What Are Portable Gantry Cranes Used For ? | Portable Gantry Uses

What are portable gantry crane & portable overhead crane used for ? General material handling, maintenace, load lifting in hazardous, low headroom & clean room applications, etc.

Category: Overhead Crane for Your Use

What are portable gantry crane & portable overhead crane used for ? General material handling, maintenace, load lifting in hazardous, low headroom & clean room applications, etc.

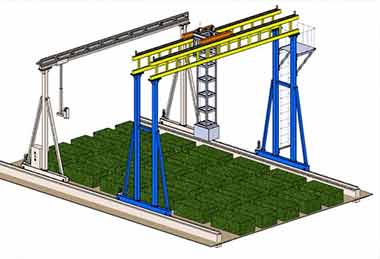

Small A frame gantry crane is a small hoisting equipment, developed and designed based on the need for material handling in medium and small processing plants and manufacturing factories. They are widely used for material loading and unloading in warehouses , assembly and maintenance of super-heavy machinery and equipment and raw material transportation, etc.

Performance advantages of small gantry crane

The mobile gantry crane has the advantages of simple structure, flexible assembly and transfer, strong mobility, economic benefits and high safety performance, and large capacity. The simple gantry crane can be used to handle the loads with the capacity of 0.5 ton to 10 ton. With customized , the small gantry can be up to 20 ton. when the height of the workshop is limited, it can be equipped with a low-headroom electric hoist to achieve higher hook patch.

General applications of portable gantry cranes

Any general material handling worksites with even ground, warehouse, logistics center, production workshop, laboratory, clean room, etc.

It is suitable for the production and manufacture of abrasive tools, automobile maintenance and processing plants, mining, construction sites and places where lifting and hoisting are necessary. For example, the loading and unloading of goods on the vehicle, the lifting of heavy diesel engine parts in the automobile maintenance workshop, etc.

The most obvious advantage of the simple gantry is that it can be moved in multiple directions, occupies a small area, and has an effective steel structure model, which are widely used for the installation, transportation and adjustment of machinery and equipment in the applicable production workshop.

Application conditions of small gantry cranes :

- 1) The altitude of the installation location does not exceed 3000m. When the altitude exceeds 1500 meters, the working ability of the diesel engine is discouraged in many ways.

- 2) Working temperature during work: –30℃~50℃.

- 3) Flammability, flammable and corrosive gas can not be stored in the office environment of lifting equipment.

- 4) It is not allowed to re-melt metal materials, which are harmful, flammable, and work under the natural environment of explosion.

- 5) Suitable for production workshops, warehouses, assembly plants, small and medium-sized processing plants and other applications.

Maintenance and repair operations

Gantry cranes are frequently utilized in applications that need versatility in day-to-day operations. They're made to transport heavy heavy loads in a number of ways. Since the maintenance and repair operations can occur on site or from one location to another, flexibility is a crucial crane designing factor.

Gantry cranes are made up of three main parts: two leg constructions in the shape of an A-frame and a wide-flange or I-beam span. Unlike conventional jib cranes, which have only one support point at the base and a boom and mast, the small gantry cranes support the load with both leg structures. The most basic A-frame gantry design has wheels on the ends of each leg component, making it easy to move.

Only one or two personnel are required to manually move the gantry crane when it is loaded from one location in the plant to another thanks to this particular support structure. They're ideal for maintenance and repair activities both inside and outside the plant because they don't rely on building structural support to carry the load, and they don't require any permanent installations or additional foundations.

While maintenance and repair applications differ from one operation to the next, the environment is a crucial consideration when determining which type of gantry crane is appropriate for your needs. One of the most significant advantages of in-factory gantry cranes is their ease of moving from one work location to another for rapid maintenance and repair.

One or two workers can roll the complete gantry crane to a new location within the shop and hoist materials as needed, depending on the size of the gantry and the weight. They have polyurethane roller for easy indoor movement, and they can even be track installed for manual or motorized travel along a predetermined path. Portable or re-locatable gantry cranes, on the other hand, are a better solution because most maintenance and repair applications involve workflow adjustments.

Depending on the needs of the operation, there are different gantry models for in-shop and outside maintenance and repair.

Portable overhead crane for engine or electrical maintenance and repair

An adjustable steel gantry crane is ideal for businesses that undertake equipment maintenance and repairs on vehicles and/or machines. Workers frequently have to remove an engine or transmission from within a vehicle—whether it's a car, light rail, or transit vehicle—and removing heavy parts from larger vehicles can be difficult without the assistance of a material handling system. Even minor items weighing 50-100 pounds may necessitate the use of a material handling system to prevent putting personnel under undue physical strain.

Adjustability and portability are essential for such applications. Height, span, and tread are frequently adjustable on adjustable gantries, making them easy to use and incredibly adaptable. A three-way adjustable gantry crane, for example, is an excellent choice for a transportation corporation that needs to pluck heavy electrical cables from rail cars since it can be moved to any place around the rail car and adjusted to lift from practically any position.

These gantries are often designed for stability, leaving the I-beam free to pivot as it self-centers over the weight. The I-beam can be cantilevered to deliver parts through the end of the gantry up to four feet past the end of the beam, and the A-frame design assists to avoid swaying. When reaching into machinery and moving huge cables or large engines that have been suspended for a long time, this is very crucial.

Solution for HVAC maintenance and repair

A light-lift system is nearly always required in HVAC applications. The problem with HVAC maintenance and repair is that it frequently demands the use of a system that is both portable and light. While one or two workers on the shop floor may readily handle multiple steel gantries, a steel gantry crane cannot be simply lifted from a service truck or work vehicle and transported from one job site to another.

Heating, ventilation, and air conditioning are abbreviated as HVAC. It is a form of automation system that manages the air quality and thermal comfort provided to humans in order to survive.

Thermodynamics, fluid mechanics, and heat transfer are all used in HVAC. HVAC is a sort of automation system, just like other types of automation systems.

When constructing a high-rise building, commercial complex, industrial unit, hospital, parking unit, hotels, and other structures where air quality and temperature parameters must be maintained so that the people within may live comfortably, HVAC is one of the most significant components.

Aluminum gantry crane for HVAC m aintenance and repair

An aluminum gantry crane is an ideal choice for situations like these. They can lift up to 3 tons and are simple to install and disassemble, as well as transport in a work truck or similar vehicle. Aluminum gantries can weigh as little as 0.25 ton when fully assembled (depending on capacity), making them an ideal alternative for employees who must maintain and repair HVAC equipment on roof tops or in other hazardous places.

Aluminum gantry cranes can be adjusted in height to accommodate specific lifts, uneven floors, or mobility in small locations. The crane's adjustable spans also allow it to be shortened for transport in compact spaces. Pneumatic tires can be added for convenient outdoor movement and good rooftop protection.

Solutions for low headroom & confined spaces

Because confined spaces come in all shapes and sizes, so do our products!

Material handling in a confined space can be extremely dangerous. Many people, including rescuers, are killed or critically injured every year in confined areas owing to a lack of training, competency, or suitable equipment. Hazardous substances, such as invisible gases, as well as hazardous circumstances, such as the risk of an explosion, heat, flood water, or unstable surfaces, are all widespread.

Work in tight locations requires careful planning by qualified and experienced personnel. It's critical to have the correct equipment for access, escape, and rescue.

Several of our products are intended to assist in gaining access to limited locations and working securely in them. We offer a wide range of highly portable, lightweight solutions to our customers, giving them the most options and flexibility to match a wide range of openings and work site conditions.

When necessary, useful, or convenient, portability is combined with the option of using permanent structural anchoring. Our products have industry-leading strength-to-weight ratios, allowing them to serve as anchors for numerous users in many circumstances. For maximum efficiency, EOTCRANEKIT prioritizes high levels of safety and increased lifting capacity.

All equipment come with a variety of accessories, including winches and self-retracting lifelines.

Portable gantry crane for low headroom applications

The main beam is cold galvanized, but the other parts are still conventional materials. Some dust-free workshops are employed, but the cleanliness requirements are not stringent. Only the main beam is galvanized for financial reasons, or you might pick the same as the main beam. A layer of stainless steel strips covers the beam, which can also help to keep dust at bay.

Portable gantry crane with low headroom hoist

Double beam gantry crane with low headroom crane design

Double beam gantry crane for low clearance application

Height adjustable gantry crane

Solutions for the Clean Room, Chemical, and Food Processing Industries

Chemical and food processing sectors, for example, frequently require a clean working environment because contamination can be disastrous. We've developed a line of hoists and motion control products to satisfy the needs of chemical and food processing companies.

Portable gantry crane for clean room

Portable gantry cranes are versatile cranes that may be used in a wide range of cleanrooms. Gantry cranes can be manually maneuvered around a cleanroom because to their (electrically driven) wheels.

Clean room portable gantry crane

Electric chain hoist portable gantry crane for clean room

Cleam room gantry crane 1 ton

Sanitary gantry crane

This is the main beam made of cold galvanized, other parts are still standard materials, some dust-free workshops are used, but the requirements for cleanliness are not high. For cost reasons, only the main beam is galvanized, or you can choose the same as the main beam. The beam is covered with a layer of stainless steel strips, which can also play a role in preventing dust.

Requests from Customers and Our Responses:

For his clean room, the client wanted a 1 ton portable gantry crane. Our design: only the main beam is cold-galvanized, and the other parts are still ordinary materials, equipped with a European chain hoist, due to the low cleanliness requirement. The main beam can be galvanized for a lower cost, or another clean room crane solution is to coat the main beam with a layer of stainless steel, which can also help to avoid dust.

Hazardous applications

In many enterprises and sectors, keeping people and hoist and crane equipment safe in difficult and hazardous environments is not only required, but critical. A chemical plant, a petrochemical operation, or a steel mill might all have hazardous conditions. You'll require specifically built lifting equipment to execute the duties safely and in accordance with hazardous environment rules, regulations, and standards. We have what you need to address your material handling equipment problems.

Aluminum gantry crane with explosion proof hoist for hazardouse application

2 sets of aluminum gantry cranes with explosion proof electric chain hoists for loads hoisting simultaneously & separately.

2 ton small gantry crane for sale Chile for steel handling

Small gantry crane for sale Chile for steel handling, cost-effectively and efficiency. 2 ton portable gantry crane & small gantry crane for sale Chile.

Plant scanning series rail mounted small gantry cranes are suitable for the Academy of Agricultural Sciences and university research institutes.

1. The whole machine is controlled by PLC, which can regularly collect data on the plants that need to be detected and scanned.

2. With the electric lift scanner, it can be used for plants of different heights.

Plant scanning series rail mounted small gantry cranes are suitable for the Academy of Agricultural Sciences and university research institutes.

1. The whole machine is controlled by PLC, which can regularly collect data on the plants that need to be detected and scanned.

2. With the electric lift scanner, it can be used for plants of different heights.

General loads lifting & materials handling

We have built an exceptional reputation for producing high-quality and durable goods for usage in a wide range of industries, where our products are trusted to raise a variety of materials and equipment.

We've effectively developed our systems using lightweight aluminum as an alternative to steel, establishing a precedent for creativity and successful experimentation that has led us to become one of the world's leading lifting developing technologies today.

Our movable gantry cranes have industry-leading strength-to-weight ratios, and with aluminum as the core material of our lifting systems, they provide the ideal option for material handling and heavy lifting.

Height adjustable gantry crane for general use

Truss leg small gantry crane

Aluminum gantry crane for light duty material handling

Small gantry crane for car handling

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch