Freestanding Portable Aluminum Gantry Crane for Vertical Lifting

500kg to 10 ton freestanding portable aluminum gantry crane with no rail & castors for vertical load handling only,light, portable, easy use & assembly.

Category: Light Crane & Portable Crane

Your Trusted Lightweighted Gantry Crane Manufacturer & Supplier

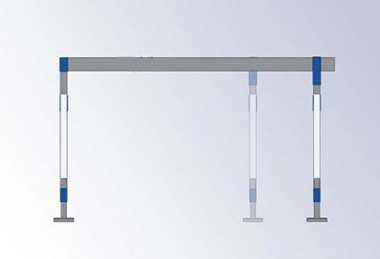

Freestanding Gantry Crane with No Rail & No Castors

Portable Aluminum Gantry Crane for Vertical Lifting, Light, Easy Use & Assembly

500kg to 10 ton freestanding portable aluminum gantry crane with stationary design for vertical material lifting only, like the feltes gantry crane with no rail & castors. Light, Foldable, Easy use & Assembly.Aluminum freestanding gantry cranes come in a variety of sizes and are built with a knockdown design for quick erection and removal. When not in use, the portable aluminum gantry crane can be folded up into a small package for transport or storage.

Freestanding gantry cranes are available in a variety of styles. They can be designed as portable gantry crane design with castor or with no castors or permentant fixed gantry crane design or floor rail travelling gantry crane design. The freestanding portable aluminum gantry crane is a small portable gantry crane with no rails and rolls on castors. Freestanding portable aluminum gantry cranes are commonly considered as light-duty lifting devices, however they can support safe operating loads of up to 10 tonnes if necessary.

Freestanding portable aluminum gantry cranes are a type of light weighted gantry crane with no castor or no rail which is design for vertical material handling operation. Portable aluminum gantry crane are also available, If you want to know more, please clieck on mobile gantry crane and portable gantry crane.

Specifications of Aluminum Portable Gantry Crane

Freestanding aluminum gantry crane is a sort of light structural lifting equipment that uses a pulley/trolley as a hoisting mechanism to move materials or parts. The freestanding gantry cranes can be customized designed with domestic and European standards.

- Capacity of freestanding gantry crane: 0.5 ton ~ 3 Ton, 10 ton

- Span of freestanding gantry crane: 2~6m

- Adjustable height of freestanding gantry crane: 2~6m

- Trolley travel of freestanding gantry crane: electric/manual

- Cart travel of freestanding gantry crane: electric /push manual

- Application: Indoor workshop/warehouse for material or parts lifting and transport.

Customized aluminum gantry cranes are available. Contact us to get the specific aluminum gantry crane price for your specific application and requirements.

Overview of Portable Aluminium Gantry Cranes

In material handling, few names carry the weight and reputation that Portable Gantry does. With a rich history and a legacy of excellence, has established itself as a prominent player in the industry, setting high standards for quality and innovation.

The journey of Portable Gantry began with a commitment to redefine the dynamics of material handling. Founded [insert founding year], the company embarked on a mission to craft gantry cranes that not only met industry requirements but exceeded them. Over the years, has evolved, adapting to technological advancements and industry demands, and has become synonymous with reliability and durability.

Portable Gantry has garnered an impeccable reputation for delivering top notch solutions to a diverse range of industries. Whether it's manufacturing, construction, or warehousing, has proven its mettle by consistently providing robust and efficient gantry crane systems. Endorsements from satisfied clients and partnerships with key industry players underscore ' position as a trusted and respected brand.

Importance of Portable Aluminum Gantry Cranes

Gantry cranes stand as an importantl tools in the field of material handling, offering a versatile solution for lifting and transporting heavy loads. Unlike traditional overhead cranes, gantry cranes operate on a runway structure supported by legs, providing flexibility in movement and application. Portable Gantry has embraced this concept, elevating it to new heights with cutting edge designs and features.

Material handling is the backbone of various industries, and the choice of equipment profoundly influences efficiency and productivity. aluminum portable gantry crane play a crucial role in streamlining processes by offering a mobile and adaptable solution for lifting and moving loads within a facility. Their significance lies not only in their lifting capabilities but also in their ability to enhance overall workflow, making them indispensable in a wide array of applications.

As we delve deeper into the features, types, and applications of portable aluminum gantry cranes, we'll uncover the reasons behind their widespread acclaim and explore how these robust systems contribute to the success of diverse industries. Stay tuned for a comprehensive guide on maximizing efficiency with aluminum portable gantry crane.

Aluminum Portable Gantry Crane Features

Structural Design

- Robust Construction -At the heart of every Portable Gantry Crane lies a commitment to robust construction. The structural design is engineered to withstand the rigors of heavy duty applications, ensuring longevity and reliability. The gantry's framework is meticulously crafted using high quality materials, providing a solid foundation for safe and efficient material handling.

- Material Quality - takes pride in sourcing and utilizing top notch materials for its gantry cranes. The selection process involves stringent quality checks to guarantee the integrity and durability of every component. This commitment to superior material quality not only enhances the crane's structural resilience but also contributes to its overall performance and operational excellence.

As we explore further into the advantages and applications of portable aluminum gantry cranes, we'll uncover how these features translate into tangible benefits for businesses seeking reliable and efficient material handling solutions. Stay tuned for insights into the real world impact of aluminum portable gantry crane.

Height & Span Adjustable Design Drawing

Aluminum Gantry Crane's adjustable design makes the small gantry crane considerably more versatile and useful. The small aluminum freestanding gantry cranes can be used to accommodate a wide range of applications with varying requirements thanks to their adjustable span and height. Please do not hesitate to contact us if you require a specific freestanding gantry crane design.

Non-movable portable aluminum gantry crane with adjustable height and span

Non-movable freestanding portable aluminum gantry crane with adjustable height and span

Non-movable freestanding gantry crane with portable and adjustable height and span

Non-movable aluminum freestanding gantry crane with adjustable height and span

Portability

- Easy Assembly and Disassembly -aluminum portable gantry crane are designed with convenience in mind. The assembly process is streamlined, allowing for quick and hassle free setup. This feature is particularly valuable for industries where agility and responsiveness are paramount. Likewise, the disassembly process is equally straightforward, facilitating efficient relocation or storage when the crane is not in use.

- Transportability -Portability extends beyond assembly and disassembly – portable aluminum gantry cranes are designed to be easily transported within a facility or from one location to another. The gantry's mobility ensures that it can be deployed where it is needed most, optimizing workflow and minimizing downtime. This characteristic is a game changer in dynamic work environments where material handling needs may vary.

Lifting Capacity

- Range of Load Capacities - understands that material handling requirements vary across industries. To accommodate this diversity, their gantry cranes come with a range of load capacities. From lighter loads to heavy machinery, offers a selection of models, each tailored to handle specific weight requirements. This flexibility makes portable aluminum gantry cranes suitable for a broad spectrum of applications.

- Versatility in Applications -Beyond lifting capacity, portable aluminum gantry cranes exhibit remarkable versatility in applications. Whether it's lifting raw materials in a manufacturing setting, assisting with on site construction projects, or facilitating efficient warehouse operations, these cranes adapt to the unique demands of each environment. Their versatility ensures that portable aluminum gantry cranes are indispensable assets across diverse industries.

Our company manufactures a variety of aluminum gantry cranes, all of which having a distinctive design. Here are four fantastic features of aluminum gantry cranes for your consideration.

- The height adjustable aluminum gantry crane, like the portable gantry, is uniquely built for easy erection and takedown. When you don't construct the aluminum crane, it comes in a compact container for carriage or storage and is ready to use at any moment.

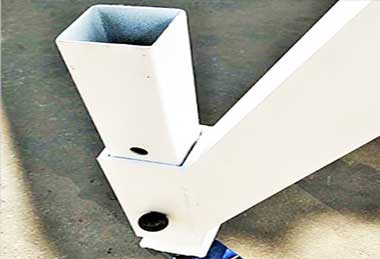

- In comparison to standard aluminum gantry cranes, the crane is built with square tubing uprights, knee braces, and a channel and base structure for smooth lifting and movement.

- High safety performance, the aluminum gantry crane's bolted beam design improves the crane parts connection, increasing the operator's safety performance.

Fine surface grinding -Fully weld the gap part.Fine polishing, making the surface smoother and the interface more compact.

Laser technology is adopted - Using laser echnology to make the product more accurate, more smooth section.

Pursue the details and rigorous process -Through rigorous process, try to reduce the error of the product, make the structure more reasonable and safe.

Detachable and portable - With detachable design, the small gantry crane can be easy assembled and dissembled which makes the crane more convenient and portable.

Customization Options

Tailoring to Specific Industry Needs

Recognizing the diversity of industries, Portable Gantry offers customization options to tailor their cranes to specific industry needs. This level of adaptability allows businesses to optimize their material handling processes by incorporating features that align precisely with their workflows. Whether it's adjusting the crane's dimensions or integrating industry specific technology, ensures that their gantry cranes are a seamless fit.

Add On Features and Accessories

To further enhance the utility of their gantry cranes, provides a range of add on features and accessories. These can include specialized lifting attachments, advanced control systems, or safety enhancements. These optional extras enable businesses to fine tune their gantry crane setups, ensuring that the equipment not only meets but exceeds their expectations.

The commitment to offering diverse models and customization options underscores Portable Gantry's dedication to providing comprehensive solutions for the varied demands of modern industries. As we delve deeper into the advantages and real world applications of portable aluminum gantry cranes, we'll explore how these options empower businesses to optimize their material handling processes. Stay tuned for insights into the tailored solutions offers to meet the specific needs of different sectors.

Typical Applications of Portable Aluminum Gantry Cranes

portable aluminum gantry cranes stand as versatile workhorses, adept at addressing a myriad of material handling challenges across various industries.Functions of aluminum freestanding gantry crane

- Moving materials throughout a facility.

- Handling in a specific area.

- Over machines for product pulling and maintenance.

- Anywhere there is a demand for lifting equipment on a regular basis.

Typical industrial applications of portable aluminum gantry crane scenarios:

Manufacturing

- Assembly Line Support -In manufacturing environments, efficiency is paramount. portable aluminum gantry cranes provide crucial support on assembly lines, streamlining the process of lifting and positioning components. Their robust construction and precise control mechanisms contribute to a seamless production flow, enhancing overall productivity.

- Heavy Equipment Handling -Manufacturing often involves dealing with hefty machinery and components. portable aluminum gantry cranes, with their diverse load capacities, excel in handling heavy equipment with precision and safety. This makes them invaluable assets in manufacturing plants where the seamless movement of substantial loads is a daily necessity.

Construction

- On Site Material Movement -Construction sites are dynamic environments where materials need to be moved swiftly and precisely. portable aluminum gantry cranes bring their portability and adaptability to on site material handling, reducing downtime and facilitating the efficient transport of construction materials.

- Structural Assembly Assistance -During the construction of buildings and infrastructure, the assembly of structural elements requires careful coordination. portable aluminum gantry cranes provide indispensable support in lifting and positioning structural components, ensuring accuracy and safety in the assembly process.

Warehousing

- Efficient Storage Solutions -Warehousing operations demand effective storage solutions. portable aluminum gantry cranes play a pivotal role in optimizing warehouse space by efficiently lifting and placing goods onto storage racks. Their maneuverability is particularly advantageous in navigating through warehouse aisles.

- Inventory Management Support -portable aluminum gantry cranes contribute to streamlined inventory management by facilitating the movement of goods within the warehouse. Their lifting capabilities aid in efficient stock rotation, ensuring that products are accessible and organized for timely order fulfillment.

Maintenance and Repairs

- Versatility in Workshops -Workshops involved in equipment maintenance benefit from the versatility of portable aluminum gantry cranes. Whether it's lifting heavy machinery for inspection or transporting components for repair, these cranes provide the agility and precision required in maintenance settings.

- Equipment Handling for Repairs -When machinery requires repair, portable aluminum gantry cranes offer a reliable solution for safely handling and positioning equipment. Their lifting capacity and adaptability make them ideal for supporting maintenance teams in various repair scenarios.

As we continue to explore the advantages and applications of portable aluminum gantry cranes, we'll uncover more real world examples of how these cranes contribute to the efficiency and success of diverse industries. Stay tuned for insights into their impact on productivity and operational excellence.

Advantages of Freestanding Portable Gantry Crane

portable aluminum gantry cranes go beyond being just lifting equipment; they are strategic assets that bring a multitude of advantages to businesses. Let's delve into the key benefits that set portable aluminum gantry cranes apart:

Increased Productivity

- Time Efficiency -portable aluminum gantry cranes are engineered for swift and efficient material handling. The ease of assembly, precise controls, and adaptable features contribute to a reduction in handling times. This time efficiency translates directly to increased productivity, enabling businesses to meet deadlines and optimize operational workflows.

- Workforce Optimization -By automating and streamlining material handling processes, portable aluminum gantry cranes optimize workforce efforts. These cranes empower operators to focus on higher value tasks, minimizing manual labor and reducing the risk of fatigue related errors. The result is a more agile and productive workforce.

Cost Effectiveness

- Reduced Labor Costs -The automation and efficiency brought by portable aluminum gantry cranes directly impact labor costs. With fewer manual tasks and streamlined processes, businesses can achieve cost savings by reducing the need for extensive manual labor. This cost effectiveness is especially crucial in industries where labor expenses significantly contribute to overall operational costs.

- Long Term Investment Benefits -Investing in portable aluminum gantry cranes is not just a short term solution; it's a strategic long term investment. The robust construction and quality materials ensure the cranes' durability, minimizing the need for frequent repairs or replacements. This longevity translates into sustained cost savings over the life of the equipment.

Safety Features

- Operator Safeguards -Safety is paramount in any industrial setting, and prioritizes operator safety in the design of their cranes. Advanced safety features, such as emergency stop mechanisms and intuitive control systems, contribute to a secure working environment. This focus on operator safeguards enhances overall workplace safety standards.

- Load Stability Measures -portable aluminum gantry cranes are equipped with features designed to ensure load stability during lifting and movement. Whether it's precision control systems or load balancing mechanisms, these measures mitigate the risk of accidents related to load instability. This not only protects the integrity of the lifted materials but also safeguards surrounding personnel and equipment.

Considerations Before Purchasing Freestanding Portable Gantry Crane

Before making the significant investment in a Portable Gantry Crane, it's crucial to thoroughly assess various factors to ensure that the chosen crane aligns seamlessly with your operational needs. Here are the key considerations to keep in mind:

Site Requirements

- Space Considerations -Evaluate the available space where the gantry crane will be deployed. Consider factors such as ceiling height and clearance, as well as the overall layout of the facility. portable aluminum gantry cranes come in various sizes, and choosing the right dimensions ensures optimal functionality without compromising space efficiency.

- Flooring and Ground Conditions -The stability and performance of a gantry crane are heavily influenced by the ground conditions. Ensure that the flooring can support the weight of the crane, including the maximum load capacity. If the ground is uneven, additional measures such as leveling may be required to guarantee safe and efficient crane operation.

Load Specifications

- Understanding Load Types -Different industries handle a diverse range of materials, each with its own set of characteristics. Understand the types of loads your operation deals with regularly. Whether it's machinery components, raw materials, or finished products, this knowledge will guide you in selecting a Portable Gantry Crane with the appropriate features and attachments for your specific load requirements.

- Weight and Size Considerations -Accurate assessment of the weight and size of the loads is essential. offers gantry cranes with varying load capacities, and selecting the right model ensures that the crane operates within its optimal range. Oversized or excessively heavy loads can compromise safety and efficiency, emphasizing the importance of precise weight and size considerations.

Regulatory Compliance

- Local Regulations and Standards -Compliance with local regulations and industry standards is non negotiable. Familiarize yourself with the regulations governing the use of gantry cranes in your region. portable aluminum gantry cranes are designed with adherence to international safety standards, but it's crucial to ensure that they meet or exceed the specific requirements of your local jurisdiction.

- Safety Certifications -Verify that the Portable Gantry Crane models under consideration carry the necessary safety certifications. These certifications validate that the equipment has undergone rigorous testing and meets the required safety standards. Prioritize cranes that come with certifications, ensuring a higher level of confidence in their reliability and safety features.

By carefully considering these factors, businesses can make informed decisions when purchasing portable aluminum gantry cranes, aligning their choices with the unique demands of their operations and ensuring a seamless integration of this advanced material handling solution. Stay tuned as we explore further insights into the procurement and application of portable aluminum gantry cranes.

Freestanding Portable Aluminum Gantry Crane for Sale

When considering the purchase of a Portable Gantry Crane, navigating the buying process is crucial to ensuring a seamless integration into your operations. Let's explore the key aspects involved in acquiring a Portable Gantry Crane:

Purchase Options

- Authorized Dealers -Choosing an authorized dealer is the first step in securing a reliable and genuine product. Authorized dealers are well versed in the intricacies of portable aluminum gantry cranes and can provide expert guidance on selecting the right model for your specific needs. They also offer assurance regarding the authenticity and quality of the equipment.

- Online Platforms and Websites -In the digital age, online platforms and websites provide a convenient avenue for exploring Portable Gantry Crane options. may have an official online presence or partner with reputable e commerce platforms. Ensure that the online source is reliable, offers secure transactions, and provides comprehensive information about the product.

Pricing Structure

- Base Model Costs -Portable Gantry Crane pricing typically starts with the base model cost. This cost reflects the essential features and load capacity of the crane. Understanding the base model's capabilities is essential for determining its suitability for your specific material handling requirements.

- Additional Expenses (Shipping, Installation, etc.) -Beyond the base model cost, consider additional expenses that may be associated with the purchase. This includes shipping fees, installation costs, and any optional features or accessories. Clarify these details upfront to avoid unexpected expenses and ensure a transparent and comprehensive understanding of the overall investment.

Warranty and Support

- Warranty Details -A warranty is a crucial aspect of any major equipment purchase. portable aluminum gantry cranes typically come with warranties that cover specific components and operational aspects. Understand the terms and duration of the warranty to assess the level of protection and support provided by us.

- After Sales Customer Support -Investigate the after sales customer support offered by us. A responsive and reliable support system is invaluable in addressing any issues, providing technical assistance, or facilitating maintenance. This ensures a smooth post purchase experience and contributes to the longevity and optimal performance of the gantry crane.

By carefully navigating the purchase options, understanding the pricing structure, and assessing the warranty and support offerings, businesses can confidently invest in a Portable Gantry Crane that aligns with their operational needs. Stay tuned as we delve deeper into the installation, maintenance, and real world applications of portable aluminum gantry cranes in the next segments of our comprehensive guide.

Installation of Freestanding Portable Aluminum Gantry Crane

Installation of freestanding gantry crane, the mini gantry crane with stationary gantry design

Ensuring proper installation and routine maintenance are essential steps in maximizing the performance and lifespan of your Portable Gantry Crane. Let's explore the key considerations for both processes:

Assembly Process

Step by Step Guide

- Step 1: Site Preparation :Ensure the designated area is level and can support the crane's weight. Follow ' guidelines for floor requirements.

- Step 2: Unpacking and Inspection :Carefully unpack all components, checking for any damage during transportation. Refer to the provided checklist to ensure all parts are present.

- Step 3: Structural Assembly :Follow the detailed step by step guide provided by us to assemble the crane's structure. Ensure proper alignment and securely tighten all bolts and connections.

- Step 4: Installation of Components :Attach hoists, trolleys, and other components as per the manufacturer's instructions. Pay close attention to load capacity specifications.

- Step 5: Electrical and Control Installation :If applicable, install electrical components and controls according to ' specifications. Ensure proper wiring and connections to guarantee smooth operation.

Safety Precautions

- Personnel Training :Ensure that the assembly team is adequately trained on Portable Gantry Crane assembly procedures. This includes understanding safety protocols and guidelines.

- Personal Protective Equipment (PPE) :Require assembly personnel to wear appropriate PPE, including hard hats, gloves, and safety glasses, to minimize the risk of injury.

- Supervision :Have a qualified supervisor oversee the entire assembly process to ensure compliance with safety standards and proper execution of each step.

Does & Don'ts of Aluminum Gantry Crane Operation

The gantry between the main beam and the legs is joined by a flange plate with high-strength bolts for easy demounting and installation, and may be transported and used with a small car.

Freestanding Gantry Crane Notices Before Operation

- First, check the brake, hook, and wire rope as required, and rule out any abnormalities.

- When the operator confirms that there is no one on the platform or on the track, the power can be switched off.

- Before turning on the power, the original necessary staff should remove the power protector lock or a bulletin board.

Freestanding Portable Aluminum Gantry Crane Notices During Operation

- After the gantry operation (assembly) is finished, a loading test should be performed, which including static load testing and dynamic load testing. Check the operational capability, carrying capacity, stability and reliability of each system, and so on.

- When lifting heavy objects for the first time, re-load them at a height of 30cm from the ground, check the brake performance, and then proceed with normal operations after reliable confirmation.

- Use of overload is banned.

- Do not twist the gantry during operation in order to keep it parallel and steady.

- Work should be under the direction of a single person, with a clear division of labor to determine a suitable contact signal.

- There should be no one standing underneath the heavy things when the gantry is running.

Routine Maintenance

Inspection Checklist

- Daily Inspections :Implement a daily inspection routine, checking for any signs of wear, loose bolts, or irregularities in the crane's structure.

- Load Testing :Periodically conduct load testing to ensure the crane continues to meet specified load capacities. This can be especially important after any modifications or repairs.

- Electrical System Checks :Regularly inspect the electrical components, controls, and wiring to identify and address any potential issues before they escalate.

Lubrication and Component Care

- Lubrication Schedule :Follow ' recommended lubrication schedule for all moving parts, including gears, pulleys, and bearings. Regular lubrication ensures smooth operation and prevents premature wear.

- Component Care :Inspect components such as hooks, cables, and sheaves for signs of wear or damage. Replace any worn out parts promptly to maintain optimal performance.

- Calibration Checks :Periodically calibrate the crane's controls and safety features to ensure accuracy and compliance with industry standards.

By adhering to a meticulous assembly process and implementing a proactive routine maintenance schedule, businesses can maximize the longevity and efficiency of their portable aluminum gantry cranes. Stay tuned for more insights into real world applications and case studies showcasing the impact of portable aluminum gantry cranes across diverse industries.

Case Studies of Portable Gantry Crane Applications

Examining real world applications and success stories provides valuable insights into how portable aluminum gantry cranes have made a significant impact across diverse industries.

Portable freestanding gantry crane, non-movable portable aluminum gantry crane design

Portable gantry crane, non-movable aluminum gantry crane design

Portable gantry crane, non-movable portable aluminum gantry crane design

Freestanding gantry crane, non-movable portable aluminum gantry crane design

Success Stories in Various Industries

Manufacturing Excellence

- Scenario:A leading automotive manufacturer integrated portable aluminum gantry cranes into their assembly line to streamline the handling of heavy vehicle components.

- Outcome:The implementation resulted in a 20% reduction in assembly time, leading to increased production output. The adaptability of portable aluminum gantry cranes allowed for efficient handling of various components, contributing to enhanced manufacturing efficiency and overall operational excellence.

Construction Site Optimization

- Scenario:A construction company adopted portable aluminum gantry cranes for on site material movement during the construction of a high rise building.

- Outcome:portable aluminum gantry cranes facilitated the precise and swift movement of construction materials, minimizing downtime and optimizing workflow. The cranes' portability proved crucial in navigating the dynamic construction site layout, resulting in a 15% reduction in overall project duration.

Testimonials from Satisfied Users

Manufacturing Sector

User Testimonial John, Production Manager:"The introduction of portable aluminum gantry cranes has been a game changer in our production facility. The robust construction and versatility have allowed us to handle a variety of components with ease. Our team appreciates the time saved during assembly, contributing directly to increased productivity."

Warehouse Management

User Testimonial Sarah, Warehouse Supervisor:"portable aluminum gantry cranes have revolutionized our warehouse operations. The ability to efficiently lift and position heavy pallets has improved storage density, optimizing our warehouse space. The ease of maneuverability ensures we can adapt quickly to changing storage needs, enhancing overall efficiency."

These real world examples and testimonials underscore the tangible benefits and positive impact that portable aluminum gantry cranes bring to different sectors. As we conclude this comprehensive guide, it's evident that portable aluminum gantry cranes are not just equipment but strategic assets that contribute to increased productivity, cost effectiveness, and safety across a spectrum of industries. For businesses seeking reliable and efficient material handling solutions, portable aluminum gantry cranes stand as a testament to innovation and excellence.

Conclusion: How to Get a Customized Aluminum Gantry Crane

There are two types of portable aluminum gantry cranes: standard and non-standard freestanding gantry cranes, which can meet all your light duty gantry crane requirements. Based on the required work sites, the customized freestanding gantry crane are available. We can supply you with personalized freestanding gantry crane service to meet the requirement of your industrial application.

Main Parameters of Freestanding Portable Aluminum Gantry Cranes

Gantry Crane Design

- Rated Load:_____?

- Outer Span Of The Beam A:_____?

- Gantry Crane Total Height F:Beam Height E:_____?

- Width Of The Bottom Beam C:_____?

- Surface Treatments:_____? Anodizing/Painting

- Assembleable Or Not:_____?

- Hoist Drive Ways:_____?

- Up and Down : _____?Manual/Electric.

- Horizontal Movement: _____? Manual/electric.

As we wrap up our comprehensive guide on portable aluminum gantry cranes, let's summarize the key points and provide some insights for the future.

Portable aluminum gantry cranes have demonstrated a multitude of advantages across various industries:

- Structural Excellence: Robust construction and superior material quality ensure durability and reliability.

- Portability and Adaptability: Easy assembly, disassembly, and transportability make portable aluminum gantry cranes versatile and suitable for dynamic work environments.

- Lifting Capacity and Versatility: A diverse range of load capacities and applications cater to the unique needs of different industries.

- Increased Productivity: Time efficient operations and workforce optimization contribute to heightened productivity.

- Cost Effectiveness: Reduced labor costs and long term investment benefits make portable aluminum gantry cranes a cost effective solution.

- Safety Features: Operator safeguards and load stability measures prioritize workplace safety.

Choosing the right material handling equipment is a critical decision for businesses. When considering portable aluminum gantry cranes, it's essential to:

- Assess site requirements, load specifications, and regulatory compliance to ensure a seamless integration into your operations. Explore purchase options through authorized dealers or reputable online platforms, keeping in mind the pricing structure and additional expenses.

- Prioritize warranty details and after sales support to guarantee a secure and long term investment.

- Follow the recommended assembly process, adhere to safety precautions, and establish a routine maintenance schedule to maximize the crane's performance and lifespan.

- Draw inspiration from real world case studies and testimonials that highlight Portable Gantry Crane success stories in diverse industries.

In conclusion, portable aluminum gantry cranes stand as a benchmark for quality, efficiency, and safety in material handling. By making informed decisions and leveraging the advantages these cranes offer, businesses can elevate their operations to new heights. As the industry continues to evolve, remains at the forefront, shaping the future of material handling solutions.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch