For instance, if the crane will handle parts of varying weights, it must be capable of adjusting its capacity or handling the heaviest loads efficiently. This includes evaluating the crane's lifting mechanism and load-sharing capabilities.

- Dynamic Loads: Assess any dynamic loads that might occur, such as moving parts or sudden shifts in weight. The crane should be designed to manage these dynamic forces without compromising stability or safety.

Considerations for Future Scalability

Future scalability is an important aspect of crane selection to ensure that the equipment can adapt to changing needs and growth in production. Factors to consider include:

- Potential for Increased Load Requirements: Evaluate whether there might be future changes in the types or sizes of components handled. Selecting a crane with a slightly higher capacity than currently required can accommodate future expansions and prevent the need for costly upgrades.

- Modular and Upgradeable Options: Look for cranes that offer modular components or upgrade options. This allows for adjustments to load capacity or functionality without needing to replace the entire system.

- Adaptability to New Technologies:Consider how well the crane can integrate with new technologies or production techniques that might be introduced in the future. A crane with advanced features or the ability to be retrofitted with new technology can provide long-term value.

- Facility Expansion: If there are plans for facility expansion or changes in layout, ensure that the crane's load capacity aligns with future requirements. This may involve assessing the crane's ability to handle larger or more diverse loads as the production facility evolves.

By thoroughly assessing these factors, you can select an overhead crane that not only meets current operational needs but also supports future growth and changes in automotive manufacturing processes.

Span and Lift Height

Matching Crane Specifications with Facility Dimensions

When selecting an overhead crane for an automotive manufacturing facility, aligning its span and lift height with the facility's dimensions is critical for effective operation. Here's what to consider:

- Assembly Line Layout: Measure the width and length of the automotive assembly lines to determine the appropriate span. The crane's span should be sufficient to cover the entire length of the assembly line where automotive parts are handled. This ensures that components can be moved efficiently along the line without interruption.

- Facility Structure: Assess the facility's structural constraints, including support columns, ceiling height, and any other overhead installations such as lighting or ductwork. The crane's span needs to fit within these structural elements while providing optimal coverage for all areas where automotive parts are assembled or moved.

- Production Zones: Identify key production zones within the facility, such as engine assembly stations, body panel installation areas, or parts storage. Ensure that the crane's span can reach these zones effectively, allowing for smooth and efficient movement of automotive parts between different stages of production.

Ensuring Adequate Reach and Clearance

To ensure the crane operates effectively within an automotive facility, adequate reach and clearance must be considered:

- Lift Height Requirements: Determine the height of the tallest automotive components and equipment that the crane needs to handle, such as engines or chassis. The crane's lift height must be sufficient to accommodate these parts without obstruction. Additionally, account for potential future changes in equipment or production processes that might require adjustments in lift height.

- Headroom: Ensure there is sufficient headroom between the crane and the facility's ceiling to allow for smooth operation. This includes accounting for any overhead installations such as conveyors, ventilation systems, or lighting that could affect crane movement.

- Clearance for Load Movement: Verify that the crane's reach allows for safe and efficient movement of automotive parts through various sections of the facility. This includes ensuring the crane can maneuver loads into and out of assembly stations, storage areas, and maintenance zones without interference from other structures or equipment.

- Safety Considerations: Ensure that the crane's design provides adequate clearance to prevent safety hazards. This involves maintaining safe distances from walls, machinery, and other obstacles to avoid collisions and ensure a safe working environment.

By carefully considering the span and lift height requirements in relation to the specific needs of the automotive manufacturing environment, you can select an overhead crane that maximizes efficiency, safety, and productivity within the facility.

Speed and Precision

Requirements for Fast and Precise Operations

In the automotive industry, overhead cranes must be designed for both speed and precision to meet the demands of high-volume production and complex assembly processes. Key considerations include:

- Lifting and Travel Speed: The crane's lifting and travel speeds should be tailored to the needs of automotive manufacturing. Fast lifting speeds are essential for quickly moving heavy components, such as engines or chassis, between different stages of production. Similarly, rapid travel speeds across the facility help maintain a steady flow of materials, minimizing delays and optimizing throughput.

- Control Precision: Precise control of the crane's movements is crucial for accurate placement of automotive parts. Features such as fine-tuned control systems and advanced positioning technology enable operators to position components exactly where needed without overshooting or misalignment. This precision is particularly important when handling delicate or complex parts that require careful placement.

- Automation and Integration: Integrating automation systems can enhance the crane's speed and precision. Automated controls and programmable settings allow the crane to perform repetitive tasks with consistent accuracy, reducing the potential for human error and speeding up production cycles.

Impact on Production Efficiency

The speed and precision of overhead cranes directly influence production efficiency in automotive manufacturing:

- Increased Throughput: Faster crane speeds lead to shorter cycle times, allowing more components to be processed within a given timeframe. This increased throughput helps meet production targets and reduces lead times for manufacturing and assembly.

- Minimized Downtime: High precision and fast operation reduce the likelihood of errors and delays. By ensuring that parts are handled and positioned correctly on the first attempt, cranes minimize downtime associated with repositioning or correcting mistakes.

- Optimized Workflow: Efficient crane operation supports a smooth workflow by keeping materials and components moving seamlessly through the production process. This integration helps maintain a steady pace, avoids bottlenecks, and ensures that production lines run without interruptions.

- Enhanced Quality Control: Precise handling and placement of automotive parts contribute to higher quality control standards. Accurate positioning of components reduces the risk of defects and ensures that parts fit correctly during assembly, leading to better overall product quality.

By focusing on speed and precision in the selection and operation of overhead cranes, automotive manufacturers can significantly enhance production efficiency, improve quality, and achieve more streamlined manufacturing processes.

Environment and Safety

Addressing Environmental Factors (e.g., Temperature, Dust)

In automotive manufacturing environments, overhead cranes must be designed to operate effectively under specific environmental conditions:

- Temperature Variations: Automotive facilities may experience a range of temperatures, from high heat in areas with intensive equipment use to lower temperatures in climate-controlled zones. The crane's components, including its hoist, motors, and control systems, should be rated for the temperature extremes expected in the facility. This ensures reliable operation and prevents performance issues caused by thermal stress.

- Dust and Debris: Automotive manufacturing processes can generate significant amounts of dust and debris, which can affect the crane's performance and longevity. Overhead cranes should be equipped with dust-resistant seals and enclosures to protect critical components from contamination. Regular maintenance and cleaning protocols should also be implemented to ensure the crane remains in good working condition despite the challenging environment.

- Corrosive Environments: In some cases, automotive facilities might involve exposure to chemicals or corrosive substances. The crane's materials and coatings should be chosen to resist corrosion and chemical damage, extending the crane's lifespan and maintaining its performance.

Compliance with Safety Standards and Regulations

Ensuring compliance with safety standards and regulations is essential for protecting personnel and maintaining a safe working environment:

- Regulatory Standards: Overhead cranes must comply with relevant local and international safety regulations, such as those set by the Occupational Safety and Health Administration (OSHA) in the U.S., or similar organizations in other countries. These regulations cover aspects like load limits, operational procedures, and maintenance requirements to ensure safe crane operation.

- Safety Features: Incorporate essential safety features such as overload protection, emergency stop functions, and safety interlocks. These features help prevent accidents and ensure that the crane operates within safe limits. Additionally, training programs for operators should include safety protocols and emergency procedures to minimize risks.

- Regular Inspections and Maintenance: Implement a routine inspection and maintenance schedule to ensure that the crane remains in compliance with safety standards. Regular checks help identify and address potential issues before they lead to failures or safety hazards.

- Environmental Safety Measures: Address potential environmental hazards related to the crane's operation. For example, ensure that the crane's design and placement do not obstruct emergency exits or create safety hazards in the facility.

By addressing these environmental factors and ensuring compliance with safety standards, automotive manufacturers can ensure that their overhead cranes operate reliably and safely, contributing to a secure and efficient production environment.

Customization and Features

Custom Options for Specific Automotive Tasks

Overhead cranes can be tailored to meet the unique demands of automotive manufacturing through various customization options:

- Specialized Hoists and Attachments: Custom hoists and attachments can be designed to handle specific automotive components, such as specialized grippers for engines or chassis fixtures. These custom tools ensure that parts are lifted and positioned accurately without damage.