Steel Structure Factory 25m*17m*11m for Sale Nigeria 35.36 Ton

Steel structure factory for sale Nigeria. Custom steel factory 25m*17m*11m dimensions, total weight 35.36 ton .Set up your steel structure factory easily.

Category: Factory Crane

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Steel Structure Factory for Sale Nigeria

Custom Steel Factory 25m*17m*11m Dimensions, Total Weight 35.36 Ton

Steel structure factory for sale Nigeria. Custom steel factory 25m*17m*11m dimensions, total weight 35.36 ton .Set up your steel structure factory easily.

Overview of steel structure factory for Nigeria project

Item | Dimensions of Steel Structured Factory | Total Weight |

Steel Structure Factory | 25m*17m*11m | 35.36t |

Customized features for Nigeria steel structure factory project

Item | Quantity | Length | Tonnages t |

Columns of steel structure factory | 10 | 11m/ piece | 15.71 |

Steel frame beam | 5long pieces/10 short pieces | Span is 17 meters. | 6.1 |

Wind Resistance columns | 4 | Around 11meters | 2.73 |

Roof bracing | 0.32 | ||

Column bracing | 1.51 | ||

Angle bracing | 0.32 | ||

Perlins | 2.1 | ||

Wall beam | 5.37 | ||

Tie bars | 0.85 | ||

Rods | 0.35 | ||

Installation of steel structrue building for Nigeria

Steel metal building project in Nigeria under installation

Steel building factory erection in Nigeria

Steel structured crane building for sale Nigeria

Metal building factory construction in Nigeria

Terms of crane steel structrue building

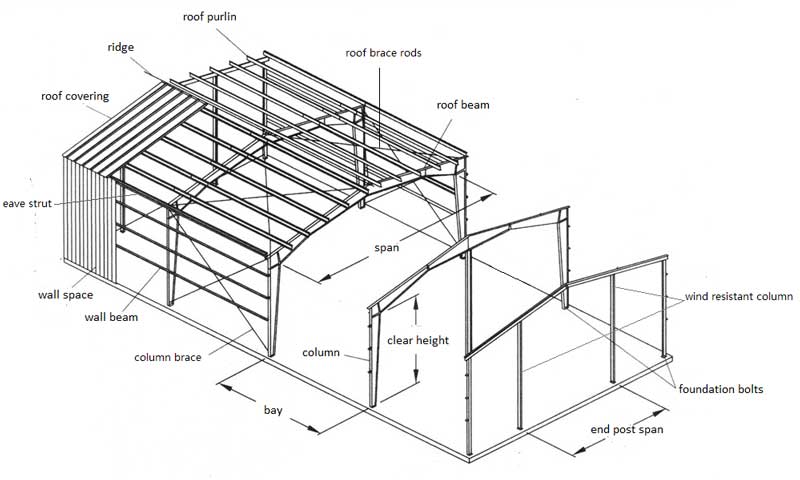

- Anchor Bolts - Anchor bolts are used to fasten construction materials to the foundation. These bolts are secured to the column base plate and embedded in the foundation in the case of primary framing.

- Bay Spacing - The separation of the main members of the frame measured perpendicular to the ridge or eave. From center line of frame to center line of frame, interior bays are measured.

- Building Height - The eave height, which is typically measured from the bottom of the main frame column base plate to the top outer point of the eave strut, is known as the building height. The distance between the finished floor and the top outer point of the eave strut is known as the eave height.

- Building Length - The building length, which is made up of several bay lengths, is determined by measuring the distance between the outside flanges of opposing end wall columns.

- Building Width - The building width is measured from the outside of one sidewall's eave strut to the outside of the adjacent sidewall's eave strut.

- Clear Height - The distance between the bottom of the rafter and the finished floor at the rafter-to-column connection.

- Clear Span - The space between columns along the building's width.

- Cold Formed Section - A structural shape created by cold-bending a thin gauge (typically 10 to 16 ga.) of material. Typically, a roll former is used for this.

- Column - Vertical structural support member for the main framing system.

- Design Loads - The forces to which the building will be subjected are known as design loads. The most recent building codes and standards that apply to pre-engineered buildings are used to apply loads.

- Haunch - A region of the column or rafter member with increased depth that is intended to account for the greater bending moments that occur at such locations. This typically happens where the rafter and column meet.

- Steel Building Systems are also known as Metal Building Systems. The same thing is referred to by both terms.

- Post-and-Beam End frame: An end wall's structural framing system made up of rake beams, corner posts, and end posts.

- Term used to refer to Steel Building Systems in Pre-Engineered Buildings (Metal Building Systems). When rigid frames were "pre-engineered" for a desired load, this terminology was used. Steel building systems are now individually engineered to fit the size and design loads required by the customer.

- Rafter - A manufactured piece that connects the frame ridge to the haunch member. any beam that is typically used in a main frame.

- Rod Bracing. A truss-style bracing system made of rods, purlins, and girts is used in both the roof and the wall planes.

- Roof purlins are auxiliary members of the roof that support the roof covering and are attached to the rafters of the frame.

- Roof Slope (x:12) - The roof's angle with respect to the horizontal is indicated here. The 0.5/10 and 1/10 roof slopes are the most prevalent. There is no practical limit to the roof slope.

- Roof system, which consists of panels, closures, and attachments, is the external roof surface.

- Sidewall - An exterior wall that runs perpendicular to the building's sidewall and ridge.

- Three-Plate - A built-up beam section with two flanges and one web that forms a "I" shape. Greater strength at a lower weight is possible when using three-plate construction as opposed to traditional structural shapes. The performance of these sections is frequently tapered.

- Wall Girt - A horizontal secondary wall member that supports the wall covering and is fastened to columns.

- Wall system - The exterior wall surface made up of panels, closures, and attachments is known as a "wall system."

Bridge crane optional for metal Buildings

Bridge cranes are an essential part of many contemporary industrial structures and manufacturing facilities because they provide a quick and affordable way to transport large, awkward, or heavy items from one location to another. The following types of overhead cranes are available for your steel-structured factories, according to bridge crane manufacturers.

Underhung bridge cranes are the best choice when it comes to moving loaded hoists and trolleys from one beam to another because they move along a crane bridge by hanging from flanges. Underhung bridge cranes are available in hand-powered or electric formats, the latter of which is typically operated via a pendant on the floor. They can lift between 1 and 10 tons and travel between 20 and 50 feet. These bridge cranes are great for large, open areas as well as partial aisles because they use support brackets that can be attached to building rafters instead of needing to extend completely between building columns. Underhung models, which are typically more affordable than top-running bridge cranes, can, if desired, be affordably timed to run alongside monorail trains.

Top-running bridge cranes are perfect for steel buildings with limited headroom because they can handle a wide range of different loads. Single-girder bridge cranes have a lifting capacity of 1 to 20 tons, and those with wide flange girders can travel 20 to 60 feet in length. Double-girder bridge cranes have a lifting capacity of up to 100 tons and can move cargo 60 to 100 feet at a time. Runway bumpers can be used to deflect the kinetic energy of the overhead bridge crane and work with hydraulics or springs. As the name implies, runway stops are used to stop moving cranes, and top-running bridge cranes require a heavy bracket to be bolted to the top of the runway girders.

A trolley used by a monorail overhead crane to transport the crane and hoist travels along the bottom flange of a runway beam. Electric and hand-geared monorail bridge cranes are both available, and they can lift between 1 and 10 tons. Monorail cranes provide an affordable way to move goods along a predetermined route that can be easily changed using switches or turntables. They are frequently used in storage facilities, industrial manufacturing plants, and maintenance facilities.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch