Gantry Crane Buyer Guide: How to Buy Gantry Crane for Your Use ?

When purchasing a gantry crane, it's important to understand the different gantry crane types, specs, parts, and selection criteria so you can choose the one that will work best for your application. An affordable custom gantry crane is available from 0.25 tons to 550 tons from gantry crane engineers. In the following, the tailed information will be discussed in the buyer guide of a gantry crane.

Truss cranes are ideal for windy environments due to their high safety, low cost, and light weight. Specifications for a truss gantry crane: Crane Truss Lifting Capacity: 1-50 tons, Span Length: 12-35 meters, Working Class: A5, A6. To buy a gantry crane, please leave a message below.

A double girder gantry crane is used for general handling and lifting work in an open warehouse or along a rail line. Specifications of a gantry crane: Lifting Capacity: 5-550 tons, Span Length: 12-35 meters, Working Class: A5, A6. To buy a gantry crane, please leave a message below.

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

What to Consider on Goliath Crane Buying

Custom Crane Design for You

The following factors should be taken into account when thinking about buying a gantry crane: When buying a gantry crane, the first thing to consider is the industrial gantry crane's overall use scope, working frequency, utilization, rated lifting capacity, traveling span, lifting height, and other factors.

Selection of gantry crane types

You can choose a single girder gantry crane if the lifting capacity is less than 32 ton, the span is less than 35m, and there are no special use requirements. If you need a large width between the gantry legs, a high operating speed, or you frequently lift heavy and long objects, a double girder gantry crane is the way to go.

- Lifting capacity: The maximum lifting capacity of a gantry crane is 320 tons.

- Cantilever and crane span- Crane self-weight is significantly impacted by gantry crane span and gantry cantilevers. When making a choice, one should attempt to shorten the span while taking into account the requirements of the span series and the crane working conditions.

- Lifting height: Height at which a gantry crane is lifted: It is the separation between the spreader's top and lower limit positions.

- Crane span: Crane span is the measurement between the vertical centerlines of the wheels on either side of the crane.

Crane speed of gantry crane

Gantry crane each mechanism operating speed

- When the lifting mechanism motor is operating at its rated speed, the gantry crane's lifting speed is that at which the device is fully loaded.

- Gantry crane traveling speed is the speed at which the crane is moving when its motor is operating at its rated speed.

- The gantry crane's trolley travel speed is determined by the trolley travel mechanism's motor's rated speed.

Working duty of gantry crane

Working class: Indicators of the entire crane lifting full load level and lifting numbers degree, working class separated into eight levels, light duty (A1-A3), intermediate duty (A4, A5), heavy duty (A6, A7), and extra heavy duty (A8).

Wheel load is the most vertical force that the rated weight and trolley may exert on the crane's wheels when the gantry frame weight and trolley are in their most extreme positions.

Gantry crane services affects gantry crane buying

Crane services have an impact on your choice to purchase a gantry crane. Complete gantry crane services will relieve you of problems, especially after-sale problems, therefore you should confirm the following services before choosing to purchase a gantry crane.

Gantry Crane Purchase Plan, General Solution,Contract & Technical Agreement, Detailed Solution,Crane Manufacturing,Crane Delivery, Onsite acceptance, On-site Installation,Experienced Gantry Crane Engineer On-site Training, Quality Guarantee,Check and Maintenance

Gantry crane components and parts supply

When purchasing a gantry crane, the supply of the necessary parts and components of gantry crane is also important.

Single girder gantry crane kit

Double girder gantry crane kit

Semi gantry crane kit

Portable gantry crane kit

Advantages to buy a gantry crane

Why should you buy a gantry crane? What are the benefits of gantry cranes? It is possible to purchase a gantry crane at a cost-effective gantry crane cost. Consider the benefits of purchasing a gantry crane.

Companies are cautious about making large investments, particularly in the material handling industry, as the economy continues to struggle. Because large permanent overhead crane lifting solutions are expensive, businesses are looking for ways to solve their material lifting needs without making large investments. Gantry cranes are a great alternative to large, permanent crane systems because they can lift up to 10 tons and are completely mobile. As for heavy loads handling, the gantry cranes can be used to handle loads with capacity up 550 tons.

- Where an overhead crane or bridge is impractical, gantry cranes with a runway on the ground can be used.

- When compared to an overhead crane system, gantry cranes are more cost-effective.

- Gantry cranes have many different uses. Both indoors and outdoors can use a gantry. When an overhead crane's wheel loads are too much for an existing manufacturing structure to support, when weights need to be handled outside the crane's span.

- The gantry crane is versatile. Gantry crane may be easily tailored to your needs.

- Power drive kits are available.

Parameters needed to buy gantry cranes

When purchasing a gantry crane, the following main parameters of gantry cranes are required:

- Gantry crane types include: Gantry crane, single or double girder? Crane with a semi-gantry? Crane with trusses? A mobile gantry crane?

- Ultimate load lifting capacity of a gantry crane is ____tons.

- The distance between the railway center and the gantry crane span is ___ meters.

- Cantilever gantry crane: with cantilever on both sides or just one? Cantilever or no cantilever?

- The lifting height of a gantry crane: meters (the hook height refers to the distance from the ground to the hook center when the hook is at the maximum position. )

- Application/use of gantry crane:

- Crane control : panel control, cabin control, and remote control

- Power supply : _____V ___Hz ___Ph

Please submit your gantry crane inquiry with the parameters listed so that we can send you a more specific gantry crane quotation with a more specific gantry crane price.

Your Trusted Gantry Crane Manufacturer & Supplier

Full Gantry Crane & Goliath Crane Buyer Guide

3 - 550 Ton Indoor & Outdoor Gantry Crane

Full gantry crane

Full gantry crane systems are the most common overhead material handling crane configuration, consisting of two supporting legs that ride on rail embedded on the top surface of the floor. They typically travel in a straight line in a designated work area. Motorized equipment such as scissor lifts, fork lifts, carts, and trucks can pass underneath the gantry crane girder.

I. Customer Information

Name | |

Customer Company | |

Phone | |

Address |

2. Application Occasion

Lifting material | ||

Temperature | Highest temperature | _______0C |

Lowest temperature | _______0C | |

3. Gantry Crane Dimensions

A - Span(m) | ||

B - Left cantilever(m) | ||

C - Left cantilever(m) | ||

D - Lifting height(m) | Main hook | |

Auxiliary hook | ||

E - Railway length(m) | ||

4. Gantry Crane Specification

SPECIFICATION | Option | |

Beam Configuration | A. Single Beam B. Double Beam | |

Capacity(ton) | Main hook | |

Auxiliary hook | ||

Speed(m/min) | Main hook | A. Single ____ B. Double ____ /____ C. Inverter Control ____--____ |

Auxiliary hook | A. Single ____ B. Double ____ /____ C. Inverter Control ____--____ | |

Cross travel | A. Single ____ B. Inverter Control ____--____ | |

Long travel | A. Single ____ B. Inverter Control ____--____ | |

Working Class | Main hook | A. M3 B. M4 C. M5 D. M6 E. M7 F. M8 |

Auxiliary hook | A. M3 B. M4 C. M5 D. M6 E. M7 F. M8 | |

Cross travel | A. M3 B. M4 C. M5 D. M6 E. M7 F. M8 | |

Long travel | A. M3 B. M4 C. M5 D. M6 E. M7 F. M8 | |

Industrial Voltage | ____V ___Hz 3phases | |

Control Mode | A. Remote Control B. Pendent Line Button Control C. Cabin Control | |

Hook Attached Accessory | A. C-hook B. Grab Bucket C. Magnet D. Magnet spreader E. Ladle D. Other____ | |

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Semi-gantry Crane Buying Guide

Economical Single Leg Gantry Crane for Sale

What exactly is a semi-gantry crane?

A semi-gantry crane is a type of crane that combines an overhead crane and a motorized gantry crane design. One end of the gantry crane span is supported on the top of building structure runway , and the other end is running on the ground crane beam.

Semi-gantry crane

Semi-gantry cranes are small or middle-sized cranes that are frequently used for material handling, loading and unloading in warehouses, and outdoor locations. Specifications of a gantry crane: Product Type: BMH, Span Length: 8-20m, Lifting Capacity: 2-10t, Working Class: A3, A4. Send us a message to buy gantry crane.

How to choose your semi-gantry crane

In general, the semi-gantry crane's lifting capacity determines the type of crane beam: single girder, double girder, or box girder. Single-girder semi-gantry cranes are designed to handle loads of about 20 tons, while double-girder semi-gantry cranes can handle loads of more than 20 tons.

It is critical to select the best material handling solution. But how do you choose the best semi-gantry crane for your needs? If the building is already constructed, the most appropriate overhead gantry crane should be chosen based on the specific application conditions and the size of your building. The following suggestions will help you find the best crane for your needs.

1. Customer Information

Name | |

Customer Company | |

Phone | |

Address |

2. Application Occasion

Lifting material | ||

Temperature | Highest temperature | _______0C |

Lowest temperature | _______0C | |

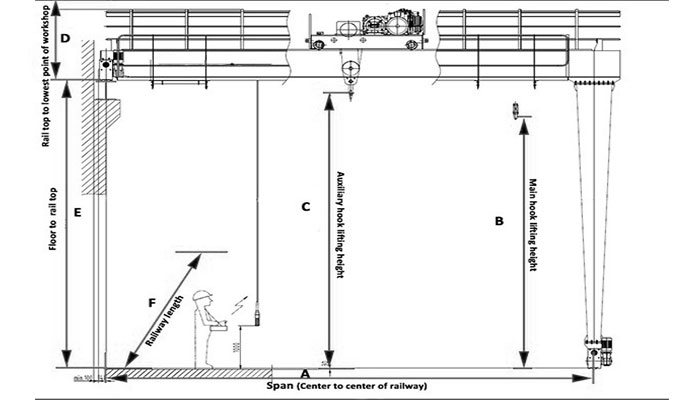

3. Semi-gantry Crane Dimensions

A - Span(m) | |

B - Main hook lifting height(m) | |

C - Auxilliary hook lifting height(m) | |

D - Rail top to lowest point of workshop(m) | |

E - Floor to rail top(m) | |

F - Railway length(m) |

4. Semi-gantry Crane Specification

SPECIFICATION | Option | |

Beam Configuration | A. Single Beam B. Double Beam | |

Capacity(ton) | Main hook | |

Auxiliary hook | ||

Speed(m/min) | Main hook | A. Single ____ B. Double ____ /____ C. Inverter Control ____--____ |

Auxiliary hook | A. Single ____ B. Double ____ /____ C. Inverter Control____--____ | |

Cross travel | A. Single ____ B. Inverter Control ____--____ | |

Long travel | A. Single ____ B. Inverter Control ____--____ | |

Working Class | Main hook | A. M3 B. M4 C. M5 D. M6 E. M7 F. M8 |

Auxiliary hook | A. M3 B. M4 C. M5 D. M6 E. M7 F. M8 | |

Cross travel | A. M3 B. M4 C. M5 D. M6 E. M7 F. M8 | |

Long travel | A. M3 B. M4 C. M5 D. M6 E. M7 F. M8 | |

Industrial Voltage | ____V ___Hz 3phases | |

Control Mode | A. Remote Control B. Pendent Line Button Control C. Cabin Control | |

Hook Attached Accessary | A. C-hook B. Grab Bucket C. Magnet D. Magnet spreader E. Ladle D. Other____ | |