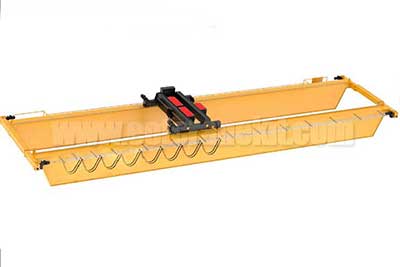

Heavy Duty 16 Ton C-Hook Crane for Large Roll in Metal Production

Heavy Duty C-Hook Cranes16 ton expertly handle large roll in demanding metal production facilities for efficient material handling. 16 ton crane for sale.

Category: Coil Handling

Your Trusted 16 Ton Crane Manufacturer & Supplier

Heavy Duty 16 Ton C-Hook Crane for Large Roll in Metal Production

Heavy Duty C-Hook Cranes16 ton expertly handle large roll in demanding metal production facilities for efficient material handling. 16 ton crane for sale.

Heavy Duty C-Hook Cranes 16 Ton for Large Rolls in Heavy-Duty Metal Production Facilities

Heavy-duty C-Hook cranes are essential equipment used in industries requiring the handling of large, heavy rolls, such as metal production facilities. These cranes are designed to lift and transport substantial loads with precision and safety. The C-Hook mechanism, an adaptable and robust lifting tool, enables the secure handling of large rolls of steel and aluminum, which are common in heavy-duty manufacturing processes.

In metal production, large rolls of steel and aluminum are fundamental to the manufacturing process. These rolls are often heavy and cumbersome, making their handling critical to the efficiency and safety of production operations. Effective handling ensures that the rolls are moved smoothly through various stages of production, reducing the risk of damage and increasing overall operational efficiency. Heavy-duty C-Hook cranes play a vital role in managing these large rolls, facilitating their movement between storage, processing, and shipping areas.

16 Ton C-Hook Cranes for Sale

Our 16-ton C-Hook cranes are engineered for high-capacity metal production and large-scale manufacturing operations. Designed to handle substantial loads with precision and reliability, these cranes are ideal for managing heavy steel and aluminum rolls in demanding environments. Featuring robust construction, advanced load stabilization, and customizable configurations, our C-Hook cranes ensure efficient and safe handling of large rolls, enhancing productivity and operational efficiency in various industrial settings. Explore our selection to find the perfect solution for your heavy-duty lifting needs.

Types of 16 Ton C-Hook Cranes for Sale

Double Girder Overhead C-Hook Cranes

- Design: Features two parallel girders that provide superior strength and stability.

- Capacity: Handles 16 tons with ease, making it suitable for heavy-duty lifting.

- Applications: Ideal for large manufacturing facilities and steel processing plants.

- Advantages: Enhanced load stability, high precision, and the ability to span large distances.

Single Girder Overhead C-Hook Cranes

- Design: Utilizes a single girder for a more compact and cost-effective solution.

- Capacity: Designed to manage 16 tons with precision.

- Applications: Suitable for warehouses, production lines, and smaller industrial facilities.

- Advantages: Reduced installation costs and space requirements, while still offering reliable performance.

Full Gantry C-Hook Cranes

- Design: Features a complete gantry structure with two vertical supports and a horizontal beam running along the top.

- Capacity: Capable of handling 16-ton loads, designed for heavy-duty lifting.

- Applications: Ideal for large outdoor environments, heavy-duty metal production facilities, and large manufacturing plants.

- Advantages: High mobility and flexibility, capable of spanning large areas and moving freely across the worksite.

Semi-Gantry C-Hook Cranes

- Design: Combines a partial gantry structure with one side supported by a building or wall while the other side is on a rail system.

- Capacity: Handles 16-ton loads with stability and precision.

- Applications: Suitable for facilities with limited space or where one side of the crane can be anchored to an existing structure.

- Advantages: Cost-effective compared to full gantry systems, ideal for partial coverage and utilizing existing building infrastructure for support.

Explosion-Proof C-Hook Cranes

- Design: Built to withstand hazardous environments with special protective measures.

- Capacity: Handles up to 16 tons safely in explosive or corrosive conditions.

- Applications: Suitable for chemical plants, oil refineries, and other hazardous industrial settings.

- Advantages: Enhanced safety features and durability in challenging environments.

Benefits of Handling 16-Ton Loads in Metal Production

Handling 16-ton loads with a C-Hook crane offers several benefits:

- Improved Efficiency: With the ability to lift heavy rolls efficiently, production lines can maintain a steady workflow, minimizing delays caused by manual handling or insufficient equipment.

- Enhanced Safety: Properly rated cranes reduce the risk of accidents and injuries associated with lifting and moving heavy loads. They provide a secure and stable method for handling large rolls, minimizing the chances of accidents.

- Operational Flexibility: A 16-ton crane can handle a range of large roll sizes and weights, offering versatility in various metal production applications. This flexibility allows for the accommodation of different types of rolls and production requirements.

Typical Loads: Large Steel and Aluminum Rolls

Characteristics of Large Rolls in Steel and Aluminum

Large rolls of steel and aluminum are integral to many manufacturing processes. These rolls typically have:

- Substantial Weight: Often ranging from 10 to 20 tons, these rolls require robust lifting solutions to ensure safe handling.

- Significant Dimensions: The rolls are large in diameter and width, making them cumbersome to move and requiring specialized equipment to manage their size and weight.

- High Value: Due to their size and material, these rolls are expensive and critical to production, necessitating careful handling to avoid damage.

Challenges Associated with Handling These Loads

Handling large steel and aluminum rolls presents several challenges:

- Weight Management: The heavy weight of these rolls demands strong and reliable cranes to prevent overloading and ensure safety during lifting and movement.

- Size Constraints: The large dimensions of the rolls can create difficulties in maneuvering them within the production facility, especially in areas with limited space or complex layouts.

- Load Stability: Ensuring the stability of large rolls during lifting and transport is crucial to prevent accidents and damage. The handling equipment must securely grip and support the rolls to avoid shifting or rolling during movement.

- Precision Handling: The need for accurate placement and positioning of large rolls requires precise control mechanisms to ensure the rolls are placed correctly without causing disruptions to the production process.

By addressing these challenges with appropriately designed heavy-duty C-Hook cranes, metal production facilities can enhance their operational efficiency and maintain high safety standards.

Hot Sale 16 Ton Cranes for Coil Handling

Double Girder Overhead C-Hook Cranes

Design and Construction

- Robust Structure: Features two parallel beams, providing superior strength and stability.

- Increased Capacity: Handles up to 16 tons with ease, ideal for heavy-duty tasks.

- Wide Span: Capable of covering larger distances, suitable for extensive production areas.

Functionality and Operation

- Enhanced Load Stability: Reduces sway and ensures secure handling of large rolls.

- Precise Control: Offers accurate positioning and minimal risk of damage.

- Advanced Controls: Equipped with radio or cabin controls and optional automation systems for improved efficiency.

Single Girder Overhead C-Hook Cranes

Design and Construction

- Compact Design: Utilizes a single beam for a more space-efficient solution.

- Cost-Effective: Lower installation and operational costs while handling up to 16 tons.

- Flexible Application: Ideal for warehouses, smaller production lines, and industrial settings.

Functionality and Operation

- Reliable Performance: Manages heavy loads with precision despite its more compact design.

- Reduced Space Requirements: Efficient in facilities with limited space, while still offering dependable load handling.

- Simplified Controls: Typically features straightforward control systems that are easy to operate.

Full Gantry C-Hook Cranes

Design and Construction

- Sturdy Framework: Supported by legs and a beam system, providing a stable base for heavy lifting.

- High Capacity: Suitable for lifting and transporting loads up to 16 tons.

- Versatile Applications: Ideal for large production areas and outdoor environments.

Functionality and Operation

- Mobility: Can be moved across large areas, offering flexibility in positioning and use.

- Enhanced Load Handling: Equipped with robust features to manage heavy rolls efficiently.

- Durable Construction: Designed to withstand harsh working conditions and heavy use.

Semi-Gantry C-Hook Cranes

Design and Construction

- Hybrid Design: Combines elements of both gantry and overhead cranes, with one end supported on wheels and the other on a fixed track.

- Capacity: Handles up to 16 tons, providing a balance between flexibility and stability.

- Adaptable Use: Suitable for various manufacturing and storage environments.

Functionality and Operation

- Flexible Movement: Can travel along a fixed track while allowing for lateral movement within the facility.

- Efficient Handling: Facilitates the handling of large rolls with precision and stability.

- Cost-Effective: Offers a compromise between full gantry systems and overhead cranes, often at a lower cost.

Design and Construction

- Safety Features: Designed for use in hazardous environments where explosive materials are present.

- Explosion-Proof Construction: Built with materials and designs that prevent ignition or sparks, ensuring safety in sensitive areas.

- Specialized Components: Includes explosion-proof motors, controls, and wiring.

Functionality and Operation

- Safe Operation: Ensures safe handling of heavy loads in hazardous environments.

- Compliance: Meets stringent safety regulations for explosive atmospheres.

- Durability: Constructed to withstand harsh and potentially dangerous working conditions.

Single Girder C-Hook Gantry Cranes

Design and Construction

- Compact Structure: Utilizes a single girder supported by two legs, offering a more space-efficient design compared to double girder systems.

- Capacity: Designed to handle up to 16 tons, making it suitable for medium to heavy-duty applications.

- Cost-Effective: More economical in terms of initial investment and maintenance costs, ideal for budget-conscious projects.

Functionality and Operation

- Versatile Movement: Can move along tracks or rails, allowing for flexibility in positioning and operation within the facility.

- Stable Performance: Provides reliable load handling and stability, essential for managing large rolls.

- Simplified Controls: Typically equipped with straightforward control systems that enhance ease of use and operational efficiency.

Double Girder C-Hook Gantry Cranes

Design and Construction

- Robust Framework: Features two parallel girders supported by robust legs, providing enhanced strength and stability for heavy-duty applications.

- High Capacity: Capable of lifting up to 16 tons, suitable for handling very large rolls and heavy loads.

- Wide Span: Can cover larger spans and extensive areas, making it ideal for large-scale production and storage facilities.

Functionality and Operation

- Superior Load Stability: The dual girder design ensures excellent load stability and minimizes deflection, crucial for safe and precise handling of heavy loads.

- Advanced Mobility: Offers flexible movement along tracks or rails, allowing for efficient positioning across large areas.

- Enhanced Controls: Often equipped with sophisticated control systems, including automation options, to improve operational efficiency and safety.

Typical Applications

Heavy-Duty Metal Production Facilities

Steel Production Plants

Use of C-Hook Cranes for Moving Large Steel Rolls In steel production plants, C-Hook cranes are crucial for efficiently handling and moving large steel rolls. These rolls, often weighing up to 16 tons, are integral to various stages of steel processing, including rolling, cutting, and packaging. C-Hook cranes are specifically designed to lift and transport these heavy rolls with precision and safety.

Typical Challenges and Solutions in Steel Processing

Challenge: Load Stability

Solution: Load Stabilizers and Adjustable Hooks

Handling large steel rolls presents the challenge of maintaining load stability during movement. To address this, C-Hook cranes are designed with advanced stabilizing features:

- Load Stabilizers: These devices are integrated into the crane system to prevent unwanted swaying and shifting of the load. Stabilizers ensure that the rolls remain securely in place while being lifted or transported, which is crucial for avoiding accidents and damage to the material.

- Adjustable Hooks: C-Hook cranes often come equipped with adjustable hooks that can be customized to fit different roll sizes and weights. This adaptability allows for a secure grip on the load, further enhancing stability and reducing the risk of load instability.

These features collectively contribute to safer and more efficient handling of heavy steel rolls, minimizing the risk of material damage and improving operational safety.

Challenge: Space Constraints

Solution: High Maneuverability and Precise Control

Steel processing facilities often operate in environments with limited space, where maneuvering large equipment can be challenging. C-Hook cranes are equipped to handle these constraints effectively:

- Overhead Crane Systems: These cranes are installed above the workspace, allowing them to operate in areas where ground space is limited. Their design enables them to move freely along tracks or rails without interfering with other equipment or processes.

- Precise Control Systems: Modern C-Hook cranes feature advanced control systems that allow operators to maneuver with high precision. This capability is essential for navigating confined spaces and executing accurate load placement without obstructing other parts of the production line or facility.

By combining overhead installation with precise control, C-Hook cranes can efficiently manage space constraints, ensuring smooth and effective operations even in congested environments.

Challenge: Heavy Load Handling

Solution: Robust Construction and High Load Capacity

Handling large steel rolls requires cranes that can withstand significant weight without compromising performance or safety. C-Hook cranes address this challenge through:

- Robust Construction: Built with heavy-duty materials and engineering, C-Hook cranes are designed to endure the stresses associated with lifting and moving heavy loads. Their structural integrity ensures they can handle the weight of large steel rolls while maintaining safety and durability.

- High Load Capacity: C-Hook cranes are specifically engineered to manage substantial loads, including those up to 16 tons or more. The cranes' load-bearing components, such as the hoists, supports, and hooks, are rated to handle these weights, ensuring reliable performance even under the most demanding conditions.

These design features ensure that C-Hook cranes can efficiently and safely manage heavy loads, contributing to streamlined operations and reduced downtime in steel processing facilities.

Aluminum Production Plants

Handling Aluminum Rolls and Associated Considerations

Material Sensitivity

Aluminum is a relatively soft and lightweight metal compared to steel, making it more prone to surface damage. In aluminum production facilities, handling large aluminum rolls requires special attention to avoid damaging the material:

- Protective Features: C-Hook cranes used for aluminum rolls are often equipped with protective features such as cushioned grips and padded contact points. These additions help prevent scratches, dents, and other surface imperfections during lifting and movement.

- Specialized Hooks: The design of C-Hook cranes for aluminum handling typically includes specialized hooks or attachments that ensure a gentle but secure grip on the rolls. These hooks are engineered to minimize pressure on the aluminum surface, reducing the risk of damage.

Temperature Control

Aluminum processing frequently involves high temperatures, particularly during melting and rolling processes. To address the challenges posed by these thermal conditions, C-Hook cranes in aluminum production facilities incorporate:

- Heat-Resistant Components: C-Hook cranes are designed with heat-resistant materials and coatings to withstand elevated temperatures present in aluminum processing environments. Components such as bearings, cables, and structural elements are selected or treated to resist heat and prevent degradation.

- Thermal Insulation: Some cranes may feature thermal insulation on critical parts to protect them from heat exposure, ensuring reliable operation and longevity of the equipment.

Integration with Other Production Equipment

Efficient operation in aluminum production plants often involves coordinating C-Hook cranes with other equipment:

- Automated Systems: C-Hook cranes are frequently integrated into automated control systems that synchronize their movements with other machinery, such as rolling mills and cutting machines. This integration allows for precise control and seamless operation throughout the production process.

- Streamlined Workflow: By connecting cranes with other production equipment, aluminum facilities can create a streamlined workflow that reduces manual handling and improves overall efficiency. Automated systems can optimize crane operation based on production needs, minimizing downtime and increasing throughput.

These considerations ensure that C-Hook cranes effectively meet the unique requirements of aluminum production, supporting efficient handling of aluminum rolls while maintaining the quality of the material and integrating smoothly with other production processes.

Large Manufacturing Plants

General Manufacturing Applications

Adaptation of C-Hook Cranes for Varied Manufacturing Needs

In large manufacturing plants, C-Hook cranes offer versatile solutions for handling diverse types of large rolls, including those used in industries such as textiles, paper, and film. Their adaptability allows for customization to fit different load types and production processes. Key adaptations include:

Adjustable Hook Designs:

- Customizable Hooks: C-Hook cranes can be fitted with adjustable hooks that can be modified to accommodate various roll sizes and types. This customization ensures that the hooks securely grip different roll dimensions, enhancing safety and efficiency during handling.

- Interchangeable Attachments: Some C-Hook systems come with interchangeable attachments or extensions, allowing the crane to adapt to various roll configurations and sizes without needing separate equipment.

Variable Load Capacities:

- Flexible Capacity Options: C-Hook cranes can be equipped to handle a range of load capacities, from lighter rolls to heavier ones, depending on the production needs. This flexibility allows manufacturing plants to use a single crane system for multiple tasks, reducing the need for specialized equipment.

- Scalable Solutions: Cranes can be designed with scalable load capacities, enabling them to handle different weights as required by the manufacturing process. This adaptability ensures that the crane remains useful as production demands evolve.

Case Studies of Successful Implementations

Case Study 1: Textile Manufacturing Facility

- Implementation: A large textile manufacturing plant integrated a double girder C-Hook crane to handle massive rolls of fabric. The crane was chosen for its precision control, load stability, and ability to manage large, heavy rolls efficiently.

- Results: The integration led to a significant increase in throughput and a reduction in product damage. The precise control features of the crane minimized the risk of fabric tearing or wrinkling, demonstrating the crane's effectiveness in improving operational efficiency and reducing downtime caused by manual handling.

Case Study 2: Paper Production Plant

- Implementation: A paper production plant adopted a robust gantry crane system to manage large rolls of paper. The crane's design featured high mobility and adaptability, allowing it to serve multiple production lines and storage areas within the plant.

- Results: The plant experienced improved workflow and reduced operational costs. The gantry crane's versatility and mobility allowed it to handle rolls across various stages of production and storage, highlighting the benefits of using C-Hook cranes for large roll handling in a high-capacity manufacturing environment.

By addressing the specific needs and challenges of each application, C-Hook cranes significantly contribute to enhanced efficiency, safety, and productivity across different industrial settings. These cranes are pivotal in streamlining operations and adapting to the diverse requirements of large manufacturing plants.

Industry-Specific Considerations

Heavy-Duty Metal Production

Operational Efficiency

Enhancing Productivity with C-Hook Cranes C-Hook cranes play a vital role in improving operational efficiency in heavy-duty metal production facilities. Key factors contributing to enhanced productivity include:

- Streamlined Handling: C-Hook cranes facilitate the quick and efficient movement of large rolls, reducing downtime and increasing throughput.

- Precision Handling: Advanced control systems allow for accurate positioning of heavy rolls, minimizing handling errors and optimizing production workflows.

- Reduced Labor Costs: Automation and efficient crane operation reduce the need for manual labor, leading to cost savings and better allocation of resources.

Maintenance and Reliability in High-Capacity Environments Maintaining reliability in high-capacity environments is crucial for continuous operations:

- Routine Maintenance: Regular inspections and maintenance of C-Hook cranes help prevent unexpected breakdowns. Key maintenance tasks include checking for wear and tear, lubricating moving parts, and ensuring proper alignment.

- Durability: Heavy-duty C-Hook cranes are designed to withstand the rigors of metal production, including handling high weights and operating in harsh environments. Choosing cranes with durable materials and robust construction ensures long-term reliability.

Safety and Compliance

Meeting Industry Safety Standards and Regulations Compliance with industry safety standards is essential for safe crane operations:

- Regulatory Compliance: Adherence to standards such as ISO, ANSI, and OSHA ensures that C-Hook cranes meet safety and performance requirements. Regular audits and certification processes verify compliance.

- Risk Assessments: Conducting thorough risk assessments helps identify potential hazards and implement appropriate safety measures.

Safety Features Specific to Heavy-Duty Cranes Heavy-duty C-Hook cranes incorporate several safety features to protect operators and equipment:

- Overload Protection: Integrated sensors and alarms detect excessive loads, preventing crane overload and potential damage.

- Emergency Stop Systems: Quick-access emergency stop controls allow for immediate halting of crane operations in case of an emergency.

- Anti-Collision Systems: Sensors and safety barriers prevent collisions with other equipment or structures, enhancing overall safety in busy production areas.

Manufacturing Plants

Customization for Large Rolls

Tailoring Cranes for Different Types of Rolls and Loads Customizing C-Hook cranes to handle various types of rolls and loads is essential for optimizing performance:

- Adjustable Hook Designs: Customizable hooks can be adapted to securely grip different sizes and shapes of rolls, ensuring a proper fit and safe handling.

- Load-Specific Features: Incorporating features like adjustable spreaders and tailored lifting mechanisms allows cranes to handle diverse loads effectively.

Special Attachments and Modifications Special attachments and modifications enhance the versatility of C-Hook cranes:

- Special Attachments: Attachments such as roll clamps or specialized grippers can be added to handle specific types of rolls, such as paper, fabric, or film.

- Modifications: Custom modifications, including extended reach or adjustable heights, enable cranes to work in varied manufacturing environments and accommodate specific production needs.

By addressing these industry-specific considerations, C-Hook cranes can be optimized for maximum efficiency, safety, and versatility in both heavy-duty metal production and manufacturing plant applications.

Advantages and Challenges

Advantages of 16-Ton Heavy-Duty C-Hook Cranes

Increased Efficiency and Productivity

- Enhanced Operational Speed 16-ton heavy-duty C-Hook cranes significantly boost efficiency by accelerating the handling of large rolls. Their ability to quickly lift, move, and place heavy loads reduces the time required for each operation, which speeds up overall production processes.

- Optimized Workflow Integration These cranes integrate seamlessly with other production equipment, such as rolling mills and cutting machines, enhancing workflow efficiency. Automated control systems enable precise handling, which minimizes interruptions and streamlines the manufacturing process.

Reduced Labor Costs The automation capabilities of 16-ton C-Hook cranes reduce the need for manual intervention. By automating repetitive and heavy lifting tasks, facilities can lower labor costs and reallocate workforce resources to more complex tasks.

Improved Safety and Load Handling

- Enhanced Load Stability C-Hook cranes are designed to handle heavy loads with superior stability. Features such as load stabilizers and secure gripping mechanisms reduce the risk of load sway and potential accidents, ensuring safer operations.

- Advanced Safety Features 16-ton C-Hook cranes are equipped with advanced safety features, including overload protection systems and emergency stop controls. These features help prevent accidents and ensure that operations adhere to safety standards.

- Durability and Reliability Built to withstand the demanding conditions of heavy-duty applications, these cranes offer long-term reliability. Their robust construction and durable materials ensure consistent performance even under the stress of handling large, heavy rolls.

Challenges and Solutions

Handling Large, Heavy Loads: Common Issues and How to Address Them

Issue: Load Sway and Instability

- Solution: Implementing advanced load stabilization systems and adjustable hooks helps secure large rolls during handling. Regular maintenance and calibration of these systems also ensure continued effectiveness.

Issue: Space Constraints

- Solution: In confined spaces, maneuverability can be challenging. Using cranes with compact designs or adding features like variable reach and height adjustments can enhance flexibility and maneuverability.

Issue: Mechanical Wear and Tear

- Solution: Routine maintenance is essential for addressing wear and tear. Implementing a proactive maintenance schedule, including inspections and timely repairs, helps prevent mechanical failures and extends the crane's lifespan.

Ensuring Crane Longevity and Performance Under Heavy-Duty Conditions

Issue: High Operational Stress

- Solution: Selecting cranes with robust construction and high-quality materials is critical. Additionally, incorporating features such as stress-resistant components and reinforced structures can enhance durability.

Issue: Maintenance and Downtime

- Solution: Establishing a comprehensive maintenance plan, including regular inspections and preventive maintenance, helps ensure the crane remains in optimal condition. Training maintenance personnel and using genuine parts also contribute to minimizing downtime and extending the crane's operational life.

Issue: Environmental Factors

- Solution: C-Hook cranes operating in harsh environments, such as extreme temperatures or corrosive conditions, require specialized coatings and protective measures. Implementing anti-corrosion treatments and ensuring proper ventilation can help protect the crane and maintain its performance.

By understanding and addressing these advantages and challenges, facilities can maximize the benefits of 16-ton heavy-duty C-Hook cranes while effectively managing potential issues associated with their operation.

Conclusion

Summary of Key Points

Recap of the Role and Benefits of 16-Ton C-Hook Cranes

Heavy-duty C-Hook cranes with a 16-ton capacity play a crucial role in managing large rolls of steel and aluminum within high-capacity metal production facilities. These cranes are designed to handle substantial loads efficiently, ensuring the safe and precise movement of heavy materials. Their robust construction and specialized design features make them indispensable for operations where high-load handling is essential.

Overview of Typical Applications and Crane Types

In metal production facilities, including steel and aluminum processing plants, 16-ton C-Hook cranes are employed to move large rolls from one point to another, facilitating the production and processing of metal sheets and coils. The two primary types of C-Hook cranes used in these settings are:

- Double Girder Overhead Cranes: Known for their durability and high load capacity, these cranes provide excellent stability and precision in handling large rolls. They are ideal for environments that require high lifting heights and precise load positioning.

- Robust Gantry Cranes: These cranes offer flexibility and mobility, making them suitable for large production areas. They can handle heavy loads and are adaptable to various manufacturing processes.

By understanding the specific benefits and configurations of these crane types, facilities can optimize their operations and improve overall efficiency.

Final Considerations

Choosing the Right C-Hook Crane for Heavy-Duty Metal Production

Selecting the appropriate C-Hook crane for heavy-duty metal production involves evaluating several factors, including load capacity, operational environment, and specific application requirements. Considerations should include:

- Load Capacity: Ensure the crane can handle the maximum load of 16 tons with ease, including any additional safety margins.

- Crane Type: Decide between double girder overhead cranes for high precision and stability or robust gantry cranes for mobility and flexibility.

- Customization: Assess any specific needs for crane customization to fit unique operational requirements or environmental conditions.

Anticipated Future Developments and Their Impact on Crane Operations

Looking ahead, advancements in crane technology, such as smart sensors, automation, and improved materials, will further enhance the performance and capabilities of C-Hook cranes. These innovations are expected to increase efficiency, safety, and operational flexibility in metal production environments.

By staying informed about these developments and considering future trends, facilities can make informed decisions about upgrading or investing in new crane systems. This forward-thinking approach will ensure continued success and adaptability in a competitive industry.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch