Custom Aluminum Gantry Crane 1 T, 2 T, 3 T, 4T, 5T : How to Get Yours

How to obtain a tailored aluminum gantry crane that meets your specific industrial needs and enhances operational efficiency. Aluminum gantry crane designed for you!

Category: Featured

Your Trusted Aluminum Gantry Crane Manufacturer & Supplier

Your Comprehensive Guide to Custom Aluminum Gantry Cranes

Custom Aluminum Gantry Crane 1 T, 2 T, 3 T, 4T, 5T : How to Get Yours

How to obtain a tailored aluminum gantry crane that meets your specific industrial needs and enhances operational efficiency. Aluminum gantry crane designed for you!

Custom Aluminum Gantry Cranes: How to Get Yours

How to obtain a tailored aluminum gantry crane that meets your specific industrial needs and enhances operational efficiency. Custom aluminum gantry crane for your need.Aluminum gantry cranes are a type of crane system designed to lift and move heavy objects. They are characterized by their lightweight, portable, and adjustable nature, making them highly versatile and easy to use. These cranes typically consist of two upright beams and a crossbeam from which the hoist is suspended. The use of aluminum in their construction makes them light enough to be easily transported and assembled by a small team or even a single person, yet sturdy enough to handle substantial loads.

Types of light wegiht gantry cranes 1 ton -5 ton

A portable aluminum gantry is a type of overhead crane that is supported by a gantry or framework made of aluminum. It is used to lift and move heavy objects in various industrial settings. A portable aluminum gantry is typically lighter than a steel gantry crane, making it easier to move and transport. It is also resistant to corrosion and rust, making it ideal for use in outdoor environments.

- Fixed height portable aluminum gantry: This type of crane has a fixed height and cannot be adjusted. It is designed for use in applications where the load size and shape are consistent.

- Adjustable width or span adjusting aluminum gantry: This type of crane has an adjustable width, allowing it to accommodate different load sizes. It is ideal for use in applications where the load size varies.

- Telescoping aluminum gantry: This type of crane has a telescoping boom that can be extended or retracted as needed. It is ideal for use in applications where the load needs to be lifted to different heights.

- Folding aluminum gantry: This type of crane can be folded up for easy storage and transport. It is ideal for use in applications where space is limited.

- Heavy-duty portable aluminum gantry: This type of crane is designed to lift heavier loads than standard portable aluminum gantries. It is ideal for use in industrial and manufacturing settings.

Overall, there are many different types of portable aluminum gantries available, each with its own unique features and benefits. Businesses can choose the type of crane that best suits their needs based on factors such as load size, weight, and application requirements.

Key Features

- Lightweight: The aluminum construction ensures that these cranes are significantly lighter than their steel counterparts, facilitating easier mobility and setup.

- Portable: Designed to be disassembled and reassembled quickly, aluminum gantry cranes can be moved from one job site to another with minimal effort. This portability is a major advantage for industries that require frequent relocation of lifting equipment.

- Adjustable: Many aluminum gantry cranes feature adjustable height and span, allowing them to be customized to fit the specific requirements of different tasks and environments. This adjustability enhances their versatility and efficiency.

Various Names

Aluminum gantry cranes are known by several names, reflecting their diverse applications and features:

- Portable Gantries: Highlighting their ease of transport and setup.

- Mobile Gantry Cranes: Emphasizing their mobility and use across multiple locations.

- Adjustable Height Gantry Cranes: Focusing on their customizable height features.

- Rolling Gantry Cranes: Describing their ability to move on wheels.

- Aluminum Beam Cranes: Referring to their primary construction material and structure.

In summary, aluminum gantry cranes are an ideal solution for lifting needs in various industries due to their lightweight, portable, and adjustable design. Known by many names, they offer flexibility and efficiency for tasks that require frequent movement and precise lifting capabilities.

5 ton aluminum gantry cranes customized for sale Philippines

Importance of Customization

Meeting Specific Industrial Needs

Customization is crucial for aluminum gantry cranes as it allows them to be tailored to the unique requirements of different industries. Each industry has specific operational challenges and lifting needs, and a one-size-fits-all approach often falls short. Customization ensures that the crane's dimensions, load capacity, and features are perfectly aligned with the tasks at hand.

For example:

- Manufacturing: In a manufacturing plant, customized gantry cranes can be designed to fit within the constraints of the production floor, accommodating the movement of heavy machinery parts and products efficiently.

- Construction: On construction sites, the crane's height and span can be adjusted to navigate through tight spaces or to lift materials to different levels of a building.

- Warehousing: Warehouses often need cranes with specific mobility features to move heavy pallets and crates across large areas, and customized wheels and bases can enhance this mobility.

Benefits Across Diverse Applications and Environments

The benefits of customization extend across a wide range of applications and environments, making aluminum gantry cranes indispensable in various settings.

- Enhanced Efficiency: Customization allows the crane to operate at peak efficiency, as it is designed specifically for the tasks it will perform. This reduces downtime and increases productivity.

- Improved Safety: A crane tailored to its environment and load requirements will operate more safely. Custom safety features can be added to prevent accidents and ensure compliance with industry regulations.

- Versatility: Customization enables the crane to handle a broader range of tasks. For instance, an adjustable height feature allows the same crane to be used in different parts of a facility or at different stages of a project.

- Durability and Longevity: By addressing specific needs and conditions, customized cranes are likely to experience less wear and tear, leading to a longer operational life and reduced maintenance costs.

- Cost-effectiveness: Investing in a customized crane can be more cost-effective in the long run. It ensures that the crane can handle the specific loads and operations required, minimizing the risk of overloading or underutilization.

In summary, the ability to customize aluminum gantry cranes to meet specific industrial needs enhances their efficiency, safety, versatility, durability, and cost-effectiveness. This makes them a valuable asset across diverse applications and environments, from manufacturing and construction to warehousing and beyond.

Assessing Your Needs

Identifying Your Requirements

Load Capacity

One of the first steps in selecting a custom aluminum gantry crane is determining the required load capacity. This involves understanding the maximum weight your crane will need to lift. For instance, Met-Track models can lift up to 4,000 lbs, which is suitable for many industrial applications. Knowing the weight of the materials or equipment you'll be handling is essential to ensure the crane can perform safely and effectively.

Operational Environment

Another critical factor is the operational environment where the crane will be used. Different environments pose unique challenges and may require specific features:

- Indoor vs. Outdoor: Determine whether the crane will be primarily used indoors, outdoors, or both. Outdoor environments may require cranes with weather-resistant features, while indoor settings might prioritize compactness and maneuverability.

- Clean Rooms: If the crane will be used in clean rooms or other controlled environments, ensure it is designed to meet the stringent cleanliness standards. Aluminum construction is often ideal for such environments due to its non-corrosive properties.

- Refrigerated Areas: For operations in refrigerated or cold storage areas, the crane must be able to function efficiently at lower temperatures. Aluminum gantry cranes are well-suited for these conditions as they resist corrosion and perform reliably in varying climates.

By accurately identifying your load capacity needs and understanding the specific conditions of your operational environment, you can select or customize an aluminum gantry crane that best suits your requirements. This ensures optimal performance, safety, and longevity of your equipment.

Specific Applications

- Warehousing:In warehouses, aluminum gantry cranes are invaluable for lifting and moving heavy items such as crates, pallets, and equipment. They can be tailored with features like adjustable height and span to navigate through narrow aisles and low ceilings, ensuring efficient use of space and improving workflow.

- Manufacturing:Manufacturing environments often require cranes for moving parts along assembly lines or transporting finished products. Customization allows for precise adjustments to fit the specific layout of a manufacturing plant. Features like variable speed controls and ergonomic design can enhance productivity and safety in these settings.

- Construction Sites:Construction sites benefit from the mobility and adaptability of aluminum gantry cranes. Custom features can include enhanced mobility options such as all-terrain wheels for uneven surfaces or foldable designs for easy transport between job sites. Adjustable height and span are particularly useful for lifting materials to different levels or maneuvering around obstacles.

- Workshops and Garages:In workshops and garages, aluminum gantry cranes can assist with lifting engines, machinery, and other heavy components. Customization can focus on compact designs that fit within limited spaces, and features like quick assembly and disassembly for flexibility in use. Additional safety features such as locking mechanisms can ensure stability during intricate tasks.

- Outdoor Events and Exhibitions:Aluminum gantry cranes are also ideal for outdoor events and exhibitions, where they can be used to set up and dismantle heavy equipment or displays. Customization can include lightweight construction for easy transport, corrosion-resistant materials for durability in various weather conditions, and quick assembly features to save time during event setup.

Tailoring to Unique Industry Requirements

Each industry has unique requirements that a one-size-fits-all crane may not meet. Customizing your aluminum gantry crane to suit these specific needs can significantly enhance operational efficiency. For example:

- HVAC Projects: Cranes can be customized for moving equipment up stairways or placing units on rooftops, with special features like compact designs and enhanced stability.

- Clean Rooms: For industries requiring sterile environments, cranes can be tailored with non-corrosive materials and easy-to-clean surfaces.

- Heavy Machinery Handling: Custom cranes can be designed with higher load capacities and reinforced structures for handling large, heavy machinery in industrial settings.

By tailoring your aluminum gantry crane to your industry's specific applications, you can optimize performance, safety, and efficiency, ensuring that the equipment meets all operational needs effectively.

Designing Your Custom Crane

Key Design Considerations

Crane Structure

When designing a custom aluminum gantry crane, the choice between a single girder and double girder structure is crucial:

- Single Girder: Offers cost-effectiveness and lighter weight, suitable for lighter loads and environments where headroom is limited.

- Double Girder: Provides greater stability, higher lifting capacities, and versatility for heavier loads and longer spans. It's ideal for demanding industrial applications where precision and durability are paramount.

Mobility Options

The mobility of your crane is determined by its application and operational needs:

- Fixed: Suitable for applications where the crane remains in a dedicated location for extended periods, providing stability and consistent performance.

- Portable: Designed for easy disassembly and reassembly, allowing the crane to be moved between different work areas or job sites. Ideal for environments requiring flexibility and frequent relocation.

- Wheeled: Enhances mobility by incorporating heavy-duty wheels that can traverse various surfaces. Wheeled gantry cranes are versatile, making them suitable for outdoor use and rough terrain.

Hoisting Mechanisms and Power Sources

The hoisting mechanism and power source of your crane are critical for operational efficiency and safety:

- Hoisting Mechanisms: Choose from options such as electric chain hoists, wire rope hoists, or pneumatic hoists based on load requirements, lifting speed, and precision.

- Power Sources: Ensure compatibility with your facility's power supply. Options include 110V, 220V, 480V AC power, or DC battery-operated systems for remote or off-grid locations.

Customizing these elements ensures your aluminum gantry crane meets specific operational demands, enhancing productivity and safety in diverse industrial environments.

Custom Features and Enhancements

Customizing your aluminum gantry crane involves incorporating features and enhancements that optimize its functionality and safety:

Adjustable Height and Span

- Adjustable Height: Allows the crane to accommodate varying ceiling heights or to lift loads to different levels within your facility. This feature enhances flexibility and usability across different tasks and environments.

- Adjustable Span: Enables the crane to cover a wider or narrower area as needed. This customization is beneficial for optimizing workspace utilization and adapting to specific project requirements.

Integration with Other Equipment

- Hoists and Winches: Integration with compatible hoists or winches enhances the crane's lifting capabilities and operational versatility. Choose from electric chain hoists for precise control or wire rope hoists for heavier loads and longer lifts.

Safety Features and Regulatory Compliance

- Safety Features: Incorporate safety mechanisms such as limit switches, overload protection, emergency stop buttons, and anti-collision systems to ensure safe operation and protect personnel and equipment.

- Regulatory Compliance: Ensure the crane meets all relevant safety standards and regulations, such as OSHA (Occupational Safety and Health Administration) requirements in the United States or CE (Conformité Européenne) standards in Europe. Compliance ensures the crane is safe for use in industrial environments and minimizes liability risks.

Customizing these features and enhancements not only tailors the aluminum gantry crane to specific operational needs but also improves overall efficiency, safety, and reliability in diverse industrial applications.

Advantages of Aluminum Gantry Cranes

Mobility

- Easy Assembly, Disassembly, and Relocation: Designed for quick setup and breakdown, aluminum gantry cranes facilitate easy relocation between work areas or job sites. This mobility enhances operational flexibility and efficiency.

- Ideal for Tasks Requiring Frequent Movement: Their lightweight construction and portable design make them ideal for applications where the crane needs to be moved frequently or used in multiple locations.

Versatility

- Customizable to Meet Specific Job Requirements: Aluminum gantry cranes can be tailored with adjustable height, span, and other features to suit specific lifting needs and operational environments. This customization ensures versatility across a wide range of tasks and industries.

- Suitable for Various Challenging Environments: From construction sites to manufacturing facilities, these cranes excel in diverse environments where flexibility and adaptability are essential.

Durability and Stability

- Lifts Up to 6,000 lbs: Despite their lightweight nature, aluminum gantry cranes are capable of lifting heavy loads, up to 6,000 pounds, depending on the model and configuration.

- Adjustable Height and Span, Stable Under Load: Their robust design includes adjustable height and span capabilities, providing stability and precise control during lifting operations. Safety features such as locking mechanisms prevent unexpected movements, ensuring safe operation.

Cost-effectiveness and Ease of Use

- More Cost-effective Than All-Steel Counterparts: Aluminum gantry cranes offer a cost-effective alternative to all-steel cranes, reducing initial investment costs without compromising on performance or durability.

- Lightweight Construction, Often Manageable by a Single Person: The lightweight aluminum construction enables easy handling and maneuverability, often allowing one person to assemble, disassemble, or operate the crane efficiently.

Suitability for Special Environments

- Corrosion-resistant Aluminum Construction: Built with corrosion-resistant materials, aluminum gantry cranes are suitable for use in clean rooms, refrigerated areas, and other climate-sensitive environments where durability and hygiene are critical.

- Usable in Clean Rooms, Refrigerated Areas, and Climate-sensitive Environments: Their ability to withstand environmental challenges expands their application range, making them versatile solutions across industries with specific environmental requirements.

Selecting the Right Manufacturer

Evaluating Manufacturers

When selecting a manufacturer for your aluminum gantry crane, consider the following criteria to ensure reliability and effective custom solutions:

- Criteria for Reliability and Experience: Look for manufacturers with a solid reputation and extensive experience in producing high-quality gantry cranes. A track record of successful installations and customer satisfaction indicates reliability and expertise.

- Importance of Expertise in Custom Solutions: Choose a manufacturer that demonstrates proficiency in customizing gantry cranes to meet specific industrial needs. Expertise in adapting crane designs ensures optimal performance and functionality tailored to your unique requirements.

Questions to Ask Potential Manufacturers

To assess their suitability, ask potential manufacturers the following questions:

- Examples of Past Projects and Case Studies: Request examples of similar projects they have completed. Case studies demonstrate their ability to handle diverse applications and showcase their workmanship and innovation.

- Customization Capabilities and Technical Support: Inquire about their ability to customize gantry cranes. Discuss your specific requirements and assess their technical expertise in designing and integrating bespoke solutions. Reliable technical support ensures smooth implementation and ongoing operational efficiency.

- Warranty Details and After-sales Service: Understand the warranty coverage for your gantry crane. A comprehensive warranty reflects the manufacturer's confidence in their product's quality and reliability. Additionally, inquire about after-sales service and support options to ensure prompt assistance and maintenance when needed.

Choosing a manufacturer that meets these criteria and satisfactorily answers these questions will help ensure you receive a customized aluminum gantry crane that meets your operational needs effectively and reliably.

Confirming Specifications and Finalizing Your Order

Reviewing Technical Specifications

Before finalizing your order for an aluminum gantry crane, thorough review of technical specifications is essential:

- Detailed Design Specs and Engineering Drawings: Carefully examine the design specifications and engineering drawings provided by the manufacturer. Ensure they accurately depict the crane's dimensions, load capacity, structural details, and any customized features requested.

- Ensuring Alignment with Operational Needs: Verify that the gantry crane specifications align precisely with your operational requirements. Double-check factors such as lifting capacity, span width, height adjustments, mobility options, and compatibility with existing infrastructure or operational constraints.

By meticulously reviewing these technical details, you can confirm that the aluminum gantry crane will effectively meet your operational demands and provide optimal performance in your specific application.

Budget and Cost Considerations

When finalizing your order for an aluminum gantry crane, it's crucial to consider budget and cost implications:

- Understanding Design, Material, and Labor Costs: Evaluate the breakdown of costs associated with the gantry crane's design, materials used, and labor involved in manufacturing and installation. Discuss with the manufacturer to gain clarity on pricing factors and ensure transparency in cost estimation.

- Long-term Benefits: Consider the long-term benefits of investing in an aluminum gantry crane. Its durability and efficiency can lead to reduced maintenance costs and enhanced operational productivity over its lifespan. Factor in these benefits when assessing the overall cost-effectiveness of your investment.

By carefully examining both immediate budget considerations and long-term benefits, you can make an informed decision that aligns with your financial goals and operational needs for the aluminum gantry crane.

Implementation and Integration

Installation Process

Ensuring a smooth installation of your aluminum gantry crane involves the following steps:

- Step-by-step Overview of Installation: Begin with a detailed plan provided by the manufacturer outlining the installation process. This plan should include preparation of the installation site, assembly of components, and integration of auxiliary equipment such as hoists and controls.

- Coordination with Facility Layout and Operations: Coordinate installation activities with your facility's layout and operational needs. Ensure that the gantry crane's placement optimizes workflow efficiency and safety. Consider factors such as clearance heights, access points, and proximity to load handling areas.

By following a structured installation plan and integrating the gantry crane thoughtfully into your facility's operations, you can maximize its utility and ensure seamless functionality in your industrial environment.

Training and Maintenance

Effective training and maintenance are crucial for maximizing the performance and longevity of your aluminum gantry crane:

- Training on Crane Operation and Safety: Provide comprehensive training to operators on safe and efficient crane operation. Cover topics such as load handling procedures, emergency protocols, and daily maintenance checks. Ensure operators are certified and understand operational controls and safety features.

- Establishing a Maintenance Schedule: Develop a proactive maintenance schedule in collaboration with the manufacturer's guidelines. Regular inspections, lubrication of moving parts, and timely repairs can prevent breakdowns and ensure consistent crane performance. Document maintenance activities and track crane usage to anticipate servicing needs.

By investing in thorough training and adhering to a structured maintenance schedule, you can enhance workplace safety, prolong the crane's operational life, and maintain optimal performance throughout its use in your industrial operations.

Case Studies and Success Stories

Examples

Explore successful implementations of aluminum gantry cranes across various industries, highlighting the benefits achieved in different applications:

- Successful Implementations in Various Industries: Showcase case studies where aluminum gantry cranes have been successfully deployed. Include examples from warehousing, manufacturing, construction sites, workshops, and outdoor events. Describe how these cranes have improved operational efficiency, safety, and flexibility in diverse industrial settings.

- Benefits Realized by Different Applications: Detail the specific benefits realized in each application. Discuss improvements in workflow productivity, reduction in downtime, enhanced workplace safety, and adaptability to unique operational challenges. Quantify these benefits where possible to demonstrate the tangible advantages of choosing an aluminum gantry crane.

By illustrating real-world examples and highlighting the practical benefits achieved, prospective users can better understand the value proposition of aluminum gantry cranes and envision their potential impact on their own industrial operations.

Testimonials from Clients

Gather valuable feedback and insights from satisfied customers regarding their experiences with aluminum gantry cranes:

- Feedback from Satisfied Customers: Share testimonials that highlight positive experiences with the aluminum gantry crane. Include comments on ease of use, reliability, and the impact on operational efficiency. Testimonials should reflect diverse perspectives from different industries and applications.

- Lessons Learned and Best Practices: Extract lessons learned and best practices from client testimonials. Identify key factors that contributed to successful crane implementation, such as customization options, training effectiveness, and responsive customer support. Highlight any innovative uses or unexpected benefits discovered by customers.

By presenting authentic client testimonials and sharing lessons learned, prospective users can gain valuable insights into the real-world performance and benefits of aluminum gantry cranes, informing their decision-making process effectively.

In conclusion, custom aluminum gantry cranes offer significant advantages that enhance efficiency and productivity in industrial operations:

- Advantages of Custom Aluminum Gantry Cranes:The key benefits discussed throughout the guide, such as mobility, versatility, durability, cost-effectiveness, suitability for special environments, and customization options. Emphasize how these features contribute to operational flexibility, safety, and overall productivity.

- Long-term Impact on Efficiency and Productivity: Highlight the lasting impact of investing in a custom aluminum gantry crane. Discuss how improved workflow efficiency, reduced downtime, and enhanced safety measures translate into long-term operational savings and increased productivity. Illustrate the crane's role in supporting agile manufacturing processes and adapting to evolving industrial needs.

By leveraging the benefits of custom aluminum gantry cranes, industries can achieve operational excellence and meet dynamic production demands effectively, positioning themselves for sustained growth and competitiveness in their respective markets.

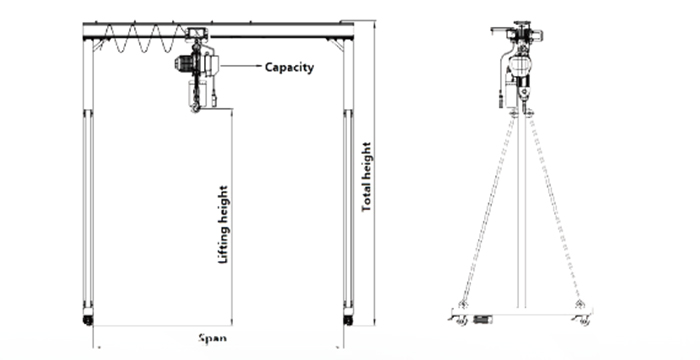

Get your customized portable aluminum gantry design and get your specific price with the following information :

- Types of portable lightweight aluminum gantries: ________ ( Portable design or height adjustable or span just design)

- Weight capacity: ________

- Span length: ________

- Height under beam: ________

- Portability: ________Manual travelling / Electric Motor travelling, Voltage __380v50hz3phae

- Lifting hoist: ________Manual hoist/ Electric hoist, Voltage __380v50hz3phae

- Environment: ________(General use, Cleanroom or Corrosion Environment, etc. )

- Customization requirements: ________

- Your good name and contact email?

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch