4 Girder Casting Crane 120~320 Tons | Hot Metal Ladle Crane

Hot metal ladle cranes for pouring steel & pouring iron ladle in steel foundry. 4 girder casting cranes for heavy duty steel mill operation. Check now.

| Casting crane | Four girder casting crane |

| Crane capacity | 120~320 tons |

| Crane span | 10~40M |

| Working class | FEM: 4m, ISO: M7 |

| Note | Custom casting crane is available. |

Category: Casting Crane

Your Trusted Overhead Casting Crane Manufacturer & Supplier

4 Girder Casting Crane 120~320 Tons

Custom Casting Crane to Ensure Safety & Efficiency

Hot metal ladle cranes for pouring steel & pouring iron ladle in steel foundry. 4 girder casting cranes for heavy duty steel mill operation. Check now.

For heavy duty hot metal handling, the overhead casting cranes are widely adopted for pouring steel ladle or pouring iron ladle to improve efficiency and ensure safety. 4 girder casting cranes are typical for large scale steel mill and foundry, which especially high safety features.

As an experienced steel mill crane designer and supplier, we can provide crane solutions for the entire value creation process, both in the metal-production and the metal-processing industry and in the metal trade. For example, in the steel sector ranging from production to applications in the automotive industry.

Complete steel mill crane system solutions for every step of the value-creation process are provided, from metal manufacturing and processing to metal trading.As a reliable partner for the ferrous and non-ferrous industries as well as downstream of the ladle, our crane factory offers comprehensive material handling solutions. We design and engineer specialized, cutting-edge heavy-duty tailored cranes in the rising markets for applications in the ferrous and non-ferrous sector that are characterized by demanding working circumstances, such as: pouring , charging and forming of a variety of metals and alloys , such as, steel,cast iron ,copper , ferrochrome, manganese,etc.

Heavy Duty Four Girder Casting Crane

During the processing of steel making, the casting crane is one of the main material handling crane for hot liquid metal handling. The hot metal ladle crane is used in the steel-making process to move liquid metal or steel in a hot, dusty working environment. According to the lifting capacity, the casting crane can be designed into single girder casting crane, double girder casting crane and four-girder casting crane. The four girder ladle handling crane is typical used for heavy duty material handling with capacity from 120 ton -320 tons.

4 girder ladle overhead crane

4 girder casting overhead crane

Main specifications of four girder casting crane

We adhere to the strictest steel industry standards and laws, combining them with the unique environment and paying attention to every detail in order to achieve dependable performance to assist our customers. The main specifications of the 4 girder casting cranes are as following:

- Capacity of Casting Crane : 120~320 tons

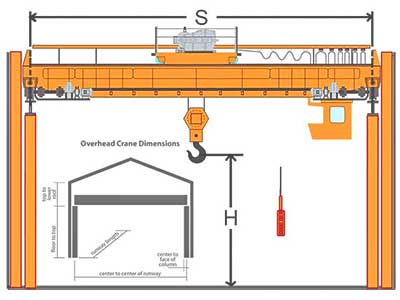

- Overhead Crane Span: 10~40M

- Max wheel pressure: 485~750 KN

- Crane track recommended: QU100/QU120

- Operational Model: Cabin control

- Working Duty: FEM: 4m, ISO: M7

- Power Supply: Three-phase A.C. 380V, 50Hz or Customized

Features of four girder casting crane

- The hot metal ladle crane could typically operate in the harsh conditions of high temperatures and high dust.

- The overhead crane is more dependable and of higher working class. because if there was any breakdown, it may bring a great loss and terrible consequences.

- The heavy duty casting crane needs a main hook and an auxiliary hook in order to complete the process of pouring steel or iron molten metal .

- The main lifting mechanism of the ladle handling crane uses a rigid connection on the output shaft and two sets of drive mechanisms.

- Each drum has a safety brake installed to ensure the highest level of safety.

Smart features of steel & iron pouring crane

Safe cabin control: The reinforced glass in the cabin protects against hot and splattering materials. well-insulated, conditioned, soundproof, and vibration-proof. While operating the casting crane, the operator can take advantage of comfortable working circumstances, increasing safety.

- For dependable operation in challenging climatic circumstances, the steel mill ladle crane electrical room is pressurized and air-conditioned.

- Even when a unit is down, backup A/C units guarantee uninterrupted, dependable A/C operation.

- Main beam or girder of the overhead casting crane is heat shielding.

- The specially designed laminated plate hooks are adopted.

- For redundancy, moving equipment is split into two groups; in an emergency, the crane may be operated by using only half of the motors.

- Heavy-duty and especially made for ladle pouring and opening scrap bucket bottoms, the auxiliary hook. It is horizontally mobile (option).

- Auxiliary hoists are used for maintenance tasks and are normal duty.

- casting cranes Motor Supplier are well know brand, Siemens.

Technique highlight of steel mill ladle crane

Modularized software function design. User-friendly CMS monitor and management system. Rectification and regeneration multi-drive solution.

The needs of the customer in terms of optimizing solutions, project design, commissioning, and after-sale support can be met by the specialized engineer group.

Our company maintains a leadership position in the field of crane research and development thanks to ongoing innovation processes.

Application of four girder casting crane

The primary purposes of the ladle handling cranes are to lift and pour melting metal, move red-hot solid metal in foundries, steel mills, and other locations. When hoisting melted metal, the primary hooks beneath the hanging beam suspend the steel ladle's two ears while the auxiliary hooks sway to release the liquid.

The numerous components utilized in our process cranes are put under great demands in terms of functional dependability and availability due to the operating conditions where molten materials are handled at extremely high or fluctuating ambient temperatures. All of the casting cranes and steel mill crane provided must operate reliably throughout the day and night.

Custom overhead crane to maximize ladle handling efficiency

Casting Cranes are a critical component of steel production plants, allowing for the safe and efficient transportation of molten metal and other materials. By selecting the right ladle crane, installing it properly, and maintaining it regularly, you can optimize efficiency and productivity while ensuring the safety of your employees.

As technology continues to advance, new developments in ladle overhead crane technology are expected to emerge. Based on your lifting applications and lifting requirement, your custom casting crane can be designed with the advanced features including :

- Improved automation and control systems

- Enhanced safety features, such as collision avoidance systems

- Advanced materials and coatings that can withstand even harsher environments

- Integration with other technologies, such as artificial intelligence and the Internet of Things

If you need casting cranes for hot ladle handling, we can be your long term partners.We can provide your one-source of crane service to improve your efficiency and save your time.

Send four girder casting overhead crane inquiry

- The crane lifting weight is__________ton.

- The crane lifting height is __________ m.

- The voltage is V__________ HZ__________ 3phase.

- 5.The span of crane is __________ m. A.5fpm B.10fpm C.15fpm D.30fpm

- What material will be lifted?

- The control model is__________. A.pendent control B.remote control C.cabin control.

- If you need rail and bus bar,please supply the travelling length is__________ m

- Leave us a message down below.

The One stop crane services for ladle crane are available from the design, manufacture, and installation of high-quality Casting Cranes for steel production plants. The processed casting overhead cranes are designed to meet the specific needs and requirements of each client, ensuring maximum efficiency, productivity, and safety. Contact us today to learn more about how our casting cranes can benefit your steel production plant.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch