5 Ton Jib Crane for Belarus, 5 Ton Pillar Jib, 24 M Lift Height

Heavy-duty 5-ton jib crane, 7+17m lifting height, tailored for Belarus’s industrial needs with efficient, durable performance.Get custom pillar jib crane!

Category: Jib Crane Capacity & Tonnages

Your Trusted 5 Ton Pillar Jib Crane Manufacturer & Supplier

5 Ton Jib Crane for Belarus, 5 Ton Pillar Jib, 24 M Lift Height

Heavy-duty 5-ton jib crane, 7+17m lifting height, tailored for Belarus's industrial needs with efficient, durable performance.Get custom pillar jib crane!

Overview of the 5 Ton Jib Crane Sale in Belarus

We’re excited to share the sale of two 5-ton jib cranes to a client in Belarus. These cranes are custom-designed for heavy-duty applications, making them a perfect fit for industries that require powerful, reliable lifting solutions. The cranes feature a lifting height of 7 + 17 meters, with specific adjustments to meet local needs and environmental factors.

These jib cranes are an important part of the operation, providing efficient lifting for demanding tasks.

Introduction to the Model: BZ-Type Pillar Jib Crane for Heavy-Duty Applications

The BZ-Type Pillar Jib Crane is built for tough jobs. It offers 5 tons of lifting capacity and an effective arm length of 6.3 meters, which makes it ideal for tasks that demand a bit more power and flexibility.

With the combination of a 7-meter column height and the added 17 meters underground lifting height, these cranes can tackle a wide range of lifting challenges, especially in environments where the crane needs to work in tough spaces or reach elevated areas. This model is especially designed for industries like steel, construction, and heavy machinery manufacturing.

Importance of Customized Heavy-Duty Jib Cranes in Industrial Applications

In industries where heavy lifting is part of the daily routine, customization is key. Not all lifting needs are the same, and that’s where a tailored solution like the BZ-Type Pillar Jib Crane comes in.

- Adaptability: Custom cranes are built to meet unique site requirements, including lifting height, load capacity, and space limitations.

- Efficiency: A crane designed specifically for the task at hand can reduce downtime, improve safety, and boost productivity.

- Longevity: By addressing specific needs, these cranes are more durable and last longer, ultimately providing a better return on investment.

In Belarus, having cranes built to these precise specifications makes all the difference in meeting the high demands of the industry.

Product Specifications

Lifting Capacity: 5 Tons

The BZ-Type Pillar Jib Crane offers a 5-ton lifting capacity, making it strong enough to handle heavy loads in industrial environments. This lifting capacity ensures that the crane can support a wide range of materials, including large machinery and steel components. It’s the right choice for applications where reliable lifting power is needed.

Effective Arm Length: 6.3 Meters

The crane’s arm length is 6.3 meters, providing the perfect reach for handling loads within a medium-range distance. This effective arm length allows the crane to work efficiently within tight spaces, while still having enough reach to move materials across the workplace.

Lifting Height

- 7 Meters of Column Lifting Height

The crane’s 7-meter column lifting height provides ample clearance for lifting heavy loads to high positions. This is especially important in workshops or plants with limited space, where maximizing vertical lift is crucial for efficient operations. - 17 Meters of Underground Lifting Height

In addition to the column height, the crane is designed with an impressive 17 meters of underground lifting height. This feature is ideal for industries that require lifting operations below ground level, such as in mining or specialized manufacturing plants. It gives the crane the flexibility to handle deep lifting tasks that other models cannot manage.

Hoist: European-Style Wire Rope Hoist

The crane is equipped with a European-style wire rope hoist, which is known for its reliability and smooth operation. This hoist is designed for heavy-duty applications, ensuring that the crane performs well even under the most demanding conditions. The European design also offers superior quality, with a focus on safety and efficiency.

Crane Power Supply: 380V 50Hz 3-Phase

The 380V 50Hz 3-phase power supply is a standard in industrial settings, ensuring compatibility with most facilities. This power setup provides the necessary strength for the crane to operate efficiently, ensuring smooth performance without power issues.

Quantity: 2 Sets

For this order, we are supplying 2 sets of the 5-ton BZ-Type Pillar Jib Cranes. This allows the client to have a backup crane on hand or set up two workstations simultaneously. The two cranes will help improve efficiency and ensure smooth operations in the client's plant.

5T Jib Crane Main Parts and Componets Offered

5T Jib Crane Main Parts and Components

Structural Components

These parts form the main framework of the crane, providing support and stability.

- 5t Column of Jib Crane (1) - The vertical column that supports the crane arm and hoisting equipment.

- 5t Crossbeam of Jib Crane (1) - The horizontal beam that connects to the column, with angle iron for extra strength.

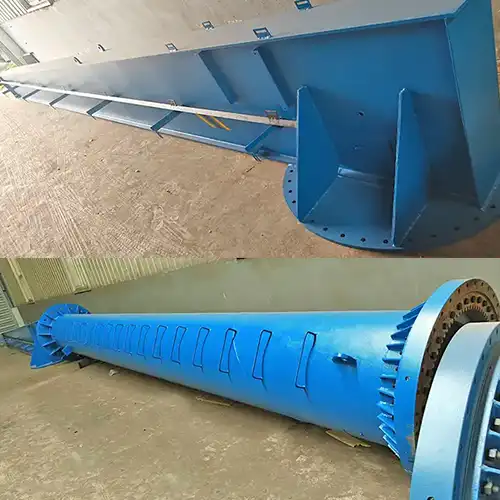

5t Column of Jib Crane

5t Crossbeam of Jib Crane

Lifting Mechanism and Control

This is where the action happens – the parts that control the lifting and rotation of the crane.

- 5t Electric Hoist Pendant Control + Remote Control (1) - Allows both manual and remote control of the hoisting operation. The electrical system is integrated into the hoist's electrical box for simplicity.

- Rotary Motor (1.5kW) (1) - Powers the crane's rotation, making sure it moves smoothly and efficiently.

- Rotary Reducer (1) - Reduces motor speed and provides the necessary torque for controlled rotation of the crane arm.

- Rotary Control Switch (1) - A manual switch that lets operators control the rotation of the crane arm easily.

- Cross Limit (1) - A safety feature that stops the hoist from moving too far, ensuring safe operation.

Safety and Monitoring

These components ensure the crane runs safely and that operators are alerted when necessary.

- Sound and Light Alarm (1) - An alarm system that alerts operators when the crane is in use or if there’s a problem.

- Carbon Brushes (4) - These are key for transferring electrical power to the motor, ensuring smooth operation.

- Carbon Brush Holder (1) - Holds the carbon brushes in place, ensuring proper electrical contact.

Rotational Support and Movement

These parts help with the smooth rotation and movement of the crane.

- Slip Ring (1) - Allows continuous rotation of the crane while maintaining the electrical connection.

- Pulley (6) - Guides the wire rope, reducing friction for smooth lifting operations.

- Rotary Support Screws (20*150) (40) - Secures the rotary support system, ensuring stable and smooth rotation.

Fasteners and Mounting

These are the essential screws and fasteners that hold everything together.

- Motor Flange Screws (12*40) (4) - Used to secure the motor to the crane frame, ensuring a stable connection.

- Reducer Flange Screws (16*50) (12) - These fasten the rotary reducer to the crane, ensuring it stays in place.

- Pulley Screws (12*30) (8) - Used to mount the pulleys, which help guide the lifting rope.

Cabling and Electrical

These components provide the electrical connections that power the crane.

- Cables (3*4mm²) (12m) - The main cables used to connect the crane’s electrical systems to the motor and hoist.

- Cables (10*1.5mm²) (12m) - These cables power other components of the crane, ensuring everything functions smoothly.

- Cables (3*1.5mm²) (2m) - Smaller cables for additional electrical connections.

Weather Protection

Parts that help protect the crane from weather damage.

- Rain Cover (1). Protects the crane components from rain and moisture, keeping it in top condition. Two rain covers are packed together for convenience.

| Item No. | Description of Goods | PCS | Remarks |

|---|---|---|---|

| 1 | 5t Column of Jib Crane | 1 | |

| 2 | 5t Crossbeam of Jib Crane | 1 | Includes angle iron |

| 3 | Rain Cover | 1 | 2 sets of rain covers packed as one piece |

| 4 | 5t Electric Hoist Pendant Control + Remote Control | 1 | The electrical system is integrated into the electrical box of the hoist. |

| 5 | Rotary Motor (1.5kW) | 1 | |

| 6 | Rotary Reducer | 1 | |

| 7 | Slip Ring | 1 | |

| 8 | Carbon Brush | 4 | |

| 9 | Carbon Brush Holder | 1 | |

| 10 | Sound and Light Alarm | 1 | |

| 11 | Cross Limit | 1 | Installed on the 5t hoist |

| 12 | Rotary Control Combination Switch | 1 | |

| 13 | Pulley | 6 | |

| 14 | Motor Flange Screws (12*40) | 4 | |

| 15 | Reducer Flange Screws (16*50) | 12 | |

| 16 | Pulley Screws (12*30) | 8 | |

| 17 | Rotary Support Screws (20*150) | 40 | |

| 18 | Cables (3*4mm²) | 12m | |

| 19 | Cables (10*1.5mm²) | 12m | |

| 20 | Cables (3*1.5mm²) | 2m |

The 5-ton jib crane system comes with everything you need for setup and operation. From structural parts like the column and crossbeam to the hoisting mechanism, safety features, and weather protection, each component is carefully selected to ensure reliable, efficient, and safe crane operation.

Industry and Application

Industries That Typically Require Heavy-Duty Jib Cranes

Heavy-duty jib cranes, like the BZ-Type Pillar Jib Crane, are commonly used in industries where lifting heavy loads is a daily requirement. Some of the key industries include:

- Steel Manufacturing: Steel plants require cranes for lifting heavy metal pieces, billets, and other large components. The 5-ton capacity and customized lifting height make this crane an ideal choice for these high-demand environments.

- Machinery Plants: In machinery manufacturing, cranes are essential for moving heavy machines and parts from one station to another. The versatility of this jib crane makes it an excellent option for machinery plants where lifting flexibility is needed.

- Construction: The construction industry frequently uses cranes to lift materials and equipment to higher levels, making heavy-duty cranes with high lifting capabilities vital.

- Automotive Manufacturing: Automotive plants need to move large components like engines, car bodies, and other heavy parts. These cranes help in improving efficiency and minimizing downtime in production lines.

- Warehouse and Logistics: Cranes are essential in large warehouses where heavy pallets and machinery need to be moved frequently.

Specific Challenges in Belarus Requiring Customized Lifting Solutions

In Belarus, industries face specific challenges that require customized crane solutions. Some of the key challenges include:

- Harsh Weather Conditions: Belarus experiences cold winters with heavy snow and low temperatures. These environmental conditions make it essential to have cranes designed with durability and reliability in mind to withstand extreme temperatures and snow accumulation.

- Limited Space in Industrial Plants: Many industrial plants in Belarus operate in confined spaces where maximizing the use of available area is crucial. The BZ-Type Pillar Jib Crane is designed to offer efficient space utilization, allowing heavy loads to be lifted without taking up too much floor space.

- Need for Deep Lifting: Industries such as mining, construction, and material handling require cranes that can lift heavy loads underground or at deep levels. The 17-meter underground lifting height of these cranes is a custom feature that solves this challenge by offering flexibility to work at different levels.

- Heavy Industrial Demand: With industries relying on large machinery and raw materials, the demand for reliable lifting solutions is high. Heavy-duty cranes ensure that operations can continue smoothly without interruptions due to breakdowns or inadequate lifting capacity.

How These Cranes Address Unique Operational Needs in the Local Market

The BZ-Type Pillar Jib Crane is specifically designed to meet the needs of industries in Belarus:

- Tailored for Local Conditions: The crane is built to handle cold weather and tough industrial environments in Belarus. The materials and design have been chosen to ensure reliable performance even in extreme temperatures.

- High Lifting Capacity for Heavy Loads: The 5-ton lifting capacity allows it to handle the heavy loads common in industries like steel manufacturing, mining, and logistics. This ensures that the plant can operate at full capacity without any delays due to lifting constraints.

- Customizable Lifting Heights: The combination of a 7-meter column lifting height and 17 meters of underground lifting height addresses specific operational needs. Whether it's lifting from high platforms or deep underground, these cranes provide the flexibility needed in complex industrial setups.

- Optimized for Space Efficiency: Given the compact nature of many industrial facilities in Belarus, the effective arm length of 6.3 meters ensures that the crane can operate efficiently in tight spaces, maximizing the available area without sacrificing lifting performance.

In short, these customized cranes are built to solve the unique operational challenges faced by Belarusian industries, making them a valuable asset for local businesses.

Customization and Design Features

Tailoring to Local Environment: Adaptations for Belarusian Climate and Industry Needs

Belarus' harsh climate requires equipment that can withstand cold winters, heavy snow, and fluctuating temperatures. The BZ-Type Pillar Jib Crane has been specifically designed with these conditions in mind. Key adaptations include:

- Weatherproofing: The crane's components, such as the hoist, are coated with anti-corrosion materials to ensure they perform well in freezing temperatures and resist rust from snow and moisture.

- Cold-Weather Components: The electrical system and hoist motor are built to operate efficiently in subzero conditions, preventing failure during the coldest months.

- Reinforced Structure: The crane’s structure is designed to handle additional weight from snow accumulation and extreme cold without compromising safety or functionality.

This makes the crane well-suited for the cold, industrial conditions typical in Belarus.

The Design and Engineering of the Crane to Handle Heavy-Duty Lifting Tasks

The BZ-Type Pillar Jib Crane is engineered for heavy-duty lifting in industrial environments. The key design features include:

- Strong Frame and Foundation: The crane’s pillar design ensures a stable structure capable of supporting heavy loads without buckling or shifting. This design also minimizes vibrations, making it safe and precise during lifting operations.

- High-Quality Materials: The crane is made using high-strength steel and durable components that are built to last under continuous heavy lifting. This guarantees long-term performance with minimal wear.

- Precision Engineering: Every aspect of the crane, from the hoist to the arm, is designed for smooth, controlled movements. This ensures that lifting tasks are executed with precision and reduces the risk of accidents or damage to loads.

These design elements make the crane capable of handling tough tasks in industries like steel manufacturing, construction, and more.

The Balance of Lifting Height, Arm Length, and Power Supply Requirements for Efficiency

The crane’s design strikes a balance between lifting height, arm length, and power supply to maximize operational efficiency:

- Lifting Height: With 7 meters of column height and 17 meters underground, the crane offers an ideal solution for both high and deep lifting tasks. This versatility makes it suitable for a wide range of applications without needing multiple cranes.

- Arm Length: The 6.3-meter arm length allows the crane to reach materials at a comfortable distance, whether it's across the factory floor or into elevated positions. This ensures smooth material handling without excessive strain on the crane or the operator.

- Power Supply: The 380V 50Hz 3-phase power supply ensures that the crane operates efficiently in most Belarusian industrial facilities. This standard power system guarantees the crane will be compatible with the client’s existing infrastructure, allowing for easy integration into their operations.

Together, these features create an efficient and powerful lifting solution that optimizes both performance and energy use.

Considerations for Underground Lifting Needs (17m Height)

One of the standout features of this crane is its ability to handle underground lifting needs with 17 meters of lifting height. This is especially useful in industries like:

- Mining: Lifting heavy materials from underground locations is a common challenge. With 17 meters of underground lifting height, this crane can lift heavy loads from deeper parts of the facility without requiring additional equipment.

- Construction: In construction sites, the crane’s ability to lift materials from basement levels or deep trenches is a significant advantage, reducing the need for multiple lifting devices.

The design ensures that the crane’s hoist, motor, and structure are built to withstand the added strain of deep lifting, with reinforced components that provide reliable, smooth operation even when reaching those deeper levels. This makes the crane highly versatile and adaptable to various industrial tasks requiring underground lifting.

Overall, the crane's customization and design features allow it to perform efficiently, safely, and reliably in challenging Belarusian environments, with specialized adaptations to meet unique lifting demands.

Hoist and Power Supply Details

European-Style Wire Rope Hoist: Key Features and Advantages for Heavy-Duty Use

The European-style wire rope hoist is an integral part of the BZ-Type Pillar Jib Crane, designed for high performance and reliability in heavy-duty operations. Here's why it stands out:

- High Strength and Durability: The hoist uses high-quality steel wire ropes, providing exceptional strength to handle heavy loads without stretching or breaking. This makes it perfect for lifting large, heavy materials in steel plants, warehouses, and other industrial settings.

- Smooth and Reliable Operation: European hoists are known for their smooth and stable operation, minimizing jerky movements when lifting or lowering loads. This ensures a more controlled and safer handling of materials, reducing the risk of accidents or damage.

- Low Maintenance: The hoist is designed for minimal wear and tear, which reduces the need for frequent maintenance. Its robust construction means fewer breakdowns and lower long-term maintenance costs.

- Precise Load Control: The hoist's precise control mechanisms ensure that operators can lift and position loads accurately. This is crucial for industries that require high levels of precision in their lifting operations.

This hoist offers high performance and reliability, key attributes for any heavy-duty lifting operation.

How the Hoist Contributes to Operational Efficiency and Safety

The European-style wire rope hoist enhances both efficiency and safety in multiple ways:

- Increased Productivity: Its reliable lifting capability allows workers to handle heavy loads quickly and efficiently, leading to less downtime and improved productivity. The hoist ensures that materials can be moved faster, keeping operations on track.

- Enhanced Safety Features: The hoist includes built-in safety features like overload protection, limit switches, and smooth braking. These safety measures prevent accidents such as lifting excessive loads or sudden drops, ensuring both the operator and materials are protected.

- Minimized Risk of Failure: With its durable design, the hoist is less prone to sudden failures, which could cause major disruptions in the workflow. This reliable performance ensures continuous operations, preventing costly delays and downtime.

- User-Friendly Operation: The hoist is designed to be intuitive for operators, with easy-to-use controls that reduce human error. This leads to a safer working environment, as operators can focus on the task at hand without worrying about complicated machinery.

All these factors contribute to a more efficient, safe, and productive working environment.

Power Supply Specifications and Their Alignment with Belarus’s Industrial Standards

The BZ-Type Pillar Jib Crane operates on a 380V 50Hz 3-phase power supply, which is standard in many industrial facilities, including those in Belarus. Here's why this power supply setup is ideal:

- Compatibility with Local Infrastructure: The 380V 50Hz 3-phase power is the most common power system used in Belarusian industries. This ensures that the crane can be easily integrated into existing facilities without the need for special electrical modifications.

- Efficient Power Use: The 3-phase power system allows for more efficient power distribution to the crane’s motor and hoist. This ensures that the crane runs smoothly without excessive energy consumption, making it a cost-effective choice for long-term use.

- Reliable Power Delivery: A 3-phase power supply offers a more stable and reliable power flow, which is crucial for heavy-duty lifting operations. The constant power supply prevents fluctuations that could cause damage to the crane or interruptions in operation.

- Meets Belarusian Standards: The crane’s power supply meets local industrial standards, ensuring that it adheres to both safety regulations and energy efficiency standards in Belarus. This helps ensure smooth and compliant operations in a regulated environment.

By aligning with Belarus’s industrial power standards, this crane ensures seamless integration and reliable performance, without the hassle of needing specialized electrical setups.

Case Study Results: Performance and Benefits

Performance Data from the Installation of the Two Sets of Cranes in Belarus

The installation of the two sets of BZ-Type Pillar Jib Cranes in Belarus marked a significant milestone for the client. After the cranes were installed and fully operational, they were tested under actual working conditions.

- Lifting Capacity Tested: Both cranes consistently handled the 5-ton lifting capacity with no issues, easily lifting large steel components and machinery parts in a steel manufacturing plant.

- Lifting Height Utilized: The 7-meter column lifting height and 17-meter underground lifting height were fully utilized during the operation, with the cranes reaching various elevated and underground positions to move materials with ease.

- Smooth Operation: The European-style wire rope hoists performed flawlessly, with no malfunctions reported. Operators appreciated the smooth and precise control during lifting tasks.

This performance data confirms that the cranes meet the demands of heavy-duty applications in Belarus.

Efficiency Gains, Operational Improvements, and Feedback from End-Users

The customized cranes provided notable efficiency gains and operational improvements:

- Reduced Downtime: The high reliability of the cranes reduced the need for maintenance and repairs, leading to less downtime. This allowed the production process to flow more smoothly.

- Increased Productivity: Operators were able to move materials quicker due to the cranes' efficient design and lifting capabilities. The precise load control ensured that tasks were completed more quickly, boosting overall productivity.

Feedback from End-Users: Operators and managers noted the following improvements:

- Enhanced Safety: The safety features, including overload protection and smooth braking, made the workplace safer. Workers felt more confident operating the cranes.

- Ease of Use: The intuitive controls made it easier for operators to perform tasks without requiring extensive training.

- Adaptability: The cranes were able to handle a variety of loads, from small parts to large machinery, offering flexibility in the production process.

How the Customized Cranes Have Met Specific Business Goals or Challenges

The installation of these customized cranes directly addressed several key challenges and goals of the business:

- Maximizing Space Utilization: The cranes’ compact design allowed for efficient use of available space, even in tight areas of the plant, where maximizing floor space was critical.

- Handling Heavy and Deep Loads: The 17-meter underground lifting height allowed the cranes to handle heavy loads in deep sections of the plant, which would have been impossible with standard cranes.

- Improved Operational Efficiency: With the ability to quickly move heavy materials, the business was able to improve their workflow, reduce delays, and meet production deadlines more effectively.

These customized cranes helped the business overcome their specific operational challenges while achieving their production and efficiency goals.

Conclusion

Recap of the Importance of Customized Heavy-Duty Jib Cranes for Businesses in Belarus

Customized heavy-duty jib cranes are crucial for businesses in Belarus that need reliable, high-performance lifting solutions. These cranes offer the flexibility to handle specific lifting tasks, especially in industries that require the movement of heavy loads, such as steel manufacturing and construction. Tailored features, such as extended lifting heights and compact design, ensure they can meet unique operational requirements, even in challenging environments like Belarus.

Summary of Key Features, Benefits, and Outcomes

Key features of the BZ-Type Pillar Jib Crane include:

- 5-ton lifting capacity for heavy loads

- 7-meter column height and 17-meter underground lifting height for versatile lifting

- European-style wire rope hoist for smooth, precise lifting

- 380V 50Hz 3-phase power supply for compatibility with local infrastructure

The benefits include improved productivity, increased safety, reduced downtime, and the ability to handle complex lifting tasks in tight spaces or deep areas. These outcomes have led to significant operational improvements for the client in Belarus.

We offer top-quality, customized lifting solutions designed to meet the unique needs of businesses. By choosing us, companies get reliable, durable, and efficient cranes tailored to their specific lifting requirements. Whether dealing with tough environmental conditions, limited space, or complex lifting tasks, our overhead material handling crane factory provids the performance and reliability needed to enhance operations and productivity. Contact us to get your customized industrial jib crane at cost-effective price, with best fit design!

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch