Industrial Overhead Crane & Industrial Gantry Crane in Ethiopia

Overhead Crane & Lifting Equipment in Ethiopia. Guide on Overhead Crane, Gantry Crane, Jib Crane & Electric Hoist in Ethiopian Industrial Sectors 1 to 100 ton.

Category: Ethiopia

Your Trusted Overhead Bridge Crane Manufacturer & Supplier

Overhead Crane & Lifting Equipment: Industrial Bridge Crane & Industrial Gantry Crane

Guide on Overhead Crane, Gantry Crane, Jib Crane & Electric Hoist in Ethiopian Industrial Sectors 1 to 100 ton.

Comprehensive Guide: Overhead Cranes and Lifting Equipment in Ethiopian Industries

Ethiopia, a country known for its rich history and diverse culture, is also experiencing significant growth in its industrial sector. With a focus on sectors such as agriculture, textiles, manufacturing, and more, Ethiopian workshops and factories are buzzing with activity. In this comprehensive guide, we delve into the intricate world of overhead cranes, gantry cranes, jib cranes, and electric hoists, exploring their applications across various industries.

In the dynamic landscape of Ethiopian industries, the importance of efficient material handling cannot be overstated. Overhead cranes and related lifting equipment play a pivotal role in streamlining operations, optimizing workflows, and enhancing overall productivity in workshops and factories. This guide aims to provide a detailed exploration of the main industrial sectors, types of workshops, and the crucial role played by various lifting solutions.

Overview of Overhead Crane

Overhead cranes play a pivotal role in material handling across various industrial sectors in Ethiopia. They provide efficient solutions for lifting, moving, and positioning heavy loads within workshops, warehouses, factories, and plants. With a diverse range of types and configurations, overhead cranes are indispensable in optimizing workflows and enhancing productivity.

In Ethiopia's rapidly advancing industrial landscape, overhead cranes have become indispensable tools, orchestrating the efficient movement of materials and products across various sectors. From the steel manufacturing hubs in Dire Dawa to the textile mills of Addis Ababa, these versatile lifting solutions play a pivotal role in optimizing workflows. Overhead cranes, available in diverse configurations such as single and double girder, articulated jib, and specialized models, showcase adaptability to the unique demands of Ethiopian industries.

- Versatility Across Industries: Overhead cranes are strategically deployed in key industries, including steel manufacturing, textile and garment production, agriculture, and agro processing. Their ability to handle diverse loads, from heavy metal components to delicate fabric rolls, highlights their versatility and suitability for Ethiopia's dynamic industrial requirements.

- Customization for Specific Needs: One distinctive feature of overhead crane operations in Ethiopia is their customization for specific industries. Manufacturers tailor these cranes to adhere to the distinct demands of foundries, textile mills, and agro processing units. This adaptability ensures seamless integration with local power supply conditions and compliance with Ethiopian regulations, reflecting a commitment to safety and efficiency.

- Technological Advancements for Efficiency: As Ethiopia embraces technological advancements, overhead cranes are evolving to incorporate automation, smart technologies, and remote monitoring capabilities. This integration enhances operational efficiency, allowing for precise control and proactive maintenance. The forward looking approach to technology positions Ethiopia's industrial sector on a trajectory of continuous improvement.

- Commitment to Sustainability: Ethiopia's industrial growth is complemented by a commitment to sustainability within overhead crane operations. The adoption of energy efficient models aligns with global environmental considerations, showcasing a responsible approach to industrial practices. The use of eco friendly materials further underscores Ethiopia's dedication to balancing industrial progress with environmental stewardship.

In conclusion, overhead cranes in Ethiopia symbolize adaptability, technological advancement, and a commitment to sustainable industrial practices. These lifting solutions play a pivotal role in steering Ethiopia's industries towards greater efficiency, safety, and innovation in line with global standards.

Main Types of Overhead Cranes

Single Girder & Double Girder Overhead Cranes

Features & Benefits:

- Single Girder: Cost effective Solution for Light to Moderate Lifting: Single girder overhead cranes are designed to provide an economical solution for handling loads that fall within the light to moderate range. Their simplicity and streamlined construction contribute to cost savings without compromising efficiency.

- Suitable for Workshops with Limited Headroom: The single girder design allows for reduced bridge weight, making these cranes suitable for workshops with limited headroom. Ideal for facilities where maximizing available vertical space is crucial.

- Double Girder: Ideal for Heavy Duty Applications: Double girder overhead cranes are robust and well suited for heavy duty lifting tasks. Their sturdy construction and increased lifting capacity make them suitable for demanding industrial applications.

- Offers Increased Lifting Height and Capacity: With dual girders, these cranes provide enhanced stability and increased lifting height compared to their single girder counterparts. Ideal for handling larger and heavier loads with precision and safety.

Application Industries in Ethiopia:

- Steel Manufacturing: Single girder cranes find applications in steel mills for tasks such as moving raw materials and semi finished products. Double girder cranes excel in heavy steel fabrication and handling finished steel products.

- Textile Mills: Single girder cranes are utilized for handling rolls of fabric, yarn, and textile machinery components. Double girder cranes contribute to the efficient movement of heavier textile machinery.

- Automotive Assembly: Both single and double girder cranes play a role in the assembly process, handling components and aiding in the production of vehicles.

Common Industrial Locations in Ethiopia:

- Dire Dawa: Single girder cranes may be found in workshops where cost effective solutions are preferred. Double girder cranes may be employed in heavy industries such as steel manufacturing.

- Mek'ele: Both single and double girder cranes can be used in various industrial applications, catering to the specific lifting needs of different workshops.

- Addis Ababa: The capital city, being an industrial hub, may host both types of cranes in different manufacturing facilities, depending on the lifting requirements.

In summary, the choice between single girder and double girder overhead cranes in Ethiopia depends on the nature of the lifting tasks, the weight of loads, and the available headroom in workshops. Each type offers distinct advantages, contributing to the efficiency and productivity of different industrial sectors.

Underhung Bridge Cranes & Top Running Bridge Cranes

Top running overhead bridge crane 35 ton

Features & Benefits:

- Underhung Bridge Cranes: Suspended from the Building Structure: Underhung bridge cranes are suspended from the building structure, utilizing existing overhead support. This design minimizes the need for additional support structures, making them suitable for workshops with limited space.

- Ideal for Workshops with Space Constraints: Due to their compact and space saving design, underhung bridge cranes are ideal for workshops where floor space is limited. They offer efficient material handling solutions without occupying valuable ground space.

- Top Running Bridge Cranes: Run on Elevated Tracks Attached to the Building Structure: Top running bridge cranes operate on elevated tracks attached to the building structure. This configuration provides stability and allows for smooth movement along the designated path.

- Offers Higher Lifting Capacities: Designed for heavier lifting tasks, top running bridge cranes offer higher lifting capacities compared to underhung counterparts. Suitable for applications demanding the handling of substantial loads.

Application Industries in Ethiopia:

- Food Processing Plants: Underhung bridge cranes may be utilized in food processing plants for the efficient movement of ingredients and finished products. Top running bridge cranes may handle heavier loads in larger processing facilities, enhancing productivity.

- Steel Fabrication: Both types of cranes find applications in steel fabrication workshops for lifting and moving raw materials, components, and finished products. Top running bridge cranes are particularly beneficial for heavy duty steel fabrication tasks.

Common Industrial Locations in Ethiopia:

- Adama: Underhung bridge cranes may be employed in workshops with space constraints, ensuring efficient material handling. Top running bridge cranes may be found in larger industrial setups, contributing to increased lifting capacities.

- Nazret: Both underhung and top running bridge cranes may be utilized in steel fabrication plants, supporting various stages of the manufacturing process. The choice between the two depends on the specific lifting requirements and available space in each workshop.

In Ethiopia, the selection between underhung and top running bridge cranes is influenced by the nature of the industrial operation, available space, and the weight of materials being handled. Each type offers unique advantages, contributing to the overall efficiency of material handling processes.

Jib Cranes

In the vibrant industrial landscape of Ethiopia, Jib cranes stand as essential components, providing precise and localized material handling solutions. These versatile lifting devices play a crucial role across various sectors, offering agility and flexibility in the movement of loads within workshops, factories, and plants. Jib cranes in Ethiopia come in different configurations, including rotating jib cranes, wall mounted jib cranes, and floor mounted jib cranes, each catering to specific needs in diverse industrial settings.

Rotating Jib Cranes for Precision Handling:Rotating jib cranes are pivotal in industries where precise positioning is crucial. With a full 360 degree rotation, these cranes facilitate efficient handling of materials in confined spaces. They find applications in machining workshops, tanneries, and other sectors where intricate movements and precise positioning are essential for the workflow.

- Wall Mounted Jib Cranes for Space Efficiency:Wall mounted jib cranes are fixtures on building walls, providing an excellent solution for maximizing floor space. This configuration is ideal for workshops with limited space, allowing for efficient material handling without occupying valuable ground area. Wall mounted jib cranes find applications in various industries, contributing to space efficient and organized operations.

- Floor Mounted Jib Cranes for Versatile Lifting:Floor mounted jib cranes offer versatility in load lifting, providing a stable and robust solution for diverse industrial settings. Their adaptability makes them suitable for handling materials in different workshops, warehouses, and factories. These cranes are integral to the smooth operation of production processes, contributing to the overall efficiency of the industrial workflow.

- Adaptability to Localized Needs:One notable characteristic of jib cranes in Ethiopia is their adaptability to localized needs. Whether in Bahir Dar, Jimma, or other industrial locations, these cranes are customized to suit the specific workflows and load requirements of different sectors. This customization ensures that jib cranes seamlessly integrate into the varied industrial landscapes across the country.

- Enhancing Efficiency and Workflow:Jib cranes, with their ability to provide localized lifting solutions, significantly enhance efficiency in material handling. Their presence in Ethiopian industries contributes to streamlined operations, reduced manual effort, and optimized workflow. From small scale manufacturing to larger industrial zones, jib cranes play a vital role in ensuring smooth and efficient material movement.

In conclusion, jib cranes in Ethiopia epitomize adaptability, precision, and efficiency in material handling. As integral components in the industrial machinery, these cranes contribute to the growth and productivity of various sectors, reflecting Ethiopia's commitment to technological advancements and streamlined industrial operations.

Features & Benefits of Jib Cranes

- Rotating Jib Cranes: Provides a Full 360 Degree Rotation: Rotating jib cranes offer a complete 360 degree rotation, allowing for versatile and precise positioning of loads. This feature enhances flexibility and efficiency in material handling, especially in confined spaces.

- Efficient for Precise Positioning in Confined Spaces: Due to their rotational capability, rotating jib cranes excel in navigating through tight spaces. Ideal for tasks that require precise placement of materials within the workstation.

- Wall Mounted Jib Cranes: Mounted on Walls to Save Floor Space: Wall mounted jib cranes are fixed to existing structures, utilizing vertical space and saving valuable floor space. This design is particularly beneficial in workshops where floor space optimization is crucial.

- Ideal for Localized Material Handling: Suited for handling materials within specific workstations, wall mounted jib cranes efficiently lift and position loads in localized areas. Enhances productivity by streamlining material flow within the designated workspace.

Application Industries in Ethiopia:

- Machining Workshops: Rotating jib cranes can be employed in machining workshops for precise positioning of heavy components during the manufacturing process. Wall mounted jib cranes may facilitate the efficient handling of tools and materials in designated workstations.

- Tanneries: Both types of jib cranes may find applications in tanneries for handling raw materials, leather goods, and components. Their ability to navigate confined spaces and optimize floor space makes them valuable in tannery operations.

Common Industrial Locations in Ethiopia:

- Bahir Dar: Machining workshops in Bahir Dar may benefit from the use of rotating jib cranes to streamline material handling. Wall mounted jib cranes may be strategically installed in tanneries for efficient localized operations.

- Jimma: Tanneries in Jimma can enhance their material handling processes by incorporating both rotating and wall mounted jib cranes. The flexibility and space saving features of these cranes contribute to improved productivity.

- In Ethiopian workshops and industrial setups, the deployment of rotating and wall mounted jib cranes is tailored to specific spatial constraints and material handling requirements, ensuring efficient and precise operations.

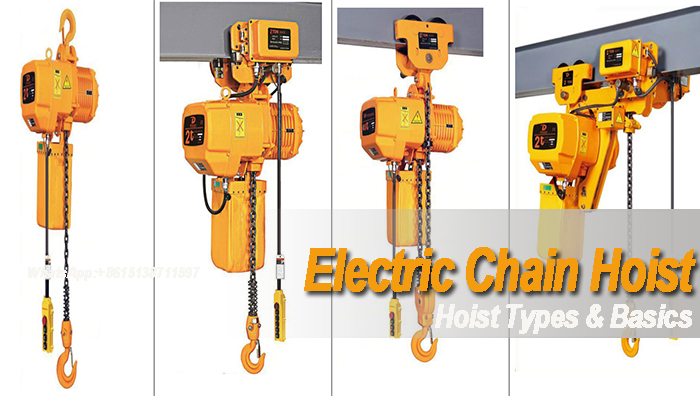

Electric Hoists

In Ethiopia's evolving industrial landscape, electric hoists have emerged as indispensable tools, revolutionizing material handling with their efficiency and precision. These versatile lifting devices play a pivotal role across diverse sectors, providing solutions for both heavy duty applications and intricate tasks. Available in various configurations, including wire rope electric hoists and electric chain hoists, they cater to the specific needs of workshops, factories, and plants, contributing to streamlined and efficient material movement.

- Versatility in Lifting Solutions:Electric hoists are deployed across Ethiopia to handle a wide range of lifting tasks. Their adaptability makes them suitable for both heavy loads in construction material yards and the precise positioning of lighter loads in food processing industries. The versatility of electric hoists spans various industrial applications, making them essential components in the country's industrial machinery.

- Wire Rope Electric Hoists for Heavy Loads:Wire rope electric hoists excel in heavy duty applications, lifting substantial loads with ease. Commonly found in steel manufacturing and construction sites, these hoists provide robust and reliable lifting solutions. Their durability and strength make them integral in material handling processes where resilience is paramount.

- Compact Efficiency with Electric Chain Hoists:Electric chain hoists offer a compact and lightweight alternative, ideal for applications that require precision and flexibility. Found in smaller scale manufacturing, workshops, and areas with limited space, these hoists provide efficient and controlled lifting. Their adaptability to various load capacities makes them valuable assets in Ethiopia's industrial operations.

- Application in Various Industries:Whether it's the bustling construction sites of Hawassa, the food processing plants in Adama, or the steel foundries in Dire Dawa, electric hoists find applications in diverse industrial sectors. Their presence enhances efficiency by automating and optimizing the lifting process, reducing manual effort and contributing to safer and more controlled material handling.

- Integration of Modern Technologies:As Ethiopia advances technologically, electric hoists are at the forefront of innovation. Integration with modern technologies, including smart controls and automation, enhances their capabilities. These features contribute to precision in material handling and align with Ethiopia's commitment to adopting cutting edge solutions for industrial efficiency.

In conclusion, electric hoists in Ethiopia symbolize efficiency, adaptability, and technological advancement in material handling. As integral components in the country's industrial infrastructure, these hoists play a crucial role in optimizing workflows and ensuring the seamless movement of materials, reflecting Ethiopia's dedication to modernizing its industrial operations.

Features & Benefits:

- Wire Rope Electric Hoists: Versatile for Various Lifting Applications: Wire rope electric hoists offer versatility, making them suitable for a wide range of lifting applications across different industries. Ideal for lifting heavy loads, they provide robust and reliable solutions for demanding material handling tasks.

- Suitable for Heavy Loads: Designed to handle substantial weights, wire rope electric hoists are effective in lifting and transporting heavy materials with precision and control. Commonly employed in industrial settings where the movement of significant loads is a regular requirement.

- Electric Chain Hoists: Compact and Lightweight: Electric chain hoists feature a compact and lightweight design, providing ease of installation and mobility. Their streamlined build makes them suitable for applications where space is a consideration, and they can be easily maneuvered.

- Ideal for Lighter Loads and Precise Positioning: Well suited for handling lighter loads, electric chain hoists excel in tasks that require precise positioning and controlled movements. Their agility makes them valuable in applications demanding careful material placement.

Application Industries in Ethiopia:

- Construction Material Yards: Wire rope electric hoists are commonly utilized in construction material yards for lifting heavy building materials such as steel, concrete, and construction components. Electric chain hoists may find applications in lighter material handling tasks within construction yards.

- Food Processing: Both types of electric hoists may be employed in the food processing industry for lifting and positioning materials during various stages of production. Their precision and control contribute to the efficient and hygienic handling of food products.

Common Industrial Locations in Ethiopia:

- Hawassa: Construction material yards in Hawassa may benefit from the versatility of wire rope electric hoists for handling diverse materials. Electric chain hoists may be employed in smaller workshops or sections where lighter loads are predominant.

- Hawzen: In food processing plants in Hawzen, electric hoists play a crucial role in ensuring efficient material handling, contributing to the overall productivity of the facility. The compact nature of electric chain hoists makes them suitable for space constrained areas within the industrial setup.

- In Ethiopian industrial landscapes, the deployment of wire rope electric hoists and electric chain hoists is tailored to the specific lifting requirements of different industries, ensuring optimal performance in diverse material handling scenarios.

Light Overhead Crane

In Ethiopia's industrial landscape, the integration of lightweight or small overhead cranes has proven instrumental in enhancing efficiency and flexibility within various sectors. These compact lifting solutions cater to the specific needs of workshops, small scale manufacturing units, and areas where space optimization and precise material handling are paramount. The deployment of these cranes across different industrial zones contributes to streamlined operations and increased productivity.

- Compact Design for Small Scale Operations:Lightweight overhead cranes are designed with a compact and portable structure, making them ideal for small scale operations. These cranes find applications in workshops and manufacturing units where the lifting requirements may be limited in scale but demand precision and ease of use. Their size and maneuverability contribute to efficient material handling in confined spaces.

- Flexibility in Material Handling:The adaptability of lightweight overhead cranes is a notable feature, allowing for the seamless handling of various loads. Whether it's moving components in a machining workshop or organizing materials in a small scale manufacturing facility, these cranes offer the flexibility needed for diverse applications. Their versatility makes them valuable assets in the agile and evolving industrial landscape of Ethiopia.

- Enhanced Precision in Workshops:In workshops across Addis Ababa or smaller industrial zones, lightweight overhead cranes play a crucial role in ensuring precise material handling. Their ability to navigate and position loads with accuracy contributes to the overall efficiency of workshop operations. These cranes are especially beneficial for tasks that require intricate movements and control.

- Portable Solutions for Dynamic Industries:The portability of lightweight overhead cranes is a key attribute, allowing for easy relocation and adaptability to changing operational needs. This characteristic is particularly valuable in dynamic industries where workflows may evolve, and material handling requirements can shift. The ability to quickly set up and use these cranes enhances the agility of Ethiopia's industrial operations.

- Application in Various Industrial Zones:Whether it's a small scale manufacturing unit in Nazret or a workshop in Hawassa, lightweight overhead cranes find applications across various industrial zones in Ethiopia. Their deployment reflects a strategic approach to optimizing material handling processes in different settings, contributing to increased operational efficiency and cost effectiveness.

In conclusion, lightweight overhead cranes in Ethiopia signify adaptability, precision, and portability in material handling. These compact lifting solutions cater to the specific needs of smaller scale operations, workshops, and evolving industrial landscapes, aligning with Ethiopia's commitment to efficient and agile manufacturing processes.

Features & Benefits:

- Lightweight Design for Small to Medium Loads: Light overhead cranes are specifically designed to handle small to medium loads efficiently. Their lightweight construction allows for easy maneuverability and minimizes the impact on the structural integrity of buildings.

- Provides Flexibility in Material Handling: The light overhead crane's design offers flexibility in material handling, making it suitable for a variety of tasks. Ideal for workshops and manufacturing units where the handling of smaller loads is prevalent.

Application Industries in Ethiopia:

- Small Scale Manufacturing: Light overhead cranes are well suited for small scale manufacturing operations, aiding in the movement of components and materials in a controlled manner. Their adaptability contributes to the efficiency of manufacturing processes in smaller setups.

- Workshops: Workshops with diverse material handling needs can benefit from the versatility of light overhead cranes. These cranes enhance the workflow in workshops where space optimization and adaptability are essential.

Common Industrial Locations in Ethiopia:

- Various Industrial Zones: Light overhead cranes can be found in various industrial zones across Ethiopia, serving the material handling requirements of different small to medium sized enterprises. Their presence in these industrial areas contributes to the overall efficiency and productivity of the manufacturing sector.

- In Ethiopia, light overhead cranes play a vital role in supporting the material handling needs of small scale manufacturing units and workshops, providing an agile and adaptable solution for handling smaller loads with precision. Their lightweight design makes them a valuable asset in industrial zones where flexibility is paramount.

Monorail Systems

Features & Benefits:

- Continuous Transport Along Fixed Paths: Monorail systems provide a continuous and predetermined path for the transport of materials. The fixed path ensures a streamlined and efficient flow of materials within the designated route.

- Connects Different Workstations for Seamless Material Flow: Monorail systems are designed to connect various workstations, facilitating the seamless movement of materials from one stage of production to another. This connectivity enhances overall efficiency in material handling processes.

Application Industries in Ethiopia:

- Electronics Manufacturing: Monorail systems are integral in the electronics manufacturing sector for transporting delicate components between different stages of production. The continuous transport along fixed paths ensures the safe and precise movement of sensitive electronic parts.

- Renewable Energy Production: In the renewable energy sector, monorail systems contribute to the efficient assembly and movement of components in the production of solar panels, wind turbines, and other renewable energy technologies. Their precision in material transport aligns with the meticulous requirements of renewable energy production.

Common Industrial Locations in Ethiopia:

- Industrial Zones in Major Cities: Monorail systems are commonly implemented in industrial zones located in major cities such as Addis Ababa. Their presence in these zones enhances the material handling capabilities of various manufacturing facilities, promoting productivity and workflow efficiency.

- In Ethiopia, the utilization of monorail systems in electronics manufacturing and renewable energy production exemplifies their role in ensuring the smooth and continuous flow of materials. These systems are strategically positioned in industrial zones, contributing to the advancement of manufacturing processes in major cities.

KBK Crane & Workstation Crane

KBK Crane for sale Ethiopia 500kg, 1000kg, 1500kg, 2000kg

Workstation crane for sale Ethiopia 500kg, 1000kg, 1500kg, 2000kg

Features & Benefits:

- KBK Crane: Modular and Flexible Crane System: The KBK crane is designed as a modular and flexible system, allowing for easy customization to meet specific material handling needs. Its modular nature facilitates quick adjustments and expansions based on evolving production requirements.

- Adaptable to Various Material Handling Needs: KBK cranes are highly adaptable and can handle a diverse range of materials, making them suitable for dynamic manufacturing environments. The flexibility of the system ensures efficient and precise material handling in various industrial applications.

- Workstation Crane: Ideal for Specific Workstations: Workstation cranes are specifically designed for use in localized workstations, optimizing efficiency in material handling tasks within confined areas. Their compact and targeted design enhances productivity in specific work areas.

- Improves Efficiency in Localized Tasks: By focusing on specific workstations, these cranes improve overall efficiency by minimizing the time and effort required for material handling within a designated workspace. Well suited for tasks that demand precision and localized movements.

Application Industries in Ethiopia:

- Textile and Garment Manufacturing: KBK cranes can be effectively employed in textile and garment manufacturing for the precise movement of rolls of fabric, components, and machinery. Workstation cranes contribute to the efficiency of localized tasks within the production line.

- CNC Machining Centers: In CNC machining centers, where precision is paramount, KBK cranes provide the flexibility to handle various materials and components. Workstation cranes enhance the efficiency of CNC machining by facilitating localized material handling.

Common Industrial Locations in Ethiopia:

- Various Industrial Zones: KBK cranes and workstation cranes can be found in various industrial zones across Ethiopia, catering to the material handling needs of different manufacturing facilities. Their presence in these zones reflects their adaptability to diverse industrial applications.

- In Ethiopian industries, the modular and adaptable nature of KBK cranes makes them a versatile choice for handling materials in textile and garment manufacturing, while workstation cranes efficiently enhance localized tasks, especially in CNC machining centers. These cranes contribute to the overall efficiency of material handling in various industrial zones.

Gantry Cranes

Gantry cranes stand as towering assets in Ethiopia's industrial panorama, offering robust solutions for lifting and transporting heavy loads with precision. These imposing structures, found in key industrial zones like Dire Dawa and Mek'ele, play a pivotal role in various sectors, from agriculture to steel manufacturing. Gantry cranes, available in configurations like single girder and double girder, provide the necessary strength and versatility demanded by Ethiopia's diverse industrial needs.

- Dominance in Outdoor Material Handling:Gantry cranes are synonymous with outdoor material handling, excelling in applications that involve lifting and transporting substantial loads. The single girder gantry crane, a cost effective solution, finds its place in scenarios where moderate loads need efficient handling, while the double girder gantry crane steps in for heavy duty outdoor operations. These cranes dominate Ethiopia's industrial landscapes, contributing to the seamless flow of materials in outdoor settings.

- Versatility Across Industries:The adaptability of gantry cranes across different industries in Ethiopia is a testament to their versatility. Whether it's the agricultural fields of Bahir Dar or the steel foundries in Dire Dawa, these cranes serve diverse sectors with precision. Their ability to handle varied loads, from grain sacks to steel beams, positions gantry cranes as indispensable tools in Ethiopia's dynamic industrial sectors.

- Enhanced Lifting Capacity:One of the defining features of gantry cranes is their ability to provide increased lifting capacity. This makes them ideal for heavy duty applications in steel manufacturing and other sectors where substantial loads need to be lifted and transported. Gantry cranes contribute to the efficiency of material handling processes, ensuring the seamless movement of large and heavy components.

- Industrial Locations and Strategic Deployment:Gantry cranes strategically populate key industrial locations in Ethiopia, aligning with the specific needs of each sector. Whether it's the agricultural hubs of Jimma or the steel manufacturing centers in Mek'ele, these cranes are deployed strategically to optimize material handling operations. Their presence in these locations reflects a commitment to efficiency and productivity.

- Contribution to Industrial Growth:As Ethiopia experiences industrial growth, gantry cranes play a crucial role in facilitating this progression. Their robust design, adaptability to outdoor environments, and ability to handle heavy loads contribute to the overall efficiency and productivity of industrial operations. Gantry cranes are vital components in the machinery driving Ethiopia's industrial advancement.

In conclusion, gantry cranes in Ethiopia symbolize strength, adaptability, and efficiency in outdoor material handling. From the agricultural fields to steel manufacturing plants, these towering structures contribute to the seamless flow of materials, positioning themselves as integral elements in Ethiopia's evolving industrial landscape.

Features & Benefits:

- Single Girder Gantry Crane: Cost Effective Solution for Outdoor Material Handling: Single girder gantry cranes offer a cost effective solution for handling materials in outdoor environments. Well suited for applications where moderate lifting capacities are required, providing an economical option.

- Suitable for Moderate Loads: Designed to handle moderate loads, single girder gantry cranes are efficient for agricultural and manufacturing operations with varying material handling needs.

- Double Girder Gantry Cranes: Ideal for Heavy Duty Outdoor Applications: Double girder gantry cranes are specifically engineered for heavy duty outdoor applications, providing robust and reliable lifting solutions. Suitable for tasks that demand higher lifting capacities and durability in challenging outdoor environments.

- Provides Increased Lifting Capacity: The dual girder design enhances lifting capacity, making double girder gantry cranes suitable for handling substantial loads with precision and stability.

Application Industries in Ethiopia:

- Agriculture: Single girder gantry cranes may find applications in agricultural settings for tasks such as lifting and transporting bulk materials, machinery, and harvested crops. Double girder gantry cranes are ideal for heavier agricultural operations, contributing to the efficiency of material handling.

- Steel Manufacturing: Both types of gantry cranes can be utilized in steel manufacturing for outdoor material handling, including moving raw materials, semi finished products, and finished steel components. Double girder gantry cranes are particularly beneficial in heavy steel fabrication tasks.

Common Industrial Locations in Ethiopia:

- Dire Dawa: Gantry cranes, both single and double girder, may be found in industrial setups in Dire Dawa, contributing to the material handling processes in diverse applications. Single girder gantry cranes may be suitable for moderate lifting tasks, while double girder gantry cranes excel in heavier operations.

- Mek'ele: In Mek'ele, where manufacturing and industrial activities are prevalent, gantry cranes play a crucial role in outdoor material handling. The choice between single and double girder gantry cranes depends on the specific lifting requirements of different industrial setups.

- In Ethiopia, gantry cranes serve as essential components in agriculture and steel manufacturing, providing efficient outdoor material handling solutions. The availability of both single and double girder gantry cranes caters to the diverse needs of industrial locations in Dire Dawa and Mek'ele.

Semi Gantry Cranes

Features & Benefits:

- Single Girder Semi Gantry Crane: Cost effective solution for material handling in limited spaces. Suited for moderate loads.

- Double Girder Semi Gantry Cranes: Ideal for applications requiring increased lifting capacity. Offers stability and precision in material handling.

- Application Industries in Ethiopia: Manufacturing workshops, construction material yards.

Common Industrial Locations in Ethiopia: Addis Ababa, Hawassa.

- Single Girder Semi Gantry Crane: Cost Effective Solution for Material Handling in Limited Spaces: Single girder semi gantry cranes provide a cost effective solution for material handling in settings with limited space. Well suited for workshops and areas where only one side of the crane needs support.

- Suited for Moderate Loads: Designed to handle moderate loads, single girder semi gantry cranes are efficient for various manufacturing operations and construction material yards.

- Double Girder Semi Gantry Cranes: Ideal for Applications Requiring Increased Lifting Capacity: Double girder semi gantry cranes are specifically engineered for applications demanding higher lifting capacities. Their stable and precise design makes them suitable for handling heavier materials with efficiency.

- Offers Stability and Precision in Material Handling: The dual girder configuration enhances stability, providing precision in material handling tasks. Suitable for scenarios where a higher level of accuracy and control is required.

Application Industries in Ethiopia:

- Manufacturing Workshops: Both single and double girder semi gantry cranes can be employed in manufacturing workshops for diverse material handling tasks. The choice between the two depends on the specific lifting requirements of the workshop.

- Construction Material Yards: Single girder semi gantry cranes may be suitable for handling construction materials in yards with limited space. Double girder semi gantry cranes excel in scenarios demanding increased lifting capacities for heavy construction components.

Common Industrial Locations in Ethiopia:

- Addis Ababa: In the capital city, manufacturing workshops may benefit from the use of semi gantry cranes for efficient material handling. Construction material yards in Addis Ababa may utilize both types of semi gantry cranes based on the nature of the lifting tasks.

- Hawassa: Manufacturing setups and construction material yards in Hawassa can optimize their material handling processes with the deployment of semi gantry cranes. The adaptability of semi gantry cranes caters to the varied lifting needs of industrial locations in Hawassa.

- In Ethiopian industrial landscapes, semi gantry cranes, both single and double girder, provide versatile solutions for material handling in workshops and construction material yards. Their cost effectiveness, adaptability, and stability make them valuable assets in enhancing the efficiency of industrial operations in Addis Ababa and Hawassa.

Portable Cranes

In Ethiopia's dynamic industrial landscape, portable cranes have emerged as versatile and agile solutions for on site lifting needs. These compact and movable lifting devices cater to the requirements of construction sites, maintenance projects, and various industries where flexibility and mobility are paramount. Found in diverse locations, from construction sites in Addis Ababa to maintenance projects across the country, portable cranes contribute significantly to efficient material handling in changing and dynamic environments.

- Flexibility for On Site Lifting:Portable cranes, characterized by their compact design and mobility, are specifically tailored for on site lifting requirements. Whether it's construction materials at a building site or the need for swift and efficient material handling in maintenance projects, these cranes offer the flexibility needed for dynamic operations. Their adaptability to different locations positions them as indispensable tools in Ethiopia's evolving industrial scenarios.

- Portable Gantry Cranes for Outdoor Versatility:Portable gantry cranes, a subset of portable lifting solutions, provide outdoor versatility with the added advantage of mobility. These cranes offer a flexible solution for outdoor material handling, making them valuable assets in Ethiopia's construction and industrial activities. Their ability to be easily transported and set up enhances efficiency in various on site applications.

- Compact Jib Cranes for Localized Lifting:Compact and portable jib cranes play a crucial role in localized material handling. Whether in small scale manufacturing workshops or construction sites, these cranes provide the necessary lifting capabilities without occupying significant space. Their mobility allows for precise positioning, contributing to efficient and controlled lifting operations.

- Efficiency in Construction and Maintenance:Portable cranes find extensive applications in Ethiopia's construction and maintenance sectors. Their presence in construction sites ensures the swift movement of construction materials, optimizing the building process. In maintenance projects, these cranes facilitate the handling of equipment and materials, contributing to timely and cost effective maintenance operations.

- Adaptability to Changing Environments:The adaptability of portable cranes to changing environments is a defining feature. Construction sites, maintenance projects, and various industrial zones across Ethiopia may present different challenges, and the mobility of these cranes allows for quick adjustments to meet specific requirements. This adaptability aligns with the dynamic nature of Ethiopia's industrial landscape.

In conclusion, portable cranes in Ethiopia epitomize flexibility, mobility, and efficiency in on site material handling. Whether it's the construction of new structures or the maintenance of existing ones, these cranes contribute to the fluidity of operations, positioning themselves as essential components in Ethiopia's construction and industrial endeavors.

Features & Benefits:

- Portable Gantry Crane: Offers Flexibility for On Site Lifting: Portable gantry cranes provide the flexibility to perform on site lifting tasks, offering a convenient solution for various applications. Their mobility allows for easy relocation to different locations within construction sites or maintenance projects.

- Easily Movable for Various Applications: Designed for easy mobility, portable gantry cranes can be quickly moved to different areas as needed. Suited for tasks that require lifting and positioning of materials in different sections of construction sites or maintenance projects.

- Portable Jib Cranes: Compact and Mobile Solution for Localized Lifting: Portable jib cranes offer a compact and mobile solution for localized lifting within specific work areas. Their design allows for efficient material handling in confined spaces or areas with limited accessibility.

Application Industries in Ethiopia:

- Construction Sites: Portable gantry cranes are valuable in construction sites for lifting and moving materials during various stages of building projects. Portable jib cranes contribute to localized lifting tasks, enhancing the efficiency of construction operations.

- Maintenance Projects: Both types of portable cranes find applications in maintenance projects for lifting equipment, components, and materials during repair and maintenance activities. Their portability facilitates easy maneuvering in maintenance areas with diverse lifting requirements.

Common Industrial Locations in Ethiopia:

- Various Construction and Maintenance Sites: Portable cranes can be commonly found in different construction and maintenance sites across Ethiopia. Their presence in these locations reflects their adaptability and convenience in addressing the dynamic lifting needs of industrial and maintenance projects.

- In Ethiopia, portable gantry cranes and portable jib cranes serve as versatile solutions for on site and localized lifting in construction and maintenance settings. Their ease of mobility and compact design contribute to the efficiency of material handling in various construction and maintenance sites across the country.

Specialized Industrial Cranes in Ethiopia

Ethiopia's industrial landscape embraces specialized cranes, addressing unique needs with precision. From articulated jib cranes for cultural artifacts to explosion proof cranes in hazardous environments, these specialized tools enhance safety and efficiency. Clean room cranes elevate Ethiopia's electronics manufacturing, while magnetic cranes streamline metal handling. Tailored for recycling facilities, scrap handling cranes contribute to sustainability. In foundries, specialized cranes tackle molten metal challenges. These purpose built solutions underscore Ethiopia's commitment to innovation and industry specific advancements.

Features & Benefits:

- Tailored Solutions for Unique Industry Requirements: Specialized industrial cranes are designed to provide tailored solutions that meet the unique lifting and handling requirements of specific industries. Customization ensures that these cranes address the distinct challenges and characteristics of the applications they serve.

- Enhanced Safety Features and Specialized Functionalities: Specialized industrial cranes come equipped with enhanced safety features and specialized functionalities designed for the specific needs of their respective industries. These features may include precision controls, advanced safety systems, and specialized attachments to ensure optimal performance and safety.

Application Industries in Ethiopia:

- Cultural Artifact Restoration Studios: Specialized industrial cranes play a crucial role in cultural artifact restoration studios, where precision and care are paramount. Tailored to handle delicate artifacts, these cranes contribute to the preservation and restoration of cultural treasures.

- Specialized Manufacturing: Various industries with unique manufacturing processes may benefit from specialized industrial cranes designed to handle specific materials or components. These cranes enhance efficiency and safety in specialized manufacturing applications.

Common Industrial Locations in Ethiopia:

- Addis Ababa: In the capital city, specialized industrial cranes may be found in cultural artifact restoration studios and various workshops with unique manufacturing processes. The customization of these cranes caters to the diverse and specialized needs of industrial locations in Addis Ababa.

- Various Specialized Workshops: Specialized industrial cranes are likely to be present in workshops across Ethiopia that focus on specific industries requiring customized lifting solutions. Their deployment in these workshops reflects the commitment to safety and efficiency in handling specialized materials or products.

In Ethiopia, specialized industrial cranes offer tailored solutions for industries with unique requirements, such as cultural artifact restoration studios and specialized manufacturing. The presence of these cranes in Addis Ababa and various specialized workshops underscores their significance in meeting the distinct challenges of specialized applications.

Specialized Overhead Cranes in Ethiopia

Articulated Jib Cranes for Cultural Artifact Restoration:

Features & Benefits: Precise and Flexible Movements: Articulated jib cranes are characterized by their ability to provide precise and flexible movements, allowing for intricate handling and positioning of delicate artifacts. This precision is crucial during restoration processes where careful manipulation of items is essential.

Application in Ethiopia: Cultural Artifact Restoration Studios: Articulated jib cranes find applications in cultural artifact restoration studios in Ethiopia, contributing to the preservation and restoration of valuable cultural treasures. Their agility and precision make them well suited for the delicate handling required in the restoration of artifacts.

Explosion Proof Overhead Cranes for Hazardous Environments:

Features & Benefits: Safety in Hazardous Environments: Explosion proof overhead cranes are designed with safety features to operate in environments where explosive or hazardous materials are present. Robust construction and safety measures prevent the risk of ignition during material handling processes.

Application in Ethiopia: Industries Dealing with Explosive Materials: Industries in Ethiopia involved in the handling of explosive or hazardous materials, such as chemical or petrochemical sectors, may utilize explosion proof overhead cranes to ensure the safety of operations. These cranes contribute to safe material handling in environments where the risk of explosion exists.

Clean Room Overhead Cranes for Manufacturing Precision Electronics:

Features & Benefits: Operation in Controlled Environments: Clean room overhead cranes are designed to operate in controlled environments with high cleanliness standards. These cranes prevent the introduction of contaminants, ensuring the integrity of manufacturing processes, particularly in precision electronics manufacturing.

Application in Ethiopia: Precision Electronics Manufacturing: Industries in Ethiopia engaged in precision electronics manufacturing, such as semiconductor production or cleanroom assembly, may employ clean room overhead cranes. These cranes contribute to maintaining the stringent cleanliness requirements essential for the production of high precision electronic components.

Magnetic Overhead Cranes for Metal Handling:

Features & Benefits: Efficient Metal Handling: Magnetic overhead cranes utilize powerful magnets to efficiently handle and transport metal materials. They provide a quick and secure method for lifting and moving metal components in industries dealing with metal fabrication or recycling.

Application in Ethiopia: Metal Fabrication or Recycling Industries: Ethiopian industries involved in metal fabrication or recycling may utilize magnetic overhead cranes for efficient material handling. These cranes enhance productivity by streamlining the movement of metal materials within the facility.

Scrap Handling Overhead Cranes for Recycling Facilities:

Features & Benefits: Optimized Scrap Material Handling: Scrap handling overhead cranes are specifically designed for the efficient handling of scrap materials in recycling facilities. Their configuration and features enable the systematic and organized movement of scrap within the facility.

Application in Ethiopia: Recycling Plants: Recycling facilities in Ethiopia dealing with various types of scrap materials may deploy specialized overhead cranes for optimized handling. These cranes contribute to the recycling process by facilitating the organized movement of scrap materials.

Foundry Crane for Molten Metal Handling:

Features & Benefits: Specialized for Molten Metal: Foundry cranes are engineered to handle the challenges associated with molten metal, including high temperatures and heavy loads. They provide a safe and efficient solution for lifting and transporting molten metal within foundry operations.

Application in Ethiopia: Metal Casting and Foundries: Industries in Ethiopia involved in metal casting and foundry operations may deploy specialized foundry cranes for the safe handling of molten metal. These cranes contribute to the overall efficiency and safety of foundry processes by providing reliable material handling solutions.

These specialized overhead cranes cater to the unique requirements of various industries in Ethiopia, ensuring safe and efficient material handling in specific applications. Their deployment contributes to the overall productivity and safety standards within diverse industrial sectors.

As Ethiopia continues to witness industrial growth, the demand for overhead cranes remains substantial across diverse sectors. Understanding the features, benefits, and applications of different types of overhead cranes is essential for making informed decisions in selecting the most suitable lifting solution for specific industrial needs. Whether in steel manufacturing, agriculture, or food processing, overhead cranes contribute to the efficiency and success of Ethiopian industries.

Main Industrial Sectors in Ethiopia

Introduction to Overhead Crane Operations in Ethiopian Industries

Ethiopia's industrial landscape has witnessed significant growth, and the efficient operation of overhead cranes stands as a critical element in facilitating seamless material handling across diverse sectors. These robust lifting devices play a pivotal role in enhancing productivity and precision in various industrial processes, contributing to the nation's economic development.

- Steel Manufacturing and Foundries:In the steel manufacturing sector, overhead cranes, including ladle cranes designed for molten metal handling, are indispensable. These cranes efficiently transport heavy steel components, ensuring the smooth flow of operations in foundries located in cities such as Dire Dawa and Mek'ele. The adaptability of these cranes to handle molten metal underscores their significance in the steel production process.

- Textile and Garment Manufacturing:Ethiopia's textile and garment manufacturing industry, thriving in locations like Addis Ababa and Hawassa, benefits from overhead cranes tailored to handle fabric rolls and garment components. The precision offered by articulated jib cranes proves invaluable in delicate tasks such as artifact restoration, emphasizing the versatile applications of these lifting solutions.

- Agriculture and Agro Processing: In regions like Bahir Dar and Jimma, where agriculture and agro processing thrive, overhead cranes are instrumental in handling grain sacks and farm equipment. These cranes contribute to the efficiency of agro processing units and greenhouse agriculture, showcasing their adaptability to the unique demands of the agricultural sector.

- Food and Beverage Production:Adama and Nazret host food processing plants and beverage manufacturing units where overhead cranes are deployed for the efficient handling of packaged foods and beverage containers. The use of these cranes ensures a streamlined production process, meeting the demands of the burgeoning food and beverage industry in Ethiopia.

- Customization and Local Adaptations:One noteworthy aspect of overhead crane operations in Ethiopia is their customization for specific industries. These cranes are not one size fits all; rather, they are adapted to suit the unique requirements of each sector. Additionally, they are engineered to integrate seamlessly with local power supply conditions, ensuring reliability in their operation across different industrial zones.

Future Trends and Sustainability:As Ethiopia looks toward the future, the integration of automation, smart technologies, and sustainability practices emerges as a significant trend. Overhead cranes are evolving to meet global industrial standards, incorporating features such as remote monitoring capabilities and energy efficient models. The commitment to sustainable practices, including the use of eco friendly materials, positions Ethiopia's industrial sector on a path of responsible and forward thinking operations.

In conclusion, overhead crane operations in Ethiopian industries serve as a testament to the nation's industrial advancement. These lifting solutions not only address the immediate material handling needs of various sectors but also reflect Ethiopia's commitment to innovation, customization, and sustainability in its industrial endeavors.

Textile and Garment Manufacturing

Ethiopia's burgeoning textile and garment manufacturing industry, particularly concentrated in urban centers like Addis Ababa and Hawassa, relies heavily on advanced material handling solutions. Overhead cranes play a pivotal role in optimizing the production processes within this sector, offering tailored solutions to the unique challenges presented by the handling of fabric rolls and garment components.

- Fabric Rolls Handling:In the textile mills and garment factories of Ethiopia, the efficient handling of large fabric rolls is a critical aspect of the production chain. Overhead cranes, with a focus on single and double girder configurations, provide a cost effective and space efficient solution for lifting and transporting these substantial textile materials. Their adaptability ensures smooth operations in the movement of fabric rolls within the workshops, contributing to increased productivity.

- Garment Component Precision:Articulated jib cranes emerge as key players in the delicate processes of garment manufacturing. These cranes offer precise and flexible movements, facilitating the careful handling and positioning of garment components. Whether it's the movement of intricate patterns or the transportation of finished garments for packaging, jib cranes contribute to the precision required in the final stages of garment production.

- Local Adaptations for Specific Industries:One notable characteristic of overhead crane operations in Ethiopian textile and garment manufacturing is their customization for specific industry needs. Overhead cranes are engineered to meet the demands of textile mills and garment factories, adapting to varying load capacities and specific workflows. The integration of these cranes with the local power supply conditions ensures their seamless operation in the dynamic industrial landscape of Ethiopia.

- Technological Advancements:Looking toward the future, the textile and garment manufacturing sector in Ethiopia is witnessing technological advancements in overhead crane operations. Automation and smart technologies are being integrated, enhancing efficiency and precision in material handling. Remote monitoring capabilities allow operators to oversee crane performance, contributing to proactive maintenance and minimizing downtime.

- Sustainable Practices:The industry's commitment to sustainable practices is reflected in the adoption of energy efficient crane models. Overhead cranes utilized in textile and garment manufacturing are designed to optimize energy consumption, aligning with global trends toward environmentally conscious industrial operations. This commitment extends to the use of eco friendly materials, contributing to Ethiopia's position as a responsible player in the global textile and garment industry.

In conclusion, overhead crane operations in Ethiopian textile and garment manufacturing showcase a blend of precision, adaptability, and technological innovation. These cranes serve as indispensable tools in the intricate processes of fabric handling and garment production, contributing to the sector's growth and positioning Ethiopia as a key player in the global textile and garment market.

- Types of Workshops: Textile Mills, Garment Factories:Textile Mills: These workshops focus on the production of fabrics, utilizing machinery for processes like spinning, weaving, and dyeing. Garment Factories: Dedicated to the creation of clothing items, garment factories involve cutting, sewing, and finishing operations.

- Workshop Features: Large Machinery, Fabric Rolls:Textile Mills: Equipped with large machinery such as looms and spinning frames, these workshops accommodate the production of fabric in various forms. Garment Factories: Feature cutting tables, sewing machines, and finishing equipment to transform fabrics into finished clothing items.

- Industrial Locations: Addis Ababa, Hawassa:Addis Ababa: The capital city houses numerous textile and garment manufacturing units, contributing significantly to the country's economy. Hawassa: An emerging industrial hub, Hawassa has seen a rise in textile and garment factories, taking advantage of its strategic location.

- Typical Loads Handled: Fabric Rolls, Garment Components:Fabric Rolls: Overhead cranes in these workshops handle the movement of large rolls of fabric between different stages of production. Garment Components: Lifting equipment assists in the transportation of garment components, ensuring a smooth workflow from cutting to assembly.

The textile and garment manufacturing sector in Ethiopia is characterized by advanced machinery, strategic industrial locations, and the efficient handling of diverse loads by overhead cranes.

Main Types of Overhead Cranes Used in Ethiopian Textile and Garment Workshops

Bridge Cranes

Applications: Efficient movement of fabric rolls within the textile mill. Loading and unloading heavy machinery in garment factories.

Capacity: Varied capacity based on the specific needs of the workshop.

Jib Cranes

Applications: Precise lifting for the maneuvering of fabric rolls. Handling garment components in confined spaces.

Capacity: Ranges suitable for lifting fabric rolls and smaller garment parts.

Monorail Systems

Applications: Continuous transport of fabric rolls along fixed paths. Connecting different workstations in garment production.

Capacity: Configurable to handle various loads, optimizing workflow.

Gantry Cranes

Applications: Versatile material handling in open spaces of textile mills. Efficient loading/unloading in outdoor areas of garment factories.

Capacity: Tailored to the specific load requirements of each workshop.

Electric Hoists

Applications: Precise lifting for garment components and accessories. Handling smaller loads in various textile processes.

Capacity: Suitable for lifting lighter loads with precision.

Explosion Proof Hoist and Cranes

Applications: Customized electric cranes annd hoists for applications or working environments, where potential hazardous substances or air may apear to ensure material handling safety and efficiency. Customized for various industrial use with capacity from 1 ton to 80 ton.

These overhead crane solutions cater to the unique demands of Ethiopian textile and garment workshops, ensuring smooth and efficient operations throughout the production process.

Agriculture and Agro Processing

Overhead Crane Operations in Agriculture and Agro Processing in Ethiopia

In the rich agricultural landscapes of Ethiopia, where Bahir Dar and Jimma stand as prominent centers, the integration of overhead cranes has become instrumental in elevating the efficiency of agricultural and agro processing operations. These robust lifting solutions play a crucial role in handling diverse materials, from grain sacks to farming equipment, contributing to the seamless flow of processes in the agricultural sector.

- Efficient Grain Sack Handling:The heart of Ethiopia's agriculture lies in the vast fields producing an abundance of crops. Overhead cranes, tailored for the agro processing units, contribute significantly to the efficient handling of grain sacks. With the ability to lift and transport substantial loads, these cranes streamline the movement of harvested crops, ensuring a swift and organized transition from the fields to processing units.

- Versatile Handling of Farming Equipment:Agriculture and agro processing in Ethiopia involve a spectrum of activities that go beyond crop harvesting. Overhead cranes adapted for these sectors exhibit versatility in handling farming equipment. From plows to irrigation machinery, these cranes facilitate the smooth transition of equipment within workshops and processing units, minimizing manual effort and maximizing productivity.

- Localization of Operations:One noteworthy aspect of overhead crane operations in Ethiopian agriculture is their localization for specific industries. These cranes are tailored to meet the unique demands of agro processing units, adapting to varying load capacities and specific workflows. The seamless integration with local power supply conditions ensures their reliable operation across different industrial zones, contributing to the agility of the sector.

- Adaptability to Varied Load Capacities:The adaptability of overhead cranes is a key feature in the agricultural and agro processing landscape. These cranes are engineered to handle varying load capacities, accommodating the diverse needs of the sector. Whether transporting sacks of grains or heavy farming machinery, overhead cranes provide a tailored solution to the specific material handling requirements of each operation.

- Future Trends and Sustainability:Looking ahead, the future of overhead crane operations in Ethiopian agriculture is poised for further advancements. The integration of smart technologies and automation is expected to enhance precision and efficiency. Additionally, a commitment to sustainability is reflected in the adoption of energy efficient crane models, contributing to environmentally conscious agricultural practices in Ethiopia.

In conclusion, overhead crane operations in Ethiopian agriculture and agro processing embody efficiency, adaptability, and a commitment to technological advancement. These cranes play a pivotal role in optimizing the handling of diverse materials, contributing to the growth and sustainability of the agricultural sector in Ethiopia.

- Types of Workshops: Agro Processing Units, Greenhouse Agriculture:Agro Processing Units: Specialized workshops focused on processing agricultural products, including sorting, cleaning, and packaging. Greenhouse Agriculture: Workshops dedicated to controlled environment agriculture, promoting optimal growth conditions for crops.

- Workshop Features: Agricultural Produce, Farming Equipment:Agro Processing Units: Equipped with machinery for washing, sorting, and packaging fruits, vegetables, and grains. Greenhouse Agriculture: Feature climate controlled environments with irrigation systems and specialized equipment for crop cultivation.

- Industrial Locations: Bahir Dar, Jimma:Bahir Dar: A hub for agro processing activities, benefiting from its proximity to fertile agricultural regions. Jimma: Known for its focus on greenhouse agriculture, utilizing advanced techniques for crop cultivation.

- Typical Loads Handled: Grain Sacks, Farm Equipment:Agro Processing Units: Overhead cranes handle the movement of sacks filled with grains, fruits, or vegetables. Greenhouse Agriculture: Lifting equipment assists in positioning and transporting agricultural supplies and equipment.

The agriculture and agro processing sector in Ethiopia integrates advanced technologies to enhance crop production and processing efficiency, with overhead cranes playing a crucial role in material handling.

Main Types of Overhead Cranes Used in Ethiopian Agriculture and Agro Processing Workshops

Gantry Cranes

Applications: Efficient handling of bulk agricultural produce in agro processing units. Loading/unloading of farming equipment in greenhouse agriculture.

Capacity: Tailored to the specific needs of each workshop, accommodating various loads.

Jib Cranes

Applications: Precise lifting for positioning agricultural products during processing. Maneuvering farming equipment in confined spaces.

Capacity: Configurable to handle different loads, promoting flexibility in workflow.

Monorail Systems

Applications: Continuous transport of processed agricultural products within agro processing units. Connecting different workstations in greenhouse agriculture for seamless operations.

Capacity: Adjustable based on the volume and weight of materials being transported.

Electric Hoists

Applications: Precise lifting of grain sacks and other agricultural products. Handling smaller loads such as tools and equipment in both agro processing and greenhouse workshops.

Capacity: Suitable for lifting lighter loads with accuracy and efficiency.

These overhead crane solutions are tailored to the unique demands of Ethiopian agriculture and agro processing workshops, ensuring the smooth flow of operations from cultivation to processing.

Steel Manufacturing

Introduction to Overhead Crane Operations in Steel Manufacturing in Ethiopia

In the dynamic landscape of Ethiopia's industrial sector, the steel manufacturing industry has emerged as a vital contributor to economic growth. Cities such as Dire Dawa and Mek'ele have become epicenters of steel production, where the efficient operation of overhead cranes stands as a linchpin for the handling of heavy metal components, steel beams, and the intricate processes inherent to foundries.

- Handling Heavy Metal Components:The heart of steel manufacturing lies in the intricate processes of handling heavy metal components. Overhead cranes, with their robust design and lifting capabilities, play a critical role in transporting substantial steel materials within workshops and foundries. Whether it's the movement of raw materials or the transportation of finished products, these cranes provide a reliable and efficient solution.

- Optimizing Foundry Operations:Foundries in Ethiopia, equipped with overhead cranes specialized for the industry, benefit from the seamless handling of molten metal. Foundry cranes are tailored to handle the challenges associated with high temperatures and heavy loads, ensuring the safe and efficient transport of molten metal within the foundry. This precision contributes to the optimization of foundry operations.

- Adaptability to Steel Beams and Large Metal Parts:The adaptability of overhead cranes in the steel manufacturing sector is evident in their ability to handle various materials, including steel beams and large metal parts. Whether lifting components for processing or transporting finished products for storage, these cranes offer versatility in accommodating the diverse material handling requirements of steel manufacturing.

- Localization and Compliance:Overhead crane operations in Ethiopian steel manufacturing are characterized by their localization for specific industries. These cranes are customized to adhere to the unique demands of steel foundries and metal fabrication shops. Compliance with Ethiopian regulations is a paramount consideration, and overhead crane manufacturers ensure that their products meet the safety and operational standards set by the country.

- Technological Advancements and Future Trends:The future of overhead crane operations in Ethiopian steel manufacturing is marked by technological advancements. Integration with automation, smart technologies, and remote monitoring capabilities is expected to enhance efficiency and safety. The commitment to sustainability is reflected in the adoption of energy efficient crane models, contributing to responsible and forward thinking industrial practices.

In conclusion, overhead crane operations in Ethiopian steel manufacturing epitomize precision, adaptability, and technological innovation. These cranes serve as indispensable tools in the intricate processes of handling heavy metal components, contributing to the sector's growth and positioning Ethiopia as a key player in the global steel manufacturing industry.

- Types of Workshops: Steel Foundries, Metal Fabrication Shops:Steel Foundries: Workshops focused on the production of steel through casting processes, producing raw steel materials. Metal Fabrication Shops: Facilities engaged in shaping, cutting, and assembling steel components into finished products.

- Workshop Features: Heavy Metal Components, Steel Beams:Steel Foundries: Equipped with furnaces, casting molds, and machinery for handling molten metal and shaping steel. Metal Fabrication Shops: Feature cutting machines, welding stations, and heavy duty machinery for fabricating steel components.

- Industrial Locations: Dire Dawa, Mek'ele:Dire Dawa: Home to steel foundries and fabrication shops, benefiting from strategic transportation links. Mek'ele: A growing industrial hub, hosting workshops involved in various stages of steel manufacturing.

- Typical Loads Handled: Steel Beams, Large Metal Parts:Overhead cranes play a vital role in moving heavy steel beams and large metal components within these workshops.

The steel manufacturing sector in Ethiopia contributes significantly to infrastructure development, with overhead cranes facilitating the efficient handling of heavy metal materials.

Main Types of Overhead Cranes Used in Ethiopian Steel Manufacturing Workshops

Double Girder Overhead Cranes

Applications: Handling and transporting heavy steel beams and large metal components. Loading/unloading materials in steel foundries and fabrication shops.

Capacity: Configured for heavy duty lifting, ranging from 5 tons to 50 tons.

Gantry Cranes

Applications: Versatile material handling in open spaces of steel foundries. Efficient loading/unloading in outdoor areas of metal fabrication shops.

Capacity: Customized to handle the specific load requirements of each workshop.

Jib Cranes

Applications: Precise lifting for maneuvering steel components during fabrication. Handling heavy metal parts in confined spaces.

Capacity: Configurable to lift various loads, providing flexibility in operations.

Monorail Systems

Applications: Continuous transport of steel components within fabrication shops. Connecting different workstations for a seamless production process.

Capacity: Adjustable based on the volume and weight of materials being transported.

These overhead crane solutions are integral to the success of Ethiopian steel manufacturing workshops, ensuring the safe and efficient handling of heavy metal materials throughout the production cycle.

Food and Beverage Production

Introduction to Overhead Crane Operations in Textile and Garment Manufacturing in Ethiopia

Ethiopia's textile and garment manufacturing industry has witnessed a remarkable evolution, becoming a pivotal force in the country's industrial landscape. In the bustling hubs of Addis Ababa and Hawassa, the efficient operation of overhead cranes has become integral to the seamless handling of fabric rolls and garment components, enhancing the overall productivity and precision of these dynamic sectors.

- Handling of Large Fabric Rolls: At the heart of textile mills and garment factories in Ethiopia lies the intricate process of handling large fabric rolls. Overhead cranes, featuring both single and double girder configurations, offer a cost effective and space efficient solution for lifting and transporting these substantial textile materials. This capability ensures a streamlined workflow within workshops, contributing significantly to increased production efficiency.

- Precision in Garment Component Handling: Articulated jib cranes play a pivotal role in the delicate and precise handling of garment components. Whether it's the movement of intricate patterns or the transportation of finished garments for packaging, these cranes provide a level of precision essential in the final stages of garment production. Their flexibility enhances the efficiency of these operations in the textile and garment manufacturing sector.

- Adaptability and Customization: A notable feature of overhead crane operations in Ethiopian textile and garment manufacturing is their adaptability and customization for specific industry needs. These cranes are engineered to meet the unique demands of textile mills and garment factories, adapting to varying load capacities and specific workflows. Their seamless integration with local power supply conditions ensures reliability across different industrial zones.

- Technological Integration for Future Growth: Looking towards the future, the textile and garment manufacturing sector in Ethiopia is embracing technological advancements in overhead crane operations. The integration of automation, smart technologies, and remote monitoring capabilities is expected to further enhance efficiency and safety. This forward thinking approach positions Ethiopia's textile industry on a trajectory of continuous growth and innovation.

- Sustainable Practices and Global Standards: The commitment to sustainability is a hallmark of overhead crane operations in Ethiopian textile and garment manufacturing. The adoption of energy efficient crane models aligns with global trends towards environmentally conscious industrial practices. These cranes also adhere to international industrial standards, ensuring quality, safety, and interoperability with global systems.

In conclusion, overhead crane operations in Ethiopian textile and garment manufacturing exemplify efficiency, precision, and a commitment to technological advancement. These cranes play an indispensable role in the intricate processes of fabric handling and garment production, contributing significantly to the growth and sustainability of the textile and garment industry in Ethiopia.

- Types of Workshops: Food Processing Plants, Beverage Manufacturing:Food Processing Plants: Workshops dedicated to the processing and packaging of various food products, including fruits, vegetables, and grains. Beverage Manufacturing: Facilities involved in the production and packaging of beverages, including soft drinks, juices, and bottled water.

- Workshop Features: Processed Food Products, Packaging Materials:Food Processing Plants: Equipped with machinery for washing, cutting, cooking, and packaging processed food items. Beverage Manufacturing: Feature bottling lines, mixing tanks, and packaging equipment for beverages.

- Industrial Locations: Adama, Nazret:Adama: A key location for food processing plants, strategically situated to access agricultural produce. Nazret: Home to beverage manufacturing facilities, benefiting from transportation links and access to water resources.

- Typical Loads Handled: Packaged Foods, Beverage Containers:Overhead cranes are crucial for handling packaged foods, moving containers of beverages, and facilitating the efficient flow of materials in these workshops.

The food and beverage production sector in Ethiopia relies on advanced processing techniques, with overhead cranes contributing to the streamlined handling of products and packaging materials.

Main Types of Overhead Cranes Used in Ethiopian Food and Beverage Workshops

Overhead Monorail Systems

Applications: Continuous transport of packaged foods and beverage containers along fixed paths. Connecting different stages of the production process for optimal efficiency.

Capacity: Configurable based on the specific requirements of each workshop.

Bridge Cranes

Applications: Efficient movement of packaged foods within food processing plants. Loading and unloading heavy machinery and materials in beverage manufacturing.