Electric Single Girder EOT Crane Installation Guide

HD type Single Girder Overhead Crane

The HD series European standard electric single girder overhead travelling cranes are designed with maximum rigidity for a minimum crane deadweight, reducing the load on the travelling crane runway. As a result, the European style single girder electric hoist crane is a cost-effective material handling crane design for warehouse plant and an ideal solution for light duty material handling in your workshop.

The main parameters of the European type single girder hoist crane are as follow:

- Type of Overhead Travelling Crane: HD European hoist crane with single girder overhand crane configuration

- Lifting Capacity of Single Girder Hoist Crane :3.2 ton to20 ton ( 5 ton, 8 ton, 10 ton, 12.5 ton, 16 ton and 20 ton)

- Span of European hoist crane :7.5 m to 28.5 m

- Lifting Height of overhead hoist crane :6m to 18m

- Working Class of European overhead crane :A5

- Ambient Temperature of European crane :-20℃ to 40℃

More information about the European style single girder overhead crane, please contact us.

European Style Electric Single Girder eot Crane Installation Guide

The installation of an electric overhead travelling crane is mainly consisted of three parts, which including the run way beam or crane bearing beam installation, crane rail system and power system, and overhead crane main structure assembly, etc.

- Main parts: Runway Beams,

- Rails system and Busbar system,

- Main structure of Overhead Bridge Crane including the Main girder, End beams and electric hoist,etc.

Part One: Runway Beam Steel Structure

Weld the runway beam on the columns brackets. Connect the bearing beams with connection bolts.

The error standard of the bearing beams is the same as the rail.

Crane supporting steel structure and column brackets

Weld crane runway beam to column brackets - runway installation

Part Two: Rail and Busbar

Rail installation

The track must be laid according to the span of the single girder overhead crane. The track laying standard is: height error within ±10mm, span error within ±5mm. The gap between the two tracks must be misaligned by about 3m.

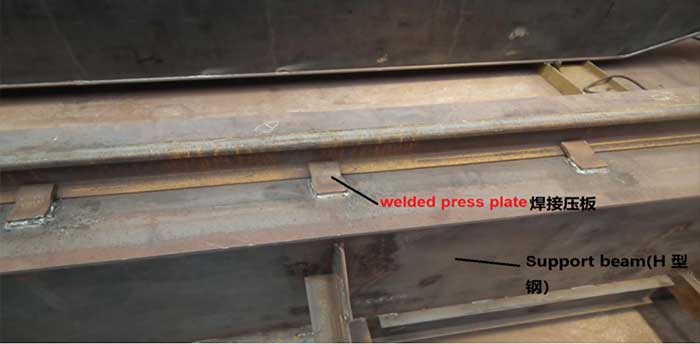

There is a 0.3mm gap between the two rails. The rails are connected by splints and tightened. The rail is welded on the bearing beam by the pressure plate, and the pressure plates are welded symmetrically with an interval of 700mm. The ends of the rail connection must be welded with double pressure plates.

Weld presss plats ton the supporting beams - overhead crane rail installation

Bolt the clamp plates to connect the crane rail sections.

Crane rail finished installation

Busbar installation

- Seamless type busbar installation: The busbar is the power feeder system of the crane. The busbar components are composed of tensioners, brackets, buckles and sliding lines.

- Install the hanger on the bracket, and then weld the bracket to the bearing beam, the distance between the two brackets is 1.5m.

- Install the busbar on the buckle, and tighten the two ends with a tensioner (the tensioner bracket is drilled with a 50×50 angle iron and welded to the end of the bearing beam, the customer must prepare materials on site)

- Straighten the busbar, make the busbar parallel to the rail, tighten the buckle nut, the level of the sliding line is ±5mm.

Overhead crane busbar installation

Busbar tensioner installation

Overhead crane busbar installed

Part Three: Main structure of Overhead Crane installation:

- Use bolts to connect the main beam

- Assemble the end beam and the main beam to complete the assembly and installation of the crane bridge.

- Install the electric hoist.

- Noted: Adjust the gap of the hoist wheel flange to make it suitable for the main beam of the crane, with a gap of 3-5mm

- Fix the electrical box of the overhead crane to one end of the main crane girder.

- Connect electrical appliances and motors according to the drawings.

- Noted: this part will be connected to the aviation plug before leaving the factory, and you only need to insert the corresponding position on site)

- After commissioning the overhead crane, use the truck crane to place the eot crane on the rail.

- Installation of the current collector, the collector is installed under the busbar, and the bracket is welded to the bearing beam.

Note: The above installation must be operated by professionals.

Demonstrations of overhead crane main structure installations

1.Use bolts to connect the main beam

Connects the main girder together by bolts and strenthed steel plates.

Main girder of the single girder eot crane connected

2.Connect the end beam and the main beam with bolts

End carriage intallation

End carriage finished installation

3.Install the electric hoist

Electric wire rope hoist installed on the main girder

4.Fix the electrical box of the crane to one end of the crane

Electic box installed on one end of the main girder

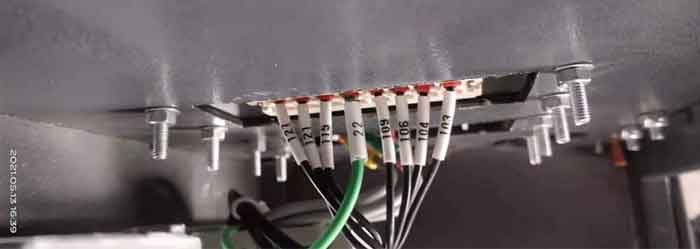

5.Connect electrical appliances and motors according to the drawings

Electrics installations

Connecting the according your drawings

Overhead driving motor installation

6.After commissioning the crane, use the truck crane to place the crane on the rail.

Place the overhead crane by truck crane after commissioning

7.Installation of the current collector

overhead crane current collector installation