Crane C Hook, Coil hook & Paper Roll Hooks & Lifters

Overhead cranes with types of C-hooks- Coil Hooks, Paper roll C Hook , Close stacking C-Hook, Pivoting coil C-Hook, Narrow &slit coil C hooks -for light & heavy lifting.

Category: Below Hook Devices

Your Trusted Overhead Crane Kit Manufacturer & Supplier

Crane C Hook, Coil hook & Paper Roll Hooks & Lifters

Overhead travelling cranes with types of C-hooks including Coil Hooks, Paper roll C Hook , Close stacking C-Hook, Pivoting coil C-Hook, Narrow & slit coil C hooks and adjustable C hooks for light duty & heavy duty steel coil rolls & paper rolls in steel coil mills and paper processing plants, and other applications, etc. Customized overhead C hooks & roll lifters are available for your specific applications.

C-hooks Overhead Travelling Cranes, Your Efficient and Safe Roll Lifting Solution

For c hook roll lifter is for efficient material handling and at same time keep your coil roll and paper rolls from damaging.

Crane c hook is a type of overhead crane below-the-hook devices or crane spreader, named as C hook because of the resemblance of literal C. The C hook crane spreader are mainly used for the horizontal coil rolls handling in hot & cold strip steel mills, also for the lifting of paper rolls in paper making plants, and for many other types of rolls lifting & transportation at working stations, freight yards, and terminal and at larger users or consumer workshops and plants. The C hook material handling cranes are featured as high flexibility, convenient operation, high safety and reliability.

Overhead crane & Gantry Crane C hook

C hook design drawing

The Main Structure of Overhead C-Hook

The lifting C-hook or coil hook is mainly consisted of the spreaders, counterweight iron, and other parts, such as, nylon plate attached to leg to prevent the coil roll or paper roll and at same time to extend the working life of the roll lifer..

- Hanging specific: The main body of the coil C-hook is made of steel plate, made of high-quality low-alloy steel and steel pipe. The cross-section of coil roll hook is a box-shape steel structure, with the features of light weight, good resistance to bending and torsion and long service life.

- Counterweight iron: it is designed to balance of the spreader by adjusting the center of gravity of the spreader and the loads lifted in one line.

- Optional parts of the roll lifter: All of the C-hook is made on customized requirements based on the load weight , configuration, headroom, and lifting area, etc. Usually, the options available are including, normal or high temperature, motorized rotation, digital weighing system, protective pads and pins, remote controls, general storage use C-hook and steel mill use coil hook, etc.

Types of Crane C Hook offering

To meet the various lifting requirements of different applications, there are different types of C-hooks available, used on industrial overhead cranes for horizontal coil rolls, paper rolls and other types of loads handling with high safety, which is always our top concern. All of our crane C hooks and overhead travelling cranes are manufactured based on customer requirements with high quality which may go and excel the national standards and the CE certificates are provided if required. Quality and safety can be fully guaranteed.

Counter Balanced C-hooks

Motorized Rotating C Hook

Adjustable C hooks for wide applications

Close Stacking C-hook for Narrow Aisles

Paper Roll C hook

C-hooks for Narrow Coil rolls

- Counter Balanced C-hooks -Counter balanced C-hook has a "L" shape dimension with the length of the low part equals the maximum width of the coil roll, offering full support to contacting area of the coil rolls, minimizing the possibility of damaging the inner wraps of coil rolls, etc.

- Motorized Rotating C Hook - Motorized rotating C-hook is a type of steel mill duty coil hooks, usually equipped on heavy duty steel mill cranes, for continuous & severe steel mill application. With larger sections and corner radii , the the steel coil hooks can keep stresses to a minimum and provide maximum lifting life. With an electric motor, the motorized rotation C hook can carry the steel coil rolls with the rotations of 360 degrees. The rotating coil hook provides additional safe and capability of high precision positioning of steel coils.

- Adjustable C hook- The specialized C hook are flexible & adjustable with wide application to handle rolls of different sizes.

- Close Stacking C-hook for Narrow Aisles -The C-hook is designed with shorter lifting arm, widely used for close stacking, which enables the lifting arm of C hook without extending beyond the outer edge of the coils within range during operating. The overall width of the C hook lifter is reduced, decreasing its requirements for aisle space, increasing the capacity of storage.

- Paper Roll C hook -The paper roll C-hook lifts the paper roll by inserting the lower hook arm through the roll core.

Hook Applications

C hook is a type of widely used overhead travelling crane under-the-hook devices for handling steel coil rolls in steel plant through the procedures of coil rolling, storage, and delivery, and also adopted in other applications where horizontal steel coil handling are necessary. Besides, the C-hook roll lifters are also adopted for handling paper rolls, aluminum coils, copper coils, wires and other coils, etc.

- Heavy Duty Material Handling

- Paper Roll Handling

- Slit Coil Handling

- Close stacking C-Hook

- Pivoting coil C-Hook

Hot Sale Crane C-Hooks

Crane C-Hooks are specialized lifting tools designed to handle various types of coils and rolls efficiently. They feature a distinctive C-shaped design that allows them to securely grip and lift cylindrical or circular objects. Made from high-strength alloy steel, these hooks are built to endure heavy loads while remaining lightweight and durable. Typically attached to an overhead crane or hoisting device, C-Hooks enhance the versatility and safety of material handling operations.

In industrial settings, Crane C-Hooks play a crucial role in streamlining the handling and transportation of heavy, cylindrical materials. Their primary applications include lifting steel coils, aluminum coils, copper coils, and paper rolls. They are also vital in loading and unloading steel pipes, tubes, and slabs into containers.

The use of C-Hooks improves operational efficiency by reducing manual handling, minimizing product damage, and increasing safety. Their design ensures a secure grip and stable lifting, which is essential for handling heavy and often unwieldy materials. By integrating C-Hooks into their operations, industries can achieve smoother workflows, faster loading and unloading processes, and enhanced overall productivity.

Heavy Duty C-Hooks (Box Beam)

Heavy Duty C-Hooks, often referred to as box beam C-Hooks, are designed with a sturdy box-type cross-section that provides enhanced structural integrity. This robust design includes several key features:

- Box-Type Cross-Section: The hook's cross-section is reinforced to handle substantial loads, making it ideal for heavy-duty lifting tasks.

- Spreader and Counterweight Iron: These components help to evenly distribute the load and maintain alignment between the hook and the lifted object, reducing the risk of slippage and ensuring stable lifting.

- Guide Handle: Equipped with a guide handle, these hooks offer improved maneuverability, allowing operators to position the hook accurately and efficiently.

- Tapered Lower Load Arm: The tapered design of the lower load arm facilitates better access to the coil, making it easier to secure and lift items.

Typical Applications

Heavy Duty C-Hooks are specifically designed for handling large and heavy loads, making them suitable for a range of demanding industrial applications:

- Steel Mills: Used extensively for lifting and transporting heavy steel coils and rolls, these hooks are crucial in steel processing facilities where high load capacities are required.

- Aluminum Production Facilities: Ideal for handling heavy aluminum coils and sheets, Heavy Duty C-Hooks support efficient operations in aluminum manufacturing plants.

- Manufacturing Plants: Employed in various manufacturing settings to lift and move large rolls, slabs, or other substantial materials, ensuring stability and safety during operations.

- Heavy-Duty Lifting Environments: Any industry requiring the handling of large and heavy items will benefit from the durability and stability provided by Heavy Duty C-Hooks.

These C-Hooks are essential for operations where reliability and strength are crucial, ensuring smooth and efficient handling of large and heavy materials.

Heavy Duty C-Hooks 2 tons to 32 tons Typical Loads and Applications

Heavy Duty C-Hooks are designed to handle substantial loads. They are typically used in environments where large steel coils or heavy materials need to be lifted. The capacity range for these hooks is broad, accommodating weights from 2 tons up to 32 tons, depending on the specific model and application. Their robust construction makes them suitable for demanding industrial tasks.

- 2 Tons : The crane c hook is used for handling the loads or objects, such as, Small to medium-sized steel coils, smaller aluminum coils, or light steel slabs. Applications: Suitable for smaller steel mills, light metal processing operations, and warehouses where moderate lifting capacity is sufficient for handling lighter heavy-duty materials.

- 5 Tons : The crane c hook is used for handling the loads or objects, such as, Medium steel coils, medium aluminum coils, or larger steel slabs and pipes. Applications: Commonly used in medium-sized steel processing plants, manufacturing facilities, and warehouses that require lifting and moving of moderately heavy materials.

- 10 Tons : The crane c hook is used for handling the loads or objects, such as, Large steel coils, heavy aluminum coils, or significant steel slabs and large pipes. Applications: Ideal for large steel mills, heavy metal processing operations, and extensive logistics facilities where substantial lifting power is required for handling heavier loads.

- 16 Tons : The crane c hook is used for handling the loads or objects, such as, Very large steel coils, oversized aluminum coils, heavy steel slabs, or large pipes and structural components. Applications: Used in major steel manufacturing plants, large-scale metal processing operations, and extensive storage facilities that need to handle very heavy materials with precision.

- 25 Tons : The crane c hook is used for handling the loads or objects, such as, Extremely large steel coils, very heavy aluminum coils, large steel plates, or substantial structural components. Applications: Common in high-capacity steel mills, large industrial plants, and major logistics centers where heavy-duty lifting is essential for moving substantial loads.

- 32 Tons : The crane c hook is used for handling the loads or objects, such as, Maximum-sized steel coils, the heaviest aluminum coils, large steel plates, and heavy-duty structural components. Applications: Used in the largest steel production facilities, extensive heavy manufacturing operations, and large-scale storage and distribution centers requiring top-end lifting capacity for the heaviest materials.

These Heavy Duty C-Hooks are essential for handling large and heavy loads efficiently across various industrial sectors, including steel mills, large manufacturing plants, and major logistics operations. Their robust design ensures reliable performance in demanding environments.

Single Coil C-Hooks

Single Coil C-Hooks are engineered for handling individual coils with efficiency and precision. Key features of these hooks include:

- Single-Plate Structure: Unlike heavier models, Single Coil C-Hooks have a simpler design, featuring a single-plate construction that supports lighter and smaller loads.

- Counterweight Iron: A counterweight iron is integrated to balance the hook's center of gravity with the load, ensuring stability during lifting operations.

- Guide Handle: These hooks are equipped with a guide handle that facilitates easy maneuvering, allowing for precise placement and alignment of the coil.

- Tapered Load Arm: The tapered load arm helps in easily securing and lifting coils, providing better access and reducing the risk of damage to the coils.

Typical Applications

Single Coil C-Hooks are versatile tools used in various industrial environments, particularly for managing smaller coils and reels. Their applications include:

- Metal Processing Plants: Commonly used for lifting and moving steel, aluminum, and copper coils that are of manageable sizes, these hooks ensure efficient handling and minimal damage.

- Warehouses: Ideal for operations in warehouses where coils need to be moved or stored, Single Coil C-Hooks provide a practical solution for managing inventory.

- Logistics Operations: In logistics settings, these hooks are used to transport coils between different stages of the supply chain, facilitating smooth and efficient operations.

- Manufacturing Facilities: Suitable for use in manufacturing plants where precise control over coil handling is essential, Single Coil C-Hooks support operational efficiency and safety.

Overall, Single Coil C-Hooks are designed to offer effective and reliable handling for individual coils, making them a valuable asset in environments where coil sizes and weights are more manageable.

Single Coil C-Hooks 0.5 tons to 10 tons Typical Loads and Applications

Single Coil C-Hooks are generally used for lifting individual coils of various materials. Their capacity ranges from 0.5 tons to 10 tons, making them versatile for different sizes and weights of coils. These hooks are ideal for operations that involve handling smaller to medium-sized coils in industries such as steel processing or paper manufacturing.

- 0.5 Tons : The crane c hook is used for handling the loads or objects, such as, Small coils of thin steel or aluminum, light paper rolls. Applications: Ideal for smaller workshops, light metal processing operations, and paper manufacturing facilities where handling of small, lightweight coils is required.

- 1 Ton : The crane c hook is used for handling the loads or objects, such as, Small to medium steel coils, small aluminum coils, or light wire reels. Applications: Suitable for medium-sized processing plants, smaller manufacturing units, and warehouses that need to lift and handle small to medium-sized coils with moderate lifting capacity.

- 5 Tons : The crane c hook is used for handling the loads or objects, such as, Medium-sized steel coils, medium aluminum coils, or heavier paper rolls. Applications: Commonly used in metal processing operations, paper mills, and general manufacturing where handling of moderately heavy coils and materials is needed.

- 5 Tons : The crane c hook is used for handling the loads or objects, such as, Large steel coils, heavy aluminum coils, or substantial wire reels. Applications: Ideal for larger manufacturing plants, steel mills, and warehouses that require significant lifting power for handling larger and heavier coils and materials.

- 7.5 Tons : The crane c hook is used for handling the loads or objects, such as, Very large steel coils, heavy aluminum coils, or oversized paper rolls. Applications: Used in high-capacity processing facilities, extensive metal production units, and large-scale storage centers where handling of heavy and large coils is essential.

- 10 Tons : The crane c hook is used for handling the loads or objects, such as, Maximum-sized steel coils, the heaviest aluminum coils, and large wire reels or paper rolls. Applications: Suitable for the largest manufacturing plants, major steel processing facilities, and high-volume logistics operations where top-end lifting capacity is necessary for managing the heaviest and largest coils.

Single Coil C-Hooks are essential tools for efficiently handling a range of coil sizes in various industrial settings, from light-duty tasks to heavy-duty operations. Their adaptability makes them invaluable in sectors such as metal processing, paper manufacturing, and general manufacturing.

Narrow Coil C-Hooks

Narrow Coil C-Hooks are tailored for handling smaller and narrower coils. Their design emphasizes lightweight and compact features, which are beneficial for specific lifting tasks. Key aspects include:

- Compact Design: These C-Hooks are designed with a narrower profile, making them suitable for lifting coils that are slim in width. This design ensures efficient handling in tight spaces.

- Load Range: They handle loads ranging from 1 to 3 tonnes, accommodating lighter and narrower coils.

- Guide Handle: Equipped with a guide handle, Narrow Coil C-Hooks offer improved control and maneuverability, making it easier to position and secure the coil during lifting.

- No Counterweights: Unlike heavier C-Hooks, Narrow Coil C-Hooks lack counterweights, which contributes to their lighter and more flexible design.

Typical Applications

Narrow Coil C-Hooks are ideal for operations where space constraints and the size of the coils are key factors. Their typical applications include:

- Smaller Processing Facilities: In facilities that handle smaller, narrower coils, these hooks provide a practical solution for efficient and safe lifting.

- Production Lines: On production lines where space is limited and quick coil handling is necessary, Narrow Coil C-Hooks facilitate smooth and effective operations.

- Warehouses: These hooks are useful in warehouses for managing narrow coils, ensuring they can be easily moved and stored in confined spaces.

- Metal Processing: They are suitable for lifting smaller coils of materials like steel, aluminum, or copper, where precise control and space efficiency are important.

Overall, Narrow Coil C-Hooks are designed to address the specific needs of handling smaller and narrower coils, making them valuable in environments where space is at a premium and efficient coil management is crucial.

Narrow Coil C-Hooks 1 ton to 3 tons:: Typical Loads and Applications

Narrow Coil C-Hooks are specifically designed for handling smaller, narrower coils. With capacities ranging from 1 ton to 3 tons, these hooks are suitable for lighter materials and applications where precision is key. They are commonly used in sectors that require handling delicate or smaller coil materials.

- 1 Ton : The crane c hook is used for handling the loads or objects, such as, Small, narrow steel coils, light aluminum coils, or narrow paper rolls. Applications: Ideal for small-scale metal processing plants, light manufacturing units, and warehouses where handling of lighter, narrow coils is needed.

- 5 Tons : The crane c hook is used for handling the loads or objects, such as, Small to medium narrow steel coils, light to medium aluminum coils, or narrow rolls of paper. Applications: Suitable for medium-sized operations, including metalworking shops and paper mills where moderate lifting capacity for narrow coils is required.

- 2 Tons : The crane c hook is used for handling the loads or objects, such as, Medium narrow steel coils, medium aluminum coils, or heavier narrow paper rolls. Applications: Commonly used in metal processing operations, manufacturing facilities, and warehouses needing a reliable hook for handling medium-weight narrow coils.

- 5 Tons : The crane c hook is used for handling the loads or objects, such as, Large narrow steel coils, heavy aluminum coils, or oversized narrow paper rolls. Applications: Appropriate for high-capacity metal processing units, large manufacturing plants, and extensive storage areas requiring the ability to lift heavier narrow coils.

- 3 Tons : The crane c hook is used for handling the loads or objects, such as, Maximum-sized narrow steel coils, heavy aluminum coils, or the largest narrow paper rolls. Applications: Ideal for the largest industrial operations, including major metal production facilities and high-volume logistics centers where heavy and large narrow coils need to be handled efficiently.

Narrow Coil C-Hooks are essential for handling a variety of narrow coil sizes across different industrial sectors. Their versatility allows for efficient management of both light and heavy narrow coils in metal processing, paper manufacturing, and other manufacturing environments.

Double Roll Lifting C-Hooks

Double Roll Lifting C-Hooks are engineered to manage the simultaneous lifting of two coils or rolls. Their design emphasizes stability and efficiency, catering to heavy-duty lifting tasks. They have a capacity range similar to that of Heavy Duty C-Hooks, from 2 tons to 32 tons. This capability allows for efficient handling of multiple items at once, improving productivity in environments such as steel mills or manufacturing plants.Key features include:

- Dual Coil Handling: These C-Hooks are designed to lift two coils or rolls at once, making them ideal for applications requiring simultaneous handling.

- Lifting Body and Counterweight Iron: The construction includes a robust lifting body and counterweight iron. The counterweights ensure the load is balanced, enhancing stability and minimizing the risk of tilting or load slippage.

- Heavy-Duty Construction: Built to endure the stresses of lifting substantial loads, Double Roll C-Hooks are suitable for heavy-duty applications involving large coils or wire rods.

Typical Applications

Double Roll Lifting C-Hooks are essential in environments where efficiency and handling capacity are critical. Their typical applications include:

- Steel Mills: In steel mills, where large quantities of steel coils need to be lifted and transported, Double Roll C-Hooks streamline operations by handling two coils simultaneously.

- Aluminum Production Facilities: These hooks are used in aluminum production facilities to manage multiple rolls of aluminum, enhancing productivity and reducing downtime.

- Metal Processing Plants: In metal processing plants, Double Roll Lifting C-Hooks facilitate the handling of large volumes of material, improving operational efficiency and workflow.

- Wire Rods Handling: They are also effective for lifting wire rods in environments where multiple rods need to be transported together.

Overall, Double Roll Lifting C-Hooks are designed to boost operational efficiency by handling multiple coils or rolls at once, making them invaluable in high-volume industrial settings where heavy-duty lifting and quick turnaround are essential.

Double Roll Lifting C-Hooks 2 Tons to 32 Tons: Typical Loads and Applications

- 2 Tons : The crane c hook is used for handling the loads or objects, such as, Small to medium-sized steel rolls, narrow aluminum rolls, or lightweight paper rolls. Applications: Used in smaller manufacturing plants, metal processing units, and paper mills where handling of smaller double rolls is required.

- 5 Tons : The crane c hook is used for handling the loads or objects, such as, Medium steel rolls, medium aluminum rolls, or moderate weight paper rolls. Applications: Suitable for medium-sized production lines, metal fabrication shops, and paper converting facilities where a balance of capacity and flexibility is needed.

- 10 Tons : The crane c hook is used for handling the loads or objects, such as, Large steel rolls, heavy aluminum rolls, or larger paper rolls. Applications: Commonly found in large manufacturing operations, heavy metal processing industries, and major paper mills that handle substantial roll sizes.

- 16 Tons : The crane c hook is used for handling the loads or objects, such as, Extra-large steel rolls, very heavy aluminum rolls, or oversized paper rolls. Applications: Ideal for high-capacity industrial operations, including large steel mills and high-volume paper manufacturing plants where large and heavy rolls are frequently handled.

- 25 Tons : The crane c hook is used for handling the loads or objects, such as, Heavy industrial steel rolls, very heavy aluminum rolls, or extra-large paper rolls. Applications: Used in heavy-duty industrial settings, including major steel production facilities and large-scale paper processing plants requiring robust lifting solutions for very heavy rolls.

- 32 Tons : The crane c hook is used for handling the loads or objects, such as, Maximum size steel rolls, extremely heavy aluminum rolls, or the largest paper rolls. Applications: Best suited for the largest industrial operations, including mega steel mills and extensive paper mills where the highest capacity for roll handling is essential.

Double Roll Lifting C-Hooks are designed for versatile and heavy-duty lifting needs, making them suitable for handling a wide range of roll sizes and weights across various industrial sectors. Their robust design ensures efficiency and reliability in managing large and heavy rolls in metal, paper, and other manufacturing processes.

C-Hooks for Container Loading and Unloading

C-Hooks designed for container loading and unloading are specialized to efficiently manage the handling of long, heavy materials. Their design focuses on high load-bearing capacity and stability, making them ideal for container operations. Key characteristics include:

- High Load-Bearing Capacity: These C-Hooks are built to support substantial weights, essential for handling large steel pipes, tubes, and slabs.

- Stability and Balance: Equipped with design features to ensure stability during operation, they prevent load slippage and maintain alignment.

- Enhanced Design Features: They often include additional elements such as reinforced arms or specialized grips to securely handle materials during container operations.

Typical Applications

C-Hooks for container loading and unloading play a critical role in various industrial and logistical settings, including:

- Ports: In port facilities, these C-Hooks are used to efficiently load and unload heavy materials from shipping containers, contributing to smoother port operations.

- Shipping Yards: They facilitate the movement of large and heavy items in shipping yards, where quick and safe handling of materials is essential.

- Warehouses: In warehouses, these C-Hooks are employed to streamline the loading and unloading process, particularly for large shipments of steel pipes, tubes, and slabs.

- Logistics: They are crucial for logistics companies involved in transporting bulk materials, ensuring efficient and secure handling of items during transit.

In summary, C-Hooks for container loading and unloading are designed to enhance operational efficiency in handling large and heavy materials. Their robust construction and specialized features make them indispensable in ports, shipping yards, and warehouses, where they significantly improve the loading and unloading processes.

C-Hooks for Container Loading and Unloading 2 tons to 10 tons: Typical Loads and Applications

C-Hooks used for container loading and unloading are built to handle various types of loads within containers. Their capacity ranges from 2 tons to 10 tons, suitable for lifting items like steel pipes, tubes, and slabs. These hooks are essential for efficient loading and unloading processes, ensuring stability and safety during transport.

- 2 Tons : The crane c hook is used for handling the loads or objects, such as, Small steel pipes, lightweight aluminum sections, and smaller slabs. Applications: Ideal for use in containerized transport of smaller items or lighter materials. Commonly used in warehouses and logistics operations where compact loads are frequently handled.

- 4 Tons : The crane c hook is used for handling the loads or objects, such as, Medium-sized steel pipes, moderate weight tubes, and medium slabs. Applications: Suited for handling a range of medium-sized items in container loading and unloading. Frequently used in construction materials logistics and small to medium industrial shipments.

- 6 Tons : The crane c hook is used for handling the loads or objects, such as, Large steel pipes, heavier tubes, and larger slabs. Applications: Designed for more substantial loads, often used in sectors such as construction, metal fabrication, and large-scale logistics operations.

- 8 Tons : The crane c hook is used for handling the loads or objects, such as, Extra-large steel pipes, very heavy tubes, and substantial slabs. Applications: Ideal for heavy-duty container operations requiring robust lifting solutions. Common in heavy industrial environments and major transport hubs where large and heavy items are regularly moved.

- 10 Tons : The crane c hook is used for handling the loads or objects, such as, Maximum size steel pipes, very large slabs, and the heaviest tubes. Applications: Best suited for the most demanding container loading and unloading tasks. Utilized in heavy industrial settings, large-scale construction sites, and high-capacity logistics centers where handling the largest and heaviest loads is necessary.

C-Hooks for container loading and unloading are specifically designed to manage a variety of loads efficiently within containers. Their robust construction ensures that even the heaviest and largest items can be lifted safely and effectively, making them essential for efficient and reliable logistics operations across various industrial sectors.

Features of Crane C-Hooks

Material and Construction

- High-Strength Alloy Steel: Crane C-Hooks are typically made from high-strength alloy steel, which provides the necessary durability and load-bearing capacity for heavy lifting. The alloy steel used ensures that the hooks can withstand significant stress and impact without compromising their structural integrity.

- Lightweight Yet Durable: Despite their robust construction, Crane C-Hooks are designed to be lightweight. This balance between strength and weight makes them easier to handle and maneuver, which enhances operational efficiency. The lightweight design does not sacrifice durability, ensuring that the hooks remain effective and reliable under demanding conditions.

Design Elements

- Spreader and Counterweight Iron: Many Crane C-Hooks feature a spreader and counterweight iron. The spreader ensures that the load is evenly distributed, while the counterweight iron helps to balance the hook and the lifted object. This combination stabilizes the load, preventing tipping or misalignment during lifting operations.

- Guide Handles: Guide handles are incorporated into the design to facilitate easy maneuvering of the C-Hook. They allow operators to control the hook with precision, reducing the risk of accidents and improving overall handling efficiency.

- Tapered Load Arms: The tapered load arms of C-Hooks are designed to provide easier access to the coils or rolls being lifted. This feature minimizes potential damage to the materials and improves the ease of operation by allowing smoother insertion and removal of the load.

Customization Options

- Electric Rotating Devices: For enhanced flexibility and control, C-Hooks can be equipped with electric rotating devices. These allow the hook to rotate, providing better positioning and alignment of the load, which is particularly useful for complex lifting tasks.

- High-Temperature Applications: Some C-Hooks are designed for high-temperature environments. Special materials and coatings can be used to ensure that the hooks remain functional and safe when exposed to elevated temperatures, making them suitable for applications in industries like metal production and processing.

- Dual-Leg and Multi-Leg Designs: Customization options also include dual-leg and multi-leg designs, which provide additional stability and support. These configurations are ideal for lifting larger or more complex loads, where increased balance and weight distribution are required.

- Digital Weighing Systems: To enhance accuracy and monitoring, C-Hooks can be fitted with digital weighing systems. These systems allow operators to precisely measure the weight of the load, ensuring that it does not exceed the hook's rated capacity and helping to prevent overloading.

Custom Capacity Solutions

Special Requirements and Adjustments

Crane C-Hooks can be tailored to meet unique capacity and operational needs, extending beyond the standard ranges of typical C-Hooks. Custom solutions offer flexibility to handle specialized loads or adapt to unique industrial conditions. Here are key aspects of custom capacity solutions:

Design Modifications

- Increased Load Capacity: Custom C-Hooks can be engineered to handle weights beyond the typical maximum of standard hooks. This includes adjusting the structural design to reinforce strength and stability for extreme loads.

- Specialized Shapes and Sizes: Customization may involve altering the hook's dimensions or shape to fit specific load profiles, such as non-standard coil sizes or unusual shapes.

Material Enhancements

- High-Strength Materials: For extreme load requirements, C-Hooks can be constructed from advanced alloys or composite materials that offer superior strength-to-weight ratios.

- Corrosion-Resistant Coatings: In harsh environments, such as marine or chemical settings, custom C-Hooks can be treated with specialized coatings to prevent corrosion and extend lifespan.

Operational Adjustments

- Weight Distribution: Modifications can be made to adjust how the load is distributed across the hook, improving balance and handling for irregularly shaped or unevenly weighted loads.

- Integration with Other Equipment: Custom C-Hooks may include features such as electric rotating devices or digital weighing systems, enhancing functionality and precision in handling operations.

Safety Enhancements

- Safety Features: Custom solutions can incorporate additional safety mechanisms, such as enhanced locking systems or sensors to monitor load stability, ensuring secure and reliable operations.

- Compliance with Standards: Customized C-Hooks are designed to meet specific industry standards and regulations, providing assurance of safety and performance.

Custom capacity solutions for Crane C-Hooks ensure that they are well-suited for specialized applications, improving efficiency and safety in handling diverse and challenging loads. By tailoring the design, materials, and features to meet specific needs, businesses can achieve optimal performance and reliability in their lifting operations.

Typical Loads Handled

Crane C HooK for Handling Steel Coils

Specifications and Handling Requirements: Steel coils are heavy and bulky, often requiring significant lifting capacity and careful handling to prevent damage. Crane C-Hooks designed for steel coils must be able to handle the high weights and the often abrasive nature of the material. Specifications include:

- Capacity: Typically from 2 tons to 32 tons.

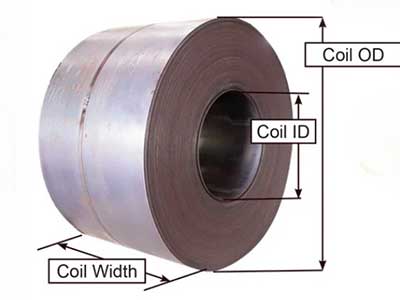

- Coil Width: Varies widely, often from 300 mm to 1500 mm.

- Coil Inner Diameter: Generally from 400 mm to 1955 mm. Handling requirements involve ensuring proper alignment and secure lifting to avoid slippage or damage during movement. C-Hooks must be designed with features that accommodate the coil's size and weight, including strong support and balanced design.

Aluminum Coils

Specifications and Handling Requirements: Aluminum coils, while lighter than steel, still require careful handling due to their size and potential for surface damage. Crane C-Hooks for aluminum coils should provide:

- Capacity: Typically from 0.5 tons to 10 tons.

- Coil Width: Commonly ranges from 300 mm to 1125 mm.

- Coil Inner Diameter: Generally from 400 mm to 850 mm. Handling aluminum coils requires a gentle touch to avoid denting or scratching. The C-Hook must ensure a firm grip and stable lifting to maintain the integrity of the coil's surface.

Copper Coils

Specifications and Handling Requirements: Copper coils are heavy and often used in electrical applications. Handling requirements include:

- Capacity: Usually from 0.5 tons to 10 tons.

- Coil Width: Often from 300 mm to 1000 mm.

- Coil Inner Diameter: Typically from 400 mm to 800 mm. Copper's weight and value necessitate precise handling to prevent damage and ensure efficient movement. C-Hooks must be equipped with features to handle the weight while protecting the copper surface from scratches and dents.

Paper Rolls Specifications and Handling Requirements: Paper rolls are generally lighter but bulky, requiring special handling to avoid crushing. Crane C-Hooks for paper rolls should offer:

- Capacity: Usually from 0.5 tons to 10 tons.

- Roll Diameter: Typically ranges from 500 mm to 2000 mm.

- Roll Width: Generally from 500 mm to 1500 mm. Handling paper rolls involves careful lifting to maintain the roll's shape and prevent deformation. C-Hooks should be designed to evenly distribute the load and prevent excessive pressure on any single point.

Wire Reels and Non-metal Coils

Fiber Optic Cabling: Fiber optic cables are delicate and require careful handling. Crane C-Hooks must be designed with a gentle grip to avoid damaging the cable's integrity.

- Capacity: Generally lighter, ranging from 0.5 tons to 2 tons.

- Reel Diameter: Varies based on the reel size.

- Rope Cabling: Similar to fiber optic cables but usually heavier.

- Capacity: Typically from 1 ton to 5 tons.

- Reel Diameter: Depends on the rope's thickness and length.

Handling these non-metal coils involves ensuring that the C-Hook does not exert excessive pressure that could damage the cables or ropes. Features such as cushioned grips and adjustable arms can be crucial.

Steel Pipes and TubesLoading and Unloading Requirements:

Steel pipes and tubes are long and heavy, requiring stable lifting solutions. Crane C-Hooks used for these should be capable of:

- Capacity: Typically from 2 tons to 10 tons.

- Pipe Diameter: Ranges from 100 mm to 2000 mm.

- Length: Can vary greatly, from a few meters to over 12 meters. Proper loading and unloading require that the C-Hook securely supports the pipe or tube to prevent rolling or shifting during transport.

Applications in Various Industrial Sectors

Steel MillsCoil Handling and Processing: In steel mills, C-Hooks are crucial for the efficient handling of heavy steel coils. These hooks facilitate:- Coil Transport: Moving coils from processing lines to storage areas or shipping.

- Coil Loading and Unloading: Efficiently managing coils in and out of trucks or railcars.

- Processing Support: Assisting in the transfer of coils to processing equipment for further treatment.

- Transport Sheets: Move sheets between different stages of the production process.

- Load and Unload: Facilitate the efficient loading and unloading of sheets onto and from processing machines or storage areas.

- Prevent Damage: Ensure that sheets are handled carefully to avoid any deformation or surface damage.

- Handling Coils and Reels: Efficiently moving various types of coils and reels from storage to dispatch areas.

- Optimizing Space: Assisting in stacking and organizing materials to maximize warehouse space.

- Speeding Up Operations: Enhancing the speed of storage and retrieval processes, contributing to overall operational efficiency.

- Moving Paper Rolls: Transporting heavy rolls of paper between production lines, storage areas, and shipping docks.

- Preventing Damage: Ensuring that rolls are lifted and moved without crushing or deforming, which can impact the quality of the final product.

- Supporting Production Efficiency: Facilitating smooth transitions between different stages of the papermaking process.

- Pipe Handling: Lifting and transporting large steel pipes used in pipelines and drilling operations.

- Material Transport: Moving other heavy materials required for construction and maintenance.

- Ensuring Safety: Managing heavy loads in a safe and controlled manner to avoid accidents and damage.

- Component Transport: Moving various components and materials to different stages of the production process.

- Custom Solutions: Adapting C-Hooks to handle unique or specialized materials used in different manufacturing sectors.

- Improving Efficiency: Enhancing the speed and accuracy of material handling, leading to increased productivity.

Advantages of Using Crane C-Hooks

Enhanced EfficiencyEasy Maneuverability and Operation: Crane C-Hooks significantly boost operational efficiency through their ease of use and maneuverability:- Streamlined Handling: C-Hooks are designed for quick and straightforward attachment to various loads, facilitating faster handling and transfer.

- Improved Workflow: Their ability to handle multiple load types seamlessly helps maintain a smooth workflow in various industrial settings.

- Increased Productivity: By reducing the time and effort required for load handling, C-Hooks contribute to higher overall productivity and reduced downtime.

- High-Strength Materials: Constructed from high-strength alloy steels and other robust materials, C-Hooks are designed to handle heavy and frequent loads without failure.

- Resistant to Wear and Tear: Their rugged design ensures longevity even in harsh environments, reducing the likelihood of equipment failure and enhancing reliability.

- Consistent Performance: Reliable performance under various conditions helps maintain safety and efficiency in load handling operations.

- Minimal Moving Parts: The relatively simple design of C-Hooks means fewer parts are subject to wear and tear, reducing the frequency of maintenance requirements.

- Ease of Inspection and Repair: Their straightforward design facilitates easy inspection and repair, ensuring that any maintenance tasks can be completed quickly and efficiently.

- Lower Maintenance Costs: The durability and ease of maintenance translate to lower overall maintenance costs, making C-Hooks a cost-effective choice for industrial operations.

Maintenance and Care

Daily Maintenance PracticesStorage and Protection: Proper storage and protection of C-Hooks are essential for maintaining their functionality and extending their lifespan:- Clean Storage Areas: Ensure that C-Hooks are stored in clean, dry environments to prevent rust and corrosion. Use protective covers if stored outdoors or in areas prone to dust and moisture.

- Safe Handling: Avoid dropping or mishandling C-Hooks, as this can cause damage. Always handle them with care to maintain their structural integrity.

- Cleaning: Regularly clean C-Hooks to remove dirt, debris, and other contaminants that can affect their performance. Use non-corrosive cleaning agents and ensure that all residues are thoroughly wiped away.

- Lubrication: Apply appropriate lubricants to moving parts and pivot points as specified by the manufacturer. This helps reduce friction, prevent wear, and ensure smooth operation.

- Visual Inspections: Frequently check for signs of wear, damage, or deformation. Look for cracks, bent parts, or excessive corrosion.

- Load Testing: Periodically perform load tests to ensure that C-Hooks can handle their rated capacities safely. Monitor for any abnormal performance during these tests.

- Troubleshooting: Common issues include uneven load distribution, difficulty in hook engagement, or squeaking noises. Address these by adjusting or repairing components as needed.

- Consultation: Seek expert advice for selecting the right C-Hook for specific applications and ensure proper configuration and customization based on your operational needs.

- Installation: Professional installation ensures that C-Hooks are properly set up and aligned, reducing the risk of operational issues and enhancing safety.

- Maintenance Services: Regular professional maintenance can include detailed inspections, repairs, and upgrades. Engaging with specialized services helps ensure that C-Hooks remain in optimal condition and comply with safety standards.

Selection of Standard and Type of Coil Spreader

On selecting the C hook for your application, the following factor should take into consideration,

- Coil hook selection should consider the scale, component, shape, volume and weight of the load lifted,the way of hoisting , and the request for the limit work force given etc.

- The application environment and the variety of loads also are important for the selection of C hooks.

- The length of the proper slings need to be confirmed to satisfy the lifting ability and meet the requirements of application.

- If multiple slings are required, the types of slings should be in accordance. The raw material for the flat slings shouldn't be subjected to the working conditions or load impact.

Routine Maintenance for Coil C Hooks

The proper routine maintenance for the C hooks can keep it in good conditions and extended its working life. Generally, the routine maintenance of C hooks may include:

- After using, the lifting c hook should be placed on a dedicated shelf, stored in a ventilated, dry, clean factory building

- The surface of coil c hook should be cared and protected against rust, and it should not be kept in acids, salts, chemical gases,humid,and high temperature environments.

- Periodically cleaning of rotating parts and regularly oil lubrication is necessary to prevent the happening of dry, friction and seizure.

More details , please check the maintenance manual or to contact us.

Safety Inspection of C hooks

The qualified C hook should be printed, with the rated capacity, manufacturer, inspection mark, production number,and others, on the low stress area of the hook to make the basic information of the C- hook well-known to the necessary working staff.

For the safety inspection, the C-hooks have to be tested with 1.5 times the rated load for human -driven lifting system and with 2 times rated load for power-driven lifting system. After testing by the required inspection load, the C-hook should not have obvious defects or deformations, and the increase of opening degree shall not exceed 0.25% of the original size.

Tailored C hook lifting device, suitable & cost-effective crane attachment

As a crane manufacturer and crane supplier, we are able to provide types of industrial cranes and related crane parts and accessories including types of below the hook devices. With process design, we can process and provide quality below-the-hook lifting device for your material handling equipment to handle your valued products with the features of durability, efficiency, and high safety.

In order to send you the specific price of C hook, could you please leave us the following information including:

- What are the loads:____(eg: Steel pipe, steel coil, paper roll, or others)

- Dead weight of loads:____ T?

- Length of the loads:____ M

- Internal diameter of roll lifted:____ MM

- Outside diameter of roll lifted:____ MM

If you have any need of below the hook lifting devices or crane attachments, please feel free to contact us to get customized below the hook lifting devices.

Conclusion

Summary of Key Points: Crane C-Hooks play a vital role in various industrial operations by providing efficient and safe handling of heavy and bulky materials. Understanding the different types of C-Hooks—such as Heavy Duty, Single Coil, Narrow Coil, Double Roll Lifting, and those designed for Container Loading and Unloading—ensures that the right tool is used for specific tasks. Their diverse features, including high-strength materials, customizable design elements, and varying capacity ranges, enhance their versatility across different applications.

Final Thoughts on the Importance and Benefits of Crane C-Hooks: Crane C-Hooks are indispensable in optimizing material handling processes, particularly in steel mills, warehouses, papermaking industries, and manufacturing plants. They significantly improve operational efficiency by facilitating the quick and secure movement of various loads, from steel coils to paper rolls. The durability and reliability of C-Hooks, coupled with their reduced maintenance needs, make them a valuable investment for industries requiring heavy lifting and precise load management.In conclusion, Crane C-Hooks offer numerous advantages, including enhanced efficiency, longevity, and ease of maintenance. Their role in streamlining material handling operations cannot be overstated, and investing in high-quality C-Hooks ensures that industries can handle their materials safely and effectively, meeting their operational needs and achieving their productivity goals.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch