Freestanding Workstation Bridge Crane 2 Ton for Auto parts Lifting

2 ton workstation bridge cranes for sale America for auto parts handling, free standing floor mounted workstation crane design, remote control. Check now.

Category: America

Your Trusted Overhead Crane Manufacturer & Supplier

Freestanding Workstation Bridge Crane 2 Ton for Auto parts Lifting

2 ton workstation bridge cranes for sale America for auto parts handling, free standing floor mounted workstation crane design, remote control. Check now.

Freestanding Workstation Bridge Crane 2 Ton for Sale America for Auto Parts Handling

Floor mounted freestanding workstation Cranes

A workstation crane is a type of light overhead kbk workstation crane that is designed to be used in a workstation, which cane be grouped into ceiling mounted workstation crane and floor mounted freestanding workstation cranes. They are one types of lightweight cranes , which are typically used for smaller and lighter loads handling and they are much more lighter and economical than the standard overhead bridge cranes. This makes them ideal for use in limited spaces, such as those found in automotive assembly plants.

Floor mounted freestanding workstation bridge crane for your reference

Floor mounted freestanding workstation bridge crane for your reference

2 Ton workstation bridge cranes for automotive industriy for autoparts handling

The automobile sector is one of America's largest and most vital industries. Over 10 million people were employed by the sector in 2022, and it brought in over $1 trillion in revenue. Workstation bridge cranes serve a vital function in the automobile assembly line, which is a critical aspect of the automotive production process.

In the automobile sector, it takes a large number of workers and equipment to keep your production line running smoothly. Overhead Bridge Cranes are often used in assembly lines, stamping and punching workshops, and warehouses.

- With our continual revolutionary crane technologies, we deliver double girder overhead cranes developed for specialized uses in press plants and maintenance plants managed by the automotive sector.

- During car assembly, you will find our light workstation crane system and single girder overhead crane with electric hoist working safely and efficiently in a variety of automotive applications.

- The explosion-proof hoist was designed specifically to meet applicable regulations for hazardous environments such as those found in automobile body paint shops.

- PLC controlling and monitoring system, variable frequency control technology, tandem operation, high precision positioning, radio controls, and anti-sway control technology are all smart features for safe and easy operation.

- Product: freestanding workstation bridge crane with electrical travelling chain hoist

- Crane Hoist: Electric chain hoist

- Lifting capacity: 2T

- Column height: 5.32m

- Lifting height: 4m

- Span: 7.84m

- Travelling length: 18.28m

- Power supply: 480V/60Hz/3P

- Control: Pendant control

- Crane traveling speed: 20/min

- Cross traveling speed: 20/min

- Lifting speed: 3.3/min

- Protection class: IP54

- Insulation grade: F

- Ambient working temperature: -20℃~+40℃

Freestanding workstation bridge crane for auto parts and components assembly

- Freestanding workstation cranes are a type of overhead light crane that is used in automotive assembly lines. They are frequently used in workingsite where there is no overhead crane system or when the overhead crane system is unsuitable to meet the assembly line's lifting needs.

- Freestanding workstation eot cranes are typically set on the assembly line's floor. The floor mounted freestanding workstation cranes are often utilized in locations with relatively continuous lifting requirements, such as the engine assembly area.

- Freestanding workstation overhead cranes can lift a wide range of materials, including engine components, body panels, and sub-assemblies. They can also be used to transport goods along an assembly line, such as when loading and unloading parts from conveyors.

- Freestanding workstation bridge cranes provide several advantages over other types of cranes, such as overhead cranes. They are usually less expensive to buy and install, and they may be relocated along the production line as needed. They also provide more versatility in terms of lifting capacity and reach.

- Floor mounted workstation cranes play a critical role in the car assembly process. They contribute to increased efficiency and production by providing a safe and effective means of lifting and moving goods along the assembly line.

2 ton electric chain hoist for workstation bridge crane

Supporting structure of freestanding workstation bridge crane

Main parts and components of workstation bridge cranes 2 ton

The 2 ton freestanding workstation bridge crane is an ideal alternative for the American automobile assembly line because it is simple to install and use. In the automotive business, the workstation bridge crane is quite versatile and may be utilized for a range of activities such as lifting automobile components, tools, and materials. The bridge crane is also extremely safe, meeting all safety criteria.

Free Standing Workstation Bridge Crane

The freestanding workstation Bridge Crane has a load capacity of 250 to 4000 pounds and can be simply moved along the bridge to any position inside the rectangle formed by the two runways.

Workstation freestanding bridge cranes provide various advantages. This light overhead lifting equipment eliminates the need for physical lifting, allowing a single worker to carry items from workstation to workstation. They've complemented or replaced several jib cranes and/or forklifts in various cases. Your existing overhead crane will be made available for bigger loads. Finally, this Freestanding Bridge Crane is great for rental facilities or when workflow changes are likely; they are simply movable and normally require only a basic concrete floor to be installed.

These long-lasting, high-efficiency bridge cranes can be fully customized with telescopic or cantilevered bridges, tractor drives, mixed capacity systems, and other features.

Supply Scope

- Lifting Capacity: 100~2000 Kg

- Span: 1-9 m

- Lifting Height: according your needs

- Voltage: 220-660V 50/60Hz 3Phase

- Working Class: M4

- Ambient Temperature: -25~40℃

Applications

- Applications with lighter loads (less than 2000 Kg.)

- Parts Assembly

- Machining

- Palletizing loads

- Injection Molding

- Warehouse loading docks

- Process Equipment Maintenance

- Truck Service Centers

Features

- Enclosed track for simple movement and a long lifespan.

- Rigid runways / improved load positioning - no bridge movement or "crabwalking"

- Ease of installation / install on any standard 6" concrete floor.

- Easier movement of the bridge and trolleys due to the smooth rolling surface.

- Multiple track profiles and spanning capabilities are available.

- Adaptable, versatile, and cost-effective.

How can you benift from workstation bridge crane

- Increased efficiency: Workstation freestanding cranes can help enhance efficiency in the automotive industry by making it easier for workers to lift and transfer large items. This allows workers to concentrate on other duties, such as car assembly.

- Reduced risk of injury: By providing a safe and efficient way to lift and move large parts, freestanding workstation cranes can assist to reduce the risk of accident in the automotive industry. This is especially crucial in confined environments like an assembly line.

- .Reduce product damage and improve quality : Freestanding workstation bridge cranes can help to improve automotive quality by making it easier to accurately assemble them. Workstation cranes enable workers to lift and move heavy pieces more precisely.

- Cost savings: Floor mounted workstation bridge cranes can assist in cost savings in the automobile industry by saving on labor and materials. This is because workstation cranes can make it easier and safer for workers to carry and transfer heavy parts.

- Enhanced applicability: A workstation bridge crane can be utilized for a number of jobs other than automobile assembly. It is also suitable for usage on building sites, warehouses, and other industrial sites.

Custom freestanding workstation bridge cranes

How to buy freestanding workstation bridge cranes:

- Lifting capacity: __Kg

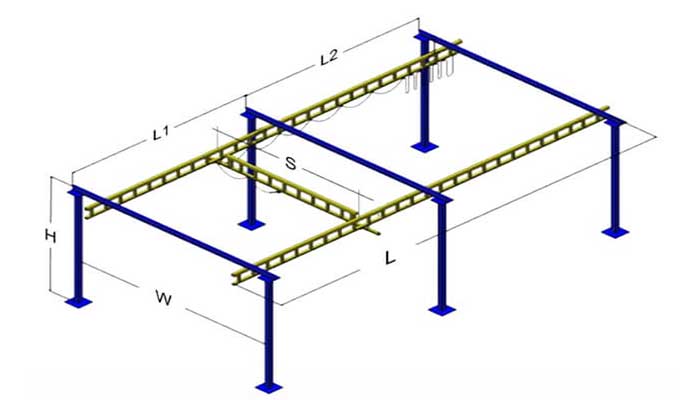

- W(S)=__m, H=__m, L=__m, L1=__m, L2=__m

- Hoist type: electric chain hoist or wire rope hoist or Manual chain hoist?

- Crane travel type: Electrical type or Manual type?

- Voltage: ____V____Hz____Phase (If electrical type)

- Control Mode: Remote control or Pendant control?

- How many KBK cranes are running on the same track?

- Transportation: tell us the sea port name near you, we can quote you shipping freight.

Customized workstation bridge cranes are available. Please feel free to contact us to get your customized design at competitive price. Contact us by leaving a message below or by contact WhatsApp : + 86 151 3871 1597.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch