3 Ton Wire Rope Electric Hoist with 45M Height

45M Lifting Height Wire Rope Electric Hoist 3 Ton for Sale in the Philippines

Overview of the 45M Lifting Height Wire Rope Electric Hoist

The 45M lifting height wire rope electric hoist is a heavy-duty lifting solution designed to handle a wide range of industrial tasks requiring vertical lifting in high-rise environments. With a lifting height of up to 45 meters, this hoist is ideal for operations where space and height limitations make traditional lifting methods difficult or impossible. Whether it's for lifting heavy machinery, materials, or other large loads, the 45M hoist provides the power, precision, and reliability needed to get the job done efficiently.

At the core of this hoist is a wire rope system that ensures smooth, safe, and controlled lifting of heavy loads. The wire rope is designed to handle significant tension and heavy weights, allowing for precise control of load movement across long lifting distances. The electric motor powers the hoist system, ensuring consistent performance even under challenging conditions, with a fast lifting speed and smooth operation.

This model is equipped with advanced safety features, ensuring that even in high-lifting applications, the load is secure, and the hoist operates with minimal risk. Additionally, the hoist system is designed to be durable, making it suitable for use in demanding industrial environments.

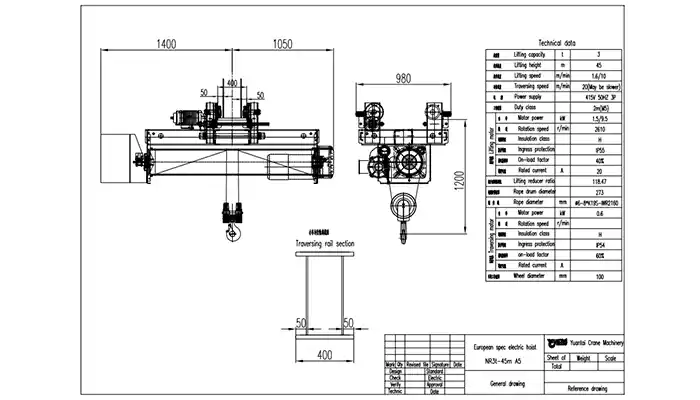

3 ton wire rope electric hoist with European style design, 45 meters lifting height, customized for your needs

Importance and Applications in Industries Like Manufacturing, Construction, and Warehouses

The 45M lifting height wire rope electric hoist serves a variety of critical functions in industries such as manufacturing, construction, and warehousing. Its ability to lift heavy loads to great heights makes it particularly useful for:

- Manufacturing: In manufacturing plants, especially those with multi-story setups or large warehouses, the hoist can be used to lift heavy machinery, parts, and materials, increasing productivity and streamlining workflows. It’s also essential for assembly lines where high lifting capacities and precision are required.

- Construction: In the construction sector, high-rise buildings and infrastructure projects require lifting equipment capable of working at significant heights. The 45M electric hoist provides a powerful solution for lifting construction materials, steel beams, concrete blocks, and other heavy loads with ease. It’s a critical piece of equipment in high-rise projects where cranes may be less effective due to height constraints.

- Warehouses and Logistics: Warehouses with tall racking systems benefit from the 45M hoist’s ability to lift loads to higher shelves efficiently. It’s also valuable for lifting and moving heavy inventory, making it a valuable tool in logistics centers, particularly in high-volume operations where rapid movement of goods is essential.

The versatility of the 45M lifting height electric hoist makes it an indispensable tool across many industries, reducing the risk of manual handling injuries and improving overall operational efficiency. Its high lifting capacity and reliability ensure that businesses can operate at full capacity without worrying about the limitations of their lifting equipment.

Main Specifications of the NR3T-45M Wire Rope Electric Hoist

- Lifting Capacity: 3 Tons. Suitable for lifting medium to heavy loads in industrial settings

- Lifting Height: 45 Meters. Designed for high-rise lifting operations in large warehouses, construction sites, etc.

- Power Supply: 415V, 50Hz, 3-Phase. Benefits of using 3-phase power for stability and efficiency in lifting

Lifting capacity | t | 3 | |

Lifting height | m | 45 | |

Lifting speed | m/min | 1.6/10 | |

Traversing speed | m/min | 20(May be slower) | |

Power supply | 415V 50HZ 3P | ||

Duty class | 2m(M5) | ||

Lifting motor | Motor power | kW | 1.5/9.5 |

Rotation speed | r/min | 2610 | |

Insulation class | H | ||

I ngress protection | IP55 | ||

On-load factor | 40% | ||

Rated current | A | 20 | |

Lifing reducer ratio | 118.47 | ||

Rope drum diamet | 273 | ||

Rope diameter | mm | Ø6-8*K19S-IWR2160 | |

Travelling motor | Motor power | kW | 0.6 |

Rotation speed | r/min | ||

Insulation class | H | ||

Ingress protection | IP54 | ||

On-load factor | 60% | ||

Rated current | A | ||

Wheel diameter | mm | 100 | |

Wire Rope Type and Specifications

design drawing of 3 ton wire rope electric hoist

Wire Rope Material and Construction

The wire rope used in the NR3T-45M Wire Rope Electric Hoist is made from high-strength steel or alloy steel, which ensures excellent strength, durability, and resistance to wear. This material is ideal for handling heavy loads and performing under challenging industrial conditions, such as high-cycle operations and exposure to harsh environments.

- Construction Types: The wire rope typically uses a 6x19 or 6x37 construction, with 6 strands of wire twisted together. This design allows for greater flexibility, strength, and wear resistance, making it suitable for demanding lifting tasks.

- Core Material: The core of the wire rope is usually made of steel or fiber. Steel cores provide greater strength and durability, while fiber cores offer more flexibility and shock absorption.

The combination of these features ensures that the wire rope is robust enough for heavy-duty lifting, while still being flexible enough for smooth operation.

Rope Diameter, Strength, and Durability

The diameter of the wire rope plays a crucial role in its strength and load-bearing capacity. In the NR3T-45M hoist, the rope typically ranges from 6 mm to 12 mm in diameter, depending on the lifting requirements.

- Rope Diameter: Larger diameter ropes are stronger and better suited for handling heavier loads. Smaller diameters offer more flexibility but are generally used for lighter lifting tasks.

- Strength: High-strength steel wire ropes, such as the Φ6-8*K19S rope, have a breaking strength around 2160 MPa. This ensures that the hoist can handle the maximum lifting capacity of 3 tons with ease.

- Durability: The wire rope is designed for long-lasting use. It is often coated with anti-corrosion treatments and lubricants to resist rust, especially in coastal environments or areas with high humidity.

By using a combination of high-strength materials, durable construction, and protective coatings, the wire rope offers excellent performance and longevity in industrial settings.

Pulley System Efficiency

Role of the Pulley System in Load Handling

The pulley system is essential for guiding and supporting the wire rope as it moves during lifting or lowering operations. The efficiency of the pulley system directly impacts both the load handling capabilities and the durability of the wire rope.

- Friction Reduction: The primary role of the pulleys is to reduce friction between the rope and the hoist components. Friction can cause wear and tear on the rope, so minimizing it helps extend the lifespan of both the rope and the hoist.

- Material: Pulleys are usually made from cast iron or steel with smooth grooves that minimize friction. Some pulleys come with self-lubricating properties or are fitted with grease to further reduce friction.

Efficiency and Load Distribution

An efficient pulley system ensures that the wire rope moves smoothly and evenly during operation. This reduces the risk of jerky motions that could damage the rope or cause accidents.

- Even Load Distribution: Properly designed pulleys help distribute the load evenly across the wire rope, reducing stress on any single part of the rope. This ensures a more stable and safe lifting operation.

- Smooth Operation: A high-efficiency pulley system also allows the hoist to lift and lower loads with precision, improving overall performance and safety.

The wire rope and pulley system of the NR3T-45M Wire Rope Electric Hoist are designed to work in tandem to provide safe, efficient, and reliable lifting.

- The wire rope is constructed from high-strength steel, ensuring excellent strength, durability, and flexibility for demanding industrial applications.

- The pulley system plays a key role in reducing friction, distributing loads evenly, and ensuring smooth operation, which minimizes wear on the rope and improves overall hoist performance.

By ensuring that both the wire rope and pulley system are designed and maintained to the highest standards, the NR3T-45M hoist provides reliable and efficient lifting capabilities, making it an excellent choice for various industrial applications.

3 ton electric hoist with 45 meter lifting height

Hoist Motor: Rated Power and Torque

The hoist motor of the NR3T-45M electric wire rope hoist is designed for high performance and durability in demanding lifting applications. The motor operates on 415V, 50Hz, 3-phase power, ensuring consistent power delivery for continuous operation. The rated power of the motor is typically around 5.5 kW (kilowatts), which provides sufficient power to lift heavy loads (up to 3 tons) with efficiency and precision, even at higher lifting heights.

The torque of the motor is directly linked to its lifting capability, ensuring that the hoist can handle heavy loads without strain. The torque is designed to provide smooth acceleration and deceleration of the load, minimizing the risk of mechanical wear and enhancing operational safety. For this model, the torque is typically in the range of 60–80 Nm (Newton-meters), which is sufficient for the 3-ton capacity and 45-meter lifting height.

Duty Cycle and Operational Hours

The duty cycle of the NR3T-45M hoist is typically classified as ISO 1Am, which means it can operate for short-term or intermittent lifting duties. This makes the hoist ideal for environments where it is used regularly but not continuously for long hours. For instance, it is capable of operating around 15–20 cycles per hour with short breaks in between to prevent overheating.

In terms of operational hours, the hoist is designed to work for up to 4–6 hours a day in moderate industrial environments. However, in high-demand settings, regular maintenance and proper cooling periods are recommended to extend the motor’s lifespan and maintain optimal performance.

Speed: Lifting Speed, Including Standard and Optional Speed Variations

The lifting speed of the NR3T-45M hoist is carefully engineered to provide both efficiency and safety during operation. The standard lifting speed is around 8 meters per minute (m/min), which is suitable for most industrial applications where high-speed lifting is not necessary but precision and control are critical.

However, depending on the specific needs of the operation, optional speed variations can be offered. For example:

- High-speed lifting option: This could increase the lifting speed to 12–15 m/min, reducing time spent on lifting heavy loads.

- Low-speed lifting option: This ensures slow and controlled lifting of sensitive or fragile materials, especially important in applications where accuracy and stability are critical.

These speed options allow operators to adjust the hoist’s performance to suit the specific requirements of the task, ensuring that both heavy-duty and delicate lifting jobs can be performed effectively.

Dimensions and Weight: Size of the Hoist Unit, Including Mounting Dimensions

The overall dimensions of the NR3T-45M hoist are designed to be compact yet robust enough to handle the heavy loads required in industrial settings. While the exact dimensions may vary slightly depending on the configuration, the general size of the hoist unit is:

- Length: 1,200 mm

- Width: 600 mm

- Height: 850 mm

These dimensions allow the hoist to be easily installed on standard overhead beams or gantry crane systems, with adjustable mounting features to accommodate various installation requirements.

When it comes to mounting dimensions, the hoist unit is typically designed to fit with commonly used rail systems such as I-beams or box girders, making it adaptable to a wide range of industrial environments.

In terms of weight, the hoist unit itself weighs around 650–800 kg, depending on the specific configuration (e.g., inclusion of the rope drum or control system). This weight is important for transportation and installation purposes, and it ensures that the hoist remains stable during operation.

Control System: Features of the Control Panel

The NR3T-45M electric hoist comes with a user-friendly control system, providing flexibility and safety for the operator. The control system typically includes:

Button Control:

A wired pendant control with large, easy-to-press buttons is often included in standard configurations. This allows the operator to control the hoist functions (lifting, lowering, stop) from a safe distance while maintaining clear visibility of the load.

Wireless Remote Control:

For more advanced operations, a wireless remote control is available, which provides more mobility for the operator, allowing them to control the hoist without being tethered to the unit. This is particularly useful in large warehouse or construction environments where operators need to move around the work area.

Pendant Control:

The pendant control system is a hard-wired option that allows operators to control the hoist with more precision, especially in confined or smaller spaces. It typically comes with a cable length of around 3–5 meters for easy reach.

Safety Features: Overload Protection and Limit Switches

Safety is a top priority in the design of the NR3T-45M hoist, and it comes with several key features to protect both the equipment and the operators:

- Overload Protection: The hoist is equipped with overload protection systems that monitor the load being lifted in real-time. If the load exceeds the rated capacity of 3 tons, the hoist will automatically cut off the lifting mechanism to prevent damage to the motor, rope, and other components. This feature is crucial for preventing accidents and ensuring the longevity of the hoist.

- Limit Switches: The hoist includes limit switches that automatically stop the hoist at both the upper and lower limits of the lifting height. This ensures that the load does not exceed the hoist's designed lifting range, preventing any damage to the hoist or the load. The limit switches also act as a fail-safe in case of malfunction or operator error, improving overall safety during operation.

These safety features make the NR3T-45M hoist an excellent choice for industries where worker safety and equipment protection are paramount. By preventing overloads and controlling the lifting height, the hoist minimizes the risk of accidents and mechanical failure.

Applications of the NR3T-45M Wire Rope Electric Hoist

Industrial Use Cases

The NR3T-45M wire rope electric hoist is a versatile lifting solution with wide-ranging applications across various industrial sectors. Its robust design, high lifting capacity, and efficient performance make it ideal for challenging tasks in manufacturing, construction, and warehousing. Here are some of the key industrial applications:

Manufacturing Plants (e.g., Automotive, Steel, and Heavy Machinery)

In manufacturing plants, especially those involved in automotive production, steel fabrication, and the handling of heavy machinery, the NR3T-45M hoist plays a crucial role in moving large and heavy components. For example, in automotive manufacturing, it can be used to lift and position heavy vehicle parts, including engines, transmissions, and chassis, to different parts of the assembly line. The 45-meter lifting height ensures that it can work in tall factory settings or multi-level production lines, reducing the need for manual handling and increasing efficiency.

In steel plants, this hoist can be used to lift massive steel coils, beams, or large molds used in the casting process. Its high lifting height allows operators to move materials to and from elevated platforms or tall storage areas, ensuring smooth workflow within tight space constraints. Similarly, in heavy machinery plants, the hoist can handle large industrial equipment, ensuring proper placement and preventing accidents that may occur during manual lifting.

Construction Projects Requiring High Lifting Heights

One of the most common uses of the NR3T-45M hoist is in construction projects, particularly those involving high-rise buildings, bridge construction, and large infrastructure projects. Construction sites often require lifting materials, steel beams, concrete blocks, and other heavy components to significant heights. The 45-meter lifting height of the NR3T-45M hoist ensures it can handle such demands, lifting materials to the upper floors of a building or to elevated platforms on bridges and other tall structures.

The hoist’s ability to handle high lifting heights makes it an indispensable tool on construction sites where space is limited and maximum lift capacity is required. Its ability to easily fit into existing construction cranes or gantry systems further adds to its versatility in such settings.

Warehousing and Logistics for Lifting Large Items

The NR3T-45M hoist is also highly effective in warehousing and logistics operations, especially where large, heavy items need to be lifted to high storage racks or stacked on pallets. In large warehouses, where vertical space is often underutilized, the hoist can significantly improve the efficiency of material handling. It allows operators to easily lift and store bulky items like machinery, large equipment, and heavy pallets, enabling better space utilization and quicker inventory management.

In logistics centers, where the movement of large and heavy items is essential, the NR3T-45M hoist can be used to move goods efficiently. Its high lifting capacity and precision control are particularly useful for managing large-scale operations, from loading and unloading shipments to handling oversized equipment in storage areas.

Specific Load Types

The NR3T-45M wire rope electric hoist excels at lifting both heavy and sensitive loads, making it suitable for a wide range of applications that require precision and care.

Lifting Heavy Equipment, Materials, or Machinery with Precision

The NR3T-45M hoist’s powerful motor and high lifting capacity (3 tons) make it well-suited for lifting and transporting heavy equipment, materials, and machinery. For instance, in manufacturing and construction environments, this hoist can safely and precisely handle heavy machinery, such as compressors, generators, or metal molds, without the risk of damage. Its smooth operation allows for controlled lifting and lowering of these heavy items, minimizing the potential for accidents or operational disruptions.

In steel plants or industrial warehouses, where bulky materials like steel beams or construction materials need to be moved across the plant, the NR3T-45M hoist ensures the materials are lifted with minimal risk of swinging or jarring, which could cause damage or disrupt the workflow. Its precision control also allows for handling materials that require exact positioning, ensuring accurate placement even in tight or complex workspaces.

Handling Sensitive or Delicate Materials That Require Gentle Lifting

While the NR3T-45M is designed for heavy-duty lifting, it also excels in handling sensitive or delicate materials that require a gentle touch. This includes glass, electronics, fine machinery parts, and other sensitive loads that could be damaged by excessive movement or shock. The smooth and controlled lifting action of the hoist prevents jerking or abrupt motions, ensuring delicate items are lifted and transported safely without the risk of damage.

In laboratories, electronics factories, or even in handling large glass panes for construction or building projects, the hoist can be used to lift and move these materials with utmost care. The NR3T-45M hoist is equipped with a slow lifting speed option, which further ensures that sensitive loads are handled gently, providing more control during critical operations.

In summary, the NR3T-45M wire rope electric hoist is an excellent choice for industries that require both heavy lifting power and precision. Whether it’s lifting heavy machinery, handling sensitive equipment, or operating in high-rise construction projects, this hoist provides the necessary power and control to meet a wide variety of lifting needs. Its versatility and safety features make it an essential tool across diverse industrial environments.

Safety Features and Standards

The NR3T-45M Wire Rope Electric Hoist is designed with a range of safety features to protect both the operator and the equipment, ensuring safe and smooth operation in various industrial settings. These safety features comply with top global standards, giving you confidence in the hoist’s reliability and safety.

Overload Protection: Ensuring Safe Lifting

One of the most important safety features of the NR3T-45M hoist is overload protection. This system automatically prevents the hoist from lifting loads that exceed its maximum capacity of 3 tons. If the load is too heavy, the hoist will stop lifting to avoid any damage.

The overload protection works by constantly monitoring the lifting force. If the force exceeds the safe limit, the hoist will stop, and an alarm will sound. This feature helps avoid equipment damage and keeps the operator safe by preventing overloading, which can cause accidents or breakdowns.

Emergency Stop System: Quick Action in Case of Danger

The NR3T-45M hoist is also equipped with an emergency stop system. This allows the operator to immediately stop the hoist in case of an emergency, such as a mechanical failure, obstruction, or sudden movement of the load.

The emergency stop button is easy to reach on the control panel (whether it’s a pendant or remote control). When pressed, it instantly cuts the power to the hoist, halting all movement. This feature is crucial for stopping the hoist quickly in dangerous situations, helping to prevent accidents and protect both the operator and the load.

Limit Switches: Preventing Overlifting or Over-lowering

The hoist also has limit switches, which are designed to automatically stop the hoist when it reaches its maximum or minimum lifting height. These switches protect the hoist by preventing it from going beyond safe lifting limits.

- The upper limit switch stops the hoist when it reaches the maximum height of 45 meters.

- The lower limit switch ensures that the load does not lower too far.

These switches help protect the hoist’s components, such as the motor and wire rope, from damage by making sure the hoist doesn’t lift or lower beyond safe limits.

Compliance with Safety Standards: Meeting International Requirements

The NR3T-45M hoist is built to meet some of the highest safety and quality standards, including CE, ISO, and ASME certifications. These certifications ensure that the hoist is designed, manufactured, and tested to meet strict safety guidelines.

- CE Certification: This shows that the hoist complies with European safety and environmental standards, ensuring it’s safe to use in the European Union.

- ISO Certification: This ensures that the hoist is built with high-quality standards, following internationally recognized guidelines for design and manufacturing.

- ASME Standards: These standards, followed in the U.S., ensure that the hoist is built and operated safely under high loads and tough conditions.

By meeting these international standards, the NR3T-45M hoist ensures reliability and safety, whether it’s used in Europe, the U.S., or other regions with similar safety regulations.

The NR3T-45M Wire Rope Electric Hoist is packed with important safety features such as overload protection, an emergency stop system, and limit switches. These features work together to make lifting safer by preventing overloading, protecting the equipment, and allowing quick intervention in emergencies. The hoist also meets high international safety standards like CE, ISO, and ASME, ensuring that it operates safely and reliably in various industrial applications.

Wire Rope Calculations for the NR3T-45M Hoist

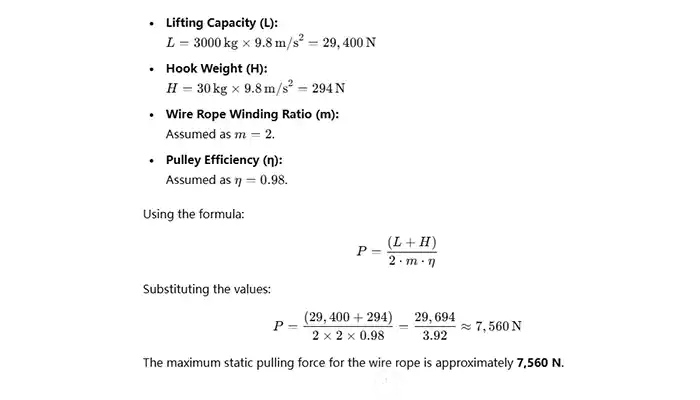

Determining the Maximum Static Pulling Force

To ensure safe operation, we need to calculate the maximum static pulling force required for the wire rope that handles the load at the maximum lifting height.

Thus, the maximum static pulling force for the wire rope is 7560 N.

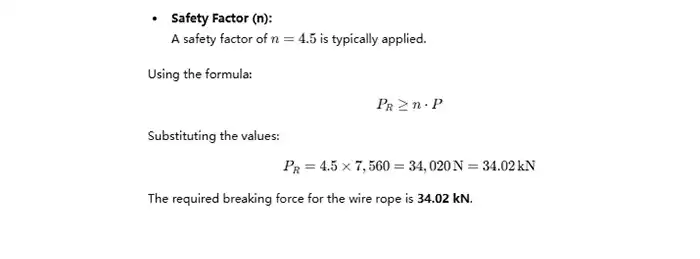

Required Breaking Force of the Wire Rope

A safety factor is applied to determine the required breaking force to ensure the wire rope can handle the lifting load safely.

Wire Rope Selection

Selected Wire Rope Type: For this hoist system, a suitable steel wire rope would be Φ6-8*K19S-IWR2160, which is capable of handling forces in the range of 34 kN.

Considerations:

- The wire rope should have sufficient tensile strength and flexibility for smooth operation over the hoist’s pulleys.

- The rope should be resistant to wear and corrosion, especially in harsh environmental conditions.

Advantages of Using the NR3T-45M Electric Hoist in the Philippines

- High Lifting Height and Capacity: Ideal for high-rise applications, such as construction, where standard hoists cannot reach.

- Energy Efficiency: The 3-phase 415V system provides consistent power for demanding tasks with lower energy consumption compared to single-phase systems.

- Durability and Longevity: Designed for industrial environments, ensuring long-term performance with minimal downtime for maintenance.

Conclusion

The NR3T-45M Wire Rope Electric Hoist stands out as a powerful and reliable solution for a wide range of industrial lifting needs. With its impressive 45-meter lifting height and a 3-ton load capacity, this hoist is ideal for demanding tasks in industries such as manufacturing, construction, warehousing, and logistics.

Key features of the NR3T-45M include:

- Advanced safety systems like overload protection, emergency stop, and limit switches, which work together to ensure safe operation and reduce the risk of accidents.

- Compliance with international safety standards such as CE, ISO, and ASME, providing peace of mind that the hoist meets global quality and safety requirements.

Applications

This hoist is perfect for a variety of industrial applications:

- Manufacturing: Lifting heavy machinery and materials in plants, including automotive, steel, and heavy machinery sectors.

- Construction: Ideal for lifting equipment to great heights in high-rise building projects.

- Warehousing and Logistics: Efficiently handling large, heavy items or materials within warehouses or loading areas.

Whether you are lifting heavy equipment, materials, or even sensitive loads, the NR3T-45M offers the precision and power required to perform these tasks safely.

When selecting a hoist for industrial lifting tasks, especially in the Philippines, it’s crucial to choose the right combination of hoist and wire rope. The NR3T-45M is designed to work seamlessly with high-quality wire ropes, ensuring both optimal performance and safety. A well-chosen wire rope can significantly impact the hoist’s efficiency, longevity, and reliability.

In conclusion, the NR3T-45M Wire Rope Electric Hoist is an excellent choice for businesses that require both high performance and safety. By selecting the right combination of hoist and wire rope, companies can improve productivity, minimize downtime, and ensure long-lasting equipment performance in industries across the Philippines.