How to ChooseRight Outdoor Electric Hoist for Double Girder Crane

Select the perfect outdoor electric hoist by considering environmental conditions, lifting height, power supply, and hoist trolley compatibility.

How to Choose the Right Outdoor Electric Hoist for Your Double Girder Crane

When it comes to selecting an electric hoist for your double girder crane, choosing the right one is crucial—especially if it's going to be used outdoors. Outdoor conditions can be tough on equipment, and if the hoist isn't suited for the environment, it can lead to issues down the road.

A well-matched hoist helps ensure that your outdoor crane runs smoothly, safely, and efficiently in all weather conditions. From harsh winds to extreme temperatures, the right hoist keeps everything working properly and reduces the need for constant repairs.

Here's why it matters:

- Reliability: You want a hoist that's tough enough to handle outdoor challenges like humidity, rain, or even salt air. A durable hoist will work consistently, even in the harshest environments.

- Safety: A hoist that's properly suited for outdoor use reduces the risk of accidents. It ensures your operations run smoothly, without breakdowns or safety concerns.

- Efficiency: When you have the right hoist, your crane will work at peak performance. It can lift, move, and handle the load without struggling, which saves you time and energy.

In short, the right outdoor electric hoist is essential for keeping your crane operation running well in any weather.

Assessing Environmental Conditions

When choosing an electric hoist for outdoor use, it's important to consider the environment where the crane will be operating. The outdoor conditions can greatly affect the hoist's performance and lifespan. Here are the key factors that can impact hoist operation:

Key Environmental Factors

- Humidity: High moisture levels can cause rust and corrosion, especially in metal components.

- Rain: Frequent exposure to rain can damage electrical parts if they aren't properly protected.

- Dust: Dust can build up inside the hoist, clogging moving parts and affecting performance.

- Salt Air: If your crane is near the coast, salt in the air can accelerate corrosion, even in high-quality materials.

- Extreme Temperatures: Whether it's freezing cold or scorching heat, temperature extremes can affect the mechanical and electrical systems of the hoist.

Impact of Coastal Areas and High Humidity

If your crane is located near the ocean or in an area with high humidity, these factors will influence the hoist's longevity and maintenance needs.

- Salt Air: Salt can easily corrode the hoist's metal parts, causing rust and damage over time. The closer you are to the ocean, the more protection the hoist needs.

- High Humidity: Excess moisture can cause electrical issues, rust on components, and even short-circuits if the hoist isn't built for these conditions.

Protective Covers or Shells

A special protective cover or shell is essential to ensure that your hoist lasts in tough weather. These covers help in several ways:

- Corrosion Resistance: Protects the hoist from rust caused by moisture and salt air.

- Weather Protection: Guards electrical components from rain and dust, preventing damage and extending the hoist's life.

- Temperature Protection: Helps maintain the hoist's internal components at an optimal temperature, especially in extreme weather conditions.

In short, considering these environmental factors and choosing a hoist with the right protection will keep it running smoothly, even in the harshest conditions.

Determining the Correct Lifting Height

When buying an electric hoist for your double girder crane, one of the most important factors to consider is the lifting height. This refers to the vertical distance the hoist will need to lift the load. In your case, you mentioned needing 8 meters of lifting height, but it's important to specify this from the start, as it impacts many aspects of the hoist's design and performance.

Why Lifting Height Matters

The lifting height influences the hoist in several ways:

- Hoist Design: The hoist must be designed to handle the required lifting height, which affects the overall size and capacity. A higher lifting height might require more powerful motors or additional structural support.

- Lifting Capacity: As the lifting height increases, the hoist's load-carrying ability might need adjustments. If your crane needs to lift heavier loads at greater heights, you'll need a hoist that can handle both the weight and the distance.

- Crane Performance: The lifting height impacts how smoothly and efficiently the crane operates. Too short a height can limit your lifting range, while too tall a height can reduce the hoist's stability and precision.

Practical Examples of Lifting Heights

- Low Lifting Heights (under 6 meters): For smaller or more compact cranes, a shorter lifting height means a lighter and more straightforward hoist design. It's typically suited for applications where you don't need to lift extremely heavy loads or perform high-precision lifting.

- Medium Heights (6 to 10 meters): This is the range where you start seeing more robust hoist designs. For example, an 8-meter lifting height, like in your case, will require a hoist with a balanced motor and lifting mechanism to ensure smooth operation. It's important that the hoist can lift loads efficiently and at a safe pace.

- High Lifting Heights (above 10 meters): For taller lifts, hoists need additional features like extended lifting ropes, reinforced gears, and stronger motors. The crane's stability and the hoist's performance also need to be carefully balanced to ensure safety at greater heights.

In short, specifying the exact lifting height helps in customizing your hoist to match the exact needs of your crane and application. The right lifting height ensures that the hoist performs efficiently, safely, and within the design limits of the crane.

Ensuring Power Supply Compatibility

When selecting an electric hoist, it's crucial to ensure that its power supply is compatible with your crane system. The power supply requirements, such as voltage, frequency, and phase, directly affect the hoist's operation and efficiency. Here's an overview of these key aspects:

Typical Power Supply Requirements

- Voltage: The hoist needs to match the voltage supplied by your power grid. Common options are 480V or 230V, depending on your region and the power requirements of your crane system.

- Frequency: The frequency, often either 50Hz or 60Hz, must align with the local electrical grid standard. The hoist must be designed for the correct frequency to ensure proper motor operation.

- Phase: Most industrial hoists operate on 3-phase power, which provides consistent and efficient energy for heavy lifting. This is typically the standard for cranes, though single-phase systems may be used in smaller or less demanding applications.

How to Determine the Correct Power Supply

To make sure your hoist operates at peak efficiency, you need to confirm that the power supply matches the hoist's requirements. Here's how:

- Check Local Power Supply: Know the voltage (e.g., 480V or 230V), frequency (50Hz or 60Hz), and phase (3-phase) in your location or facility. This information can usually be found on your electrical system or by consulting with your local power provider.

- Hoist Specification: The hoist you choose must be designed to handle the voltage, frequency, and phase supplied in your region. It's essential that the hoist matches these specifications to avoid performance issues.

- Power Supply Compatibility with Hoist Motor: Ensure that the motor of the hoist is rated for the specific power conditions you have. For instance, a 480V hoist will not perform properly on a 230V supply, and vice versa.

Adapting Hoists to Different Power Supply Conditions

In some cases, the power supply in your location may differ from the hoist's requirements. If that's the case, there are solutions available to adapt the hoist to your power conditions:

- Voltage Converters: If the hoist requires a different voltage, you can use a voltage converter or transformer to adjust the supply.

- Frequency Converters: If your region uses a different frequency than what the hoist is designed for, you may need a frequency converter to ensure proper operation.

- Phase Converters: In cases where you're using a single-phase power supply but need a three-phase system for the hoist, a phase converter can be used to convert the power and ensure smooth operation.

Ensuring your hoist's power supply is compatible with your electrical system is key to avoiding damage, ensuring smooth operation, and maximizing efficiency. By confirming the voltage, frequency, and phase, and adapting when necessary, you can ensure that your hoist performs at its best without any hiccups.

Double girder crane hoist trolley - more types of double girder crane hoist and trolleys

Matching the Hoist Trolley with Your Crane

When purchasing a hoist for your double girder crane, one of the most important considerations is making sure the hoist trolley is compatible with your existing crane system. This step is crucial for ensuring smooth operation, stability, and safety during lifting operations.

Why It's Critical to Match the Hoist Trolley to Your Crane

The hoist trolley is the component that moves the hoist along the crane's bridge. If the trolley is not compatible with your crane, you may face issues like:

- Improper Fit: If the trolley doesn't match the crane's design, it can lead to poor movement or even jamming. This can affect crane performance and cause delays or safety hazards.

- Reduced Efficiency: A mismatched trolley could cause friction or misalignment, making the hoist move less smoothly and increasing wear and tear on both the hoist and crane.

- Safety Risks: A trolley that's not properly fitted can lead to instability, making it more difficult to control the load and increasing the risk of accidents.

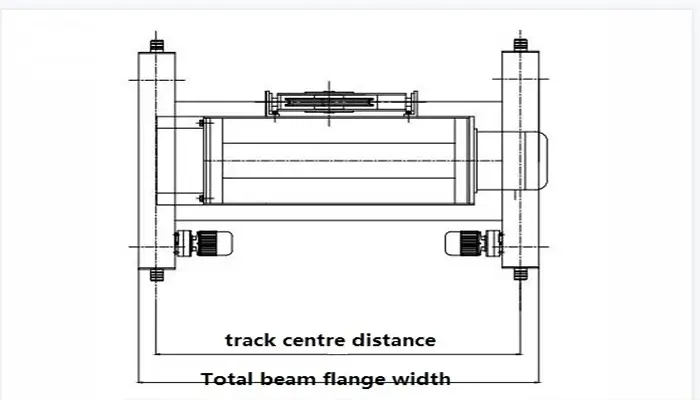

The Role of Track Center Distance

One important factor in ensuring compatibility is the track center distance. This refers to the distance between the tracks on which the hoist trolley moves. The track center distance impacts the following:

- Movement: If the track center distance is too wide or too narrow for the hoist trolley, it can affect how smoothly and evenly the trolley moves along the crane.

- Stability: The correct track center distance ensures that the trolley stays stable on the tracks and doesn't sway or become misaligned during operation.

- Safety: Correct alignment of the trolley with the tracks ensures that loads are lifted and moved safely without any risk of tipping or unbalanced movements.

Track center distance or Track gauge or rail gauge

Requesting Photos of the Crane and Hoist Trolley

To make sure everything fits correctly, it's highly recommended to provide photos of your existing crane and hoist trolley. This helps in the following ways:

- Accurate Compatibility Confirmation: Photos allow us to verify the track center distance and the overall size and design of the crane and trolley, ensuring everything matches.

- Customization: With clear images, we can make any necessary adjustments to the trolley or hoist design to ensure a perfect fit.

- Faster Process: Sending photos speeds up the process of confirming compatibility and helps avoid errors that could delay your project.

In summary, matching the hoist trolley with your double girder crane is essential for safe and efficient operations. Ensuring the correct track center distance and requesting photos for accurate confirmation will help avoid any compatibility issues and ensure smooth, safe lifting.

Customizing for Outdoor Conditions

When selecting an electric hoist for outdoor use, customization is key to ensuring it can handle the tough conditions it will face. Outdoor environments can be harsh, with elements like rain, dust, salt air, and extreme temperatures all taking their toll on equipment. Here's how to customize your hoist for the best performance in outdoor settings:

Custom Features for Outdoor Electric Hoists

To make sure your hoist can handle these conditions, it's essential to incorporate specific features designed to protect it:

- Protective Covers: These covers shield the hoist's sensitive electrical components from exposure to rain, dust, and debris. They act as a first line of defense, ensuring that the motor, wiring, and control systems remain safe and functional, even in challenging weather.

- Weather-Resistant Components: Key parts like the hoist frame, motor housing, and electrical connections should be made of weather-resistant materials to prevent rust, corrosion, and wear. These materials help the hoist withstand rain, snow, or high humidity.

- Corrosion-Resistant Finishes: For hoists that operate in coastal or high-humidity areas, corrosion resistance is a must. Special finishes or coatings, such as galvanization or powder coating, can help protect the hoist from salt air and moisture that would otherwise lead to rust.

Tailoring the Hoist to Meet Specific Environmental Challenges

Outdoor conditions vary widely depending on location, and it's important to tailor the hoist to handle specific challenges. For example:

- Exposure to Rain: If your hoist will be exposed to heavy rain or snow, the protective covers and weather-resistant components should be able to prevent water ingress. Sealed electrical boxes and waterproof switches can help ensure that the hoist operates reliably, even in wet conditions.

- Dust and Debris: In environments with dust or dirt, such as construction sites or agricultural areas, the hoist must be sealed well to keep debris out of moving parts. This can include dust-tight enclosures and additional filters on ventilation systems.

- Salt Air: If the crane operates near the coast, where salt air is prevalent, the hoist needs extra protection. Salt accelerates corrosion, so corrosion-resistant coatings and stainless steel components should be incorporated to prevent rust and ensure the hoist's longevity.

Long-Term Reliability and Reduced Maintenance

The goal of customizing your hoist for outdoor conditions is not just to make it function in the short term, but to ensure it lasts for years with minimal maintenance. Here's why this matters:

- Reduced Downtime: By investing in high-quality, weather-resistant materials and protective features, you'll reduce the chances of the hoist breaking down due to exposure to harsh conditions. Less frequent repairs and maintenance mean your crane will spend more time working and less time in the shop.

- Lower Maintenance Costs: Hoists designed to handle the specific challenges of outdoor environments are less likely to need constant attention. By selecting a hoist with the right features upfront, you avoid the high costs of frequent repairs, replacements, or part upgrades.

- Increased Lifespan: Hoists that are customized for outdoor conditions are built to last longer. With proper protection, the hoist's critical components will stay in top condition, even after years of exposure to the elements.

In summary, customizing your electric hoist for outdoor use is about ensuring it's built to handle the specific environmental challenges of your location. With the right features, such as protective covers, weather-resistant components, and corrosion-resistant finishes, you can ensure the hoist will operate reliably for years while reducing maintenance needs.

Requesting a Tailored Proposal and Quotation

When it comes to purchasing an outdoor electric hoist, providing detailed information about your project is crucial to receiving the right solution. The more information you can share about your needs, the better your tailored proposal and quotation will be. Here's why this matters:

Why Detailed Information is Important

- Environmental Conditions: Let us know about the specific weather conditions in your area, such as high humidity, exposure to salt air, or extreme temperatures. This helps us design a hoist that's protected against the elements, ensuring it lasts longer and operates smoothly in your location.

- Lifting Height: The exact lifting height is vital for determining the hoist's capacity and the necessary design adjustments. It ensures that the hoist can lift loads efficiently and safely, while also avoiding potential issues with stability or motor overload.

- Power Supply: Providing details about your power supply, such as voltage, frequency, and phase, ensures the hoist will be compatible with your electrical system. This is essential for optimal performance and to prevent electrical malfunctions.

By sharing all these details, you ensure that the hoist you receive is perfectly matched to your specific requirements.

How This Ensures the Right Solution

With all the necessary information, we can offer a customized proposal that directly addresses your needs. This ensures that you get:

- The Right Hoist: The hoist will be designed for your specific lifting height, environmental conditions, and power supply.

- Competitive Pricing: Detailed information allows us to quote a fair and accurate price, taking into account your unique requirements.

- Tailored Recommendations: We can suggest any additional features or upgrades based on your environment (e.g., corrosion-resistant finishes or specialized protective covers).

Conclusion

Choosing the right outdoor electric hoist for your double girder crane is essential to ensure reliable, efficient, and safe lifting operations. To make the best decision, consider key factors like environmental conditions, lifting height, power supply compatibility, and matching the hoist trolley to your crane. Customizing the hoist to suit your specific needs will save you time, money, and ensure long-term performance.

If you're ready to move forward or have any further questions, don't hesitate to reach out. We'd be happy to provide more details and assist you in selecting the perfect hoist for your project.

Feel free to send us your project information, and we'll prepare a tailored proposal and competitive quotation. If you have any additional requirements or questions, we're here to help!