0.5 Ton to10 Ton Fixed Gantry Crane, Freestanding Portal Cranes for Hoisting

Fixed gantry cranes is a permanent freestanding portal cranes,installed without the need for existing structures, for lifting heavy loads in a fixed area.

Category: Light Crane & Portable Crane

Your Trusted Fixed Gantry Crane Manufacturer & Supplier

0.5 Ton to10 Ton Fixed Gantry Crane, Freestanding Portal Cranes

Permanent Freestanding Gantry Cranes for Heavy Loads Lifting in Fixed Area, Custom Fixed Gantry Cranes for Sale

Fixed gantry cranes is a permanent freestanding portal cranes,installed without the need for existing structures, for lifting heavy loads in a fixed area.

Fixed Gantry Cranes

Fixed gantry cranes, also known as freestanding portal cranes, are essential pieces of equipment in industrial settings where permanent craneage is required. These cranes are designed to be installed without the need for existing structures and offer a stable and reliable solution for lifting heavy loads within a fixed area.

Fixed gantry cranes, also referred to as freestanding portal cranes, are pivotal assets in industrial environments necessitating permanent lifting solutions. Unlike mobile gantry cranes, which offer portability, fixed gantry cranes are engineered for steadfast installation, eliminating the necessity for preexisting structures. These cranes epitomize stability and reliability, catering to the exigencies of lifting substantial loads within a designated area.

Overveiw of Fixed Gantry Cranes Available for Sale

Light fixed gantry crane hot sale capacity 500kg, 1000kg, 2000kg, 5000kg

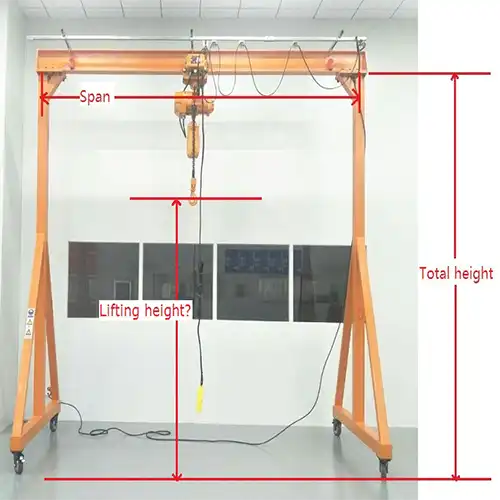

Light fixed gantry crane hot sale capacity 500kg, 1000kg, 2000kg, 5000kg Specifications of Fixed Gantry Crane:

Capacity: 500kg, 800kg, 1000kg, 1600kg, 2000kg, 3200kg, 4000kg, 5000kg,

Crane Span (m): 2, 3, 4, 5, 6, 7, 8, 9, 10

Lifting Height (m): Customizable to your requirements

- Standard Configuration: This fixed gantry crane features a simple structure with a 2-floor anchored gantry frame supporting a monorail beam.

- Freestanding Portal Crane Design: The fixed gantry crane represents a lifting structure that operates independently of any building. Its installation requires no alterations to walls, steel framework, or ceilings. This structure is chemically anchored in a concrete slab with a minimum depth of 160mm, making it suitable for buildings with varying ground levels.

- Easily Extendable Fixed Gantry: With the flexibility to accommodate additional equipment as your workstation expands, it's possible to mount one or more jib cranes on the legs using appropriate plates.

Options for Fixed Gantry Cranes Include:

Anchorage Type

Electric or Manual Hoist

Motorization of Moving Devices

Wireless Industrial Remote Control

Special Paint Options

Corrosion Protection: Paint, Galvanization, Metallization

Outdoor Covering

Stainless Steel Bolts

Supply Ducting

Galvanized or Stainless Steel Power Supply Line

ATEX or Food Industry Version

Full Stainless Steel 360L Version

Fixed gantry crane for sale, hot sale 2 ton, 3 ton, 5 ton, up to 10 ton

Fixed gantry crane for sale, hot sale 2 ton, 3 ton, 5 ton, up to 10 ton Personalized Fixed Gantry Crane Design: Our fixed gantry cranes come in various capacities and feature a knockdown design for quick assembly and disassembly. When not in use, they fold into a compact package for easy transport or storage.

Variety of Fixed Gantry Crane Styles: These cranes can be mounted to goal post supports, similar to a monorail crane, or utilize an A-frame crane design like our portable options.

A fixed gantry crane, though primarily intended for light use, can be customized to suit your specific job site and lifting requirements. At our company, you can acquire high-quality gantry crane equipment made from premium components at factory prices. Additionally, we offer comprehensive after-sales support to address any concerns throughout the ordering process.

Features and Characteristics:

- Stability: Anchored securely to the ground or a designated foundation, fixed gantry cranes provide unparalleled stability, ensuring safe lifting operations even with hefty loads.

- Customization: Designed to accommodate specific lifting requirements, these cranes can be tailored to varying span lengths, lifting heights, and load capacities, offering versatility to suit diverse industrial applications.

- Durability: Constructed from robust materials and engineered to withstand rigorous operational demands, fixed gantry cranes exhibit exceptional durability, facilitating prolonged service life with minimal maintenance.

- Adaptability: Despite their stationary nature, fixed gantry cranes can be integrated seamlessly into existing workflows, optimizing material handling processes and enhancing operational efficiency.

- Safety: Equipped with comprehensive safety features and adhering to stringent industry standards, these cranes prioritize safety, mitigating risks associated with lifting operations and safeguarding personnel and assets.

- Costeffectiveness: While requiring initial investment for installation, fixed gantry cranes offer longterm costeffectiveness by streamlining material handling operations, minimizing downtime, and maximizing productivity.

Applications:

- Manufacturing Facilities: Fixed gantry cranes facilitate the movement of raw materials, workinprogress components, and finished products within manufacturing environments, expediting production processes and ensuring timely delivery.

- Warehouses and Distribution Centers: In warehouse and distribution settings, these cranes expedite loading and unloading operations, optimizing storage space utilization and enhancing logistics efficiency.

- Construction Sites: Fixed gantry cranes play a pivotal role in construction projects, facilitating the lifting and positioning of heavy construction materials, equipment, and prefabricated components with precision and ease.

- Shipping Yards and Ports: At shipping yards and ports, these cranes streamline cargo handling operations, facilitating the loading and unloading of containers, bulk materials, and heavy machinery from vessels and trucks.

- Automotive Industry: Within automotive manufacturing facilities, fixed gantry cranes facilitate the assembly and movement of vehicle components, engines, and chassis, contributing to streamlined production processes and stringent quality control.

Fixed gantry cranes epitomize reliability, stability, and efficiency in industrial lifting operations. With their steadfast installation, customizable configurations, and robust construction, these cranes serve as indispensable assets across diverse industrial sectors, enhancing productivity, safety, and operational efficiency.

10 ton Fixed Gantry Crane v.s. Portable gantry crane

10 Ton Fixed Gantry Crane

Load capacity: 10t

Span:7.4m

Lift height:7.4m

Hoist speed:2.7m/min

Travel speed:11/min

10 Ton Portable Gantry Crane

Load capacity: 10t

Span:5m

Lift height:6m

Hoist speed:2.5m/min

Travel speed:12/min

Light fixed gantry crane with electric chain hoist

Fixed gantry crane frame

Portable gantry crane with electric chain hoist

Portable gantry crane frame

Installation Process of Floor Mounted Fixed Gantry Cranes

Proper installation of fixed gantry cranes is crucial to ensure their structural integrity, stability, and safe operation. The installation process involves several key steps:

- Civil Design: Engage a professional civil engineer to assess the installation site and provide recommendations for the crane's foundation. Factors such as soil conditions, loadbearing capacity, and environmental considerations must be taken into account. The civil engineer will design a foundation that can support the weight and dynamic forces generated by the crane during operation.

- Site Preparation: Before installation begins, the site must be prepared to accommodate the crane and its foundation. This involves clearing the installation area of any obstacles, debris, or vegetation. Additionally, the ground must be leveled to ensure a stable and even surface for the crane's foundation. Proper site preparation is essential to prevent uneven settlement or shifting of the crane structure.

- Assembly: Follow the manufacturer's instructions for assembling the crane components and erecting the gantry structure. This typically involves assembling the horizontal bridge, vertical legs, and any other components according to the provided specifications. It's important to use proper lifting equipment and follow safety protocols during assembly to prevent accidents or damage to the crane.

- Testing and Commissioning: Once the crane is fully assembled, conduct thorough testing of its operation to ensure it meets safety standards and performs as expected. This includes testing the hoisting mechanism, trolley movement, bridge travel, and any other functions. Perform load tests to verify the crane's lifting capacity and stability under load. Once testing is complete and any issues are addressed, the crane can be commissioned for regular use.

- Safety Considerations: Throughout the installation process, prioritize safety by adhering to relevant safety regulations and guidelines.

Ensure that all personnel involved in the installation are properly trained and equipped with appropriate personal protective equipment.

Regularly inspect and maintain the crane components to ensure safe and reliable operation over time.

By following these steps and prioritizing safety, you can ensure the successful installation and operation of fixed gantry cranes in industrial environments. Proper installation lays the foundation for efficient material handling and contributes to a safe working environment for personnel.

Maintenance Guidelines for Fixed Gantry Cranes

Maintaining fixed gantry cranes is essential to ensure their optimal performance, longevity, and most importantly, the safety of personnel and assets. Here are comprehensive maintenance guidelines:

Regular Inspections:

Frequency: Schedule routine inspections at regular intervals, ideally monthly or quarterly, depending on the crane's usage and operating environment.

Components to Inspect: Thoroughly examine all crane components, including the hoist mechanism, bridge structure, legs, electrical systems, and safety features.

Identify Issues: Look for signs of wear, corrosion, cracks, loose bolts, or any other damage that may compromise the crane's integrity or safety.

Lubrication:

Scheduled Lubrication: Implement a lubrication schedule as recommended by the crane manufacturer. Lubricate all moving parts, such as gears, bearings, wheels, and joints, to minimize friction and prevent premature wear.

Appropriate Lubricants: Use appropriate lubricants compatible with the crane's components and operating conditions. Consult the manufacturer's guidelines for recommended lubrication products.

Repairs and Replacements:

Prompt Action: Address any issues identified during inspections promptly. Do not delay repairs or replacements to prevent further damage or potential safety hazards.

OEM Parts: When replacing components, use genuine OEM (Original Equipment Manufacturer) parts to maintain the crane's performance and safety standards.

Professional Assistance: For complex repairs or replacements, seek assistance from qualified crane technicians or service providers to ensure proper execution and compliance with safety regulations.

Training:

Operator Training: Provide comprehensive training for crane operators on safe operating practices, proper load handling techniques, emergency procedures, and awareness of potential hazards.

Maintenance Personnel Training: Train maintenance personnel on crane maintenance procedures, including inspection protocols, lubrication techniques, and troubleshooting common issues.

Regular Refresher Courses: Conduct regular refresher courses to reinforce knowledge and ensure compliance with safety standards and best practices.

Documentation and Records:

Maintenance Logs: Maintain detailed records of all maintenance activities, including inspections, repairs, lubrication schedules, and parts replacements.

Compliance Documentation: Keep documentation of compliance with regulatory requirements, manufacturer recommendations, and industry standards for crane maintenance and safety.

By adhering to these maintenance guidelines, crane operators and maintenance personnel can ensure the optimal performance, reliability, and safety of fixed gantry cranes throughout their service life. Regular maintenance not only minimizes downtime and repair costs but also enhances operational efficiency and prolongs the crane's lifespan.

How to Get Your Custom Fixed Gantry Cranes

When it comes to purchasing a fixed gantry crane, we offer a seamless process through our official website's contact forms. Alternatively, you can reach out to us via email or phone, providing the specific parameters of the crane you require. Once we receive your order, our dedicated sales manager and crane engineer will collaborate with you to finalize the details.

Based on your design brief, our skilled design department will craft a custom-made structure tailored to your needs. This includes considerations such as the height under the beam (HSF), span, overall height, and anchorage on several ground levels.

As your one-stop solution for gantry crane services, we pride ourselves on offering personalized fixed crane solutions, ensuring that your crane meets your exact specifications. Additionally, we provide rapid product delivery service, operator training, and professional after-sales support.

Should you have any specific needs or requirements, please do not hesitate to contact us. We are here to assist you every step of the way, ensuring a smooth and satisfactory purchasing experience for your fixed gantry crane.

Get Your Custom Fixed Gantry Crane Design

Fixed gantry cranes are invaluable assets in industrial environments, offering stability, reliability, and efficiency in lifting and handling heavy loads. By understanding the different types, selection criteria, installation process, and maintenance guidelines, crane buyers and users can make informed decisions to ensure optimal performance and safety.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch