Overhead Hoist for Sale, Custom Overhead Hoist System 1 Ton -80 Ton

Overhead hoist for sale good price. Custom overhead hoist systems for types of overhead cranes 2 ton, 3 ton, 5 ton, 10 ton, 20 ton, 30 ton, 50 ton, 80 ton.

| Overhead hoist | 1 ton -80 ton |

| Lifting height | As your requirement |

| Hoist design | Custom hoists are provided on your specification and application conditions |

Category: Overhead Hoist

Your Trusted Overhead Hoist Crane Manufacturer & Supplier

Overhead Hoist for Sale, Custom Overhead Hoist System 1 Ton -80 Ton

Overhead Hoists : Types, Uses, and Maintenance Comprehensive Guide

Overhead hoists are the unsung heroes of numerous industries, silently and efficiently performing the heavy lifting that keeps production lines moving, construction projects on schedule, and warehouses stocked. These versatile devices play a vital role in material handling and movement, and their significance in various industries cannot be overstated.Overhead hoist for sale good price. Custom overhead hoist systems for types of overhead cranes 2 ton, 3 ton, 5 ton, 10 ton, 20 ton, 30 ton, 50 ton, 80 ton. Get you custom overhead hoists for your overhead crane system.

Types of Overhead Hoists

Overhead hoists are not one-size-fits-all devices; they come in various types, each designed to cater to specific lifting needs and industrial applications. Overhead hoists can be classified based on various criteria, including their power source, design, and application. Let's explore overhead hoist types from different perspectives:

Power Source:

- Electric Hoists: These hoists are powered by electricity and are commonly used in indoor settings. They provide precise control and are suitable for a wide range of lifting tasks.

- Pneumatic Hoists: Pneumatic hoists, also known as air hoists, are powered by compressed air. They are often preferred in environments where electricity is not practical or where explosive gases are present.

- Manual Hoists: Manual hoists are operated by hand, using a hand chain or lever. They are simple, cost-effective, and ideal for light to moderate lifting tasks where power sources are limited or unnecessary.

Design and Configuration:

- Wire Rope Hoists: These hoists use a wire rope as the lifting medium. They are known for their strength and durability, making them suitable for heavy-duty applications.

- Chain Hoists: Chain hoists utilize a chain as the lifting medium. They are compact, versatile, and widely used for various lifting tasks.

- Low-Headroom Hoists: Low-headroom hoists are designed for spaces with limited vertical clearance. They feature compact designs that allow for efficient use of space.

- Monorail Hoists: Monorail hoists are typically used in conjunction with a single overhead rail or beam. They are suitable for linear lifting and transporting loads along a single path.

- Double-Girder Hoists: These hoists are designed to work with a double-girder overhead crane system, providing increased load capacity and stability for heavy loads.

Application-Specific Hoists:

- Explosion-Proof Hoists: Explosion-proof hoists are engineered to operate safely in environments where flammable gases, vapors, or dust are present. They are essential in industries like petrochemical and mining.

- Clean Room Hoists: Clean room hoists are specially designed for use in environments with strict cleanliness and contamination control requirements, such as pharmaceutical and semiconductor manufacturing.

- Food-Grade Hoists: Food-grade hoists are constructed with materials that meet food industry standards and are used in food processing and handling facilities.

- Theater Hoists: Theater hoists are designed for stage rigging and lifting equipment in theaters and performance venues, providing smooth and controlled movement.

- Nuclear Hoists: Nuclear hoists are built to operate safely in nuclear power plants and other nuclear facilities, where radiation exposure and contamination risks must be minimized.

Hoist Capacity:

- Light-Duty Hoists: These hoists are designed for tasks with relatively low weight requirements, such as small-scale assembly or light material handling.

- Medium-Duty Hoists: Medium-duty hoists are suitable for a wide range of industrial applications, offering a balance of capacity and versatility.

- Heavy-Duty Hoists: Heavy-duty hoists are engineered for demanding applications that involve lifting exceptionally heavy loads, such as in shipyards or steel mills.

These classifications offer a glimpse into the diversity of overhead hoists, each tailored to specific operational requirements and industry needs. Choosing the right type of hoist is crucial for optimizing performance and safety in lifting operations.

Other types of overhead hoists

Overhead Shop Hoist

The overhead shop hoist is a trusty companion in garages, workshops, and maintenance bays. Its versatility and ability to handle a wide range of tasks make it a staple in these settings. Here's what you need to know about it:

- Precision and Control: Overhead shop hoists offer precise control over lifting and lowering, making them ideal for tasks that demand accuracy. Whether you're removing an engine, positioning heavy equipment, or hoisting components, this hoist gets the job done with finesse.

- Variety of Capacities: Overhead shop hoists are available in various weight capacities, so you can choose the one that matches your specific needs. Common capacities range from smaller models, like 1/4 ton, to larger ones, such as 2 tons or more.

- Ease of Installation: These hoists are typically straightforward to install, whether mounted on a fixed structure or on a trolley for increased mobility within your workspace.

Overhead Lifting Winch

In situations where heavy-duty lifting muscle is required, the overhead lifting winch steps up to the plate. This type of hoist is commonly found in construction sites, maritime operations, and anywhere that demands robust lifting capabilities:

- Heavy Lifting Power: Overhead lifting winches are designed for heavyweight lifting. They are often used for tasks like erecting steel structures, lifting heavy machinery, or handling oversized construction materials.

- Remote Operation: Many overhead lifting winches come with remote control systems, allowing operators to manage the hoist from a safe distance, enhancing safety and precision.

- Diverse Applications: Their impressive lifting power and adaptability make overhead lifting winches indispensable in various industries, from building bridges to hoisting cargo on ships.

Overhead Lifting Hoist

The overhead lifting hoist is a versatile workhorse used across a spectrum of industries and applications. It comes in different configurations, including electric chain hoists and wire rope hoists, making it adaptable to a wide range of load types and sizes:

- Universal Applicability: Overhead lifting hoists are the Swiss Army knives of hoisting equipment. They can lift, lower, and maneuver loads with ease, making them suitable for tasks ranging from manufacturing to warehousing.

- Configurations for All Needs: Electric chain hoists are popular for their compact design and reliability, while wire rope hoists are known for their strength and durability.

- Customization Options: Overhead lifting hoists often offer customization options, allowing you to tailor the hoist to your specific requirements.

In the world of overhead hoists, choosing the right type is the first step to successful lifting operations. Whether you need precision, brute force, or versatility, there's an overhead hoist type perfectly suited to your needs. In the next sections, we'll dive deeper into the components of an overhead hoist and the mounting options available for these essential tools.

Components of an Overhead Hoist

To understand the inner workings of an overhead hoist and its remarkable lifting capabilities, it's crucial to explore the key components that make these machines tick. Let's take a closer look at the fundamental building blocks of an overhead hoist:

Motor and Power Source:

At the heart of every overhead hoist is the motor, which serves as the powerhouse that drives the lifting action. The motor's role is pivotal, as it converts electrical, pneumatic, or manual energy into mechanical force. Here's what you should know:

- Types of Motors: Overhead hoists can feature various types of motors, such as electric motors, air (pneumatic) motors, or even manual crank mechanisms for lighter-duty hoists.

- Electrical Control: Electric motors are commonly used, and they provide precise control over the hoist's movements, including lifting, lowering, and, if applicable, horizontal motion.

- Energy Sources: Depending on the setup, overhead hoists draw power from the electrical grid, rechargeable batteries, or compressed air. The choice of power source often depends on the hoist's intended use and location.

Lifting Medium (Chain or Wire Rope):

The lifting medium is the bridge between the hoist and the load being lifted. It is responsible for bearing the weight and transmitting the force from the motor to the load. Overhead hoists typically employ either a chain or a wire rope for this purpose:

- Chain Hoists: Chain hoists use a sturdy chain made of alloy steel to lift and lower loads. They are durable, resistant to abrasion, and well-suited for heavy-duty applications.

- Wire Rope Hoists: Wire rope hoists, as the name suggests, utilize a strong wire rope made of steel strands. They excel in handling extremely heavy loads and are known for their strength and reliability.

- Load Capacity: The choice between chain and wire rope often depends on the hoist's load capacity and the specific requirements of the lifting task.

Lifting Hook or Attachment Point:

The lifting hook or attachment point is the link that connects the hoist to the load. This component must be robust and secure to ensure the load remains safely suspended:

- Hook Types: Overhead hoists typically feature various hook designs, such as clevis hooks, swivel hooks, and eye hooks, to accommodate different load attachment methods.

- Safety Considerations: Proper hook design and maintenance are critical for safety. Hooks should be inspected regularly for signs of wear, deformation, or damage.

Control System:

The control system of an overhead hoist is the operator's interface with the machine. It enables precise management of lifting, lowering, and, in the case of trolley-mounted hoists, horizontal movement:

- Control Methods: Control systems can range from simple pendant controls with push buttons to more advanced remote control systems, providing operators with flexibility and safety.

- Variable Speed Control: Some hoists feature variable speed control, allowing operators to adjust lifting and lowering speeds for more precise handling of loads.

Understanding these essential components is the first step in operating and maintaining an overhead hoist effectively. These components work in harmony to ensure the safe and efficient movement of heavy loads, making overhead hoists invaluable tools across a multitude of industries. In our next section, we'll explore the mounting options available for these versatile machines, shedding light on how they can be customized to suit specific workspace needs.

Mounting Options

When it comes to overhead hoists, the method of installation or mounting plays a crucial role in determining their functionality and adaptability to specific work environments. There are three primary mounting options to consider:

Fixed Mounting

Trolley Mounting

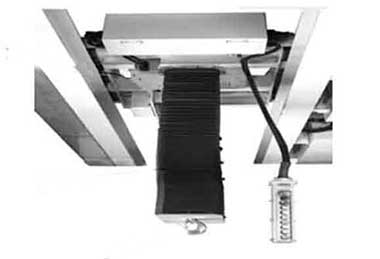

Motorized Trolley Crab Hoist System

Fixed Mounting:

Fixed mounting is the simplest and most common method for installing overhead hoists. In this setup, the hoist is securely attached to a fixed structure, such as a steel beam or an overhead support system within a workspace. Here's what you should know about fixed mounting:

- Stability: Fixed mounting provides exceptional stability and is ideal for situations where loads need to be lifted and lowered in a controlled, stationary manner.

- Common Applications: Fixed-mount hoists are often used in manufacturing facilities, workshops, and maintenance bays for tasks that do not require extensive horizontal movement.

- Installation Simplicity: This mounting option is relatively easy to install, making it a popular choice for a wide range of industries.

Trolley Mounting:

For applications that demand horizontal mobility or the ability to transport loads within a workspace, trolley-mounted hoists are the go-to choice. These hoists are mounted on a trolley that moves along a beam or rail system. Key features of trolley mounting include:

- Enhanced Versatility: Trolley-mounted hoists offer the flexibility to move loads horizontally, making them suitable for tasks that require precise positioning or transferring materials.

- Workspace Efficiency: This mounting option is commonly used in manufacturing settings, assembly lines, and warehouses, where loads need to be moved efficiently between different workstations.

- Variety of Configurations: Trolley-mounted hoists come in various configurations, including manual and motorized trolleys, allowing operators to choose the level of automation that best suits their needs.

Motorized Trolley:

For heavy-duty applications and larger workspaces, a motorized trolley-mounted hoist provides the ultimate in both vertical and horizontal lifting capabilities. Here's what you should know about this advanced mounting option:

- Precise Control: Motorized trolley-mounted hoists offer precise control over both vertical and horizontal movements, allowing for efficient load positioning.

- Heavy-Duty Performance: These hoists are designed to handle substantial loads and are commonly used in industries like construction, shipbuilding, and large-scale manufacturing.

- Reduced Operator Fatigue: The motorized trolley simplifies load transportation, reducing the physical strain on operators and enhancing productivity.

Selecting the appropriate mounting option depends on the specific requirements of your lifting tasks and the layout of your workspace. Whether you need the stability of fixed mounting, the versatility of a trolley-mounted hoist, or the combined power and mobility of a motorized trolley, there's a mounting solution that can be tailored to meet your needs.

In the upcoming sections, we will explore the role of overhead hoist track systems, essential for guiding and optimizing the movement of hoists within a workspace, and delve into the critical aspects of overhead hoist repair, maintenance, and safety.

Overhead Hoist Track Systems

Overhead hoist track systems are the unsung heroes of hoist installations, quietly but effectively enabling the movement and positioning of heavy loads within a workspace. These systems play a crucial role in enhancing the efficiency, safety, and versatility of overhead hoists. Here's why they are indispensable:

- Guided Movement: Overhead hoist track systems provide a guided path for hoists and trolleys to follow. This guidance ensures that loads are moved along a predefined route, minimizing the risk of collisions or accidents. The tracks act as a safeguard, preventing hoists from straying into unauthorized areas.

- Improved Precision: Precision is paramount in many lifting tasks. Overhead hoist track systems allow for smooth, controlled movement, facilitating accurate positioning of heavy loads. This is especially valuable in tasks where precision is critical, such as manufacturing and assembly processes.

- Enhanced Safety: Safety is a top priority when working with heavy loads. Overhead hoist track systems contribute significantly to safety by reducing the chances of loads swinging or swaying during lifting and lowering operations. This stability prevents potential accidents and damage to materials.

- Increased Efficiency: Efficiency is essential for productivity in industrial settings. Hoist track systems optimize the use of space and reduce the time and effort required to move loads from one location to another. This can lead to substantial time and cost savings over the long term.

- Versatility: Overhead hoist track systems can be customized to suit the layout of your workspace and the specific requirements of your lifting tasks. Whether you need a straight-line track or a complex system with curves and switches, these systems can be tailored to meet your needs.

- Load Distribution: In situations where loads are exceptionally heavy or require multiple hoists for lifting, overhead hoist track systems excel. They distribute the weight evenly across the tracks, ensuring that the load is carried safely and without strain on any single hoist.

- Workspace Optimization: Overhead track systems are designed to maximize the use of available vertical and horizontal space. This can be particularly advantageous in environments where floor space is limited, allowing for efficient storage and movement of materials.

- Reduced Wear and Tear: Using a track system reduces wear and tear on the hoist and its components. Hoists operating on tracks experience less friction, resulting in less maintenance and longer equipment lifespan.

In summary, overhead hoist track systems are integral to hoist installations, providing the structure and guidance necessary for safe, efficient, and precise material handling. Whether you're looking to enhance safety, increase productivity, or optimize workspace usage, these systems offer a multitude of benefits that make them an invaluable addition to any industrial or manufacturing setting.

Overhead Hoist Repair and Maintenance

Maintenance is the lifeblood of any piece of machinery, and overhead hoists are no exception. To ensure safe and reliable operation, it's essential to understand the significance of regular maintenance, know how to find reliable repair services, and perform DIY maintenance checks when needed.

The Significance of Regular Maintenance:

Regular maintenance is not just a recommendation; it's a necessity when it comes to overhead hoists. Here's why it's so crucial:

- Safety: Safety is paramount in any industrial or construction setting. Overhead hoists lift heavy loads, and any malfunction or failure can result in accidents, injuries, or damage to materials.

- Lifespan: Proper maintenance extends the lifespan of your hoist. Neglecting maintenance can lead to premature wear and tear, ultimately costing you more in repairs or replacement.

- Reliability: A well-maintained hoist is a reliable hoist. It ensures that your operations run smoothly without unexpected downtime.

Overhead Hoist Repair :

When your overhead hoist requires repair or servicing, finding a reputable and nearby repair service is essential. Here's how you can locate reliable repair services:

- Online Search: A simple online search using the keyword Overhead Hoist Repair Near Me can yield results for local repair companies. Be sure to check their reviews, certifications, and customer testimonials to gauge their reliability.

- Recommendations: Ask colleagues, industry peers, or your hoist supplier for recommendations. Personal referrals can be a valuable way to find trustworthy repair services.

- Supplier Contacts: If you purchased your hoist from a reputable supplier or manufacturer, they may have a list of authorized repair centers or technicians.

- Local Directories: Consult local business directories or industry-specific directories to find repair services in your area.

DIY Maintenance Checks:

While some maintenance tasks should be performed by trained professionals, there are DIY checks you can perform to ensure your hoist is in good working condition between professional inspections:

- Visual Inspection: Regularly inspect the hoist for signs of wear, damage, or loose components. Pay attention to the condition of the lifting medium, hooks, and chains or wire ropes.

- Listen for Unusual Sounds: Unusual sounds during operation, such as grinding or squeaking, can indicate issues that require attention.

- Check for Leaks: If your hoist is powered by a hydraulic system, check for hydraulic fluid leaks. Leaks can compromise the hoist's performance and safety.

- Test Safety Features: Regularly test the hoist's safety features, such as overload protection and emergency stop buttons, to ensure they are functioning correctly.

- Lubrication: If your hoist requires lubrication, follow the manufacturer's guidelines for proper lubrication intervals and methods.

- Documentation: Maintain detailed records of maintenance and inspections. This documentation can be invaluable for tracking the hoist's history and identifying recurring issues.

Remember that while DIY checks are essential for basic maintenance, professional inspections by certified technicians are equally crucial. These experts have the training and experience to identify hidden or complex problems that may not be apparent during routine visual inspections.

In conclusion, regular maintenance and timely repairs are essential for the safe and reliable operation of overhead hoists. Whether you need to search for Overhead Hoist Repair Near Me or perform DIY checks, prioritizing maintenance ensures that your hoist remains an asset rather than a liability in your industrial or construction operations.

Safety Features and Inspections

Ensuring the safety of overhead hoist operations is paramount, and this involves understanding the safety features built into these machines and conducting regular inspections to identify and address potential issues.

Safety Features Commonly Found in Overhead Hoists:

Overhead hoists are equipped with a range of safety features designed to protect both operators and materials being lifted. Here are some of the most common safety features:

- Overload Protection: Overload protection mechanisms are designed to prevent the hoist from lifting a load beyond its rated capacity. This feature helps avoid overloading, which can lead to accidents or equipment damage.

- Emergency Stop Button: An emergency stop button allows operators to quickly halt hoist operations in case of an emergency or unsafe conditions. It provides an immediate way to stop all hoist movements.

- Limit Switches: Limit switches are used to set predefined upper and lower travel limits for the hoist. They prevent the hoist from traveling beyond these limits, avoiding potential collisions with obstacles or damaging the hoist itself.

- Load Limit Indicator: Load limit indicators, often displayed on the hoist's control panel, provide real-time information about the weight being lifted. This helps operators stay within safe load limits.

- Dual Brake System: Many hoists are equipped with a dual brake system, which includes a primary brake for normal operation and a secondary brake that engages automatically if the primary brake fails.

- Chain or Wire Rope Inspection: Some hoists feature a chain or wire rope inspection mechanism that alerts operators to potential issues with the lifting medium, such as wear or damage.

- Thermal Overload Protection: In electric hoists, thermal overload protection safeguards the motor by shutting it down if it overheats. This prevents damage to the motor and reduces the risk of fire.

The Importance of Regular Inspections:

Regular inspections of overhead hoists are crucial for several reasons:

- Safety Assurance: Inspections help ensure that all safety features are functioning correctly. This is essential to prevent accidents, injuries, or damage to materials.

- Compliance: Many regulatory authorities and industry standards require regular inspections of hoisting equipment. Compliance with these standards is necessary to maintain a safe working environment and avoid legal issues.

- Early Problem Detection: Inspections can detect potential issues or wear and tear before they become serious problems. Addressing these issues early can prevent costly breakdowns and repairs.

- Lifespan Extension: Proper maintenance and inspections can extend the lifespan of your overhead hoist, saving you money in the long run.

- Peace of Mind: Regular inspections provide peace of mind, knowing that your hoist is operating safely and efficiently.

Overhead Hoist Inspection:

- Professional Inspections: Look for professional inspection services that specialize in overhead hoists. These services will have the expertise and tools needed to perform thorough inspections.

- Checklists and Guidelines: You can also find checklists and guidelines online for conducting your own basic inspections. These resources can help you identify potential issues and schedule professional inspections as needed.

- Certified Inspectors: Ensure that any inspection service or inspector you hire is certified and experienced in hoist inspections. They should be well-versed in industry standards and safety regulations.

In conclusion, safety features and regular inspections are essential aspects of overhead hoist operation. Understanding the safety features and conducting inspections, including those using the keyword Overhead Hoist Inspection, are vital steps in maintaining a safe and efficient work environment while maximizing the lifespan of your hoisting equipment.

Choosing the Right Overhead Hoist

Selecting the right overhead hoist is crucial to ensure safety, efficiency, and productivity in your lifting tasks. Here's guidance on how to choose the appropriate hoist based on capacity and application, along with considerations for purchasing using the keyword Overhead Hoist for Sale.

Capacity Considerations:

The first and most critical factor in choosing the right overhead hoist is its lifting capacity. The hoist's capacity should match or exceed the weight of the heaviest load you intend to lift. Here's how to determine the right capacity:

- Identify Your Heaviest Load: Determine the maximum weight of the loads you'll be lifting. This should include not only the weight of the load itself but also any attachments, rigging, or slings used.

- Consider Future Needs: Think about potential future needs. It's often a good idea to choose a hoist with a slightly higher capacity than your current requirements to accommodate future growth or changes in your operations.

Application-Specific Considerations:

Different applications require different types of overhead hoists. Here are some common applications and the hoist types that are typically suitable for them:

- Manufacturing and Assembly: Electric chain hoists are versatile and suitable for most manufacturing and assembly tasks due to their precision and control.

- Construction and Building Sites: Overhead lifting winches are ideal for construction applications where heavy materials and equipment need to be hoisted to elevated positions.

- Warehousing and Material Handling: Overhead lifting hoists, especially those with trolley-mounted options, are efficient for moving materials within a warehouse or distribution center.

- Maintenance and Repair: Overhead shop hoists are commonly used for maintenance tasks, such as engine removal and equipment servicing.

- Heavy Machinery and Equipment: In cases where extremely heavy machinery or equipment needs to be moved, consider motorized trolley-mounted hoists for the required strength and mobility.

Keyword Overhead Hoist for Sale for Purchasing:

When you're ready to purchase an overhead hoist, using the keyword Overhead Hoist for Sale in your online search can yield results from suppliers and manufacturers offering a range of hoists. Here are some considerations for purchasing:

- Supplier Reputation: Look for reputable suppliers with a history of providing quality hoists and excellent customer service.

- Product Specifications: Carefully review the specifications of the hoist, including its lifting capacity, voltage requirements, and any additional features that may be important for your application.

- Warranty and Support: Inquire about the warranty and after-sales support offered by the supplier. A solid warranty can provide peace of mind.

- Price and Budget: While cost is a consideration, prioritize the suitability of the hoist for your needs over price alone. A well-matched hoist will provide better value in the long run.

- Compliance: Ensure that the hoist complies with safety standards and regulations applicable to your industry and location.

In conclusion, selecting the right overhead hoist involves considering its capacity in relation to your lifting needs, matching it to your specific application, and conducting thorough research when searching for Overhead Hoist for Sale. A well-chosen hoist will not only enhance efficiency but also contribute to the safety and success of your lifting operations.

Overhead Hoist Track and Rail Systems

Overhead hoist track and rail systems are integral components of material handling solutions in various industries. These systems are designed to guide and support the movement of overhead hoists, ensuring efficient and safe transportation of heavy loads. Let's explore the concept of these systems and how they facilitate smooth hoist movement:

Concept of Overhead Hoist Tracks and Rails:

Overhead hoist tracks and rails are elevated structures, typically made of steel or other robust materials, that are installed in the ceiling or on elevated supports within a workspace. These structures serve as designated pathways for the hoist and its load to move along. Here's an overview of their key components and functions:

- Track Configuration: Overhead hoist tracks can be configured in various ways to accommodate different layouts and lifting needs. They may include straight sections, curves, switches, and junctions to create customized pathways.

- Mounting: Tracks are securely mounted to the building's structure or a supporting framework. Proper installation is crucial to ensure stability and safety.

- Track Components: Tracks are often equipped with components such as track connectors, hangers, and supports to maintain alignment, distribute weight evenly, and ensure smooth movement.

- Track Material: Tracks are typically made of durable materials to withstand the load-bearing demands of overhead hoists. Steel is a common choice due to its strength and durability.

Facilitating Smooth Hoist Movement:

Overhead hoist track and rail systems play a pivotal role in facilitating smooth hoist movement, and they offer several benefits:

- Guided Movement: Hoists and trolleys are designed to run along the tracks, providing guided movement. This guidance ensures that loads are moved in a controlled and precise manner, reducing the risk of collisions or accidents.

- Reduced Friction: Tracks are designed to minimize friction between the hoist and the load, allowing for more efficient and energy-saving operation. This reduced friction also contributes to the longevity of hoist components.

- Versatility: Overhead hoist track systems can be customized to match the specific layout and needs of your workspace. Whether you require straight-line movement or complex multidirectional pathways, track systems can be adapted accordingly.

- Safety: By following a predetermined path, hoists on tracks are less likely to deviate or sway during lifting and lowering operations. This stability enhances safety by preventing potential accidents and damage to materials.

- Load Distribution: In cases where exceptionally heavy loads or long spans are involved, overhead track systems help evenly distribute the weight across the tracks, ensuring that the load is safely carried without straining any single hoist or component.

- Space Optimization: Overhead tracks make efficient use of vertical space, allowing for the storage and transportation of materials without cluttering the floor. This is especially valuable in settings where floor space is limited.

- Integration with Control Systems: Many overhead hoist track systems are designed to seamlessly integrate with control systems, enabling operators to manage hoist movements, including speed and direction, from a central control panel or remote device.

In summary, overhead hoist track and rail systems are essential components in material handling and lifting operations. They provide the structure and guidance necessary to ensure safe, precise, and efficient movement of heavy loads within a workspace. Whether in manufacturing, warehousing, construction, or other industries, these systems enhance productivity while prioritizing safety.

Overhead Hoist System Applications

Overhead hoist systems find a wide range of applications across various industries, providing efficient and reliable solutions for lifting, positioning, and transporting heavy loads. Here are real-world examples of where overhead hoist systems are commonly used and their roles in different industries:

Manufacturing Industry:

In manufacturing, precision and efficiency are critical. Overhead hoist systems play a crucial role in streamlining production processes and ensuring the safe handling of materials and components:

- Assembly Lines: Overhead hoists are often used to position and move components along assembly lines, allowing for precise and efficient assembly of products.

- Material Handling: Overhead hoist systems are used to lift and transport raw materials, work-in-progress items, and finished products within manufacturing facilities.

- Die Handling: Overhead hoists are employed to handle heavy dies and molds used in metal stamping and plastic injection molding processes.

- Painting and Finishing: Overhead hoists facilitate the movement of items through painting booths and finishing stations, ensuring consistent and high-quality coatings.

Construction Industry:

The construction industry relies on overhead hoist systems to move heavy materials, equipment, and components to various levels of construction sites. Common applications include:

- Concrete Pouring: Overhead hoists are used to transport concrete buckets or pumps to upper floors during high-rise construction projects.

- Material Lifting: Hoist systems efficiently lift and lower building materials, such as steel beams, precast concrete panels, and scaffolding components.

- Heavy Machinery Installation: Overhead hoists play a crucial role in installing and positioning heavy machinery and equipment in construction projects.

- Personnel and Materials Transportation: Some hoist systems are designed to transport both materials and workers to elevated work areas safely.

Warehousing and Logistics:

Efficient material handling and inventory management are key in warehousing and logistics. Overhead hoist systems are applied in the following ways:

- Pallet and Container Handling: Hoists are used to move pallets, containers, and bulk materials within warehouses and distribution centers.

- Order Picking: Overhead hoists assist workers in picking and placing items onto shelves or conveyor systems, optimizing order fulfillment processes.

- Loading and Unloading: In logistics hubs, hoist systems help load and unload heavy cargo from trucks and shipping containers.

Automotive Industry:

The automotive industry relies on overhead hoist systems to streamline vehicle manufacturing processes and handle heavy components:

- Engine and Transmission Installation: Hoists assist in positioning engines and transmissions into vehicles on assembly lines with precision.

- Part Handling: Overhead hoist systems are used to move components like doors, chassis, and body panels during vehicle assembly.

- Maintenance and Repair: Automotive repair shops and service centers use hoists for lifting and lowering vehicles during maintenance and repair tasks.

Aerospace Industry:

In the aerospace sector, precision and safety are paramount. Overhead hoist systems are used for:

- Aircraft Component Handling: Overhead hoists aid in the precise movement and assembly of aircraft components, such as wings, fuselages, and engines.

- Tool and Equipment Transportation: Hoists transport specialized tools and equipment to workstations for aircraft maintenance and manufacturing.

These are just a few examples of the diverse applications of overhead hoist systems across industries. Their adaptability, safety features, and capacity to handle heavy loads make them indispensable tools for enhancing efficiency, ensuring safety, and optimizing material handling processes in a wide range of settings.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch