Overhead Cranes, Gantry Cranes and Hoists for Textile Industry

Overhead Cranes, Gantry Cranes and Hoists for Textile Industry. Industrial overhead cranes, gantry cranes and hoists for textile industry. Custom single girder, double girder, overhead, goliath crane, jib crane, chain & rope hoist.

Overhead Cranes and Hoists for Textile Industry Overview

The textile industry is a sector of the economy that involves the production of various types of fabrics and textile materials. It encompasses the processes of spinning, weaving, knitting, dyeing, printing, and finishing textiles to create a wide range of products used in clothing, household goods, industrial applications, and more.

Textiles can be made from natural fibers such as cotton, wool, silk, and linen, or synthetic fibers like polyester, nylon, and acrylic. Additionally, there are also blended fabrics that combine both natural and synthetic fibers to leverage their individual properties.

The textile industry plays a crucial role in the global economy and has a significant impact on various aspects of life, including fashion, interior design, and industrial applications. The industry's supply chain typically involves several stages, from the cultivation or extraction of fibers to the manufacturing of finished goods. Some key stages in the textile production process include:

- Fiber production: The process of growing or extracting fibers from plants, animals, or creating synthetic fibers through chemical processes.

- Spinning: The process of converting fibers into yarn or threads by twisting and drawing out the fibers.

- Weaving or Knitting: Involves interlacing the yarns to create fabric. Weaving involves a perpendicular arrangement of yarns (warp and weft) to create a woven fabric, while knitting uses a series of interconnected loops.

- Dyeing and Printing: The application of color or patterns to the fabric using various methods, such as dyeing, printing, or digital printing.

- Finishing: The final treatment of the fabric to enhance its appearance, texture, and performance. This can include processes like bleaching, softening, or adding water or stainresistant coatings.

The textile industry is one of the oldest industries globally and has undergone significant advancements with the advent of technology and the use of modern machinery. However, it is also an industry that faces challenges related to sustainability, environmental impact, and labor practices, and there is an increasing focus on adopting more ecofriendly and ethical practices in textile production.

Why does the textile industry needs overhead cranes?

The overhead cranes are essential for the textile industry, especially in manufacturing facilities and warehouses where large quantities of raw materials and finished products need to be handled efficiently. Overhead cranes play a crucial role in material handling, production processes, and logistics within the textile industry. Here are some reasons why overhead cranes are important for the textile sector:

- Heavy material handling: The textile industry deals with large and heavy rolls of fabrics, bales of raw materials (e.g., cotton, wool, synthetic fibers), and spools of yarn. Overhead cranes are designed to lift and transport these heavy loads safely and efficiently, reducing the risk of worker injuries and damage to materials.

- Efficient production processes: Overhead cranes can move materials vertically and horizontally, making it easier to position raw materials at the right location for processing or transporting finished products between different production stages. This streamlines the production processes and improves overall efficiency.

- Storage and warehousing: Textile companies often need to store large quantities of raw materials and finished products in warehouses. Overhead cranes can assist in stacking, organizing, and retrieving items from storage shelves, optimizing the use of available space and facilitating inventory management.

- Versatility: Overhead cranes come in various configurations, such as bridge cranes, gantry cranes, and jib cranes. This versatility allows textile manufacturers to choose the right type of crane for their specific needs and available space.

- Safety and precision: Overhead cranes are operated by trained personnel, ensuring that materials are lifted, moved, and placed with precision. This reduces the risk of accidents and damages to valuable textile materials.

- Time and costsaving: The use of overhead cranes can significantly reduce manual labor and handling time, leading to cost savings and increased productivity.

- Bulk handling: Textile industries often deal with large quantities of materials and finished products, and overhead cranes can handle bulk loads efficiently, saving time and effort.

In conclusion, overhead cranes are indispensable tools in the textile industry, enhancing material handling processes, optimizing production, and improving overall operational efficiency. They enable textile manufacturers to manage heavy loads, improve safety, and streamline their logistics and production systems.

Overhead cranes improve your safety and production efficiency in each procedure of textile industry

In the textile industry, overhead cranes are used in various production procedures to facilitate material handling, improve efficiency, and ensure the smooth flow of operations. Here are some common production procedures where overhead cranes are utilized and the typical types of overhead cranes used for each procedure, along with their main functions:

Raw Material Handling:

- Types of overhead cranes: Bridge cranes and Gantry cranes.

- Main functions: Overhead cranes are used to unload raw materials from trucks or containers and transport them to designated storage areas. They can also move the raw materials from storage to the production line or directly to the machines for processing.

Yarn Production:

- Types of overhead cranes: Bridge cranes and Jib cranes.

- Main functions: Overhead cranes are employed to move spools of yarn between different stages of production, such as from winding to twisting or from twisting to dyeing. They help maintain a smooth flow of materials, reducing downtime and improving efficiency.

Weaving and Knitting:

- Types of overhead cranes: Bridge cranes and Gantry cranes.

- Main functions: Overhead cranes are used to handle large rolls of fabrics produced from weaving or knitting machines. They transport the rolls to inspection areas, cutting tables, or packing stations, ensuring a seamless production process.

double girder overhead crane for the dying workshop of textile industry

double girder overhead crane for the dying workshop of textile industry

Dyeing and Finishing:

- Types of overhead cranes: Bridge cranes and Jib cranes.

- Main functions: Overhead cranes are used to move heavy textile materials, such as fabric rolls or batches, to dyeing or finishing machines. They play a critical role in handling delicate fabrics and preventing damage during transportation.

Fabric Inspection and Quality Control:

- Types of overhead cranes: Jib cranes and Bridge cranes.

- Main functions: Overhead cranes assist in lifting and positioning fabric rolls for inspection and quality control purposes. They provide flexibility in moving the fabric to different inspection stations, ensuring thorough examination.

Finished Product Handling:

- Types of overhead cranes: Bridge cranes and Gantry cranes.

- Main functions: Overhead cranes are used to transport finished textile products, such as clothing or home textiles, from the production area to packaging or storage. They also facilitate loading finished goods onto trucks for distribution.

Overall, overhead cranes are crucial in the textile industry for their ability to handle heavy loads safely, streamline production processes, and improve material flow within the facility. Different types of overhead cranes are utilized depending on the specific requirements of each production procedure, and their main functions revolve around efficient material handling and logistics.

What are the typical overhead crane used for textile industry?

In the textile industry, various types of overhead cranes are used to handle different materials and perform specific tasks efficiently. The typical overhead cranes used in the textile industry include:

Single Girder Overhead Crane

Single girder overhead cranes have a single horizontal beam that supports the hoist and trolley. The beam is usually attached to the building structure or supported by freestanding columns.

Application: Single girder cranes are commonly used in textile facilities where lighter loads need to be handled, such as moving spools of yarn, intermediate fabric rolls, or other smaller materials.

Features:

- Single horizontal beam for support.

- Usually attached to the building structure or supported by freestanding columns.

- Benefits for Textile Industry:

- Costeffective option for handling lighter loads like spools of yarn and intermediate fabric rolls.

- Spacesaving design, suitable for textile facilities with limited space.

- Offers versatility for material handling in different workstations.

Double Girder Overhead Crane :

Double girder overhead cranes have two parallel horizontal beams, offering increased lifting capacity and stability compared to single girder cranes.

Application: Double girder cranes are utilized in textile manufacturing plants when dealing with heavier loads, larger rolls of fabric, or bales of raw materials.

Features:

- Two parallel horizontal beams for increased lifting capacity and stability.

- Benefits for Textile Industry:

- Suitable for handling heavier loads, such as large rolls of fabric or bales of raw materials.

- Provides enhanced stability and durability, making it suitable for longterm use in textile manufacturing plants.

- Offers higher lifting heights and longer spans for larger facilities.

Gantry Crane :

Gantry cranes are similar to overhead cranes, but they are supported by freestanding legs running on rails or wheels. This allows them to move independently of the building structure.

Application: Gantry cranes are suitable for outdoor or indoor areas where there is limited or no overhead support. They are often used for handling materials in textile warehouses or outdoor storage yards.

Features:

- Supported by freestanding legs running on rails or wheels.

- Benefits for Textile Industry:

- Offers mobility and independence from building structures, making it suitable for outdoor or indoor areas with limited overhead support.

- Ideal for handling large fabric rolls, loading/unloading shipments, and organizing materials in storage yards.

- Provides flexibility for material handling in various locations within the textile facility.

Jib Crane :

Jib cranes consist of a vertical mast mounted on a stable base with a horizontal jib arm. The hoist and trolley move along the jib arm.

Application: Jib cranes are ideal for localized material handling tasks within the textile industry, such as loading and unloading machines, or transferring materials between workstations.

Features:

- Consists of a vertical mast and a horizontal jib arm.

- Benefits for Textile Industry:

- Provides localized material handling within a specific area, such as loading and unloading machines or transferring materials between workstations.

- Saves floor space and allows for efficient use of the available workspace.

- Suitable for tasks that require precise and controlled movements.

Monorail Crane:

- Description: Monorail cranes have a single rail along which the hoist and trolley move, providing linear material movement.

- Application: Monorail cranes are used for repetitive linear movements, such as transporting materials along an assembly line or between workstations in the textile manufacturing process.

Electric Chain Hoist:

- Features:

- Uses an electric motor to lift and lower the load with a chain mechanism.

- Benefits for Textile Industry:

- Suitable for various lifting applications in textile facilities, such as lifting fabric rolls or components.

- Compact and easy to install, making it suitable for workshops with limited space.

- Provides precise and controlled lifting operations.

Wire Rope Hoist :

- Uses a wire rope and drum mechanism to lift and lower the load.

- Benefits for Textile Industry:

- Ideal for heavyduty lifting tasks in the textile industry, such as lifting heavy fabric rolls or equipment.

- Provides smooth and steady lifting operations.

- Offers higher lifting capacities and longer lifting heights.

The selection of the appropriate overhead crane type depends on the specific requirements of the textile industry facility, including lifting capacity, material dimensions, available space, and the production processes involved. To ensure optimal performance and safety, it is essential to choose a crane system that best suits the unique needs of the textile industry application.

Main Functions in the Textile Industry:

- Raw Material Handling: Overhead cranes and hoists are used to unload and transport raw materials, such as bales of cotton, wool, or synthetic fibers, to the processing area.

- Yarn and Fabric Production: Cranes facilitate the movement of materials between different stages of yarn production and fabric weaving or knitting processes.

- Dyeing and Finishing: Overhead cranes are used to handle fabric rolls during dyeing and finishing processes.

- Material Inspection: Cranes are employed to position fabric rolls or materials for inspection and quality control.

- Finished Product Handling: Overhead cranes and hoists assist in moving finished textile products, such as clothing or home textiles, for packaging and distribution.

By utilizing the appropriate overhead cranes and hoists, textile manufacturers can streamline their material handling processes, increase efficiency, and optimize production workflows. Each type of crane and hoist offers specific advantages tailored to the unique needs of the textile industry, enhancing safety and productivity throughout the manufacturing process.

What are the requirements for overhead cranes used in textile industry?

Overhead cranes used in the textile industry must meet specific requirements to ensure safe and efficient material handling and production processes. Some key requirements for overhead cranes in the textile industry include:

- Lifting Capacity: The crane should have an adequate lifting capacity to handle the heaviest loads typically encountered in the textile industry, such as large rolls of fabric or bales of raw materials.

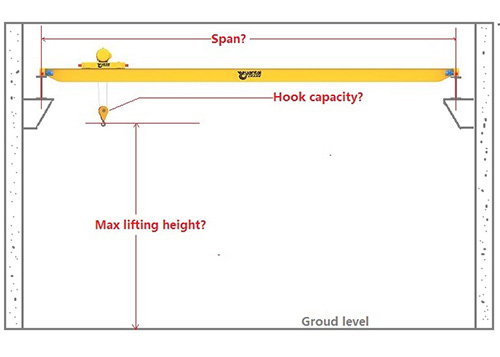

- Span and Hook Height: The crane's span (distance between the runways) and hook height (distance from the floor to the highest point the hook can reach) should be designed to accommodate the dimensions of the textile materials being handled.

- Precise Control: Overhead cranes in the textile industry require precise and responsive controls to handle delicate fabrics and materials without causing damage.

- Speed Control: Variable speed controls are essential to allow for smooth and controlled movement, especially when positioning materials for production or inspection processes.

- Durability and Reliability: Textile manufacturing often involves continuous production, so the overhead crane should be robust and reliable to withstand frequent use and demanding conditions.

- Safety Features: Safety is of utmost importance in any industry. Overhead cranes used in textiles should have safety features such as overload protection, emergency stop buttons, limit switches, and collision avoidance systems to prevent accidents.

- Environmental Considerations: Some textile facilities may have specific environmental conditions, such as humidity or dust, which can affect the crane's performance. The crane should be designed to withstand such conditions.

- Ergonomics: The crane's design should prioritize ease of use for the operators, considering factors like comfortable cabin design, intuitive controls, and visibility.

- Compliance with Regulations: The overhead crane should meet all relevant safety standards and regulations set by local authorities and industry bodies.

- Maintenance and Serviceability: Regular maintenance is crucial for the smooth operation of overhead cranes. The crane should be designed for easy maintenance and quick access to critical components.

- Customization: Textile facilities may have unique layouts and requirements. The crane should be customizable to suit the specific needs of the facility and production processes.

- Integration with Production Process: The overhead crane should seamlessly integrate with the overall production process, facilitating the smooth flow of materials and products.

To ensure that the overhead crane meets all necessary requirements, it's essential to work with reputable crane manufacturers or suppliers who have experience in providing solutions for the textile industry. They can assess the specific needs of the facility and recommend the most suitable crane system that meets safety, efficiency, and productivity standards.

Overhead cranes for different related sectors of textile industries

The textile industry is a vast and interconnected sector that interacts with various other industries. Some of the key industry sectors related to the textile industry include:

- Fashion and Apparel: The fashion and apparel industry is one of the most significant consumers of textile products. Textile materials are used to manufacture clothing, footwear, accessories, and other fashionrelated items. Bridge cranes are commonly used in fashion and apparel manufacturing facilities for handling rolls of fabric, moving garments between workstations, and organizing materials in storage areas.

- Home Textiles: This sector includes products used for home furnishing, such as bed linens, curtains, towels, upholstery, and other textilebased decorative items. Textile Machinery and Equipment: The textile machinery industry manufactures equipment used in textile production, such as spinning machines, weaving looms, knitting machines, dyeing and printing machinery, and finishing equipment.

- Fiber Production: The fiber production industry is responsible for producing various types of fibers used in textiles, including natural fibers (cotton, wool, silk, linen) and synthetic fibers (polyester, nylon, acrylic).

- Raw Materials: The production of textiles relies on sourcing raw materials like cotton, wool, silk, and synthetic fibers from agriculture, animal husbandry, and chemical industries.

- Textile Chemicals: This sector produces chemicals used in textile processing, including dyes, pigments, sizing agents, and finishing chemicals.

- Retail and Distribution: Retailers and distributors play a crucial role in connecting textile manufacturers with end consumers, making textile products available in stores and online platforms.

- Textile Recycling and Sustainability: As sustainability becomes a growing concern, the textile recycling industry focuses on the collection, processing, and reuse of discarded textiles to reduce waste and promote environmental conservation.

- Technical Textiles: Technical textiles are specialized materials designed for industrial and technical applications, including geotextiles, medical textiles, automotive textiles, and protective clothing.

- Fashion Design and Retail: Fashion designers and retail companies are involved in creating and marketing textilebased clothing and accessories to consumers.

- Interior Design and Home Décor: Interior designers and home décor companies use textiles to enhance the aesthetic and functional aspects of interior spaces.

- Apparel and Textile Trade: The trade industry facilitates the import and export of textiles and apparel products between countries, promoting global exchange.

These industries collectively form a complex supply chain that begins with fiber production and extends to the creation, distribution, and consumption of various textile products in everyday life and various industrial applications. The textile industry is deeply interconnected with multiple sectors, making it a significant contributor to the global economy.

What are the typical cranes used in the above mentioned textile related industrial sectors ?

In the textilerelated industrial sectors mentioned earlier, various types of cranes are used to handle materials, facilitate production processes, and support logistics. The choice of crane depends on the specific needs and requirements of each sector. Here are some typical cranes used in the textilerelated industries:

- Home Textiles: Gantry cranes are utilized in home textiles production to move and store large rolls of fabrics, arrange finished products in warehouses, and facilitate loading/unloading of materials.

- Textile Machinery and Equipment Industry: Jib Cranes: Jib cranes are often found in textile machinery and equipment manufacturing units, where they help in assembling and moving heavy machine parts during production.

- Fiber Production Industry: Bridge cranes are used in fiber production facilities for material handling during the manufacturing process and moving raw fibers to different stages of production.

- Textile Chemicals Industry : Jib cranes are used for handling containers of textile chemicals and positioning them at specific points for mixing or processing.

- Raw Materials Industry Gantry Cranes: Gantry cranes are employed in raw materials handling to load/unload shipments of fibers or other materials from trucks or ships.

- Textile Recycling and Sustainability Industry : Monorail cranes are suitable for material movement in textile recycling plants, where they transport recycled textiles for processing and reutilization.

- Technical Textiles Industry : Bridge cranes are used in technical textiles manufacturing facilities to handle specialized materials and support the production of products like geotextiles, medical textiles, and automotive textiles.

- Apparel and Textile Trade Industry : Gantry cranes are commonly found in textile trade and logistics centers, where they assist in loading/unloading containers and managing inventory.

- Interior Design and Home Décor : Jib cranes are useful in interior design and home décor settings for handling and positioning textilebased products like curtains, upholstery, and home textiles.

The choice of the specific type of crane and its configuration depends on factors such as the weight of materials being handled, available space, lifting requirements, and production processes involved in each industry sector.

Customizing Overhead Cranes for Textile Industry:

Customizing Overhead Cranes for Textile Industry: Tailoring crane systems to meet the specific needs and layout of textile manufacturing plants, ensuring efficient material flow and space optimization.

Customizing overhead cranes for the textile industry is essential to optimize material handling processes, ensure efficient production, and maximize space utilization. Each textile manufacturing plant has unique requirements and layouts, and a tailored crane system can address these specific needs effectively. Here are some considerations for customizing overhead cranes for textile facilities:

- Lifting Capacity and Span:Determine the required lifting capacity of the overhead crane based on the heaviest loads encountered in the textile facility. The crane's span should match the layout and dimensions of the production area to provide optimal coverage.

- Hook Height and Clearance:Ensure that the crane's hook height is sufficient to accommodate the tallest materials or rolls used in the textile manufacturing process. Consider any obstructions or clearance requirements when designing the crane system.

- Single Girder vs. Double Girder Cranes:Select the appropriate type of crane (single girder or double girder) based on the weight and dimensions of the materials to be handled. Double girder cranes are suitable for heavier loads and larger spans.

- Crane Speed and Control:Customize the crane's speed and control systems to match the specific material handling requirements of the textile facility. Variable speed controls allow for precise movements and positioning.

- Environmental Considerations:Consider the environmental conditions of the textile plant, such as humidity and dust, and select materials and coatings that can withstand these factors to ensure the crane's longevity.

- Automation and Technology Integration:Implement automation features, such as remote control, radio frequency identification (RFID), and antisway systems, to enhance crane efficiency and reduce the risk of human errors.

- Safety Features:Ensure that the customized crane system includes necessary safety features, such as overload protection, limit switches, and collision avoidance systems, to prevent accidents and promote worker safety.

- Ergonomics:Design the crane cabin and controls with ergonomic considerations to enhance operator comfort and efficiency during long working hours.

- Space Optimization:Tailor the crane system to fit within the available space in the textile facility, making the most of the vertical clearance and ensuring efficient use of floor space.

- Integration with Production Workflow:Integrate the crane system into the overall production workflow to facilitate seamless material flow and minimize material handling delays.

- Future Expansion:Consider the possibility of future expansions or changes in the textile facility's layout and ensure that the crane system is adaptable to accommodate these developments.

- Compliance with Standards:Ensure that the customized overhead crane complies with relevant safety standards and regulations specific to the textile industry and the location of the facility.

By customizing overhead cranes to meet the specific needs and layout of textile manufacturing plants, textile companies can optimize material flow, increase productivity, and create a safer and more efficient working environment. Collaborating with experienced crane manufacturers and suppliers is crucial to designing and installing a crane system that caters to the unique requirements of the textile industry facility.

Parameters or specification needed for customized overhead crane for textile industry

- Lifting Capacity

- Span

- Hook Height

- Single Girder or Double Girder

- Speed and Control

- Environmental Considerations

- Automation and Technology Integration

- Safety Features

- Space Optimization

- Integration with Production Workflow

Why to select our overhead crane and hoists ?

- Customized Solution: Tailored to your textile facility's specific needs.

- Expertise and Experience: Extensive experience in the textile industry.

- Safety Features: Equipped with the latest safety features.

- Reliable Performance: Built with highquality materials for consistent performance.

- Efficient Material Handling: Streamlined processes and optimized workflows.

- Compliance with Standards: Adheres to industry safety regulations.

- Excellent AfterSales Support: Comprehensive maintenance services.

- CostEffectiveness: Affordable solution tailored to your requirements.

- Operator Training: Ensuring safe and efficient crane operation.

- Customer Satisfaction: Dedicated to meeting and exceeding expectations.