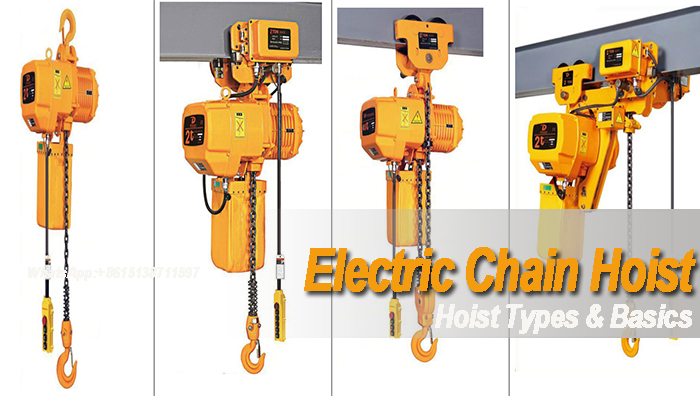

What is Electric Chain Hoists? Overview of Electric Chain Fall Hoist & Chain Hoist

What is electric chain hoist ?Electric chain hoist is used to lift or lower materials or loads. To lift, lower, and accelerate or slow the speed of the hoist, an electric motor and controller are used. Electric hoists are suited for usage in industrial production lines and small machine shops that demand more frequent and faster lifting.

During hoisting or lowering, all chain hoists provide pure vertical lift, which means the load does not move away from the hoist centerline.

Main specifications of electric chain hoists

No crane without hoists - they are the heart of all crane systems.

Main specifications of electric chain hoists

- Lifting Capacity of Electric Chain Hoists:1t to 32t

- Lifting Height of Electric Chain Hoists:6m to 48m

- Lifting Speed of Electric Chain Hoists:0.4/1.2 to 2.4/11.8m/min

- Working Class of Electric Chain Hoists:M3, M4, M5

- Ambient Temperature of Electric Chain Hoists:-20℃ to 40℃

The typical electric chain hoist has a capacity of 500 kg to 32 tons, but it may be customized to have a capacity of 50 tons. The modular architecture provides for a wide range of lifting rates, from 0.4/1.2 to 2.4/11.8 m/min, with hook paths up to 48 m. Electric chain hoists that are used on a daily basis at workstations must be durable, dependable, and low-maintenance.

Precision lifting, a safety sliding clutch, and quick plug-type connectors are all standard features, as is the tried-and-true robust direct control for GM2, GM4, and GM6 sizes. Please do not hesitate to contact us if you require additional information.

Wide Application

The electric chain hoist is widely used to improve material handling efficiency. Molds, machinery manufacture, warehousing logistics, shipbuilding, bridge construction, and other industries, factories, and other particular purposes all employ electric chain hoists.

Electric chain hoists & electric chain fall hoists have a wide application. The electric chain fall hoists are mainly used in various types of plants, factory, storage, wind-power stations, logistics, ports, construction field, and other places or workshops for loading & unloading in factories,warehouses, or other workshops for machinery installation, dispatching goods, equipment maintenance with capacity of 500 kg, 1 ton, 2 ton, 3 ton, 5 ton ,10 ton 20 ton , 35 ton ton, and customized .

Generally, the electric chain fall hoists and chain blocks are ideal hoisting solutions for low headroom applications , high production working environments, and workshops or workstations required periodic lifting and positioning. With different mountings ,ie, hook mounted, lug mounted, trolley mounted, the electric chain fall hoists are widely used on overhead cranes, gantry cranes, jib cranes, monorail cranes & H & I beam cranes, etc. All of our electric chain fall hoist cranes can be customized for your specific setup with good and reliable performances to make the best value of your investment!

Single girder electric chain fall hoist crane

The electric chain fall hoist crane is a single girder overhead travelling crane, equipped with electric chain fall hoists as the hoisting system for material handling with capacity up to 16 ton.

Double girder electric chain fall hoist crane

The double girder electric chain fall hoist crane is a double girder overhead crane, equipped with electric chain fall hoists as the hoisting system with capacity up to 32 ton designs.

Slewing jib chain hoist cranes

Slewing jib hoist cranes is ideal for short distance material handling, with various designs and configurations are available such as free standing jib hoist crane, wall mounted and wall travelling jib hoist crane, and port jib hoist crane, etc.

Electric chain hoist kbk crane

Electric chain hoists are perfect for light duty kbk cranes, monorail kbk cranes , suspension kbk crane, and free standing kbk crane either in flexible crane configuration or in rigid crane configurationl.

A frame gantry electric chain fall hoist crane

For A frame gantry cranes, electric chain fall hoists also can be used as the hoisting system of a single girder gantry crane design and a double girder gantry crane design with a double girder hoist trolly.

Portable gantry electric chain fall hoist crane

Manual trolley electric chain fall hoists are widely used with the portable gantry crane or small gantry cranes which is for light duty material handling. With your requirement, the electric motor chain hoist portable gantry cranes are also available. Contact us to get customized portable electric chain fall hoist crane.

- Jib cranes or workstation cranes with free-standing or wall/pillar mounted design are ideal for applications where material handling is centered in a specific working areas with rotating up to 360 degree.

- A monorail crane is light overhead single beam crane, straight or curved, widely in applications such as manufacturing automation and production lines.

- An A frame gantry crane is an I-beam or box shaped girder that runs on ground rails in a defined space to assist heavy loads handling.

The electric chain fall hoists are able to cooperate with various types of overhead travelling cranes to meet your material handling requirements in many applications with high safety,and efficiency. The electric chain fall hoist cranes will be a good and cost-effective options for you. Contact us to check the chance that we may save your money.

As an electric chain fall hoist & crane manufacturer and suppliers, we can ensure your electric chain fall hoists cranes are operating at its very best which are very much suitable to your application conditions. If you need an electric chain fall hoists, either standard chain hoists or custom designed electric chain fall hoists with features of spark resistant, explosion proof, or others please feel free to contact us.

Types of electric chain hoist

Hook mounted chain fall electric hoist

Hook type - With fixed hook on the top of electric chain hoists shell which are usually used in fixed lifting places, such as freight elevators. Its advantage is that it is relatively stable, but its disadvantage is that it cannot run.

Electric trolley chain hoist

Electric trolley type - with electric motorized trolley makes the horizontal travelling more efficient with lifting capacity up to 35 tons.

Maual trolley electric chain hoist

Manual trolley type - with electric hand operated trolley which is wiedly used for application with less horizontal movement with hoisting capacity up to 20 tons.

Low headroom chain electric hoist up to 35 ton

Low hearoom chain hoist - with low headroom hoist design with are widely used in application with limited workshop or facility but with higher lifting requirement.

Main components of electric chain hoists

Shell

It is built of a light aluminum alloy shell that is both light and tough. The cooling fin has been built specifically to provide rapid heat dissipation of up to 40% and prolonged service. Chemical plants and electroplate factories are examples of sites where the integral enclosed structure can be used. To obtain electric chain hoist parts, please contact us.

Motor

Specially designed for the electric chain hoist and manufactured by Dedong Motor Factory. There is no need for upkeep. Class F insulation. IP55 is the highest level of protection. Inside, there is a magnetic breaking system on the side.To obtain electric chain hoist parts, please contact us.

Electric trolley

Compact and easy to install, high strength low alloy steel structure with electric motor and high-wearing feature wheels. To obtain electric chain hoist parts, please contact us.

Chain

Imported super heat-treatable aluminum alloy chain will be used for the chain. It may be utilized safely in hazardous situations like rain, sea water, and chemicals. To obtain electric chain hoist parts, please contact us.

Chain bag

When the lifting chain is free to slide, it is stored in a high wear-resistant nylon material to prevent it from being entangled with the main card or the chain. To obtain electric chain hoist parts, please contact us.

Hook

It's a form of hot forging that has ideal strength and is difficult to break. The bottom hook's operating safety is maintained by its 360-degree rotation and safety flap. To obtain electric chain hoist parts, please contact us.

Electrics

Inverse phase sequence protection device, Chint brand, China famous brand. To obtain electric chain hoist parts, please contact us.

Limit switch

The limit switch device is fitted where the weight is lifted on and off to automatically stop the motor and prevent the chains from exceeding the safety limit. To obtain electric chain hoist parts, please contact us.

Pendant with cable

Master Controller by Yueqing Brand, the best in China, with waterproof Push Button for UP, DOWN, Forward, Reverse, Start, and Emergency Stop. It is lightweight and long-lasting. To obtain electric chain hoist parts, please contact us.

Electric Hoist Service Classifications

SERVICE CLASSIFICATION | TOTAL EQUIPMENT RUNNING TIME | MAX. START/STOPS PER HOUR | TYPICAL AREAS OF APPLICATION | |||

H4 | Approaching 50% of the work period | 300 | High-volume handling Steel warehousing, machine shops, fabrication factories, mills, and foundries all have high-volume handling. Heat-treating and plating procedures can be cycled manually or automatically. | |||

H3 | Not to exceed 25% of the work period | 150 | General general machine shop, fabrication, assembly, storage, and warehousing where loads and operations are randomly dispersed, | |||

H2 | Not to exceed 15% of the work period | 75 | Light Loads and use are randomly distributed in machine shops, fabricating industries, and service and maintenance operations, with capacity loads handled seldom. | |||

Working principle of electric chain hoists

Chain wheels or rope drums are used in modern electric hoists to provide smooth functioning. To make lifting a load easier, they have a closed chain that looks like a loop. You may get these electric chain hoists for your construction and manufacturing firms. To make the load lifting operation easier, you must drag the chain.

An electric hoist must be installed on an I-shaped steel-rolled beam of the necessary height and span. The size of this I-beam varies depending on the span and the weight lifting capabilities of the electric hoist.

An electric hoist's first job is to turn on the hoist motor, lift the load to a certain height, and then trigger the trolley motor to move the weight. On a lifting procedure, there is an electromagnetic brake to prevent the load from falling.

Moving heavyweights from one location to another is a breeze using electric chain hoists. You can do it with a single button press. This user-friendly technology does not require a highly skilled operator to use. As a result, you can save money by not hiring professionals. In the long run, the entire operations will be affordable.

Maintenance tips and proper usage instructions for electric chain hoists

We've proposed some rules for using chains to reduce dangers. You will avoid any mishaps if you inspect your equipment on a regular basis.

Before using the electric chain hoist, you should apply oil to your chain. Your usage determines how often you should lubricate your chain and how much oil you'll need. The electric hoist chain moves at a speed of 2 to 15 meters per minute. The integrated braking mechanism guarantees that the chain rotates safely. Other instructions for these electric chain hoists can be found below.

- You must not use the hoist if you are not physically fit.

- Hook latch, load brakes, limit switch, and emergency stop are all safety features on your hoist. Before utilizing this hoist, make sure you are familiar with the gadgets.

- The hoisting equipment should not be re-rated, modified, or changed.

- In an explosive setting, never use your standard electric hoist system.

- Never believe that one of the welding electrodes is the hoist.

- You must not leave the load unattended when lifting it.

- Lifting a load that exceeds the capability of your electric chain hoist is dangerous.

- The inching action must not exceed the motor's rated start/stops limit.

The load chain's bottom hook, as well as the pendant button switch cable, must be vertically stable.

Choosing a reliable Electric Chain Hoist

Finding a dependable manufacturer and supplier of electric chain hoists is one of the most critical stages. However, in order to make the best decision, it is also necessary to consider the considerations listed below.

- The weight of the cargo to be hoisted dictates which hoists you will need to purchase.

- Lifting speed must be calibrated in order for goods to be loaded and unloaded successfully.

- Your working environment- Some factory settings can abrade your machinery. For example, if the temperature is extremely high, your hoist may begin to malfunction. Similarly, extremely low temperatures cause interior part cracking and freezing. Another risk of your system is frequent temperature fluctuations, which might lead to short circuits.

- Hoist height- You wish to lift your load to a certain height. This is a key consideration when selecting a hoist model. A container with an electric hoist is available. A longer chain and a larger container are indicated by the increased height. However, having too many huge containers can become a stumbling block in your load lifting operation.

- The duty cycle specifies the length of time you will use the hoist. This aspect has something to do with how long you live. As a result, the duty cycle duration is critical, as your system must distribute heat from motors.

Items to consider when selecting a hoist:

- Weight of load

- Power supply

- Speed of lifts

- Lifting height

- Frequency of lifts

- Duty cycle

The powered hoist industry uses a service classification system to help you select the proper hoist. See the chart below for details.

FAQs of electric chain hoists

1.Do you provide products that can be customized?

Thank you for your inquiry. Yes, because working conditions vary, all of our products are designed to meet specific requirements! So, if you provide us with additional information about the lift capacity, span, lift height, power source, and other specialties, we will provide you with a very quick price!

2.What information do I need to give when making an inquiry?

Thank you for your inquiry. We can prepare a more accurate solution for you if you supply additional information!

You require details such as lift capacity, control mode, lift height, power supply, and other specialties.

3.What is the electric hoist's maximum lifting capacity?

Thank you for your inquiry. The electric chain hoist has a maximum lifting capacity of 5 tons.

If this isn't enough to meet your needs at work,Please contact us so that we can recommend an other model.

4.My workplace has a restricted amount of space, can the electric chainhoist work for me?

Thank you for your inquiry. Other types of hoists are available for workshops with limited headroom. Our expert engineer is required to consult on the specific dimensions.

5.Do you have any additional lifting equipment?

Thank you for your inquiry. Yes, we can provide any type of lift tool you desire, such as an electric chain hoist, a hand chain hoist, an electric winch, or any specific product! These hoists come in a variety of models and characteristics.