5 T Exproof Service Crane for Lact Equipment Maintenance Nigeria

Explosion proof service crane for sale Nigeria for Lact Equipment Maintenance. 5 set of 5 ton single girder overhead crane with explosion proof features to USA customer for their maintenance crane projects in Nigeria for lact equipment replace unit handling and maintenance. The explosion proof service crane is used to ensure your crane operation safety in the hazardous application with customized three layer explosion proof paint, explosion proof parts and crane control, etc. Check 5 sets of explosion proof mainteance crane for sale Nigeria projects to get your safety crane.

Explosion-proof overhead crane

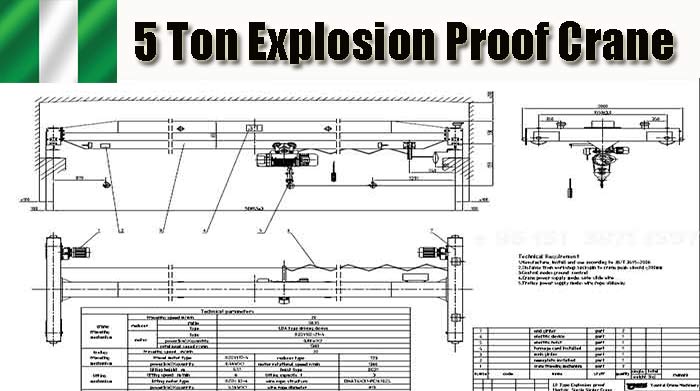

The 5 ton explosion proof service crane to our customer is a single-girder overhead crane, equipped with an explosion-proof electric hoist, explosion proof parts and components , and explosion proof control, etc.

5 ton overhead crane served for Lact Equipment Maintenance Nigeria

Our customer in USA buy the 5 sets of single girder explosion proof service cranes for their customer in Nigeria. The 5 ton overhead crane will be used as a service crane or maintenance crane for replacement parts handling of a lact unit equipment which has a total weight of 27 tons and the heaviest replacment parts and component is calculated up to3 tons. Since they have five 5 warehouses in total, the 5 ton cranes are required to be 5 sets.

Explosion proof service crane requirements

After learning the specifics of our customer's request, we quickly delivered him a pricing proposal and technical sketch.

Technical drawing of explosion proof ovehread crnae and service crane

Our customer is satisfied with our 5 ton service crane technical design and crane price and then he has some special demands on the color of the explosion proof overhead crane, below is his requirements:

- The crane's running length is 50 feet, making the total rail length 100 feet.

- The following paints must be used:

- 1) Dimer coat 9 primer( 75 microns drt)

- 2) Amercoat 385 ( 150 microns drf)

- 3) Amercoat 450S( RAI 1004 OR 1018) (75 microns drt)

We can precisely satisfy our customer's needs after confirmation with our overhead crane engineer.

Explosion proof service crane production

We prepared the supplies and began construction of the Explosion Proof Service Crane after receiving the 50% deposit.

Girder of the explosion-proof crane

First layer of the explosion proof paint

Second layer of the explosion proof paint

Third layer of the explosion proof paint

End carriages or end girder of the 5 ton maintenance crane

Explosion proof hoist of the 5 ton maintenance crane

In order to make our client well-known on the produciton, we will send an email to our customer at each stage of the crane manufacturing to keep them up to date on the progress and to make sure they understand the production timeline. They will have more faith in us once they realize this.

We, the Yuantai Crane EOTCRANEKIT Group, always prioritize our customers and their material handling requirements. If you have any question, please feel free to contact us by leaving a message below or by WhatsApp: + 86 151 3871 1597.

Hoist and crane safety in explosive environment

In an explosive environment, hoist and crane safety is critical. What's an explosion?An explosion is a high-energy chemical reaction between a flammable material and oxygen that occurs suddenly. Gases, mists, vapours, and dusts are examples of flammable substances. An explosion can only happen if three things happen at the same time: a combustible substance (in the right amount and distribution), oxygen (in the air), and an ignition source (e.g. electric spark).

As a result, it's critical to avoid an ignition or to reduce the impacts of an explosion to a safe level. To do this, all operating equipment utilized in potentially explosive environments must be designed, built, and labeled in accordance with the applicable rules. According to ATEX product guidelines or EPL according to IECEx standards, equipment is divided into groups and categories based on its intended use, the level of safety provided by protective measures, and the frequency with which a potentially explosive atmosphere arises. In each scenario, the maximum conceivable potential hazard must be taken into account.

In situations where explosive atmospheres are possible despite all precautions, only explosion-proof equipment may be employed. In compliance with the applicable construction rules, this equipment is built in various ignition protection classes. The manufacturer's choice of ignition protection class is determined by the equipment's type, usage and functions. In a category, all standardised ignition protection classes are equivalent. The producer verifies that the product conforms with the ATEX directives in the EU declaration of conformity included in the technical documentation.

Integrated Explosion Protection

All explosion-prevention measures must be applied in a specific order, according to the integrated explosion protection principle. There are three types of protective measures: primary, secondary, and tertiary (constructional).

- Primary explosion protection -Preventing the formation of hazardous explosive atmospheres

- Secondary explosion protection -Preventing the ignition of hazardous explosive atmospheres

- Tertiary explosion protection - Restricting the effects of an explosion to an innocuous level

Classification into Zones

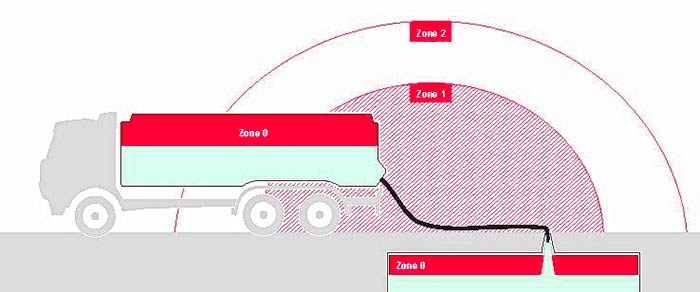

Potentially explosive regions are classified into zones according to the German Ordinance on Hazardous Substances (GefStoffV) definitions to make selecting acceptable and suitable equipment and electrical systems easier. The zone categorization denotes the likelihood of an explosive environment developing.

Gases

- Zone 0: This is an area where hazardous, possibly explosive atmospheres exist as a mixture of air and combustible gases, vapours, or mists on a continuous, long-term, or frequent basis.

- Zone 1: This is an area where, in normal operation, a hazardous, possibly explosive environment can exist as a mixture of air and combustible gases, vapours, or mists.

- Zone 2:A hazardous, potentially explosive atmosphere as a mixture of air and flammable gases, vapours, or mists does not generally exist in normal operation, and if it occurs, it does so only rarely and for a short time in Zone 2.

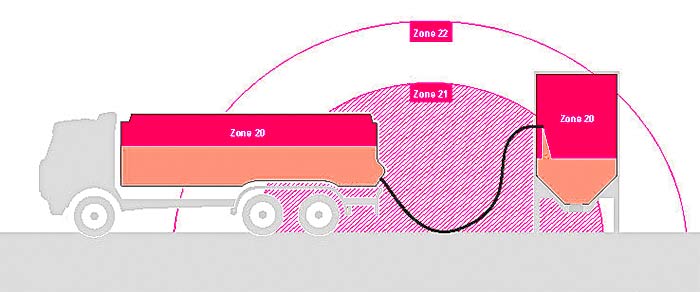

Dusts

- Zone 20 :It is defined as a location where hazardous, possibly explosive atmospheres exist in the form of a cloud of flammable dust that is present in the air constantly, for long periods of time, or on a regular basis.

- Zone 21: A dangerous, potentially explosive environment can occasionally emerge in the form of a cloud of flammable dust contained in the air during routine operation.

- Zone 22: This is an area where a hazardous, possibly explosive atmosphere in the form of a cloud of dust enclosed in the air does not generally occur in normal operation, and if it does, it occurs only seldom and for a short period of time.

Overview of ignition protection classes

General regulations for electrical equipment and component design, testing, and labelling.

Standard: IEC 60079-0 | EN 60079-0 | UL 60079-0

Ex d

Flameproof enclosure

Ex p

Pressurised apparatus

Ex q

powder filling

Ex o

oil immersion

Ex e

Increased safety

Ex i 666666

Intrinsic safety

Ex n

Zone 2 equipment

Ex m

Encapsulation

Ex op

Opticalradiation,

Ex t

Protection by housing

- IEC 60079/EN 60079 for the use of electrical equipment in areas exposed to gas/dust explosion hazards

- IEC 60079-/EN 60079-0 General requirements on design, testing and marking electrical equipment and Ex components

Design, testing, and marking regulations for non-electrical equipment and components.

Standard: ISO 80079-36 | EN ISO 80079-36

Ex d

Flame proof enclosure

Ex c

Constructional safety

Ex b

monitoring s ources of ignition

Ex p

Pressurised

Ex k

liquid immersion

Ex t

protection by enclosure

Top 1 crane service

Overhead cranes that are customized fix the problem and make the customer satisfied.

To begin with, the customized overhead cranes for the USA client are created based on his workshop conditions and lifting requirements, and can fully meet the lifting requirements. Second, the Yuantai Crane EOTCRANEKIT Group makes every effort to assist customers in lowering crane prices in order to satisfy working expectations and generate more profit.

Top 1 crane services, 5 ton Explosion proof service crane, 3 layers special explosion proof paint EOTCRANEKIT Hoist and Crane can handle all of your custom overhead crane, gantry crane, jib crane, and electric hoist requirements. Please contact us if you need a custom crane at a reasonable price.

Types of explosion proof equipment for sale Nigeria

Contact us to get your customized explosion proof hoist and crane.