Dynamic Lifting Hook Tracking System for Overhead &Gantry Cranes

Advanced dynamic lifting hook tracking system enhances safety and precision for overhead and gantry cranes in hazardous and challenging applications.

Category: Hazardous Environment Cranes

Your Trusted Hazardouse Environment Overhead Crane Manufacturer & Supplier

Dynamic Lifitng Hook Tracking System for Safe& Precision Operation of

Industrial Overhead Crane and Gantry Cranes in Hazardous and Challenging Environments

Overview of Lifting Hook Tracking Technology

In industrial lifting, precision is everything. A small misalignment can lead to accidents, damage, or costly delays. Traditional crane operations rely heavily on human judgment, which can be challenging in fast-paced or hazardous environments.

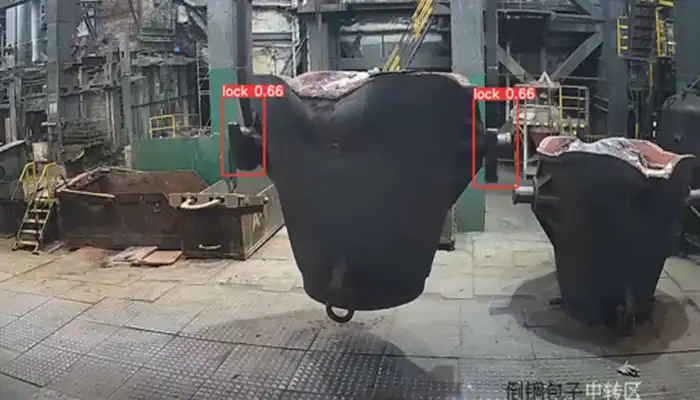

A Dynamic Lifting Hook Tracking System changes the game. It uses AI-powered visual tracking to monitor the hook's position in real time. The system automatically adjusts focus, ensuring clear visibility at all times. Operators can see exactly where the hook is and whether it is securely attached. This reduces guesswork and improves efficiency.

Importance of Precision and Safety in Hazardous Environments

Hazardous worksites, like steel mills, chemical plants, and shipyards, come with extreme conditions—high heat, smoke, dust, and limited visibility. In these environments, precision is not just about efficiency—it's about safety.

- Misplaced hooks can cause load instability, leading to accidents.

- Workers often get too close to heavy loads, increasing injury risks.

- Poor visibility makes manual tracking unreliable.

A dynamic tracking system helps solve these issues. It keeps the hook in clear view, ensuring operators make the right moves. It also reduces the need for workers to be near dangerous loads, keeping them safe.

How AI and Automation Improve Crane Operations

AI-driven tracking takes crane operation to the next level. Unlike manual monitoring, AI continuously analyzes the hook's position and automatically adjusts the camera's focus.

Here's how it works:

- AI detects the hook's location and keeps it centered in view.

- The system automatically zooms in and out to show critical details.

- If the hook is misaligned, it alerts the operator instantly.

This means fewer errors, faster lifting cycles, and safer operations. It also reduces operator fatigue since they no longer need to adjust cameras or strain to see the hook. In short, AI makes crane work smarter, safer, and more reliable.

Key Challenges in Hazardous and Challenging Environments

Industrial overhead and gantry cranes operate in some of the toughest conditions. Extreme temperatures, poor visibility, and unpredictable movements make lifting operations difficult. Without proper tracking, even experienced operators struggle to maintain precision. Here's a closer look at the key challenges:

High Temperatures, Flames, and Smoke Interference

In steel mills, foundries, and chemical plants, heat and flames are constant hazards. Rising temperatures can distort visuals, while smoke and fumes reduce visibility. Standard cameras struggle in these conditions, making it hard for operators to track the lifting hook accurately.

A dynamic tracking system overcomes this by using AI-powered image processing that can filter out interference from smoke and bright light. It keeps the hook visible, ensuring safe and controlled lifting, even in extreme environments.

Low Visibility and Poor Lighting Conditions

Not all lifting operations happen in well-lit areas. Warehouses, docks, and construction sites often have dim lighting, making it difficult to see the hook's position.

Without a proper tracking system:

- Operators may misjudge the hook's position.

- Accidents can happen due to incorrect alignment.

- More time is spent adjusting and repositioning loads.

A smart tracking system adapts to lighting changes automatically. It enhances images, making the hook and load clearly visible, whether in low light or direct glare.

Strong Winds, Vibrations, and Sudden Load Shifts

Outdoor cranes, shipyards, and ports face strong winds and sudden load movements. Even indoor cranes experience vibrations from machinery and heavy loads. These unexpected shifts make it hard to keep the hook stable and aligned.

An AI-driven tracking system solves this by:

- Automatically adjusting the camera focus to keep the hook in frame.

- Predicting and compensating for sudden movements, ensuring steady tracking.

- Reducing operator workload, allowing them to focus on safe lifting instead of constant camera adjustments.

Safety Risks for Workers and Operational Inefficiencies

Manual hook tracking means workers often need to be near the load to confirm alignment. This increases the risk of injuries from falling objects, heavy loads, or unstable lifting.

A dynamic hook tracking system minimizes these risks by:

- Allowing operators to monitor lifting remotely with clear visuals.

- Reducing the need for workers to approach dangerous areas.

- Improving accuracy, which leads to faster and safer lifting cycles.

Hazardous environments demand a smarter approach. AI-powered tracking systems help overcome visibility issues, handle unpredictable movements, and improve safety. This means less risk, fewer errors, and more efficient crane operations.

How the Dynamic Lifting Hook Tracking System Works

Modern crane operations require precision and safety, especially in tough environments. This system automatically monitors the hook in real time, ensuring stable and accurate lifting. Here's how it works:

Visual Tracking: Real-Time Hook Monitoring

The system continuously follows the hook's position, adjusting as it moves. Unlike manual tracking, which relies on operator judgment, this automated approach ensures the hook is always in view.

- The camera locks onto the hook and follows its movements.

- Interference from smoke, bright light, or dust is filtered out.

- Operators get a clear and uninterrupted view at all times.

This eliminates guesswork, reducing errors and improving lifting accuracy.

Automatic Focus Adjustment: Keeping a Clear and Stable View

Lifting happens at different heights and angles, making it difficult to maintain visibility. The system automatically adjusts zoom and focus, ensuring the hook remains sharp and centered.

- Zooms in when the hook moves further away for a detailed view.

- Zooms out when it comes closer, keeping the full lifting area visible.

- Adjustments are smooth and stable, avoiding distractions for the operator.

This means no blurry images, no manual adjustments—just a consistently sharp view.

Secure Hook Engagement: Ensuring Proper Connection

A common challenge in lifting operations is making sure the hook is properly attached before lifting begins. The system analyzes its position in relation to the lifting point and confirms whether it is securely in place.

- If misalignment is detected, an alert notifies the operator.

- If the hook is stable, a confirmation message appears on the screen.

- This prevents lifting errors that could lead to accidents.

By ensuring proper positioning, the system improves safety and prevents costly mistakes.

Real-Time Alerts: Assisting Operators with Instant Feedback

Lifting in hazardous environments requires fast decision-making. The system provides immediate feedback, helping operators react quickly.

- Highlights instability before lifting begins.

- Enhances visibility when conditions like smoke or low light affect tracking.

- Keeps the hook in frame, even if the load shifts suddenly.

These real-time adjustments allow operators to work more efficiently and with greater confidence.

With automatic tracking, clear visuals, and real-time alerts, this system removes uncertainty, improves efficiency, and enhances safety in crane operations. Operators can now focus on precision lifting with confidence.

Core Features and Benefits

The Dynamic Lifting Hook Tracking System is designed to improve safety, efficiency, and precision in crane operations. Here's how its key features bring real benefits:

Stable and Accurate Hook Tracking: Continuous Monitoring in Harsh Environments

The system provides uninterrupted tracking of the lifting hook, even in extreme conditions like heat, smoke, and poor lighting. It adapts to environmental challenges, ensuring that the hook remains clearly visible.

- Maintains steady tracking despite vibrations, wind, or sudden load shifts.

- Filters out visual interference like flames, dust, or high brightness.

- Provides a consistent and reliable view for operators.

This stability helps prevent lifting errors and improves load control.

Automatic Zoom and Focus Adjustment: Enhanced Visibility at Different Heights

Visibility is a challenge when operating cranes at varying elevations. The system automatically adjusts the zoom and focus based on the hook's position.

- Zooms in for a detailed view when the hook is far away.

- Zooms out to keep the entire lifting area visible when needed.

- Adjustments happen smoothly and without delays, reducing distractions for operators.

This ensures a clear, high-resolution view at all times, eliminating the need for manual focus adjustments.

Position Confirmation Algorithm: Ensuring Correct and Secure Lifting Operations

A critical aspect of lifting safety is ensuring the hook is properly engaged before lifting. The system automatically checks alignment and stability.

- Detects whether the hook is securely latched onto the lifting ear.

- Provides an on-screen confirmation to inform the operator.

- Alerts the operator if misalignment or instability is detected.

This feature reduces human error, preventing accidents and load drops.

Seamless Integration with Ground Cameras: Expanded Observation for Better Decision-Making

For larger or more complex lifting tasks, additional ground cameras can be connected to provide more perspectives.

- Improves visibility in blind spots or obstructed areas.

- Helps supervisors and remote operators monitor lifting operations from a safe distance.

- Supports better coordination between the crane operator and ground crew.

This expanded view enhances safety and decision-making for complex lifts.

Worker Safety Enhancement: Reducing Manual Inspections in Dangerous Zones

In traditional crane operations, workers often need to get close to loads to inspect alignment. This system minimizes that need by providing real-time monitoring and position confirmation.

- Reduces the risk of injuries from falling loads or unstable lifting.

- Allows workers to supervise lifts from a safe indoor location.

- Cuts down on manual intervention, improving overall efficiency.

By keeping workers out of high-risk areas, this feature helps create a safer and more controlled work environment.

With stable tracking, automatic adjustments, and enhanced safety features, this system optimizes crane operations while reducing risks. It ensures precision, efficiency, and a safer working environment for everyone involved.

Adaptability to Various Industrial Applications

The Dynamic Lifting Hook Tracking System is designed to perform reliably in industries where precision, safety, and efficiency are critical. Its advanced tracking and monitoring capabilities make it suitable for a wide range of challenging environments.

Steel Mills and Foundries

In steel production and metal casting, the steel mill cranes handle molten metal, heavy billets, and large steel components under extreme conditions. High temperatures, smoke, and bright flames can interfere with visibility, making manual tracking difficult.

- Real-time hook monitoring ensures accurate lifting, even in intense heat.

- Automatic focus adjustment helps operators see through smoke and glare.

- Position confirmation alerts prevent unstable lifting and reduce the risk of load drops.

This system helps steel mills improve efficiency, reduce accidents, and ensure smooth material handling.

Chemical Plants and Refineries

Hazardous chemicals, explosive materials, and strict safety regulations make lifting operations in these industries particularly challenging. Cranes must operate with precision and stability to prevent leaks, spills, or dangerous incidents.

- AI-driven tracking ensures proper alignment when handling chemical containers.

- Remote monitoring reduces worker exposure to toxic or hazardous areas.

- Stability detection prevents sudden load shifts, minimizing operational risks.

By improving control and reducing human exposure to dangerous zones, this system enhances both safety and efficiency in chemical plants.

Shipbuilding and Heavy Machinery Manufacturing

Large ship components, turbines, and industrial machinery require cranes to lift and position oversized, irregularly shaped loads with extreme precision. Outdoor conditions, high winds, and complex assembly areas add further challenges.

- Automatic zoom and tracking allow operators to lift and align large components accurately.

- Stability detection reduces risks when handling heavy machinery at varying heights.

- Ground camera integration improves coordination between crane operators and ground crews.

This system streamlines assembly processes, reduces lifting errors, and enhances safety in shipbuilding and heavy machinery manufacturing.

Ports and Logistics Hubs

Ports and logistics hubs rely on cranes for container handling, cargo loading, and heavy freight movement. Wind, rain, and continuous operations require a system that can adapt quickly and maintain precision.

- Continuous hook tracking ensures containers are lifted and placed accurately.

- Real-time alerts help operators adjust in unpredictable weather conditions.

- Seamless integration with other monitoring systems improves efficiency in high-traffic areas.

By ensuring stable and precise lifting, this system enhances productivity and reduces cargo handling errors in ports and logistics hubs.

This system is versatile and adaptable, making it a valuable asset for industries where precision, safety, and efficiency matter. Whether in steel mills, chemical plants, shipyards, or logistics hubs, it helps optimize lifting operations and reduce workplace risks.

Summary and Future of Smart Hook Tracking Technology

Key Benefits and System Impact

The Dynamic Lifting Hook Tracking System transforms crane operations by enhancing safety, precision, and efficiency in challenging environments. Key advantages include:

- Stable and accurate hook tracking ensures reliable lifting in hazardous conditions.

- Automatic zoom and focus adjustment provide a clear view at any height.

- Position confirmation alerts prevent misalignment and unsafe lifts.

- Seamless ground camera integration expands visibility for better decision-making.

- Enhanced worker safety reduces the need for manual inspections in high-risk zones.

By automating critical aspects of lifting operations, this system reduces human error, minimizes downtime, and improves overall productivity.

As industrial automation advances, intelligent tracking systems will become essential for next-generation crane safety. Future developments may include:

- More advanced predictive analytics to anticipate lifting risks before they occur.

- Integration with industrial IoT systems for seamless operation monitoring.

- Enhanced remote control capabilities to further reduce worker exposure to hazardous areas.

With continuous innovation, these systems will play a crucial role in creating safer, smarter, and more efficient crane operations worldwide.

Crane safety and efficiency are no longer optional—they're essential. Adopting a smart lifting hook tracking system helps companies reduce risks, improve precision, and boost operational efficiency.

Ready to enhance your lifting operations? Contact us today to learn how this cutting-edge overhead crane tracking system can transform your workflow. Leave a message down below.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch