Tailored C Hook : How to Custom C Hook for Steel Coil Handling

Steel coil C hook 5 Ton, 10 Ton, 16 Ton, 25 ton, 32 ton for sale. How to select suitable C hook design for steel coil handling? Get your crane C Hook.

Category: Coil Handling

Your Trusted Overhead Crane Manufacturer & Supplier

Tailored C Hook : How to Custom C Hook for Steel Coil Handling

Steel Coil C hook 5 Ton, 10 Ton, 16 Ton, 25 Ton, 32 Ton for Sale, Tailored for Your Steel Coil Mill

Steel coil C hook 5 Ton, 10 Ton, 16 Ton, 25 ton, 32 ton for sale. How to select suitable C hook design for steel coil handling? Get your crane C Hook.

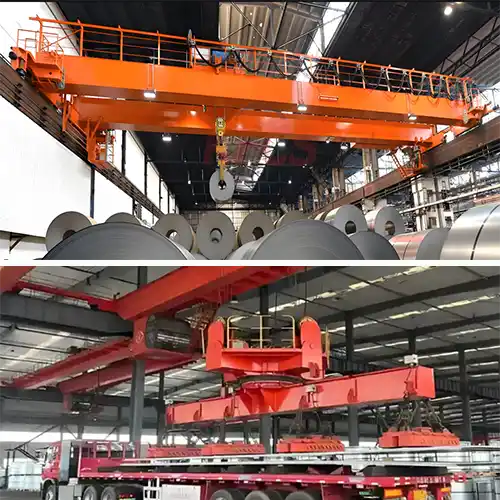

C hooks are essential tools in material handling, particularly for lifting cylindrical objects like steel coils. Their design, resembling the letter "C," enables them to securely grasp and lift these heavy objects. However, their importance goes beyond just lifting; they are integral to ensuring efficient and safe operations in industrial environments.

Steel coils are large and unwieldy, necessitating specialized equipment for their handling. C hooks are uniquely suited for this task because they can securely cradle the cylindrical shape of the coils. This ability is crucial for safe transportation within industrial settings.

Selecting the appropriate C hook is critical due to the varying sizes and weights of steel coils encountered in industrial applications. Using a C hook with insufficient weight capacity can lead to accidents and material damage. Conversely, a properly matched C hook ensures stable lifting and transport, reducing the risk of accidents and costly mishaps.

In summary, C hooks play a vital role in steel coil handling operations, facilitating smooth material flow while prioritizing safety. Their adaptability to different coil sizes and weights underscores their indispensability in industrial settings, highlighting the importance of selecting the right tool for the job.

Types of C Hooks for Various Coils Handlings

C hooks come in a variety of types, each designed to address specific challenges and requirements in steel coil handling. Understanding the differences between these types can help you choose the right tool for your unique needs:

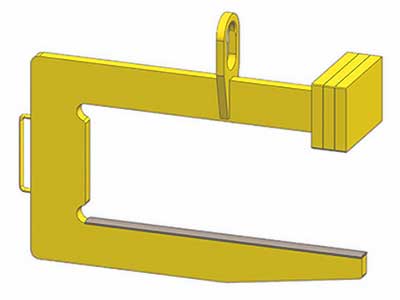

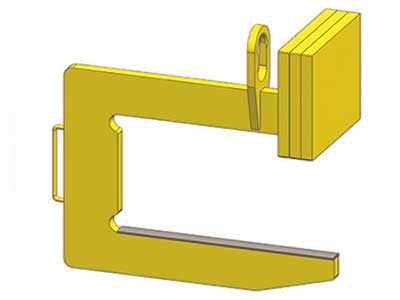

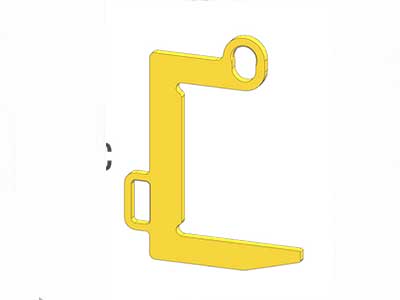

- Standard C Hooks: These are the most basic and commonly used type of C hooks. They feature a simple "C" shape design with rounded edges to securely cradle cylindrical objects like steel coils. Standard C hooks are versatile and suitable for a wide range of coil sizes and weights.

- Adjustable C Hooks: Adjustable C hooks feature movable arms or adjustable mechanisms that allow for customization of the hook's opening diameter and configuration. This flexibility makes them suitable for handling coils of varying sizes within a certain range, offering versatility and adaptability in coil handling operations.

- Fixed Arm C Hooks: Fixed arm C hooks have rigid arms or fixed dimensions, making them suitable for handling specific coil sizes or applications where consistent dimensions are encountered. These hooks offer simplicity and reliability in handling coils with uniform dimensions.

- Motorized C Hooks: Motorized C hooks are equipped with electric or hydraulic-powered mechanisms for automated lifting and handling of heavy coils. These hooks offer enhanced efficiency and control, particularly in high-volume or repetitive lifting operations, where manual handling may be impractical or labor-intensive.

- Telescopic C Hooks: Telescopic C hooks feature telescoping arms or adjustable extensions that can extend or retract to accommodate coils of different diameters or lengths. These hooks offer flexibility and versatility in handling coils with varying dimensions, minimizing the need for multiple hook configurations.

- Coil Tong C Hooks: Coil tong C hooks are specialized hooks designed specifically for gripping and lifting coils from the inside, rather than cradling them from the outside like standard C hooks. These hooks provide a secure grip on the inner diameter of the coil, making them suitable for handling coils with limited clearance or where external gripping is not feasible.

- Vertical Lift C Hooks: Vertical lift C hooks are designed for lifting coils in a vertical orientation, rather than the horizontal orientation typical of standard C hooks. These hooks are suitable for applications where vertical stacking or storage of coils is required, offering efficient handling and storage solutions.

By understanding the different types of C hooks available and their specific features and capabilities, organizations can select the most appropriate option for their coil handling needs, optimizing efficiency, safety, and productivity in industrial operations.

Slit Coil C-Hooks

The C Hook coil handling system is used for lifting several coils that are equivalent to the maximum coil width using a longer lift arm silt coil c hook. The silt coil C-hook is made of high-strength alloy steel and is ideal for loading and unloading in tight locations.

- Only for heavy-duty applications.

- Handles multiple cut coils at once, maximizing handling effectiveness. When the counterweight is retracted, it reduces interference from equipment or other impediments.

- Physically, high tensile alloy steel plate is lighter and smaller.

- When empty, counterbalance to hang level.

- Hooks with an inside radius keep coil edges from coming into touch.

- Saddles with standard curved coils.

- The C hook lifter may be easily positioned thanks to the guide handles.

- Extra padding is supplied for further coil protection.

Close Stacking C-hook for Narrow Aisles

The C Hook coil handling device is typically fitted with a close staking c hook for narrow place or tight stacking coil handling.From the pick-up point (center of gravity) to the end, the length of the C hook is reduced. Because the lifting arm is shorter, all coil widths within the operational range (from widest to narrowest) can be handled without the lifting arm extending over the coil's outside edge. The decreased overall width of this type of C hook lifter can help reduce the demand for aisle space, increasing storage capacity.

Motorized Rotating C Hook - Steel Mill Crane C Hook

The mill duty coil lifter, the motorized rotating crane C-hook, includes a continuous 360° spinning motorized rotator. This function adds an additional tool to the c hook crane for the secure and exact placement of steel coils.

The steel mill overhead Handling of coils C hooks are designed to endure the severe, continuous environments prevalent in steel mills. To maximize service life, larger sections and corner radii lower stresses.

C-hooks for Narrow Coils

- Deals more sensitively with thin coils.

- Weightlessness allows for easier handling.

- The integrated guiding handle simplifies the coil positioning process.

- With a curved coil saddle that is an optional extra.

- Coil edge contact is avoided by hooks with an inner radius.

Counter Balanced C-hooks 5 ton

Maximum coil width is equal to the lower member length ("L" measurement) of the C-hook. The risk of harm to the inner wraps of lighter gauge coil stock is decreased by increasing the surface area in contact with the steel coil thanks to the whole length providing support of the C-hook.

Functions of C Hooks for Steel Coil Handling

C hooks play several crucial functions specifically tailored for handling steel coils:

- Secure Grasping: One of the primary functions of C hooks is to securely grasp steel coils. The design of the hook, resembling the letter "C," allows it to envelop the coil's cylindrical shape, providing a stable grip for lifting and transportation. This secure grasping minimizes the risk of slippage or displacement during handling.

- Weight Distribution: C hooks are engineered to distribute the weight of the steel coil evenly, reducing stress concentration points and minimizing the risk of deformation or damage to the coil. Proper weight distribution ensures that the coil remains intact and undamaged throughout the handling process.

- Safe Lifting: Safety is paramount in steel coil handling operations, and C hooks are designed with safety features to facilitate safe lifting practices. By securely cradling the coil and providing a stable lifting platform, C hooks help prevent accidents such as load shifting, tipping, or falling, thereby ensuring the safety of personnel and equipment.

- Compatibility with Coil Sizes and Weights: Steel coils come in various sizes and weights, and C hooks are designed to accommodate this variability. They can be customized or selected based on the specific dimensions and weight capacities of the coils being handled, ensuring compatibility and optimal performance across different coil types.

- Efficient Handling: C hooks are engineered for efficiency, allowing for smooth and controlled lifting and transport of steel coils. Their design minimizes the time and effort required for loading, unloading, and moving coils within industrial facilities, contributing to overall operational efficiency and productivity.

- Damage Prevention: Steel coils are valuable assets, and any damage incurred during handling can result in significant financial losses. C hooks help prevent damage to coils by providing a secure and stable lifting solution that minimizes the risk of impact, abrasion, or deformation during transportation and storage.

- Versatility and Adaptability: C hooks are versatile tools that can be used with various lifting equipment, such as overhead cranes, forklifts, or coil handling systems. Their adaptability makes them suitable for different industrial applications and environments, providing flexibility and convenience in steel coil handling operations.

Overall, the functions of C hooks for steel coil handling revolve around ensuring safe, efficient, and damage-free lifting and transportation of steel coils within industrial settings. Their specialized design and features make them indispensable tools for handling these heavy and valuable cylindrical objects.

Typical Applications of C Hooks for Steel Coil Handling

C hooks are commonly used in various applications for handling steel coils due to their versatility, efficiency, and safety features. Some typical applications include:

- Steel Mills: Within steel mills, C hooks are utilized for handling steel coils during the manufacturing process. This includes tasks such as transferring coils from one stage of production to another, loading coils onto processing equipment such as slitting lines or rolling mills, and moving finished coils to storage or shipping areas.

- Warehousing and Distribution Centers: In warehousing and distribution facilities that deal with steel products, C hooks are employed for loading and unloading steel coils from trucks, railcars, or storage racks. They facilitate the efficient movement of coils within the facility, optimizing storage space and streamlining logistics operations.

- Metal Service Centers: Metal service centers that supply steel coils to various industries rely on C hooks for handling and processing coils according to customer specifications. C hooks enable the safe and efficient loading and unloading of coils onto cutting or processing equipment, as well as for organizing and staging coils for delivery to customers.

- Construction Sites: Construction projects that involve steel structures or components often require the handling of large steel coils. C hooks are used on construction sites to lift and position coils for fabrication, assembly, or installation purposes. This includes tasks such as erecting steel buildings, installing roofing materials, or fabricating structural elements.

- Shipping and Logistics: In shipping yards and logistics terminals that handle steel coil shipments, C hooks are essential for loading coils onto cargo vessels, barges, or containers for transportation. They ensure the safe and efficient handling of coils during loading and unloading operations, minimizing the risk of damage or accidents.

- Automotive Manufacturing: Automotive manufacturers utilize steel coils extensively in the production of vehicle components and assemblies. C hooks are employed in automotive plants for handling coils of steel sheet or strip that are used in stamping, forming, and welding processes to manufacture car body panels, chassis components, and other structural parts.

- Metal Fabrication Shops: Metal fabrication shops that specialize in custom manufacturing or fabrication of steel products often use C hooks for handling raw materials or semi-finished components. C hooks aid in the loading and unloading of steel coils onto cutting, bending, or welding equipment, facilitating the fabrication process.

Overall, C hooks are indispensable tools for steel coil handling across various industries and applications, enabling the safe, efficient, and precise handling of these heavy and unwieldy cylindrical objects throughout their lifecycle—from production to distribution to final use.

Specialized C Hooks:

Some steel coil handling challenges require specialized solutions beyond the capabilities of standard or customized C hooks. Specialized C hooks are designed to tackle unique challenges such as narrow aisle spaces, extreme coil weights, or unconventional coil shapes. These hooks may feature innovative designs, such as adjustable arms or reinforced structures, to overcome specific obstacles and optimize handling efficiency.

Why Specialized C Hooks Matter:

- Addressing Unique Challenges: Specialized C hooks are designed to tackle specific handling challenges that standard or customized hooks may not adequately address. These challenges could include narrow aisle spaces, extreme coil weights, irregular coil shapes, or other unconventional handling requirements.

- Optimizing Efficiency: By providing tailored solutions for unique challenges, specialized C hooks help optimize efficiency in coil handling operations. They allow for smoother, more streamlined workflows, reducing downtime and improving productivity in challenging environments.

- Enhancing Safety: Specialized C hooks often incorporate advanced safety features and innovative designs to mitigate risks associated with handling difficult loads. These features help protect personnel and equipment, ensuring safe and reliable lifting operations.

- Maximizing Flexibility: Some specialized C hooks are designed with adjustable or adaptable features that enhance flexibility in handling various types of coils or adapting to changing operational needs. This versatility allows for greater adaptability in dynamic industrial environments.

Features of Specialized C Hooks:

- Adjustable Arms: Specialized C hooks may feature adjustable arms or extensions that can be customized to accommodate different coil sizes, shapes, or handling requirements. This flexibility allows for precise adjustments to optimize grip and stability during lifting.

- Reinforced Structures: Specialized C hooks designed for handling extremely heavy or oversized coils may incorporate reinforced structures or heavy-duty components to withstand the increased load capacities and stresses encountered in such applications.

- Narrow Profile: C hooks for handling coils in narrow aisle spaces or confined environments may feature a slim or compact profile to maneuver through tight spaces without compromising lifting capacity or stability.

- Customized Gripping Mechanisms: Some specialized C hooks are equipped with customized gripping mechanisms or attachments tailored to specific coil shapes or materials. These mechanisms ensure a secure grip on irregular or non-standard coil configurations, minimizing the risk of slippage or damage during handling.

- Integrated Safety Features: Specialized C hooks often include integrated safety features such as locking mechanisms, load monitoring systems, or anti-slip surfaces to enhance safety and reliability during lifting operations, particularly in challenging environments.

Applications of Specialized C Hooks:

- Narrow Aisle Handling: C hooks with a narrow profile are suitable for handling coils in narrow aisle spaces or confined areas where traditional lifting equipment may not fit.

- Heavy-duty Lifting: Specialized C hooks with reinforced structures are designed for lifting extremely heavy or oversized coils, commonly encountered in industries such as steel manufacturing or metal processing.

- Handling Irregular Shapes: C hooks with customized gripping mechanisms are ideal for handling coils with irregular shapes or configurations, ensuring a secure grip and minimizing the risk of damage during lifting.

- High Precision Operations: Specialized C hooks with adjustable arms or precise gripping mechanisms are used in high precision operations where accuracy and control are critical, such as in automotive manufacturing or aerospace applications.

By providing tailored solutions for specific challenges, specialized C hooks enhance efficiency, safety, and flexibility in coil handling operations, allowing industries to overcome obstacles and optimize their material handling processes. Working with experienced manufacturers ensures that specialized C hooks are designed and engineered to meet the unique requirements of each application, delivering reliable and cost-effective solutions.

Custom C Hooks

Custom C hooks offer tailored solutions for specific coil handling needs, providing precision, efficiency, and safety in industrial lifting operations. Here's an overview of the benefits and considerations when opting for custom C hooks:

Benefits of Customized C Hooks:

When off-the-shelf solutions don't quite meet your requirements, customized C hooks offer tailored solutions to address specific industry needs. Manufacturers can design and fabricate C hooks according to your precise specifications, taking into account factors such as coil size, weight, and handling environment. Customized C hooks ensure optimal performance and efficiency, catering to the unique demands of your operations.

- Precise Fit: Customized C hooks are designed to perfectly match your specific coil handling requirements. By tailoring the dimensions, weight capacity, and features of the hook to your exact specifications, you can ensure a precise fit for your unique application.

- Optimized Performance: Customized C hooks are engineered to deliver optimal performance in your specific operating environment. By considering factors such as coil size, weight, material type, and handling conditions, manufacturers can design hooks that maximize efficiency, safety, and productivity.

- Enhanced Safety: Customized C hooks can incorporate advanced safety features and mechanisms tailored to your industry's safety standards and regulatory requirements. This ensures that your lifting operations are conducted with the highest levels of safety and compliance.

- Increased Efficiency: By eliminating the need for adaptations or modifications to off-the-shelf solutions, customized C hooks streamline your coil handling processes. They are optimized for your workflow, reducing downtime, minimizing manual adjustments, and maximizing operational efficiency.

- Long-Term Cost Savings: While the initial investment in customized C hooks may be higher than off-the-shelf alternatives, the long-term cost savings can be significant. Custom hooks are built to withstand the demands of your specific application, reducing maintenance costs, minimizing downtime, and prolonging the lifespan of the equipment.

Factors to Consider When Custom a C Hook

Selecting the perfect C hook for your steel coil handling needs requires careful consideration of several key factors. Let's explore these essential elements to ensure you make an informed decision:

Weight Capacity:

The weight capacity of the C hook must match or exceed the weight of the steel coil being lifted. It's imperative to accurately assess the maximum load your operations will encounter to avoid overloading the hook, which can compromise safety and lead to equipment failure.

Accurately assessing the weight capacity requirement is fundamental for selecting the right C hook. Here's why it's crucial and how to do it effectively:

Why Weight Capacity Matters:

- Safety: Exceeding the weight capacity of a C hook poses significant safety risks. Overloading can cause the hook to deform or fail, leading to sudden drops or accidents that endanger personnel and equipment.

- Equipment Integrity: Overloading not only compromises the safety of personnel but also risks damaging the lifting equipment itself. This can result in costly repairs or replacement of the C hook and any other associated machinery.

- Legal Compliance: In many jurisdictions, there are strict regulations and standards governing lifting operations, including weight limits for lifting equipment. Failure to adhere to these regulations can result in legal consequences and liability issues in case of accidents.

How to Assess Weight Capacity:

- Know Your Coil Specifications: Obtain accurate information about the weight of the heaviest steel coil you'll handle. This may involve consulting coil specifications provided by suppliers or conducting on-site measurements for custom coils.

- Consider Safety Margins: It's advisable to factor in safety margins when determining the weight capacity requirement. A margin of safety ensures that the C hook can handle unexpected variations in coil weight, deviations from specifications, or additional load factors during lifting.

- Consult Manufacturer Recommendations: Manufacturers typically provide guidelines and specifications for their C hooks, including recommended weight capacities for different models. These recommendations are based on engineering calculations and testing, ensuring the safe and reliable operation of the equipment.

- Professional Assessment: In complex or high-risk lifting operations, consider consulting with a qualified engineer or lifting specialist to assess weight capacity requirements. They can conduct detailed analyses, considering factors such as dynamic loading, environmental conditions, and structural integrity of the lifting equipment.

By carefully evaluating the weight capacity requirement and selecting a C hook that meets or exceeds this requirement, you can ensure safe and efficient steel coil handling operations. Prioritizing safety and compliance with regulations minimizes the risk of accidents and ensures the longevity of your lifting equipment.

Coil Size Compatibility:

Ensure the hook's opening diameter and overall dimensions align with the diameter and dimensions of the steel coils in your inventory. A snug fit promotes stability during lifting and minimizes the risk of slippage or damage to the coil.

Why Coil Size Compatibility Matters:

- Stability and Security: A C hook that properly fits the dimensions of the steel coil provides a snug and secure grip, promoting stability during lifting and transport. This minimizes the risk of slippage or shifting of the coil, reducing the likelihood of accidents or damage to the coil and surrounding equipment.

- Load Distribution: A C hook that matches the size of the coil distributes the load evenly, minimizing stress concentrations and potential deformations on the coil. Proper load distribution helps preserve the integrity of the coil and ensures its structural stability throughout the handling process.

- Operational Efficiency: Using a C hook that is appropriately sized for the coil streamlines handling operations, reducing the time and effort required for loading, unloading, and positioning coils. This enhances overall operational efficiency and productivity in steel coil handling processes.

How to Assess Coil Size Compatibility:

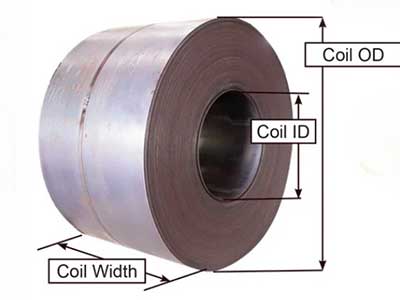

- Measure Coil Dimensions: Obtain accurate measurements of the diameter and dimensions of the steel coils in your inventory. This may involve measuring the outer diameter, inner diameter (if applicable), and height of the coils using calibrated tools such as calipers or tape measures.

- Compare with C Hook Specifications: Consult the specifications provided by the manufacturer of the C hook to determine its opening diameter and overall dimensions. Ensure that these dimensions align with the size of your steel coils, allowing for a proper fit and secure grip.

- Consider Tolerance and Adjustability: Take into account any tolerance or variability in coil dimensions and the adjustability of the C hook. Some C hooks may have adjustable features or interchangeable components that allow for flexibility in accommodating a range of coil sizes within certain limits.

- Test Compatibility: Before full-scale implementation, conduct tests or trials to verify the compatibility of the C hook with different coil sizes in real-world conditions. This allows you to assess the effectiveness of the hook in securely gripping and lifting various coil dimensions.

By ensuring coil size compatibility between the C hook and your steel coils, you can enhance safety, efficiency, and reliability in handling operations. A proper fit promotes stability and load distribution, minimizing the risk of accidents or damage and optimizing overall performance in steel coil handling processes.

Material and Design:

The material and design of the C hook should be tailored to your industry's specific requirements. Consider factors such as the environment in which the hook will be used (e.g., indoor versus outdoor), the type of steel being handled, and any corrosive elements present. Opting for high-quality materials such as alloy steel or stainless steel can enhance durability and longevity, reducing maintenance costs in the long run.

Why Material and Design Matter:

- Environmental Compatibility: The environment in which the C hook will be used can impact its performance and lifespan. Factors such as temperature extremes, exposure to moisture, chemicals, or abrasive materials, and indoor versus outdoor usage all influence the choice of materials and design features.

- Corrosion Resistance: In industries where corrosive elements are present, such as steel mills or marine environments, choosing materials with high corrosion resistance is essential. Stainless steel or specialized alloy steels are often preferred for their ability to withstand corrosion and maintain structural integrity over time.

- Strength and Durability: The material composition of the C hook determines its strength, durability, and resistance to wear and tear. Opting for high-quality materials and robust design features enhances the hook's ability to withstand heavy loads, repetitive use, and harsh operating conditions without premature failure or deformation.

- Maintenance Requirements: The choice of material and design can impact the maintenance requirements of the C hook. Materials that are resistant to rust, corrosion, and abrasion may require less frequent maintenance, resulting in cost savings and increased operational efficiency over the hook's lifespan.

How to Choose Material and Design:

- Assess Environmental Factors: Evaluate the specific environmental conditions in which the C hook will be used, including temperature, humidity, exposure to chemicals or corrosive substances, and potential abrasive materials. Select materials and design features that can withstand these conditions effectively.

- Consider Steel Type: Depending on the type of steel being handled (e.g., carbon steel, stainless steel), choose a C hook material that is compatible with the steel's properties and potential corrosiveness. For example, stainless steel C hooks are often preferred for handling stainless steel coils to prevent contamination and corrosion.

- Consult Manufacturer Recommendations: Manufacturers of C hooks often provide guidance on suitable materials and design options based on industry standards and best practices. Consider consulting their recommendations and specifications to ensure compatibility with your specific requirements.

- Evaluate Long-Term Costs: While initial investment costs are important, also consider the long-term costs associated with maintenance, repairs, and replacement. Investing in high-quality materials and design features upfront can result in lower overall lifecycle costs and higher return on investment.

By carefully considering the material and design of the C hook in relation to your industry's requirements, you can ensure reliable performance, longevity, and cost-effectiveness in steel coil handling operations. Prioritizing environmental compatibility, corrosion resistance, and durability enhances safety and operational efficiency, ultimately contributing to the success of your material handling processes.

Safety Features:

Safety should always be a top priority in industrial operations. When selecting a C hook, prioritize models equipped with robust safety mechanisms to prevent accidents and protect personnel and equipment. Look for features such as latch mechanisms, locking devices, and anti-slip surfaces that enhance stability and reliability during lifting and transport.

Why Safety Features Matter:

- Personnel Protection: Robust safety features help prevent accidents and injuries by minimizing the risk of load slippage, uncontrolled movements, or equipment failures during lifting and transport operations. This protects personnel working in the vicinity of the lifting operation from harm.

- Equipment Protection: Safety features also safeguard the integrity of the lifting equipment and surrounding infrastructure by reducing the likelihood of damage caused by dropped loads, sudden movements, or excessive stresses on the equipment components.

- Compliance with Regulations: Many jurisdictions have strict regulations and standards governing lifting operations to ensure workplace safety. Incorporating safety features into the design of C hooks helps organizations comply with these regulations and mitigate legal and liability risks associated with workplace accidents.

Key Safety Features to Consider:

- Latch Mechanisms: C hooks equipped with latch mechanisms ensure that the coil remains securely engaged during lifting and transport. These mechanisms prevent accidental release of the load and provide an additional layer of safety against slippage.

- Locking Devices: Locking devices, such as locking pins or cams, help secure the C hook in the closed position, preventing accidental opening during lifting operations. This enhances stability and reliability, particularly when handling heavy or irregularly shaped loads.

- Anti-Slip Surfaces: Anti-slip surfaces on the contact points of the C hook help improve grip and stability when lifting steel coils. These surfaces reduce the risk of slippage, especially in wet or oily conditions, enhancing safety during handling operations.

- Load Monitoring Systems: Advanced C hook models may incorporate load monitoring systems that provide real-time feedback on the weight and balance of the lifted load. These systems help operators make informed decisions and adjustments to ensure safe lifting practices.

Manufacturer Recommendations and Standards: Consult the manufacturer's recommendations and industry standards for guidance on appropriate safety features for C hooks. Manufacturers often design their products with safety in mind and may offer optional features or configurations to meet specific safety requirements.

By prioritizing safety features such as latch mechanisms, locking devices, anti-slip surfaces, and load monitoring systems, you can enhance the safety and reliability of steel coil handling operations while protecting personnel and equipment from potential hazards. Investing in C hooks with robust safety mechanisms is a proactive measure to ensure compliance with regulations and promote a safe working environment.

By carefully evaluating these factors and selecting a C hook that meets your specific requirements, you can enhance the efficiency, safety, and overall effectiveness of your steel coil handling operations. Remember, investing time and effort in choosing the right tool upfront can yield significant dividends in terms of operational performance and peace of mind.

Process of Customizing C Hooks:

Consultation and Assessment:

The customization process begins with a consultation between the manufacturer and the customer to assess the specific requirements and challenges of the coil handling application. This may involve on-site evaluations, discussions about operational needs, and identification of key performance criteria.

-

On-Site Evaluations: Manufacturers may conduct on-site visits to observe current handling practices, assess equipment limitations, and gather essential data about the coils being handled.Operational Needs Analysis: Discussions with the customer help identify critical aspects such as coil dimensions, weights, material types, handling frequencies, environmental conditions, safety considerations, and any unique challenges encountered in the handling process.Identification of Key Performance Criteria: Together, the manufacturer and the customer define key performance criteria that the customized C hooks must meet. These criteria may include load capacity, lifting height, maneuverability, safety features, compatibility with existing equipment, and compliance with industry standards and regulations.

- The consultation and assessment phase lay the foundation for the design and engineering process, ensuring that the customized C hooks are tailored precisely to the customer's needs and operational requirements.

Engineering and Design:

Based on the gathered information, the manufacturer's engineering team develops a detailed design proposal for the customized C hook. This includes determining the appropriate dimensions, weight capacity, material selection, and any specialized features or safety mechanisms required.

-

Data Analysis: The engineering team analyzes the collected data to understand the specific requirements and challenges of the coil handling application. They carefully review factors such as coil dimensions, weights, material types, environmental conditions, safety considerations, and any unique operational constraints.Conceptualization: Using the gathered information as a foundation, the engineering team develops conceptual designs for the customized C hook. They explore various design options and configurations to address the identified requirements and optimize performance, safety, and efficiency.Detailed Design: Once a preferred design concept is selected, the engineering team proceeds to develop a detailed design proposal for the customized C hook. This involves specifying the exact dimensions, weight capacity, material selection, and any specialized features or safety mechanisms required to meet the customer's needs.CAD Modeling: Computer-aided design (CAD) software is used to create detailed 3D models of the customized C hook. These models allow the engineering team to visualize the design, assess its feasibility, and make refinements as needed before moving forward with fabrication.Engineering Analysis: Finite element analysis (FEA) and other engineering analysis techniques may be employed to evaluate the structural integrity, load-bearing capacity, and performance of the proposed design. This helps ensure that the customized C hook will meet all functional and safety requirements.Prototype Development (Optional): Depending on the complexity of the design and the customer's preferences, a prototype of the customized C hook may be developed for testing and validation purposes. Prototyping allows for real-world assessment of the design's performance, functionality, and compatibility with existing equipment.Design Review: The completed design proposal is subjected to a thorough review process involving the manufacturer's engineering team, quality assurance personnel, and the customer. Any necessary revisions or refinements are made based on feedback received during the review.

By meticulously engineering and designing the customized C hook to meet the customer's exact specifications and requirements, the manufacturer ensures that the final product will deliver optimal performance, safety, and reliability in the coil handling application.

Fabrication and Production:

Once the design is finalized and approved, the manufacturer proceeds with the fabrication and production of the customized C hook. Skilled craftsmen and advanced manufacturing processes are employed to ensure precision and quality in every aspect of the hook's construction.

-

Material Procurement: High-quality materials specified in the approved design, such as alloy steel or stainless steel, are procured from trusted suppliers. The selection of materials is critical to ensure the durability, strength, and performance of the C hook in its intended application.Precision Machining: Skilled craftsmen and advanced machining equipment are employed to fabricate the various components of the C hook with precision and accuracy. Computer numerical control (CNC) machining processes are often utilized to achieve tight tolerances and intricate geometries as per the approved design specifications.Welding and Assembly: The fabricated components are welded together and assembled according to the approved design. Highly skilled welders use techniques such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding to ensure strong, reliable joints that meet stringent quality standards.Surface Treatment: Surface treatments such as shot blasting, sandblasting, or chemical treatments may be applied to remove any surface impurities, improve corrosion resistance, and enhance the aesthetic appearance of the C hook. Powder coating or painting may also be applied for additional protection and durability.Quality Control Inspections: Throughout the fabrication and production process, quality control inspections are conducted at various stages to verify compliance with design specifications, dimensional accuracy, structural integrity, and surface finish. Non-destructive testing methods such as visual inspection, dimensional inspection, and ultrasonic testing may be employed to ensure the highest quality standards are met.Final Assembly and Testing: Once all components are fabricated and inspected, the C hook is assembled according to the approved design. Final assembly includes the installation of any specialized features, safety mechanisms, or additional components specified in the design. The completed C hook undergoes comprehensive testing to validate its performance, functionality, and safety before delivery to the customer.Packaging and Delivery: The finished C hook is carefully packaged to ensure protection during transportation and delivery to the customer's facility. Packaging materials such as crates, pallets, or protective wrapping are used to safeguard the C hook from damage during transit. Timely delivery schedules are adhered to, ensuring that the customized C hook reaches the customer as per the agreed-upon timeline.

By employing skilled craftsmen, advanced manufacturing processes, and stringent quality control measures, the manufacturer ensures that the customized C hook is fabricated to the highest standards of precision, quality, and reliability. This meticulous approach to fabrication and production guarantees that the C hook will meet or exceed the customer's expectations for performance, durability, and safety in their coil handling application.

Testing and Quality Assurance:

Before delivery, the customized C hook undergoes rigorous testing and quality assurance procedures to verify its performance, safety, and reliability. This may include load testing, stress analysis, and functional testing to ensure compliance with industry standards and customer specifications.

-

Load Testing: The customized C hook is subjected to load testing to assess its capacity to lift and support the specified maximum load safely. This involves applying loads that exceed the hook's rated capacity to verify its structural integrity and resilience under extreme conditions. Load testing may be performed using calibrated weights or simulated loads to simulate real-world operating conditions accurately.Stress Analysis: Advanced stress analysis techniques, such as finite element analysis (FEA), may be employed to evaluate the structural strength and integrity of the C hook under various loading scenarios. FEA helps identify potential areas of stress concentration, deformation, or failure, allowing for design refinements or modifications as needed to enhance performance and safety.Functional Testing: The functional performance of the customized C hook is thoroughly evaluated through a series of functional tests. This includes testing the operation of any specialized features, safety mechanisms, or control systems specified in the design. Functional testing ensures that the C hook functions as intended and meets all functional requirements and specifications.Safety Testing: Safety features and mechanisms integrated into the customized C hook are tested to ensure their effectiveness in preventing accidents and protecting personnel and equipment during lifting operations. This may include testing latch mechanisms, locking devices, anti-slip surfaces, and other safety features to verify compliance with industry standards and regulatory requirements.Quality Assurance Inspections: Throughout the testing process, quality assurance inspections are conducted to verify compliance with design specifications, dimensional accuracy, surface finish, and overall quality standards. Any deviations or discrepancies are documented, addressed, and rectified to ensure that the final product meets or exceeds customer expectations.Certification and Documentation: Upon successful completion of testing and quality assurance procedures, the customized C hook may be certified to comply with relevant industry standards and regulatory requirements. Comprehensive documentation, including test reports, inspection records, certifications, and user manuals, is provided to the customer for reference and compliance purposes.

By subjecting the customized C hook to rigorous testing and quality assurance procedures, the manufacturer ensures that it meets the highest standards of performance, safety, and reliability. This commitment to quality and excellence instills confidence in customers, assuring them that the customized C hook will deliver optimal performance and longevity in their coil handling application.

Delivery and Installation Support:

Upon completion, the customized C hook is delivered to the customer's facility, where installation and commissioning may be assisted by the manufacturer's technical team. Training and support services may also be provided to ensure proper operation and maintenance of the equipment.

After the successful fabrication, testing, and quality assurance of the customized C hook, the manufacturer ensures a smooth delivery process and provides installation support to the customer. Here's how this phase is managed:

-

Delivery Coordination: The manufacturer coordinates the delivery of the customized C hook to the customer's facility, ensuring timely arrival according to the agreed-upon schedule. Transport arrangements are made to safely transport the C hook to its destination, taking into account any logistical considerations or special requirements.Installation Assistance: Upon delivery, the manufacturer's technical team may provide on-site installation assistance to ensure that the customized C hook is properly installed and integrated into the customer's existing equipment or infrastructure. This may involve assembling components, aligning connections, and verifying the correct operation of the C hook.Commissioning: Once installation is complete, the customized C hook undergoes commissioning to validate its performance and functionality in the actual operating environment. Functional tests are conducted to ensure that the C hook operates as intended and meets all performance requirements and specifications.Training Services: The manufacturer may offer training services to the customer's personnel to familiarize them with the operation, maintenance, and safety protocols of the customized C hook. Training sessions may cover topics such as proper usage, routine maintenance procedures, safety precautions, and troubleshooting techniques.Technical Support: Ongoing technical support is provided to the customer to address any questions, concerns, or issues related to the customized C hook. The manufacturer's technical team remains available to provide assistance, guidance, and troubleshooting support as needed to ensure the continued reliable operation of the equipment.Documentation and Manuals: Comprehensive documentation, including installation manuals, operation manuals, maintenance guidelines, and safety instructions, is provided to the customer for reference and compliance purposes. These documents help facilitate proper installation, operation, and maintenance of the customized C hook.

By offering delivery and installation support, training services, and ongoing technical assistance, the manufacturer ensures that the customer receives comprehensive support throughout the lifecycle of the customized C hook. This commitment to customer satisfaction helps optimize the performance, reliability, and longevity of the equipment, ultimately contributing to the success of the customer's coil handling operations.

By investing in customized C hooks tailored to your specific requirements, you can achieve optimal performance, efficiency, and safety in your coil handling operations. Working closely with experienced manufacturers ensures that your custom hooks are designed and built to deliver reliable and cost-effective solutions that meet your unique needs and challenges.

Main Parameters and Specifications Needed to Get Custom C Hooks for Your Needs.

To get custom C hooks tailored to your specific needs, it's essential to provide the manufacturer with detailed information about your coil handling requirements. Here are the main parameters and specifications needed:

Main parameters needed for metal roll lifter quotation

- What are the dimensions of the rolls:

- Dead weight of rolls :____ ton,

- Width of coils:____ m,

- Internal diameter:____ mm

- Outside diameter:____ mm

- If you have any need or want to learn more on coil lifter and coil handling equipment, please feel free to contact us. WhatsApp: 0086 151 3871 1597.

- Coil Dimensions: Provide accurate measurements of the coils you'll be handling, including the diameter, width, and weight range. This information helps determine the appropriate size and capacity of the C hook.

- Material Type: Specify the type of material the coils are made of, as different materials may require specific handling considerations. For example, handling stainless steel coils may require different surface treatments or gripping mechanisms compared to handling carbon steel coils.

- Handling Environment: Describe the environment in which the C hook will be used, including indoor or outdoor use, temperature extremes, presence of corrosive substances, or any other environmental factors that may affect the C hook's performance or longevity.

- Load Capacity: Determine the maximum weight capacity required for the C hook to safely lift and transport the heaviest coils in your inventory. This ensures that the C hook is properly rated for the intended workload and prevents overloading.

- Safety Requirements: Identify any specific safety features or mechanisms required for safe coil handling operations. This may include latch mechanisms, locking devices, anti-slip surfaces, or load monitoring systems to enhance safety and prevent accidents.

- Mounting and Attachment: Specify how the C hook will be mounted or attached to your lifting equipment, such as overhead cranes, forklifts, or hoists. Provide details about the attachment points, connections, and compatibility requirements to ensure seamless integration with existing equipment.

- Specialized Features: If your application requires any specialized features or adaptations, such as adjustable arms, reinforced structures, or custom gripping mechanisms, communicate these requirements to the manufacturer for inclusion in the design.

- Regulatory Compliance: Ensure that the customized C hook complies with relevant industry standards, regulations, and safety guidelines applicable to your specific application. This may include standards set by organizations such as OSHA (Occupational Safety and Health Administration) or ASME (American Society of Mechanical Engineers).

- Budget and Timeline: Clearly define your budgetary constraints and project timeline to ensure that the manufacturer can deliver the custom C hooks within your desired timeframe and budget.

By providing detailed information about your coil handling requirements, including coil dimensions, material type, handling environment, load capacity, safety requirements, mounting specifications, specialized features, regulatory compliance, budget, and timeline, you enable the manufacturer to design and fabricate custom C hooks that precisely meet your needs and specifications. This collaborative approach ensures that the customized C hooks deliver optimal performance, safety, and reliability in your coil handling operations.

Key Considerations in Selecting a C Hook Supplier

When choosing a supplier for your C hook needs, several crucial factors should guide your decision-making process. Here are the key considerations to keep in mind:

- Reputation and Experience: Look for a supplier with a solid reputation and extensive experience in the industry. A supplier with a proven track record demonstrates reliability, quality, and expertise in providing C hook solutions. Research customer reviews, testimonials, and case studies to gauge the supplier's reputation and reliability.

- Customization Capabilities: Every industrial operation is unique, with specific requirements and challenges. Ensure your chosen supplier has the capability to customize C hooks to meet your exact specifications. Whether it's adjusting dimensions, modifying materials, or incorporating special features, a supplier that offers customization ensures that your C hooks are tailored to your precise needs.

- Quality Assurance and Compliance: Quality and safety are paramount when it comes to C hooks, which are essential components of material handling systems. Choose a supplier that adheres to stringent quality assurance processes and complies with industry standards and regulations. Certifications such as ISO 9001 signify a commitment to quality management systems, ensuring that your C hooks meet rigorous quality standards.

- After-Sales Service and Support: The relationship with your C hook supplier extends beyond the initial purchase. Evaluate the supplier's after-sales service and support offerings, including maintenance, repairs, and technical assistance. A responsive and knowledgeable support team can provide invaluable assistance throughout the lifespan of your C hooks, helping to maximize their performance and longevity.

By considering these key factors in your selection process, you can choose a C hook supplier that not only delivers high-quality products but also offers personalized solutions, reliable support, and peace of mind for your industrial operations.

Conclusion

In the dynamic landscape of industrial operations, the importance of selecting the right tools cannot be overstated. When it comes to steel coil handling, the choice of C hook plays a pivotal role in ensuring efficiency, safety, and overall productivity.

Throughout this exploration, we've emphasized the critical role of tailored solutions in maximizing efficiency and safety. From matching the weight capacity and dimensions of the C hook to the specific requirements of your steel coils to leveraging customized and specialized solutions, every aspect of the selection process contributes to optimized performance.

By carefully considering factors such as supplier reputation, customization capabilities, quality assurance, and after-sales support, industries can make informed decisions that lead to enhanced operational efficiency and peace of mind.

In conclusion, we encourage industries to prioritize careful consideration when choosing C hook solutions. The right C hook isn't just a tool; it's a strategic investment in the success and sustainability of your operations. By selecting the perfect C hook for your steel coil handling needs, you're not just lifting loads – you're elevating your entire operation to new heights of efficiency and safety.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch