Efficient Ambient Temperature Scrap Steel Handling Electromagnets

Powerful electromagnets designed for reliable scrap steel lifting in ambient temperatures, offering high performance, durability, & low maintenance costs.

Category: Below Hook Devices

Your Trusted Scrap Steel Handling Overhead Crane Manufacturer & Supplier

Efficient Ambient Temperature Scrap Steel Handling Electromagnets

Powerful electromagnets designed for reliable scrap steel lifting in ambient temperatures, offering high performance, durability, and low maintenance costs.

Ambient Temperature Scrap Steel Handling Electromagnets

Ambient Temperature Scrap Steel Handling Electromagnets are specifically designed to efficiently lift and move scrap steel and other ferrous materials in various industrial environments. These electromagnets are commonly used in steel mills, scrap yards, foundries, and recycling plants, where the handling of large amounts of metal is required. With their robust design and reliable operation, they ensure optimal performance in everyday industrial conditions.

The primary function of these electromagnets is to assist in the lifting and transportation of scrap steel and other ferrous metals. Their design allows for easy handling of heavy materials, reducing the need for manual labor and improving overall operational efficiency.

Key Benefits:

- Efficient Lifting: Designed to lift large volumes of scrap steel, cast iron, and steel turnings.

- Strong Magnetic Force: Ensures secure attachment to ferrous materials for safe and precise handling.

- Durable and Reliable: Built to perform reliably in standard ambient temperature conditions, with minimal maintenance needs.

- Time-Saving: Reduces the time and effort required for moving scrap, improving overall productivity in industrial settings.

These electromagnets provide a safe and effective solution for scrap handling in industries, contributing to more streamlined operations and increased workplace safety.

Main Specifications of Lifting Electromagnet for Handling Steel Balls, Cast Iron Ingots, and Scraps

MW5 Ambient Temperature Model

(Rated Voltage: DC-220V, Duty Cycle: TD-60%)

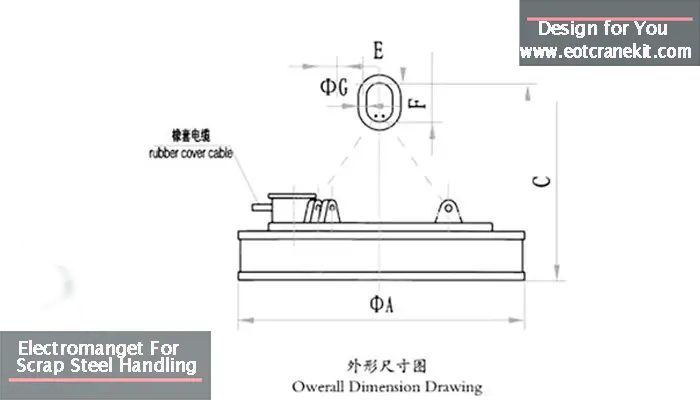

scrap steel handling electromangetic spreader for scrap handling cranes

Crane electromagnet drawing for your reference, Customized design for your needs

MW5 Series Specifications

The MW5 series is designed for a variety of industrial scrap steel handling needs, offering reliable performance in diverse environments.

- Power: Ranges from 2.6 kW to 41.6 kW, depending on the specific model.

- Voltage: DC-220V, ensuring steady and dependable operation.

- Lifting Capacity: Varies from 220 kg to 39,000 kg, catering to different scrap steel handling capacities.

- Dimensions: Available in multiple sizes, tailored to fit specific operational requirements.

Temperature Range:

- Ambient Temperature Models: Suitable for standard operational temperatures.

- High-Temperature Models: Some models are designed to handle scrap steel at up to 700°C for extreme conditions, ideal for environments such as foundries and steel mills.

Model | Cold Power (KW) | Current (A) (Cold/Hot) | Dimensions (mm) | Weight (kg) | Lifting Capacity (kg) | ||||||

|

|

| A | C | F | E | G |

| Steel Balls | Cast Iron Ingots | Scraps |

MW5-50L/1 | 2.6 | 11.8/7.7 | 500 | 700 | 160 | 90 | 25 | 220 | 1200 | 220/130 | 80/65 |

MW5-60L/1 | 3.0 | 13.6/8.9 | 600 | 750 | 160 | 90 | 25 | 340 | 2000 | 290/170 | 95/80 |

MW5-70L/1 | 3.3 | 15/9.8 | 700 | 800 | 160 | 90 | 30 | 490 | 2500 | 380/200 | 120/100 |

MW5-80L/1 | 4.0 | 18/12 | 800 | 800 | 160 | 90 | 30 | 620 | 3000 | 480/250 | 150/130 |

MW5-90L/1 | 5.9 | 26.8/17.5 | 900 | 1090 | 200 | 125 | 40 | 800 | 4500 | 600/400 | 250/200 |

MW5-110L/1 | 7.7 | 35/22.8 | 1100 | 1140 | 220 | 150 | 45 | 1350 | 6500 | 1000/800 | 450/400 |

MW5-120L/1 | 10 | 45.5/29.5 | 1200 | 1100 | 220 | 150 | 45 | 1700 | 7500 | 1300/1000 | 650/500 |

MW5-130L/1 | 12 | 54.5/35.5 | 1300 | 1240 | 250 | 175 | 50 | 2010 | 8500 | 1400/1100 | 700/600 |

MW5-150L/1 | 15.6 | 70.9/46.1 | 1500 | 1250 | 350 | 210 | 60 | 2830 | 11000 | 1900/1500 | 1100/900 |

MW5-165L/1 | 16.5 | 75/48.8 | 1650 | 1590 | 370 | 230 | 75 | 3200 | 12500 | 2300/1800 | 1300/1100 |

MW5-180L/1 | 22.5 | 102.3/66.5 | 1800 | 1490 | 370 | 230 | 75 | 4230 | 14500 | 2750/1100 | 1600/1350 |

MW5-210L/1 | 28.4 | 129/84 | 2100 | 1860 | 400 | 250 | 80 | 7000 | 21000 | 3500/2800 | 2200/1850 |

MW5-240L/1 | 33.9 | 154/100 | 2400 | 2020 | 450 | 280 | 90 | 9000 | 26000 | 4800/3800 | 2850/2250 |

MW5-260L/1 | 35.6 | 162/105 | 2600 | 2100 | 450 | 280 | 90 | 10100 | 30000 | 6100/4900 | 3600/3850 |

MW5-280L/1 | 39 | 178/116 | 2800 | 2700 | 500 | 300 | 100 | 12450 | 34000 | 7100/5700 | 4450/3400 |

MW5-300L/1 | 41.6 | 189/123 | 3000 | 2300 | 500 | 300 | 100 | 14980 | 39000 | 8350/6700 | 5250/4100 |

Key Features

Durable Construction

- Made from high-quality materials designed for long-lasting performance.

- Engineered to be robust and resistant to harsh industrial environments, ensuring durability in demanding conditions.

- Ideal for applications where electromagnets are subjected to constant use and high stress.

Efficient Power Consumption

- Energy-saving design minimizes power usage while maximizing output.

- Advanced technology built into the electromagnet allows for low operational costs without sacrificing performance.

- Helps reduce the overall energy footprint of operations, leading to significant cost savings.

Customizable Design

- Available in various sizes and lifting capacities to meet specific industrial needs.

- Can be tailored to fit the requirements of different scrap steel handling environments, ensuring optimal performance.

- Custom solutions available for unique lifting challenges, offering flexibility in design.

High Lifting Capacities

- Capable of handling a wide variety of scrap steel, including cast iron ingots, steel balls, and scrap turnings.

- Multiple models are available, each designed to handle different lifting capacities, from light to heavy-duty applications.

- Suitable for a range of materials and industries, ensuring versatility in scrap handling.

Temperature Handling Capabilities

- Some models are specially designed to lift materials at high temperatures, up to 700°C.

- These electromagnets are built with advanced insulation and heat-resistant features to operate safely and efficiently in environments with extreme temperatures.

- Ideal for industries where scrap steel is subjected to high heat, such as foundries and steel mills.

MW61 Ambient Temperature Model

(Rated Voltage: DC-220V, Duty Cycle: TD-60%)

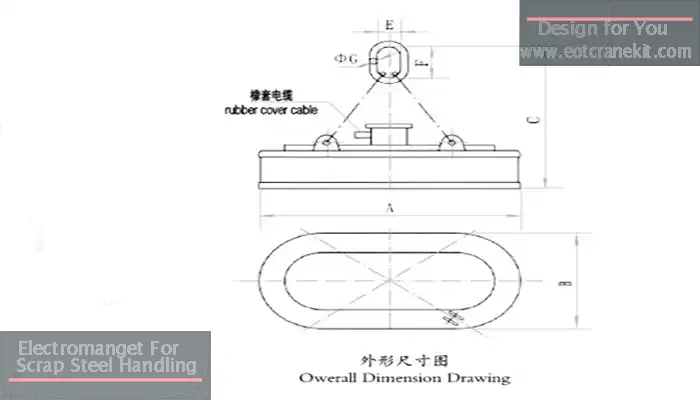

Oval scrap steel electromagnetic below hook device for electric magnetic overhead crane and gantry crane

drawing of oval steel scrap handling below hook device drawing for narrow space train or truck

MW61 Series Specifications

The MW61 series offers specialized features for high-efficiency scrap steel handling, particularly in narrow container environments and high-temperature applications.

- Power: Varies from 12 kW to 42.5 kW, ensuring powerful lifting capabilities.

- Voltage: DC-220V, for consistent and effective performance.

- Lifting Capacity: Ranges from 1,150 kg to 15,600 kg, providing flexibility across various scrap steel handling tasks.

- Dimensions: Customizable to fit specific application needs, including narrow container handling.

Temperature Range:

- Ambient Temperature Models: Designed for regular industrial conditions.

- High-Temperature Models: Some MW61 models are capable of lifting materials at temperatures up to 700°C, ideal for handling hot scrap in extreme environments.

This separation ensures clarity when comparing the different specifications and applications of the MW5 and MW61 series.

Model | Cold Power (KW) | Current (A) (Cold) | Dimensions (mm) | Weight (kg) | Lifting Capacity(kg) (Cold /Hot) | ||||||

A | B | C | F | E | G | Casting ingot | Turnings | ||||

MW61-400240L/1-75 | 40.01 | 181.9 | 4000 | 2400 | 1600 | 350 | 200 | 65 | 15600 | 7000/6000 | 3500/3000 |

MW61-380160L/1-75 | 30.36 | 138 | 3800 | 1600 | 2380 | 410 | 260 | 90 | 9700 | 6000/5000 | 3000/2500 |

MW61-350220L/1-75 | 42.5 | 193 | 3500 | 2200 | 1955 | 400 | 300 | 90 | 12000 | 6000/5000 | 3000/2500 |

MW61-300210L/1-75 | 34.5 | 157.1 | 3000 | 2100 | 1810 | 400 | 250 | 80 | 10500 | 5000/4000 | 2500/2000 |

MW61-300150L/1-75 | 28 | 127.3 | 3000 | 1500 | 1550 | 390 | 210 | 70 | 7660 | 3500/2800 | 1800/1500 |

MW61-250200L/1-75 | 24.6 | 136.5 | 2500 | 2000 | 2000 | 390 | 280 | 90 | 8400 | 5000/4200 | 2300/1800 |

MW61-250160L/1-75 | 29.2 | 133 | 2500 | 1600 | 1700 | 310 | 210 | 60 | 7500 | 4800/3900 | 2400/1950 |

MW61-250150L/1-75 | 24.2 | 110 | 2500 | 1500 | 1700 | 300 | 210 | 60 | 5936 | 4000/3200 | 2000/1600 |

MW61-240120L/1-75 | 24.57 | 112 | 2400 | 1200 | 1680 | 250 | 180 | 60 | 3970 | 3000/2400 | 1500/1200 |

MW61-200150L/1-75 | 17.93 | 81.5 | 2000 | 1500 | 1300 | 250 | 180 | 70 | 4200 | 2200/1900 | 1000/800 |

MW61-300150L/1 | 32.3 | 146.7 | 3000 | 1500 | 1530 | 390 | 210 | 70 | 6086 | 3500/2800 | 1800/1500 |

MW61-300100L/1 | 23.5 | 107 | 3000 | 1000 | 1530 | 350 | 210 | 60 | 5800 | 3000/2400 | 1500/1200 |

MW61-240100L/1 | 19.9 | 90.5 | 2400 | 1000 | 1800 | 250 | 180 | 60 | 3600 | 2500/1700 | 1300/900 |

MW61-220120L/1 | 23.4 | 106.3 | 2200 | 1200 | 1695 | 250 | 180 | 60 | 3650 | 2800/2240 | 1400/1120 |

MW61-200150L/1 | 21.01 | 95.5 | 2000 | 1500 | 1560 | 250 | 180 | 60 | 4000 | 2500/2000 | 1300/1000 |

MW61-200120L/1 | 15.68 | 73.26 | 2000 | 1500 | 1560 | 250 | 180 | 60 | 3650 | 2100/1000 | 1050/950 |

MW61-200100L/1 | 17.13 | 77.87 | 2000 | 1000 | 1450 | 300 | 190 | 60 | 2700 | 2000/1800 | 1000/900 |

MW61-140100L/1 | 12 | 55 | 1400 | 1000 | 1120 | 220 | 140 | 50 | 2350 | 1400/1100 | 700/600 |

MW61-11070L/1 | 7.7 | 35.1 | 1120 | 720 | 1020 | 220 | 150 | 45 | 1150 | 1000/800 | 600/540 |

Applications

Steel Industry

- Scrap Metal Handling: Perfect for lifting scrap metal, cast iron ingots, and steel balls in steel plants, recycling centers, and scrap yards.

- Efficient Recycling: Provides an efficient solution for material sorting and transporting in steel production and recycling processes.

Furnace Operations

- High-Temperature Environments: Designed to lift and handle scrap steel in extreme conditions, such as furnace operations, where materials may reach up to 700°C.

- Seamless Integration: These electromagnets ensure smooth handling of hot scrap, reducing manual labor and improving safety.

Narrow and Confined Spaces

- Containerized Scrap Handling: Ideal for handling scrap in tight, narrow containers where space is limited. Perfect for transporting steel in small transport units.

- Tailored Solutions: The design is customizable to meet the specific needs of confined spaces, ensuring effective material handling without compromising performance.

Electromagnetic Overhead Cranes

- Safe and Efficient Lifting: Electromagnetic overhead cranes are perfect for lifting and transporting scrap steel, using an electromagnetic lifting system that increases both safety and efficiency.

- Steel Mills & Foundries: Especially beneficial in environments such as scrap yards, steel mills, and foundries where heavy-duty operations are common.

- Customization: Available for handling various scrap sizes and material types, ensuring adaptability to different industrial applications.

- Space Efficiency: Designed for overhead installations, these cranes save valuable floor space while maximizing lifting capacity, making them ideal for environments with limited space.

Electromagnetic Gantry Cranes

- Mobile Scrap Handling: Equipped with electromagnetic lifting systems, gantry cranes provide the flexibility and mobility required to move scrap steel across large areas.

- Heavy-Duty Applications: Perfect for large-scale scrap handling and transport, particularly in scrap yards, warehouses, and steel production facilities where material movement is a key component of operations.

- Versatility in Environment: These cranes can be used in both indoor and outdoor environments, especially where overhead clearance is limited, offering a flexible solution for different operational settings.

This section highlights the variety of ways in which ambient temperature scrap steel handling electromagnets can be effectively used in various industries, emphasizing their adaptability and efficiency.

Benefits

Improved Productivity

- Faster Operations: The electromagnetic system enables rapid lifting and transportation of scrap materials, improving overall operational throughput.

- Continuous Performance: Consistent, reliable lifting reduces delays and increases the efficiency of production lines and scrap handling processes.

Energy Efficiency

- Lower Operational Costs: The energy-efficient design minimizes power consumption, helping businesses reduce their overall operational expenses.

- Sustainable Use: Advanced technologies ensure that the electromagnets are efficient without sacrificing performance, making them an eco-friendly choice.

Enhanced Safety

- Safety Features: These electromagnets are equipped with safety mechanisms designed to prevent accidents during scrap handling.

- Reduced Risk: By eliminating manual handling, the risk of injuries and accidents is significantly reduced, promoting a safer workplace environment.

Longer Service Life

- Durable Construction: The high-quality materials used in the design of these electromagnets ensure that they are built to last.

- Reduced Downtime: With improved durability, maintenance needs are reduced, allowing for longer operation times between repairs, which minimizes downtime and associated costs.

Easy Installation & Maintenance

- Quick Setup: The electromagnets are designed for easy and quick installation, allowing for minimal disruption during setup.

- Low Maintenance: Designed for long-term operation with minimal maintenance, businesses can focus more on productivity rather than frequent upkeep.

Versatility in Applications

- Flexible Handling: Whether it’s scrap metal, cast iron, or steel balls, the electromagnetic overhead and gantry cranes can handle a wide range of materials.

- Adaptability to Space: These systems are versatile enough to be used in both confined spaces and open areas, offering businesses the flexibility to use them across various applications and operational environments.

This section outlines the key benefits of using ambient temperature scrap steel handling electromagnets, emphasizing productivity, cost savings, safety, and versatility in different industrial settings.

Complementary Equipment

Electromagnetic Overhead Cranes

- Ideal for Scrap Handling: Designed specifically for use with scrap steel electromagnets, these cranes offer an effective overhead lifting solution in scrap yards and steel plants.

- Increased Lifting Speeds: Optimized for fast lifting, they can handle heavy scrap loads quickly, improving overall productivity.

- Customization: Custom-built to fit specific material handling needs, ensuring maximum efficiency in various environments, whether it’s scrap yards or recycling centers.

Electromagnetic Gantry Cranes

- Versatile and Mobile: Perfect for large-scale scrap handling operations, gantry cranes provide flexibility and mobility across expansive areas, especially in outdoor environments and scrap yards.

- Adjustable Lifting Heights: These cranes come with adjustable lifting heights, making them suitable for handling various scrap sizes and materials.

- Heavy-Duty Design: Built for robust performance, they can withstand the demands of heavy-duty scrap steel handling, ensuring reliability and durability over time.

Control Panels & Electrical Systems

- Precision Control: Advanced control panels are designed to operate the electromagnetic cranes with high precision, allowing for smooth and efficient material handling.

- Remote Operation: Some systems offer remote control capabilities, allowing operators to manage cranes from a distance, further improving safety and ease of use.

- Safety & Efficiency: The electrical systems are designed to improve safety during operation, ensuring that the cranes can lift and transport scrap steel efficiently and without risk of malfunction.

These complementary equipment options, including overhead and gantry cranes as well as control systems, enhance the functionality and efficiency of the electromagnetic scrap steel handling process, ensuring reliable and safe operations in various industrial settings.

Why Choose Our Electromagnets?

Expert Engineering

Our electromagnets are engineered with the most advanced electromagnetic technology, ensuring they provide efficient and reliable performance in even the most demanding environments.

- Cutting-edge Technology: Equipped with the latest advancements, allowing for precise lifting and efficient scrap steel handling.

- Durable Construction: Built with high-quality materials for longevity, ensuring the electromagnets can withstand the toughest industrial conditions.

- Reliable Performance: Designed to provide consistent and dependable lifting capabilities, even under high stress and long hours of operation.

Tailored Solutions

We understand that each facility has unique requirements, so we offer customizable solutions to meet your specific needs.

- Custom Sizes and Lifting Capacities: Whether you need a smaller electromagnet for compact spaces or a larger model for heavy-duty applications, we offer a variety of sizes and lifting capacities.

- Temperature Handling: Some models are designed to handle high-temperature environments (up to 700°C), ideal for scrap steel in furnace operations.

- Seamless Integration: Our electromagnets can be tailored to seamlessly integrate into your existing operations, maximizing efficiency and minimizing disruptions.

Proven Performance

With years of experience in the industry, our electromagnets have proven themselves in real-world applications, earning the trust of companies worldwide.

- Global Trust: Our electromagnets are trusted by industries across the globe for safe and efficient handling of scrap steel.

- Efficient Scrap Handling: Designed to ensure fast and effective lifting and transport of scrap materials, improving overall throughput.

- Long-Lasting: Our electromagnets are built to last, reducing downtime and maintenance costs, ensuring continuous operation with minimal interruptions.

Comprehensive Equipment Compatibility

Our electromagnets are compatible with both overhead and gantry crane systems, making them versatile and adaptable for a variety of operational settings.

- Overhead Cranes: Perfect for scrap yards and steel plants where overhead cranes are needed for efficient and safe material handling.

- Gantry Cranes: Ideal for larger scrap yards, warehouses, or areas where mobility across wide spaces is required.

- Versatility in Facilities: Whether working in confined spaces or large open yards, our electromagnets provide flexible solutions for all types of scrap handling environments.

Certifications and Quality Standards

International Standards

Our electromagnets meet and exceed international safety and quality standards, ensuring that they deliver reliable performance every time.

- Compliance with Industry Standards: Our products adhere to global safety, environmental, and quality certifications, ensuring they are safe to use and high-performing.

- Reliable Operation: By complying with international standards, our electromagnets offer the reassurance of safe, reliable, and efficient operation in any environment.

Testing and Reliability

Before reaching our customers, all electromagnets undergo rigorous testing to ensure they perform reliably under demanding conditions.

- Real-World Testing: We test each unit for durability and performance in environments similar to those where they will be used, ensuring reliability and longevity.

- Proven Performance: Only after passing stringent testing procedures do our electromagnets get approved for use, guaranteeing dependable service for your operations.

Pricing and Availability

Competitive Pricing

We offer high-quality electromagnets at prices that are affordable for businesses of all sizes, ensuring that you receive excellent value for your investment.

- Cost-Effective Solutions: We understand the importance of staying within budget, which is why our electromagnets are priced to offer a balance of quality and affordability.

- Reducing Operational Costs: The energy-efficient design of our electromagnets helps reduce ongoing operational costs, providing significant savings over time.

Customization Options

We provide pricing tailored to meet the unique needs of your business. Custom configurations are available to meet specific requirements, whether for lifting capacities or specialized material handling.

- Tailored to Your Needs: Pricing will vary depending on the electromagnet size, lifting capacity, and other customization options, ensuring you get exactly what you need.

- Value-Driven Pricing: Get the most out of your investment with customized solutions that meet your operational requirements without overspending.

Availability and Lead Times

Our electromagnets are available for quick delivery, ensuring that you can get your equipment when you need it.

- Stock Availability: We maintain a stock of electromagnets ready for shipment, so you don’t have to wait for production times.

- Fast Turnaround: We understand the urgency in your operations, so we strive for quick delivery and setup to avoid downtime.

- Reliable Lead Times: Our team provides accurate delivery times to help you plan accordingly and ensure your operations are running smoothly.

This section elaborates on the reasons to choose our electromagnets, emphasizing the expert engineering, customization options, proven performance, and compliance with international standards. It also highlights competitive pricing, availability, and fast lead times to help businesses get the right equipment quickly and affordably.

This section highlights the reasons to choose our electromagnets, focusing on their expert engineering, tailored solutions, proven performance, and compliance with international standards. We also offer competitive pricing, availability, and customization options to meet the unique needs of your facility.

FAQs

Common Questions

- What is the installation process for the electromagnets? The electromagnets are designed for easy installation, whether mounted on overhead or gantry cranes. Our team provides guidance for smooth setup, ensuring everything works as expected.

- Can I customize the lifting capacity? Yes, we offer a variety of customization options for lifting capacities to suit your specific scrap steel handling needs. Speak with our team to determine the best fit for your application.

- How do I maintain the electromagnet? Maintenance is straightforward. Regular inspection, cleaning, and testing are recommended to ensure optimal performance. Our team can also provide advice on specific maintenance requirements.

If you're ready to enhance your scrap steel handling operations with powerful, efficient, and reliable electromagnets, contact us today for a quote or consultation. We’re here to provide the perfect solution tailored to your needs. Get in touch now!

How to Get Electromagnetic Lifting Equipment for Steel Balls, Cast Iron Ingots, and Scraps

When seeking the right electromagnetic lifting equipment for Steel Balls, Cast Iron Ingots, or Scraps, it's crucial to consider specific operational requirements and material handling capabilities. Different types of lifting equipment are designed to handle various material characteristics, such as weight, magnetic properties, and environmental conditions. By clearly defining these parameters, you can ensure a more accurate quotation, fast processing, and better equipment selection.

Key Parameters to Consider for a Quote:

Lifting Capacity:

- Steel Balls: Steel balls can vary in size and weight, and the electromagnet should be capable of lifting them safely and efficiently. Indicate the weight and quantity of steel balls to be lifted at a time.

- Cast Iron Ingots: Cast iron ingots often require heavy-duty electromagnets. Specify the maximum weight and dimensions of the ingots to be handled.

- Scraps: Scraps can vary widely in weight, size, and composition. For scraps, provide a range of material types and weights to be handled, as the electromagnet design may differ based on scrap composition (e.g., mixed metals, rust, or coatings).

Material Dimensions and Shape:

- Steel Balls: Steel balls come in various sizes, so it's important to specify the diameter range of the balls. This will help determine the electromagnet’s design and the magnetic field strength required.

- Cast Iron Ingots: The size and shape of ingots (e.g., rectangular, square, or irregular) influence the size and number of coils or magnets needed for efficient lifting.

- Scraps: Provide dimensions or estimates of the scrap's largest and smallest pieces. The electromagnet’s size, lifting power, and efficiency are optimized based on this data.

Voltage and Current Requirements:

- Different electromagnets operate with different voltage and current specifications. You will need to determine whether the lifting system will be used in a low or high-voltage environment. Provide your facility's available power and whether you require AC or DC power.

- Additionally, the current (A) ratings for cold and hot operations must be provided. For instance, the cold current rating is for when the electromagnet is not under load, while the hot current is for maximum load conditions.

Operating Environment:

- Temperature: High temperatures (from hot metal handling) can affect the efficiency and longevity of electromagnets. If your application involves handling hot materials, it's important to mention the maximum temperature range the equipment will face.

- Corrosive or Harsh Conditions: If your scrap yard or manufacturing environment involves exposure to chemicals, moisture, or salt air (e.g., coastal regions), indicate this so that the electromagnet can be coated with corrosion-resistant materials.

- Outdoor vs. Indoor Use: If the electromagnet is to be used outdoors, specify the environmental conditions like humidity, temperature extremes, and exposure to weather elements. Outdoor electromagnets may need additional weatherproofing or special coatings.

Magnetic Field Strength and Holding Force:

- Different materials require different magnetic field strengths. For example, cast iron ingots may need a stronger magnetic field compared to steel balls due to their irregular shape and density. Specify whether your materials require heavy-duty magnetic lifting or if standard field strengths will suffice.

Duty Cycle and Power Efficiency:

- The duty cycle refers to how long the electromagnet can operate at full capacity before it needs a break to cool down. If your application requires continuous lifting, such as in high-throughput scrap yards, you will need an electromagnet with a high duty cycle rating.

- Power efficiency is also important in managing operating costs. An electromagnet with higher efficiency will consume less energy, making it more cost-effective in the long run.

Customization Requirements:

- If you have unique needs (e.g., integration with existing lifting equipment, need for custom power ratings, or special lifting configurations), be sure to provide these details.

- Customization options might include electromagnets with adjustable lifting capacities, varying lifting heights, or those designed for special applications such as hazardous material handling.

Safety Features:

- Electromagnets can come with built-in safety features such as fail-safe circuits, overload protection, and manual or automatic release mechanisms. If you are working in a hazardous environment, discuss the need for additional safety features.

- Additionally, remote control operation or automatic magnet switching may be required for ease of use in dangerous or challenging environments.

Requesting a Quote:

To receive a precise quote, please provide the following information:

- Weight and Dimensions: Details about the specific steel balls, cast iron ingots, or scrap materials, including their weight and size.

- Voltage and Current: The electrical specifications based on your facility's available power supply.

- Duty Cycle: Indicate how frequently the electromagnet will be used in continuous operations.

- Environmental Conditions: Provide information on whether the equipment will be used indoors, outdoors, and in environments with extreme temperatures or corrosive agents.

- Customization Options: Let us know if you require any unique design features or if you are working with specialized lifting scenarios (e.g., high-temperature material handling).

Once we receive these parameters, we can provide a detailed quote tailored to your operational needs, ensuring you get the best value for your investment in electromagnetic lifting equipment.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch