Aluminum Lightweight Gantry Crane System, Light Duty, Portable, Ajustable & Foldable Gantry Crane

500kg, 5 ton, 10 ton light duty aluminum gantry crane, your lightweighted gantry crane system with designs of light duty, lightweight, portable,foldable.

| Gantry Crane Type | Aluminum lightweight gantry crane |

| Gantry Capacity | 0.5 ton, 1 ton, 3 ton, 5 ton |

| Lifting span | 2~6m |

| Trolley travel | electric/manual |

| Note | Customized light duty gantry cranes are available. |

Category: Gantry Crane

500kg -10 Ton Aluminum Light Weight Gantry Crane Manufacturer & Supplier

Aluminum Light Weight Gantry Crane System

Light Duty, Ajustable, Portable & Foldable

500kg -10 ton light weight gantry crane system , a type of aluminum lightweight gantry crane system with stationary design or portable gantry crane design with the features of Light duty ,Foldable, Easy use & Quick assembly, etc. Aluminum light weight gantry crane systems come in a variety of sizes and designs to quick erection and removal. When not in use, the alumninum lightweight ganty crane can be folded up into a small package for transport or storage.

Light weight gantry crane systems are available in a variety of styles. They can be designed as a small fixed gantry crane design, lightweight aluminum gantry crane, an fixed height gantry crane design , adjustable gantry crane design or foldable aluminum gantry crane design, etc.The light weight gantry crane systems are commonly considered as light-duty lifting devices, however they can support safe operating loads of up to 10 tonnes if necessary

Specifications of aluminum light weight gantry crane system

alumninum lightweight ganty crane is a sort of light structural lifting equipment that uses a pulley/trolley as a hoisting mechanism to move materials or parts. The light weight gantry crane system s can be customized designed with domestic and European standards.

- Capacity of light weight gantry crane system : 0.5 ton, 1 ton, 2 ton, 3 ton, 5 ton

- Span of light weight gantry crane system : 2~6m

- Adjustable height of light weight gantry crane system : 2~6m

- Trolley travel of light weight gantry crane system : electric/manual

- Cart travel of light weight gantry crane system : electric /push manual

- Application: Indoor workshop/warehouse for material or parts lifting and transport.

Customized aluminum lightweight gantry crane systems are available. Contact us to get the specific aluminum lightweight gantry crane system price for your specific application and requirements.

Types of light wegiht gantry cranes 1 ton -5 ton

A portable aluminum gantry is a type of overhead crane that is supported by a gantry or framework made of aluminum. It is used to lift and move heavy objects in various industrial settings. A portable aluminum gantry is typically lighter than a steel gantry crane, making it easier to move and transport. It is also resistant to corrosion and rust, making it ideal for use in outdoor environments.

- Fixed height portable aluminum gantry: This type of crane has a fixed height and cannot be adjusted. It is designed for use in applications where the load size and shape are consistent.

- Adjustable width or span adjusting aluminum gantry: This type of crane has an adjustable width, allowing it to accommodate different load sizes. It is ideal for use in applications where the load size varies.

- Telescoping aluminum gantry: This type of crane has a telescoping boom that can be extended or retracted as needed. It is ideal for use in applications where the load needs to be lifted to different heights.

- Folding aluminum gantry: This type of crane can be folded up for easy storage and transport. It is ideal for use in applications where space is limited.

- Heavy-duty portable aluminum gantry: This type of crane is designed to lift heavier loads than standard portable aluminum gantries. It is ideal for use in industrial and manufacturing settings.

Overall, there are many different types of portable aluminum gantries available, each with its own unique features and benefits. Businesses can choose the type of crane that best suits their needs based on factors such as load size, weight, and application requirements.

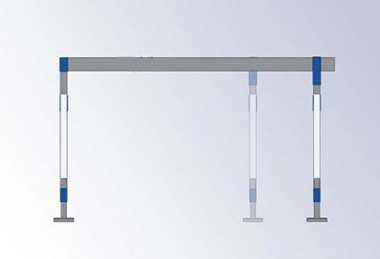

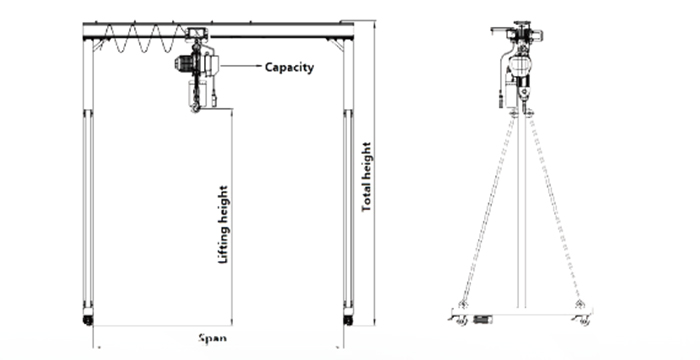

Height & span adjustable design drawing

aluminum lightweight gantry crane system's adjustable design makes the small gantry crane considerably more versatile and useful. The small aluminum light weight gantry crane system s can be used to accommodate a wide range of applications with varying requirements thanks to their adjustable span and height. Please do not hesitate to contact us if you require a specific light weight gantry crane system design.

Non-movable light weight gantry crane system with adjustable height and span

Non-movable light weight gantry crane system with adjustable height and span

Non-movable light weight gantry crane system with adjustable height and span

Non-movable light weight gantry crane system with adjustable height and span

Folding and undfolding of lightweight gantry crane system

Unfolding of foldable aluminium gantry crane

Folding of foldable aluminium gantry crane

Main Specificaitons of Aluminum Gantry Crane

LT-1 Height Adjustable Gantry Crane

The LT-1 Seriers aluminum alloy gantry is a lightweight, durable, economical, flexible, and easy-to-install special lifting equipment. One of the best feature is the overall height can be adjustable.

Capacity |

WxH |

WxH |

WxH |

WxH |

WxH |

1 ton |

3m*(2-3)m |

4m*(2-3)m |

3m*(2.6-4)m |

4m*(2.6-4)m |

3m*(4-6)m |

2 ton |

3m*(2-3)m |

4m*(2-3)m |

3m*(2.6-4)m |

4m*(2.6-4)m |

3m*(4-6)m |

3 ton |

3m*(2-3)m |

4m*(2-3)m |

3m*(2.6-4)m |

4m*(2.6-4)m |

3m*(4-6)m |

Remarks: Bigger capacity and bigger size can be customized.

LT-2 Height Fixed Gantry Crane

The height fixed gantry crane is a simple gantry which has a permanent overall height. It is easy to assembly and deassembly. The I-beam is compatible to electrical or manual hoists.

Capacity |

WxH |

WxH |

WxH |

WxH |

WxH |

0.5 ton |

2*3m |

3*3m |

3*4m |

4*4m |

4*5m |

1 ton |

2*3m |

3*3m |

3*4m |

4*4m |

4*5m |

2 ton |

2*3m |

3*3m |

3*4m |

4*4m |

4*5m |

3 ton |

2*3m |

3*3m |

3*4m |

4*4m |

4*5m |

5 ton |

2*3m |

3*3m |

3*4m |

4*4m |

4*5m |

Remarks: Bigger capacity and bigger size can be customized.

LT-3 Two Stage Height Adjustable

The overall height can be assended by 2 parts: leg and aux. leg. This designing can make the gantry has a super height than that of other cranes.

LT-4 Super Light-weight Crane

This is a super light weight crane, and each unit is only 50kg-115kg. It only take a few minutes to assemble it by 2 persons. Span and overall height can be adjustable by reposion the bolts and nuts.

Capacity |

WxH |

WxH |

WxH |

WxH |

WxH |

0.5 ton |

2mx(2-3m) |

3mx(2-3m) |

4mx(2-3m) |

3mx(2.5-4m) |

4mx(2.5-4m) |

1 ton |

2mx(2-3m) |

3mx(2-3m) |

4mx(2-3m) |

3mx(2.5-4m) |

4mx(2.5-4m) |

2 ton |

2mx(2-3m) |

3mx(2-3m) |

4mx(2-3m) |

3mx(2.5-4m) |

4mx(2.5-4m) |

Applications of light weight gantry crane systems

Light weight gantry crane system s with adjustable designs are perfect for maintenance, manufacturing, repairs, and other material handling applications. A single adjustable gantry crane with adjustable height and/or span can provide a versatile lifting option. Our adjustable light weight gantry crane system s are used by a variety of businesses for HVAC, assembly, and repairs of physical plant equipment ,which are widley used by users such as, electric utilities, municipal maintenance (including subways, buses, and building amenities), research organizations, and the military.

Mold manufacturing companies, mines, auto repair factories, building sites, logistics organizations, mechanical processing and manufacturing companies, and warehouses are applications where the portable and adjustable alumimum gantry cranes are widely used. Please do not hesitate to contact us if you require bespoke adjustable light weight gantry crane systems.

- Moving materials throughout a facility.

- Handling in a specific area.

- Over machines for product pulling and maintenance.

- Anywhere there is a demand for lifting equipment on a regular basis.

Light weight gantry crane system testing

500kg to 5 ton height and span adjustable light weight gantry crane system s for sale. Contact us to get your adjustable gantry crane design drawing and gantry crane price .

Light weight gantry crane system with portable gantry crane design

500kg to 5 ton height and span adjustable light weight gantry crane system s for sale. Contact us to get portable adjustable light weight gantry crane system design and price.

Light weight gantry crane system for light duty load handling

500kg to 5 ton height and span adjustable light weight gantry crane system s for sale, economical light duty load handling, cost-effective lightweight gantry cranesystem.

Light weight gantry crane system with portable gantry crane design

500kg to 5 ton height and span adjustable light weight gantry crane system s for sale, good light weight gantry crane system price , light weight gantry crane system system.

Light weight gantry crane system with manual hoist

500kg to 5 ton height and span adjustable light weight gantry crane system s, cost-effective manual gantry crane for light duty and lightweighted load handling, good adjustable gantry crane price.

Light weight gantry crane system with castors

500kg to 5 ton height and span adjustable light weight gantry crane system s for various application for light duty material handling. Get your customized light weight gantry crane system design drawing now.

The aluminum lightweight A frame gantries are commonly used in applications where a lightweight and portable lifting solution is required. They are often used in cleanroom environments, as they do not produce any particles or contaminants that could affect sensitive equipment or products.

When comparing steel gantry cranes to light aluminum gantries, some factors to consider include weight, durability, and cost. Steel gantry cranes are typically heavier and more durable the portable aluminum gantries, but they are also more expensive.

Applications:

- Pharmaceutical manufacturing facilities

- Biotech research labs

- Semiconductor manufacturing facilities

- Electronics manufacturing facilities

- Food processing plants

For cleanrooms:

A cleanroom is a controlled environment that is designed to minimize the presence of airborne particles, dust, and other contaminants. Cleanrooms are used in various industries, including pharmaceuticals, biotechnology, electronics, and aerospace. The dustfree cleanroom cranes are often used in cleanrooms because they are lightweight, easy to move around, and do not produce particles or contaminants. This is important in cleanroom environments where even small particles can cause contamination and affect the quality of products or experiments. Additionally, aluminum gantry cranes are resistant to corrosion and can be easily cleaned, making them ideal for use in cleanrooms.

The anti-corrosion aluminum gantries are commonly used in cleanroom environments, such as pharmaceutical manufacturing facilities, where cleanliness and particle control are critical.This clean room portable aluminum gantry is designed to meet the specific requirements of clean room environments, providing a safe and efficient lifting solution that minimizes the risk of contamination.

For Laboratories:

- Aluminum cranes are often used in labs because they are lightweight, durable, and resistant to corrosion. They are also easy to move around and can be used in tight spaces. Additionally, aluminum cranes are non-magnetic, which is important in labs where magnetic fields can interfere with experiments. Overall, aluminum cranes are a good choice for labs because they are safe, reliable, and can handle a range of tasks.

For semiconductor manufacturing facilities:

The lightweight aluminum gantries are commonly used in semiconductor manufacturing facilities due to their non-corrosive properties. In semiconductor manufacturing, it is important to maintain a clean and contaminant-free environment to prevent defects in the production process. The aluminum hoist gantries are non-corrosive, which means they will not produce rust or other contaminants that can affect the manufacturing process. Additionally, portable aluminum gantries are lightweight and easy to move, which is important in a facility where equipment and materials need to be frequently moved around to accommodate different production processes. Finally, aluminium a frame lifting gantries can be easily cleaned and sterilized, which is important in a cleanroom environment where cleanliness is critical.

For electronics manufacturing facilities:

Portable aluminum gantries are commonly used in electronics manufacturing facilities due to their lightweight construction and non-corrosive properties. In electronics manufacturing, it is important to prevent contamination of the products being manufactured. portable aluminum gantries are non-corrosive, which means they will not produce rust or other contaminants that can affect the manufacturing process. Additionally, aluminium gantry beam cranes are lightweight and easy to move, which is important in a facility where equipment and materials need to be frequently moved around to accommodate different production processes. Finally, portable aluminum gantries can be easily cleaned and sterilized, which is important in a cleanroom environment where cleanliness is critical. The use of aluminum a frame gantries helps ensure a clean and contaminant-free environment, which is essential for producing high-quality electronic products.

Food processing plants:

The portable aluminum gantries are commonly used in food processing plants due to their non-corrosive properties and ease of cleaning. In food processing, it is important to maintain a clean and hygienic environment to prevent contamination of the food products being processed. The small aluminum gantries are non-corrosive, which means they will not produce rust or other contaminants that can affect the food products. Additionally, The light duty aluminum gantries can be easily cleaned and sterilized, which is important in a food processing plant where cleanliness is critical. The lightweight construction of small aluminum gantries also makes them easy to move around the facility to accommodate different production processes. Finally, the rolling aluminum gantries are resistant to moisture, which is important in a food processing plant where water and other liquids are frequently used. The use of movable aluminum gantries helps ensure a clean and hygienic environment, which is essential for producing safe and high-quality food products.

Aluminum light weight gantry crane system with stationery design

light weight gantry crane system , non-movable aluminum lightweight gantry crane system design

Aluminum light weight gantry crane system with fixed gantry

light weight gantry crane system , non-movable aluminum lightweight gantry crane system design

Aluminum light weight gantry crane system with manual hoist

light weight gantry crane system , non-movable aluminum lightweight gantry crane system design

Aluminum light weight gantry crane system with no rail and castor

light weight gantry crane system , non-movable aluminum lightweight gantry crane system design

Features of aluminum lightweight gantry crane system design:

Our company manufactures a variety of aluminum lightweight gantry crane systems, all of which having a distinctive design. Here are four fantastic features of aluminum lightweight gantry crane systems for your consideration.

- The height adjustable aluminum lightweight gantry crane system, like the portable gantry, is uniquely built for easy erection and takedown. When you don't construct the aluminum crane, it comes in a compact container for carriage or storage and is ready to use at any moment.

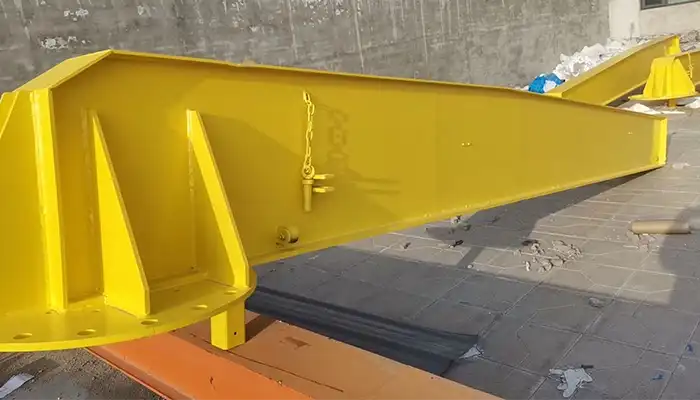

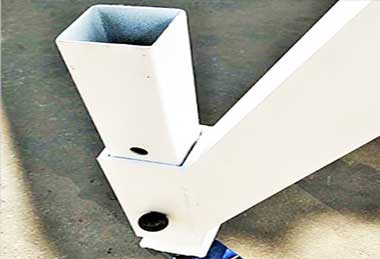

- In comparison to standard aluminum lightweight gantry crane systems, the crane is built with square tubing uprights, knee braces, and a channel and base structure for smooth lifting and movement.

- High safety performance, the aluminum lightweight gantry crane system's bolted beam design improves the crane parts connection, increasing the operator's safety performance.

Fine surface grinding -Fully weld the gap part.Fine polishing, making the surface smoother and the interface more compact.

Laser laser technology is adopted - Using laser laser technology to make the product more accurate, more smooth section.

Pursue the details and rigorous process -Through rigorous process, try to reduce the error of the product, make the structure more reasonable and safe.

Detachable and portable - With detachable design, the small gantry crane can be easy assembled and dissembled which makes the crane more convenient and portable.

Safety and Installation of lightweight aluminum gantry crane

Take notes before installation:

- After the aluninium light weight gantry crane has arrived at its destination, inspect it according to the packing list for any damages or deformities. Repair the portable crane if necessary.

- A solid and smooth installation floor is required.

Installation Method I :

- Assemble the two side legs and the ground beam on the floor properly.

- Lift the end of the leg to a 60-degree angle and brake the wheel.One side of the beam should be lifted.Join the flanges together.

- Using high-strength bolts, spacers, and spring washers, assemble the flanges.Glue the pieces together.

- Lift the completed beam and place it on the opposite side legs.Step 3 should be repeated.

- Assemble the hoist to the beam and test it for safety and functionality.

- If the lifting hoist is an electrical hoist,install the festoon system and electrics.

- Connect the motors to the electrical box with the electrics.The installation is now complete.

Installation Method II:

- Assemble the two side legs and you're good to go.

- Apply the brakes to the wheels.Place the two leg components in the right place based on the length of the beam.

- Align the flanges between the beam and the leg and place the beam in the right position.

- Use high-strength bolts, spacers, spring washers, and nuts to assemble the flanges.Glue the pieces together.

- After assembly, use a worker or lifting equipment to straighten the crane.

- Assemble the hoist and secure it to the beam.

- If hoisting hoist is an electric hoist, install the festoon system and electrics.

Does & Don'ts of aluminum lightweight gantry crane system operation

The gantry between the main beam and the legs is joined by a flange plate with high-strength bolts for easy demounting and installation, and may be transported and used with a small car.

Light weight gantry crane system notices before operation

- First, check the brake, hook, and wire rope as required, and rule out any abnormalities.

- When the operator confirms that there is no one on the platform or on the track, the power can be switched off.

- Before turning on the power, the original necessary staff should remove the power protector lock or a bulletin board.

Light weight gantry crane system notices during operation

- After the gantry operation (assembly) is finished, a loading test should be performed, which including static load testing and dynamic load testing. Check the operational capability, carrying capacity, stability and reliability of each system, and so on.

- When lifting heavy objects for the first time, re-load them at a height of 30cm from the ground, check the brake performance, and then proceed with normal operations after reliable confirmation.

- Use of overload is banned.

- Do not twist the gantry during operation in order to keep it parallel and steady.

- Work should be under the direction of a single person, with a clear division of labor to determine a suitable contact signal.

- There should be no one standing underneath the heavy things when the gantry is running.

How to inspect and maintain portable aluminum gantries?

To ensure the safe and efficient operation of A portable aluminum gantry, regular inspection and maintenance are essential. Here are some tips on how to inspect and maintain portable aluminum gantries:

- Inspect the crane before each use: Before using the crane, inspect it for any signs of damage or wear and tear. Check the condition of the wheels, casters, and bearings, and make sure that all bolts and fasteners are tight.

- Lubricate moving parts: Regularly lubricate the wheels, casters, and bearings to ensure smooth operation and prevent wear and tear.

- Clean the aluminumcrane: Regularly clean the crane to remove any dirt, dust, or debris that may have accumulated. This will help prevent corrosion and prolong the life of the crane.

- Check the cables and hoist: Inspect the cables and hoist for any signs of damage or wear and tear. Replace any damaged cables or hoists immediately.

- Check the brakes: Test the brakes regularly to ensure that they are functioning properly. If the brakes are not working correctly, do not use the crane until they have been repaired.

- Inspect the structure: Regularly inspect the structure of the crane for any signs of damage or corrosion. If any issues are found, have them repaired immediately.

- Follow manufacturer guidelines: Follow the manufacturer's guidelines for inspection and maintenance, as well as any recommended schedules for replacement of parts.

By following these tips, you can help ensure that your portable aluminum gantry remains in good condition and operates safely and efficiently.

What affect your lightweight aluminum crane design,selection & price ?

Portable aluminum gantries are a versatile and cost-effective solution for businesses with lifting needs. They are lightweight, durable, and easy to move, making them ideal for various industrial settings. By choosing the right portable aluminum gantry for your business and following proper safety and maintenance procedures, you can ensure the safety of your employees and equipment while increasing productivity and efficiency.

To get a custom portable aluminum gantry, the main parameters that are needed include:

- Lifting capacity: This refers to the maximum weight that the gantry crane will be required to lift.

- Span length: This refers to the distance between the two uprights of the gantry crane. It is important to determine the required span length to ensure that the gantry crane can safely and efficiently lift the required loads.

- Height under beam: This refers to the vertical distance between the ground and the bottom of the beam. It is important to determine the required height under beam to ensure that the gantry crane can be used in the required application.

- Portability: This refers to how easily the gantry crane can be moved from one location to another. It is important to determine whether the gantry crane will need to be moved frequently or if it will be used in a fixed location.

- Power source: This refers to how the gantry crane will be powered. It is important to determine whether an electric or manual gantry crane is required.

- Environment: This refers to the conditions in which the gantry crane will be used. It is important to determine whether the gantry crane will be used in a cleanroom environment or a hazardous environment, as this will affect the required safety features.

- Customization requirements: This refers to any additional customization requirements, such as modifications to the frame or beam, that may be needed to meet specific application requirements.

By considering these parameters, a custom portable aluminum gantry can be designed and manufactured to meet specific application requirements.

How to get a customized aluminum lightweight gantry crane system

There are two types of alumninum lightweight ganty crane s: standard and non-standard light weight gantry crane system s, which can meet all your light weight gantry crane system requirements. Based on the required work sites, the customized light weight gantry crane system are available. We can supply you with personalized light weight gantry crane system service to meet the requirement of your industrial application.

Get your customized portable aluminum gantry design and get your specific price with the following information :

- Types of portable lightweight aluminum gantries: ________ ( Portable design or height adjustable or span just design)

- Weight capacity: ________

- Span length: ________

- Height under beam: ________

- Portability: ________Manual travelling / Electric Motor travelling, Voltage __380v50hz3phae

- Lifting hoist: ________Manual hoist/ Electric hoist, Voltage __380v50hz3phae

- Environment: ________(General use, Cleanroom or Corrosion Environment, etc. )

- Customization requirements: ________

- Your good name and contact email?

Besides the above aluminum gantry cranes, there are types of aluminum cranes, light cranes and dust-free cranes that can be used in cleanrooms, such as, Light aluminum kbk crane or workstation crane, stainless jib canes, etc. If you have any need of aluminum crane, please feel free to contact us. Contact us today to check what we can do for you to save your crane cost.

Main Projects

Related Products

6.3 ton overhead crane kit for sale Philippines, complete single girder top running overhead crane system, low headroom design for workshop indoor use.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch