Horizontal Steel Coil Lifting Equipment: C Hook, Clamp, Magnet Crane

Overhead steel coil lifting equipment overview , ie. overhead bridge cranes, goliath gantry cranes, c hook crane, clamp cranes & magnet crane,etc. Custom design for you.

Category: Coil Handling

Your Trusted Overhead Crane Manufacturer & Supplier

Horizontal Steel Coil lifting equipment: C Hook, Clamp, Magnet, Hook

3 ton, 4 ton, 5 ton, 10 ton, 15 ton, up 35 ton steel coil material handling equipment

Overhead steel coil lifting equipment overview , ie. overhead bridge cranes, goliath gantry cranes, c hook crane, clamp cranes & magnet crane,etc. Custom design steel cil material handling crane equipment with capacity of 3 ton, 4 ton, 5 ton, 10 ton, 15 ton, up 35 ton. Contact us to get your best overhead steel coil lifting equipment.

Steel coils are often placed in a horizontal position to prevent deformation or damage to the coils. When stored vertically, the weight of the coils can cause them to deform or become misshapen, which can lead to issues during processing or transportation. Placing them horizontally helps distribute the weight evenly and reduces the risk of damage.

Challenges of horizontal steel coil lifting

The challenge of horizontal steel coil handling cranes is to safely and efficiently handle large and heavy steel coils, while also preventing damage to the coils and ensuring the safety of personnel operating the cranes. Some of the specific challenges of horizontal steel coil handling cranes include:

- Coil weight and size: Steel coils can be extremely heavy and large in size, which requires cranes with high weight capacities and adequate reach to safely lift and transport the coils.

- Coil shape: Steel coils can have irregular shapes or damaged edges, which requires specialized lifting devices to securely grip the coils and prevent damage during handling.

- High temperatures: In some cases, steel coils may be hot or at elevated temperatures, which requires specialized lifting devices that can withstand exposure to high temperatures.

- Limited space: In some production facilities or transportation settings, there may be limited space for maneuvering the crane, which requires specialized cranes with compact designs that can operate in tight spaces.

- Safety: The safety of personnel operating the crane and those working in the vicinity of the crane is of utmost importance. Proper training, adherence to safety protocols and regulations, and regular maintenance of the crane are essential to ensure safe operation.

Overall, the challenge of horizontal steel coil handling cranes is to safely and efficiently handle large and heavy steel coils while also preventing damage to the coils and ensuring the safety of personnel operating the cranes.

What is the requirement for horizontal steel coil lifting crane?

Most steel mills and processing facilities require robust and dependable gantry cranes and overhead cranes for their steel coil lifting operations. At Yuantai Crane, we prioritize optimizing uptime while reducing maintenance expenses when designing overhead crane solutions for horizontal steel coil lifting.

The requirements for horizontal steel coil lifting cranes will depend on the specific application and industry standards. However, some common requirements for horizontal steel coil lifting cranes include:

- High weight capacity: Steel coils can be extremely heavy, so the crane must have a high weight capacity to safely lift and transport the coils.

- Adequate reach and height: The crane must have adequate reach and height to safely lift and transport the coils over short or long distances within the production facility or transportation setting.

- Specialized lifting devices: The crane must have specialized lifting devices, such as C-hooks, coil grabs, or magnetic lifters, to securely grip the coils and prevent damage during handling.

- Heat-resistant materials: In some cases, steel coils may be hot or at elevated temperatures, so the crane must be made from heat-resistant materials that can withstand exposure to high temperatures.

- Safety features: The crane must have proper safety features, such as emergency stop buttons, overload protection, and warning signals, to ensure safe operation and prevent accidents.

- Compliance with industry standards: The crane must comply with all relevant industry standards and regulations to ensure safe operation and prevent accidents.

Overall, the requirements for horizontal steel coil lifting cranes will depend on the specific application and industry standards. It's important to carefully consider these requirements when selecting a crane to ensure that it can safely and efficiently handle the specific requirements of the job.

For horizontal steel coil handling, what types of overhead cranes are used ?

For handling horizontal steel coils, overhead cranes with specialized lifting attachments are typically used. Some common types of overhead cranes used for this purpose include:

Bridge cranes: these cranes are typically used in steel mills and other industrial settings to lift and transport heavy loads, including steel coils. They consist of a bridge that spans the width of the facility and moves along rails, with a hoist and trolley system that moves along the bridge.

The gantry cranes are one types of overhead crane which are widely used for steel steel coil lifting outdoors. Based on different lifting requirements and application, the gantry cranes can be designed into box girder gantry crane, truss girder gantry crane, single girder gantry cranes and double girder gantry cranes, etc.

Our overhead cranes are designed to handle a wide range of steel coil lifting tasks, and we also offer automated and semi-automated options to meet your specific lifting requirements and application conditions.

C hooks cranes: These cranes have a specialized C-shaped hook attachment that is designed to lift and transport steel coils in a horizontal position.

Advantages :

- Can handle a wide range of coil sizes and weights.

- Easy to use and maneuver.

- Can be used for both horizontal and vertical coil handling.

Disadvantages:

- May require additional equipment to lift coils with damaged or uneven edges.

- Can cause damage to the coil if not used properly.

Coil clamp cranes: These cranes use a specialized clamp attachment that is designed to securely grip the coil and lift it in a horizontal position.

Advantages:

- Can handle a wide range of coil sizes and weights.

- Provides a secure grip on the coil.

- Can be used for both horizontal and vertical coil handling.

Disadvantages:

- May not be suitable for coils with damaged or uneven edges.

- Requires additional equipment to adjust the clamp for different coil sizes.

Magnetic overhead cranes: These cranes use a magnetic lifting attachment to lift and transport steel coils in a horizontal position or vertical positions.

Advantages:

- Provides a secure grip on the coil.

- Can handle a wide range of coil sizes and weights.

- Does not require additional equipment to adjust for different coil sizes.

Disadvantages:

- May not be suitable for non-magnetic materials.

- Requires a clean surface to ensure proper magnetic adhesion.

- May require additional safety measures to prevent accidental release of the coil.

Horizontal steel coil lifting Crane with C-Hooks / Coil Lifters

A horizontal steel coil lifting C-hook crane is a type of crane that uses a C-shaped hook to lift and transport steel coils horizontally. The C-hook is designed to securely grip the coil, allowing it to be lifted and moved safely.

C hook overhead crane -customized overhead steel coil lifting equipment

Horizontal c hook bridge crane, economical steel coil material handling equipment

C hook lifting gantry crane for outdoor horizontal steel coil lifting

- Increased efficiency in handling and transporting steel coils

- Reduced risk of damage to the coils during transport

- Improved safety for workers compared to manual handling

- Can be used with a variety of different types and sizes of steel coils

Disadvantages of C-hook cranes:

- Higher initial cost compared to manual handling methods

- Requires specialized training for operators

- May not be suitable for handling certain types of steel coils

Features of C-hook cranes:

- Typically designed to lift and transport steel coils horizontally

- Available in a range of sizes and weight capacities

- Can be customized to suit specific applications

Uses and applications of C-hook cranes: Steel mills,Warehouses,Shipping yards,Anywhere large quantities of steel coils need to be moved quickly and efficiently, etc

Options for C-hooks include different sizes and weight capacities, as well as different materials and coatings to suit specific applications. Some C-hooks also feature adjustable arms or other customization options.The best C-hook for your work will depend on your lifting requirements and be dependent on your material, lifting distance, and clearance. The most popular coil hangers that can be made specifically for your company are Vertical Coil Lifters, Tubular C-Hooks, Narrow Aisle Coil Hooks, Telescoping Horizontal Coil Lifters, and Compact C-Hooks,etc.

Double leg steel coil lifting devices for horizontal steel coil lifting

Double leg steel coil lifter, economical two-sided coil lifer for horizontal steel coils handling with overhead cranes & gantry cranes. Get your coil lifter!

30 ton coil lifter with adjusting beam design for horizontal steel coil handling crane

32 ton double leg lifting device for horizontal steel coil handling overhead crane

30 ton overhead bridge crane with double leg lifter for steel coil handling

Double leg steel coil lifting cranes are overhead cranes and gantry cranes equipped with double leg steel coil lifting devices for horizontal steel coil lifting, transportation and handling.

Advantages:

- Can handle heavy coils with ease.

- Provides a secure grip on the coil.

- Can be used for both horizontal and vertical coil handling.

Disadvantages:

- May not be suitable for smaller coils.

- Requires additional equipment to adjust the legs for different coil sizes.

The specific advantages and disadvantages of each type of crane will depend on the specific requirements of the job, such as the size and weight of the coils, the frequency of use, and the available space for maneuvering the crane.

Horizontal steel coil handling clamp cranes

Steel coil clamp cranes are cranes that are designed to lift and transport steel coils using a specialized clamp attachment. The clamp is designed to securely grip the coil and prevent it from slipping or shifting during transport. These cranes are commonly used in steel mills, warehouses, and shipping yards to move large quantities of steel coils quickly and efficiently.

15 ton steel coil lifting equipment - overhead crane with 15 ton clamp

25 ton steel coil material handling equipment indoor crane for horizontal coil lifting

35 ton overhead clamp cranes

Advantages of coil clamp cranes:

- Increased efficiency in handling and transporting steel coils

- Reduced risk of damage to the coils during transport

- Improved safety for workers compared to manual handling

Disadvantages of coil clamp cranes:

- Higher initial cost compared to manual handling methods

- Requires specialized training for operators

- May not be suitable for handling certain types of steel coils

Typical applications of horizontal steel coil clamp cranes include steel mills, warehouses, and shipping yards where large quantities of steel coils need to be moved quickly and efficiently.

There are several types of crane clamps available, including vertical and horizontal clamps, mechanical and hydraulic clamps, and single and double clamps.

To customize a steel coil clamp for horizontal coil handling, factors such as the size and weight of the coils, the type of clamp needed, and any specific requirements for the application should be taken into consideration. A manufacturer or supplier of coil clamp cranes can assist with customization and selection of the appropriate clamp for the job.

Magnetic overhead crane for horizontal steel coil lifting

magnetic overhead cranes can also be used for horizontal coil handling. These cranes use a magnetic lifting attachment to lift and transport steel coils in a horizontal position. The magnetic attachment is designed to securely grip the coil and hold it in place during transport. However, it's important to note that magnetic cranes may not be suitable for all types of steel coils, as some materials may not be magnetic or may require a different type of lifting attachment. Additionally, the weight and size of the coil will need to be within the capacity of the magnetic crane and its lifting attachment.

Magnetic overhead crane for horizontal steel coil lifing -customized steel coil material handling crane

Double girder overhead crane with 5 ton magnetic lifter for horizonal steel coil handling

Permenant magnet for your selection

Advantages of magnetic cranes for horizontal steel coil handling:

- Increased efficiency in handling and transporting steel coils

- Reduced risk of damage to the coils during transport

- Improved safety for workers compared to manual handling

- No need for additional clamps or attachments, as the magnet can securely grip the coil

Disadvantages of magnetic cranes:

- Higher initial cost compared to manual handling methods

- May not be suitable for handling certain types of steel coils, such as those with non-magnetic properties

- Requires specialized training for operators

Typical applications of magnetic cranes for steel coil handling include steel mills, warehouses, and shipping yards where large quantities of steel coils need to be moved quickly and efficiently.

Types of crane magnets for horizontal steel coil handling include:

- Electro-permanent magnets: these magnets use a combination of electric and magnetic fields to securely grip the steel coil.

- Permanent magnets: these magnets use a permanent magnetic field to grip the steel coil.

It's important to note that the type of magnet used will depend on the specific requirements of the application, such as the size and weight of the steel coil and any environmental factors that may affect the magnet's performance.

Hot coil lifting devices

There are several types of hot coil lifting devices that are designed to lift and transport hot steel coils in high-temperature environments. Some common types of hot coil lifting devices include:

- Coil hooks: These are specialized lifting hooks that are designed to lift and transport hot steel coils. They are typically made from heat-resistant materials and can withstand exposure to high temperatures.

- C-hooks: These are similar to coil hooks but have a curved shape that allows them to cradle the coil. They are also made from heat-resistant materials and can withstand exposure to high temperatures.

- Coil grabs: These are specialized lifting devices that are designed to grip the coil securely and lift it in a horizontal position. They are typically made from heat-resistant materials and can withstand exposure to high temperatures.

- Coil tongs: These are specialized lifting devices that grip the coil from the sides and can be used for both horizontal and vertical lifting. They are typically made from heat-resistant materials and can withstand exposure to high temperatures.

- Magnetic lifters: These are specialized lifting devices that use a magnetic field to lift and transport hot steel coils. They are typically made from heat-resistant materials and can withstand exposure to high temperatures.

- The specific type of hot coil lifting device used will depend on factors such as the size and weight of the coil, the specific requirements of the job, and the available space in the production facility. It's important to use lifting devices that are specifically designed for hot steel coil lifting to ensure safe and efficient handling of the coils.

Where the steel coil lifting cranes are used for horizontal steel coil handling

Steel coil lifting cranes are used for horizontal steel coil handling in a variety of industries, including:

Steel manufacturing: Steel coil lifting cranes are commonly used in steel mills and other manufacturing facilities to lift and transport steel coils during the production process.

- Shipping and logistics: Steel coils are often transported by ship or rail, and steel coil lifting cranes may be used to load and unload the coils from cargo containers or railcars.

- Construction: Steel coils are sometimes used in construction projects, such as for reinforcing concrete structures, and steel coil lifting cranes may be used to transport the coils to the construction site.

- Automotive industry: Steel coils are used to manufacture automotive parts, and steel coil lifting cranes may be used to transport the coils within the manufacturing facility.

- Heavy equipment industry: Steel coils are used to manufacture heavy equipment, and steel coil lifting cranes may be used to transport the coils within the manufacturing facility.

Overall, steel coil lifting cranes are used in any industry where large, heavy steel coils need to be transported horizontally. The specific type of crane used will depend on factors such as the size and weight of the coils, the specific requirements of the job, and the available space in the production facility or transportation setting.

Custom horizontal steel coil lifting crane & devices

Steel coil lifting cranes and material handling equipment for all types of steel coil handling

The weight and sizes of general steel coils can vary depending on the specific type of steel and its intended use. However, here are some general guidelines:

- Hot rolled coil (HRC) typically weighs between 6 and 35 tons and has a width of 600 to 2,000 millimeters (mm) and a thickness of 1.2 to 16 millimeters.

- Cold rolled coil (CRC) typically weighs between 0.5 and 4 tons and has a width of 600 to 2,000 mm and a thickness of 0.3 to 3 mm.

- Galvanized coil (GI) typically weighs between 3 and 15 tons and has a width of 600 to 2,000 mm and a thickness of 0.3 to 3 mm.

- Electro-galvanized coil (EGI) typically weighs between 0.5 and 4 tons and has a width of 600 to 2,000 mm and a thickness of 0.3 to 3 mm.

It's important to note that these are general guidelines and the weight and sizes of steel coils can vary depending on the specific manufacturer and product.

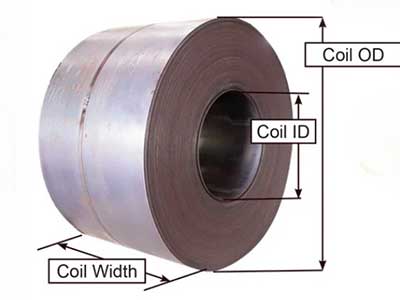

Main dimensions of horizontal steel coils

The main dimensions of horizontal steel coils can vary depending on the specific type and application of the coil. However, the following are some common dimensions that are often used to describe steel coils:

- Outer diameter: This refers to the diameter of the coil when measured from one edge to the opposite edge.

- Inner diameter: This refers to the diameter of the hole in the center of the coil, which is often used to mount the coil on a spindle or mandrel.

- Width: This refers to the distance between the two edges of the coil.

- Thickness: This refers to the thickness of the steel material used to create the coil.

- The specific dimensions of a horizontal steel coil will depend on factors such as its intended use, manufacturing process, and industry standards.

How these factor affect steel coil lifting devices? -The factors that affect steel coil lifting devices include the size and weight of the coil, the shape of the coil, and the specific requirements of the job. Here are some ways in which these factors can impact the design and performance of steel coil lifting devices:

- Size and weight: The size and weight of the coil will determine the capacity of the lifting device needed to safely lift and transport the coil. Larger and heavier coils will require stronger lifting devices with higher weight capacities.

- Shape: The shape of the coil can also affect the type of lifting device needed. For example, some coils may require lifting devices with specialized hooks or clamps to securely grip the coil and prevent damage.

- Job requirements: The specific requirements of the job, such as the distance the coil needs to be transported or the frequency of lifts, will also impact the design and performance of lifting devices. For example, if the coil needs to be lifted and transported over long distances, a crane with a longer reach may be needed.

Overall, it's important to carefully consider these factors when selecting a steel coil lifting device to ensure that it can safely and efficiently handle the specific requirements of the job.

How to select a coil lifting crane and steel coil lifting devices?

When selecting a coil lifting crane and steel coil lifting devices, there are several factors to consider to ensure safe and efficient handling of the coils. Some key factors to consider include:

- Coil size and weight: The size and weight of the coil will determine the capacity of the lifting device needed to safely lift and transport the coil.

- Coil shape: The shape of the coil can also affect the type of lifting device needed. For example, some coils may require lifting devices with specialized hooks or clamps to securely grip the coil and prevent damage.

- Lifting position: The position in which the coil needs to be lifted will also impact the type of lifting device needed. For example, if the coil needs to be lifted in a horizontal position, a coil grab or C-hook may be needed, while a magnetic lifter may be more suitable for vertical lifting.

- Environmental factors: The specific environment in which the lifting device will be used, such as temperature, humidity, and available space, will also impact the type of device needed.

- Safety requirements: It's important to select lifting devices that meet all relevant safety standards and regulations to ensure safe operation and prevent accidents.

Overall, it's important to carefully consider these factors when selecting a coil lifting crane and steel coil lifting devices to ensure that they can safely and efficiently handle the specific requirements of the job. It may be helpful to consult with a qualified engineer or lifting equipment specialist to determine the best options for your specific application.

What are the parameters needed for horizontal steel coil lifters ?

The parameters needed for horizontal steel coil lifters depend on the specific type of lifter being used, but may include:

- Weight capacity: the maximum coil weight that the lifter can safely lift and transport

- Coil width: the width of the steel coil that the lifter is designed to handle

- Coil diameter: the diameter of the steel coil that the lifter is designed to handle

- Arm length: the length of the arms that hold the steel coil

- Clamp type: the type of clamp used to grip the steel coil

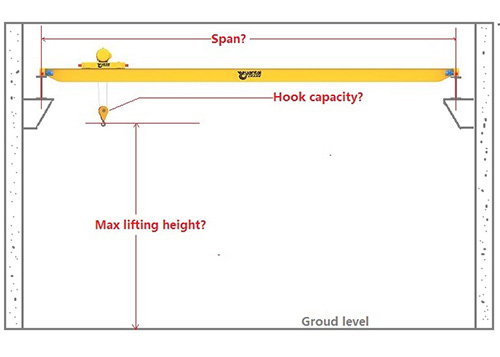

What are the parameters needed for horizontal steel coil lifting cranes?

The parameters needed for horizontal steel coil lifting cranes may include:

- Crane type: the specific type of crane being used, such as a bridge crane, gantry crane, or jib crane

- Weight capacity: the maximum weight that the crane can safely lift and transport

- Crane span: the distance between the crane's supports or rails

- Hook height: the maximum height that the crane's hook can reach

- Trolley speed: the speed at which the crane's trolley can move along its rails

- Hoist speed: the speed at which the crane's hoist can lift and lower loads

It's important to note that these parameters may vary depending on the specific manufacturer and product, and that selecting the appropriate parameters for a given application is critical for safe and efficient operation. Contact us to get your customized horizontal steel coil lifting equipment and lifting devices. Contact us today to check what we can do to save your steel coil handling and lifting cost.

Main Projects

Related Products

22/5 Ton Overhead Crane Double Hook System: Robust double girder crane with 22-ton main and 5-ton auxiliary hooks for heavy lifting. Get double hook crane!

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch