Variable Speed Hoist | Low Headroom Variable Speed Electric Hoist

Variable Speed Hoists 1 to 80 ton for single single & double girder cranes for high precision material handling,ie., electronic component, mold & die.

| Electric Hoist Type | Variable Speed Hoist |

| For single girder crane | 1 ton to 20 ton |

| For double girder crane | 3 ton to 80 ton |

| Lifting height | Customized |

Category: Overhead Hoist

Your Trusted Overhead Crane Manufacturer & Supplier

Variable Speed Hoists: Low Headroom Wire Rope Variable Speed Electric Hoists

Variable Speed Hoists has revolutionized traditional lifting electric hoists. These electric hoists, known for their adaptability and precision, introduce a dynamic element to material handling operations by allowing users to regulate lifting speeds as needed. Variable Speed Hoists 1ton to 80 ton for single single & double girder cranes. Low headroom & wire rope variable speed electric hoists for high precision loads handling in electriconic components or mold handling.

What are Variable Speed Hoists? Variable Speed Hoists are a sophisticated category of lifting equipment engineered to provide a diverse range of lifting speeds. They enable operators to control the lifting velocity of loads, allowing for more precise, controlled movements. This adaptability is especially advantageous in scenarios where different lifting speeds are required to accommodate varying loads or delicate materials.

Importance of Variable Speed Control in Material Handling Operations

The significance of variable speed control in material handling cannot be overstated. Traditional hoists often operate at fixed speeds, limiting their versatility and precision in handling different types of loads. However, Variable Speed Hoists address this limitation by offering adjustable lifting speeds, providing operators with more control and accuracy during lifting and positioning tasks.

Low Headroom and Wire Rope Variable Speed Electric Hoists

Within the realm of Variable Speed Hoists, two distinct types stand out for their specialized functionalities:

- Low Headroom Variable Speed Electric Hoists: These hoists are specifically designed to operate in spaces where vertical clearance is limited. Their compact design optimizes vertical space utilization without compromising lifting capacities or control.

- Wire Rope Variable Speed Electric Hoists: Featuring a wire rope design, these hoists offer exceptional strength and durability. They are adept at handling heavy loads with precision, allowing for smooth and controlled movements.

Both low headroom and wire rope variable speed electric hoists represent cutting-edge advancements in lifting technology, providing solutions tailored to diverse operational needs in various industries.

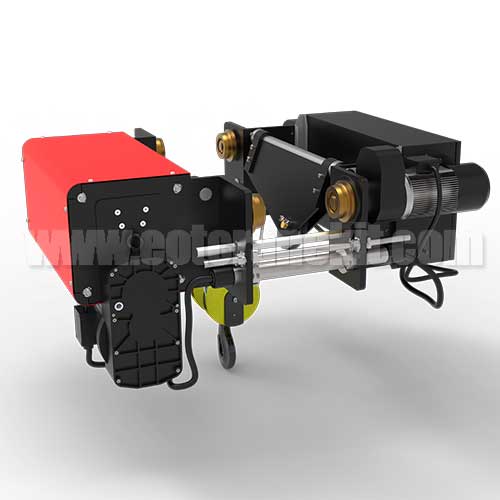

Variable speed electric hoist with low headroom design for single girder overhead crane and single girder gantry crane

Low headroom electric cable hoist for double girder overhead crane and double girder gantry crane with variable speed control

Low Headroom Variable Speed Electric Hoists

Low Headroom Variable Speed Electric Hoists are ingeniously designed lifting devices tailored for operations where vertical space is limited. Their defining characteristic lies in their compact construction, allowing for optimal utilization of available overhead space without compromising on lifting performance.

These hoists are engineered with reduced headroom requirements, meaning they occupy minimal space vertically. Their innovative design minimizes the distance between the hook and the hoist body, maximizing lifting capacity while operating in confined spaces.

Benefits and Advantages of Low Headroom Design in Restricted Spaces

The utilization of Low Headroom Variable Speed Electric Hoists presents numerous advantages in constrained environments:

- Enhanced Maneuverability: Their low headroom design allows these hoists to navigate through tight spaces with ease, enabling operators to work efficiently in areas with limited clearance.

- Optimized Vertical Space: By minimizing the required overhead space, these hoists provide ample room for operations in environments where every inch matters.

- Versatility in Various Settings: Their adaptability to restricted spaces makes them indispensable in industries such as manufacturing, assembly lines, and workshops, where efficient use of space is crucial.

Applications Showcasing Scenarios Where Low Headroom Hoists Excel

Low Headroom Variable Speed Electric Hoists find invaluable applications in several industrial settings:

- Manufacturing Sector: Ideal for assembly lines and production floors where overhead space is at a premium, ensuring seamless material handling without compromising productivity.

- Workshops and Maintenance Areas: These hoists are a preferred choice in workshops and maintenance zones, allowing technicians to perform tasks effectively in confined spaces.

- Restricted Construction Sites: In construction, especially within constrained or urban settings, these hoists facilitate lifting operations in areas with limited vertical clearance.

The adaptability and efficiency of Low Headroom Variable Speed Electric Hoists make them a vital asset across industries where space optimization is essential. In the subsequent section, we'll explore Wire Rope Variable Speed Electric Hoists and their distinct advantages in material handling operations.

Functionality of Variable Speed Wire Rope Hoists

Wire Rope Variable Speed Electric Hoists represent a pinnacle of strength, durability, and precision in material handling equipment. These hoists are equipped with wire ropes instead of traditional chains, providing exceptional lifting capabilities while integrating variable speed functionality for enhanced control.

Key Features and Technical Specifications of Wire Rope Variable Speed Electric Hoists

Wire Rope Variable Speed Electric Hoists boast several distinguishing features:

- Strength and Durability: Utilizing wire ropes, these hoists offer superior strength, capable of handling heavy loads with ease and precision.

- Variable Speed Control: Incorporating adjustable speed control mechanisms, these hoists enable operators to regulate lifting speeds, ensuring precise movements tailored to specific requirements.

- Smooth and Controlled Operation: Their design facilitates smooth and controlled lifting and lowering operations, enhancing accuracy during material handling tasks.

Applications and Industries Benefiting from Wire Rope Variable Speed Hoists

Wire Rope Variable Speed Electric Hoists find applications in various industries, including but not limited to:

- Heavy Manufacturing: Particularly suited for heavy manufacturing operations, these hoists efficiently handle large and heavy components, ensuring precise positioning during production processes.

- Construction and Infrastructure: In construction, where robust lifting solutions are essential, these hoists prove invaluable for their ability to maneuver and place bulky materials with precision at varying speeds.

- Mining and Extractive Industries: Their robust build and variable speed capabilities make them indispensable in mining operations, where heavy loads need to be handled safely and precisely.

The adaptability and strength of Wire Rope Variable Speed Electric Hoists make them a preferred choice across industries where robust lifting solutions with variable speed control are imperative.

Monorail Variable Speed Hoists

Monorail variable speed hoist, low headroom wire rope hoist

Single girder overhead variable speed wire rope hoist

Variable speed electric wire rope hoist

Technical Parameters of FEM standard single girder hoist

Capacity | Working grade | Working grade | Lifting height | Lifting speed | Travelling speed |

3.2 ton | 2m | M5 | 6/9/12/15/18 | 0-5.0 | 0-20 |

3.2 ton | 2m | M5 | 6/9/12/15/18 | 0-8.0 | 0-20 |

5 ton | 2m | M5 | 6/9/12/15/18 | 0-5.0 | 0-20 |

5 ton | 2m | M5 | 6/9/12/15/18 | 0-8.0 | 0-20 |

8 ton | 2m | M5 | 6/9/12/15/18 | 0-4.0 | 0-20 |

8 ton | 2m | M5 | 6/9/12/15/18 | 0-4.5 | 0-20 |

10 ton | 2m | M5 | 6/9/12/15/18 | 0-4.0 | 0-20 |

10 ton | 2m | M5 | 6/9/12/15/18 | 0-4.5 | 0-20 |

12.5 ton | 2m | M5 | 6/9/12/15/18 | 0-4.0 | 0-20 |

12.5 ton | 2m | M5 | 6/9/12/15/18 | 0-5.0 | 0-20 |

16 ton | 2m | M5 | 6/9/12/15/18 | 0-4.4 | 0-20 |

16 ton | 2m | M5 | 6/9/12/15/18 | 0-5.0 | 0-20 |

20 ton | 2m | M5 | 6/9/12/15/18 | 0-3.5 | 0-20 |

20 ton | 2m | M5 | 6/9/12/15/18 | 0-5.0 | 0-20 |

Double Girder Variable Speed Electric Hoist

Double girder electric variable speed hoist

Double beam variable speed electric cable hoist

Variable speed cable hoist for high pricision loads handling such as mold and dies, etc.

Technical Parameters

Capacity (Kg) | Working grade FEM | Working grade IOS | Lifting height (m) | Lifting speed (m/min) | Travelling speed (m/min) |

2 ton | 2m | M5 | 6/9/12/15/18 | 0-5.0 | 0-20 |

2 ton | 2m | M5 | 6/9/12/15/18 | 0-8.0 | 0-20 |

5 ton | 2m | M5 | 6/9/12/15/18 | 0-5.0 | 0-20 |

5 ton | 2m | M5 | 6/9/12/15/18 | 0-8.0 | 0-20 |

8 ton | 2m | M5 | 6/9/12/15/18 | 0-4.0 | 0-20 |

8 ton | 2m | M5 | 6/9/12/15/18 | 0-4.5 | 0-20 |

10 ton | 2m | M5 | 6/9/12/15/18 | 0-4.0 | 0-20 |

10 ton | 2m | M5 | 6/9/12/15/18 | 0-4.5 | 0-20 |

15 ton | 2m | M5 | 6/9/12/15/18 | 0-4.0 | 0-20 |

15 ton | 2m | M5 | 6/9/12/15/18 | 0-5.0 | 0-20 |

16 ton | 2m | M5 | 6/9/12/15/18 | 0-4.4 | 0-20 |

16 ton | 2m | M5 | 6/9/12/15/18 | 0-5.0 | 0-20 |

20 ton | 2m | M5 | 6/9/12/15/18 | 0-5 | 0-20 |

20 ton | 2m | M5 | 6/9/12/15/18 | 0-5.0 | 0-20 |

25 ton | 2m | M5 | 6/9/12/15/18 | 0-8 | 0-20 |

25 ton | 2m | M5 | 6/9/12/15/18 | 0-8 | 0-20 |

32 ton | 2m | M5 | 6/9/12/15/18 | 0-8 | 0-20 |

32 ton | 2m | M5 | 6/9/12/15/18 | 0-8 | 0-20 |

50 ton | 2m | M5 | 6/9/12/15/18 | 0-0 | 0-20 |

50 ton | 2m | M5 | 6/9/12/15/18 | 0-4.0 | 0-20 |

50 ton | 2m | M5 | 6/9/12/15/18 | 0-5.0 | 0-20 |

63 ton | 1Am | M4 | 6/9/12/15/18 | 0-0 | 0-20 |

63 ton | 1Am | M4 | 6/9/12/15/18 | 0-4.0 | 0-20 |

80 ton | 1Am | M4 | 6/9/12/15/18 | 0-5 | 0-20 |

Main Parts and Components

Variable speed wire rope hoists with European-style designs typically consist of several key components that enable their functionality. Here are the main parts commonly found in such hoists:

- Frame/Body: The hoist's main structural component, providing support and housing for internal mechanisms and components. In European-style designs, this frame is often built with sturdy materials to ensure durability and reliability.

- Wire Rope Drum: It's a cylindrical spool around which the wire rope is wound or unwound. The wire rope is attached to the load and wound onto the drum when the hoist lifts the load.

- Gearbox: Responsible for transmitting power from the motor to the drum. The gearbox controls the hoisting speed by adjusting gear ratios, facilitating variable speed operations.

- Motor: Usually an electric motor that provides the power necessary for lifting and lowering loads. In variable speed hoists, the motor is often equipped with a Variable Frequency Drive (VFD) to control the speed smoothly.

- Braking System: A crucial safety feature, it controls the stopping and holding of the load when the motor stops. European-style hoists often incorporate sophisticated braking systems to ensure safety during operations.

- Control System: This includes various components such as a control pendant, remote control, or control panel. It allows the operator to start, stop, and control the hoist's speed and direction.

- Limit Switches: These are safety devices that limit the motion of the hoist by detecting the rope's position or the hoist's movement, preventing over-travel or collision with the hoist's structural components.

- Electrical Components: Wiring, connectors, and other electrical elements that facilitate the functioning of the hoist's electrical system, including the motor, control systems, and safety features.

- Hook Block or Lifting Hook: The device at the end of the wire rope where the load is attached for lifting and lowering.

- Safety Features: Additional safety features may include overload protection, emergency stop systems, thermal protection, and others, ensuring safe and reliable hoisting operations.

These components collectively contribute to the smooth and safe operation of a variable speed wire rope hoist with a European-style design, allowing for efficient and controlled lifting of various loads.

Frequency Converters:

Frequency converters possess several key features that make them essential in controlling motor speed and optimizing energy usage. These include the ability to control variable speeds precisely, ensuring motors operate at different rates as needed. They offer energy efficiency by adjusting power consumption, leading to reduced energy costs. Additionally, they facilitate soft start/stop functions, enabling smooth acceleration and deceleration, which reduces wear and tear on machinery. Furthermore, frequency converters include overload protection mechanisms that help prevent damage to motors by limiting excessive current flow.

Benefits of Frequency Converters:

Utilizing frequency converters in industrial settings yields numerous advantages. Their primary benefit lies in energy savings achieved through optimized power consumption, thereby reducing overall energy costs. By mitigating wear on motors and machinery, these converters extend the operational lifespan of equipment, reducing maintenance and replacement expenses. Moreover, their ability to finely tune motor speeds according to specific tasks optimizes processes, enhancing overall operational efficiency.

Functions of Frequency Converters:

Frequency converters perform various functions crucial for their operation. They control the frequency of the electric power supplied to the motor, thereby regulating the motor's speed. Moreover, these devices can convert input power into varying voltage and frequency outputs, enabling versatility in powering different types of motors. They also include protective mechanisms to monitor motors for overloads or faults, safeguarding against potential damages. Additionally, frequency converters are equipped with efficiency monitoring systems that track and optimize energy usage for improved operational efficiency.Check more on VDF Control Electric Hoist and Crane.

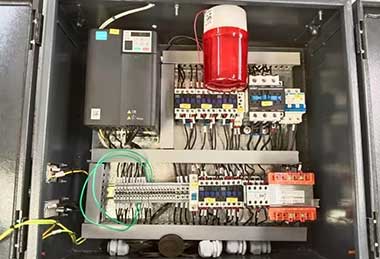

Electric panel

The electric panel of a variable speed wire rope hoist serves as a critical control center, housing electrical components and controls that manage the hoist's operation. Here's an overview of its main components and functions:

Components within the Electric Panel:

- Variable Frequency Drive (VFD): The heart of the panel, the VFD controls the motor's speed by adjusting the frequency and voltage of the electrical supply. It enables smooth speed modulation essential for variable speed operation.

- Control Circuitry: This includes the control buttons, switches, or touch panel interface that allows operators to initiate and regulate hoisting operations, adjust speeds, and control directions (up/down).

- Safety Devices: The electric panel often integrates various safety features like emergency stop buttons, overload protection, limit switches, and phase protection to ensure safe and secure hoisting operations.

- Power Supply Components: Transformers, contactors, and circuit breakers manage power distribution, regulate voltages, and protect the hoist and its components from electrical faults.

- Monitoring and Display Systems: Some panels include digital displays, indicator lights, or screens that provide real-time information about the hoist's status, load capacity, and warnings for safer operations.

Functions of the Electric Panel:

- Speed Control: The VFD within the electric panel regulates the motor's speed, allowing smooth and precise adjustments for various lifting requirements.

- Safety Management: It houses safety features and emergency stop systems that instantly halt operations if any unsafe conditions or overloads are detected.

- Control Interface: Operators use the control panel to start, stop, and control the hoist's movement, including lifting and lowering functions, as well as direction and speed adjustments.

- Monitoring and Diagnostics: The panel provides crucial data on the hoist's performance, such as load status, motor parameters, and potential issues, aiding in maintenance and troubleshooting.

- Power Distribution: It manages and distributes electrical power to the hoist's components, ensuring reliable and efficient operation while safeguarding against electrical faults.

The electric panel serves as the nerve center of a variable speed wire rope hoist, facilitating safe, efficient, and controlled lifting operations through its diverse range of components and functionalities.

An overload limiter is a safety feature in lifting machines that stops them from lifting loads heavier than they're meant to. It does this by measuring the weight being lifted and comparing it to a set limit. When the weight nears or exceeds this limit, it triggers a warning, stops the lifting, or even shuts off the machine. This helps prevent accidents caused by lifting too much weight and keeps everyone safe.

The wire rope guide is a component designed to guide and control the wire rope's movement. It helps maintain the rope's alignment and prevents it from deviating from its intended path during lifting and lowering operations. The guide ensures that the wire rope wraps around the drum uniformly, minimizing the risk of rope slippage or jamming.

Wire Rope:

The wire rope is a key component responsible for lifting and supporting the load. It consists of multiple strands of metal wires twisted or braided together to form a strong and flexible rope. These ropes are typically constructed from high-strength steel wires that provide durability and resilience.

Functions of Wire Rope:

- Load Bearing: The primary function of the wire rope is to bear the weight of the load during lifting operations.

- Transmission of Force: It transmits the lifting force from the hoist's drum to the load being lifted.

- Flexibility and Strength: Designed for flexibility, durability, and high tensile strength to withstand heavy loads and repeated use.

Wire Rope Guide:

The wire rope guide is a component designed to guide and control the wire rope's movement. It helps maintain the rope's alignment and prevents it from deviating from its intended path during lifting and lowering operations. The guide ensures that the wire rope wraps around the drum uniformly, minimizing the risk of rope slippage or jamming.

Functions of Wire Rope Guide:

- Alignment: Guides the wire rope onto the hoist's drum in a controlled manner, ensuring it wraps uniformly without overlapping or crossing.

- Prevention of Rope Flapping: Helps prevent the wire rope from flapping or straying off its intended path, reducing the risk of damage or accidents.

- Enhanced Safety: A properly functioning guide contributes to safe and efficient hoisting operations by maintaining the rope's position and preventing potential hazards.

Both the wire rope and wire rope guide work in tandem to facilitate smooth and controlled lifting operations in wire rope variable speed hoists. Proper maintenance, inspection, and adherence to manufacturer guidelines are crucial to ensure the effectiveness and safety of these components during hoisting operations.

Advantages and Benefits of Variable Speed Hoists

Precision and Accuracy Achieved Through Variable Speed Control

Variable Speed Hoists offer a paramount advantage in the realm of material handling—precision and accuracy. The ability to regulate lifting speeds with finesse allows operators to execute intricate maneuvers and delicate handling tasks with pinpoint accuracy. This level of control ensures objects are lifted, positioned, and lowered exactly where required, reducing the margin for errors and optimizing operational efficiency.

Efficiency Enhancements in Material Handling Processes

The introduction of Variable Speed Hoists brings forth notable enhancements in efficiency within material handling operations. By providing adjustable lifting speeds, these hoists streamline workflows by accommodating different load characteristics and operational requirements. This adaptability minimizes downtime, improves productivity, and expedites material movement, resulting in overall operational efficiency gains.

Safety Advantages and Compliance with Industry Regulations

Safety is paramount in any material handling operation. Variable Speed Hoists contribute significantly to enhancing safety standards. Their incorporation of safety features, combined with precise control over lifting speeds, mitigates the risk of accidents and ensures compliance with stringent industry regulations. By allowing operators to execute controlled movements and adjustments, these hoists enhance workplace safety, protecting both personnel and assets.

Applications of Low Headroom and Wire Rope Variable Speed Hoists

Industrial Sectors Where Low Headroom Hoists Find Extensive Use

Low Headroom Variable Speed Electric Hoists are deployed across a spectrum of industries owing to their adaptability in confined spaces. Some key sectors where these hoists are extensively utilized include:

- Manufacturing Industry: From automotive assembly lines to electronics manufacturing, low headroom hoists facilitate efficient material handling in spaces with restricted vertical clearance, optimizing production workflows.

- Workshops and Maintenance Facilities: In maintenance areas and workshops, where space is limited, these hoist models enable technicians to handle equipment and conduct repairs with ease, maximizing operational efficiency.

Specific Applications and Tasks Optimized by Wire Rope Variable Speed Electric Hoists

Wire Rope Variable Speed Electric Hoists, renowned for their robustness and variable speed control, excel in various industrial tasks, including:

- Heavy Machinery Manufacturing: Their strength and precision make wire rope hoists indispensable in the production of heavy machinery, allowing for controlled and accurate handling of large components.

- Construction and Infrastructure Development: Within the construction sector, wire rope hoists shine in lifting and placing hefty construction materials precisely, contributing to project efficiency and safety.

Illustrating Their Effectiveness in Different Operational Environments

Real-world examples showcasing the effectiveness of both Low Headroom and Wire Rope Variable Speed Electric Hoists:

- Automotive Manufacturing: Low headroom hoists aid in streamlining operations in auto assembly plants, precisely lifting and positioning vehicle components in tight spaces.

- Mining Operations: Wire rope hoists play a pivotal role in mining, efficiently hoisting heavy loads while offering controlled movements for mining equipment installation and maintenance.

The versatility and efficiency demonstrated by Low Headroom and Wire Rope Variable Speed Electric Hoists across diverse industrial settings underscore their indispensable role in optimizing material handling operations.

Considerations When Choosing Between Low Headroom and Wire Rope Variable Speed Hoists

Selecting the appropriate hoist type—be it Low Headroom or Wire Rope Variable Speed Electric Hoists—requires meticulous consideration of several factors:

- Space Constraints: Assess the available vertical clearance in the intended working area to determine whether a low headroom hoist is essential for optimal space utilization.

- Load Characteristics: Evaluate the weight, size, and shape of the loads to be lifted, ensuring the hoist selected aligns with the load-bearing capacities and lifting requirements.

- Suitability for Diverse Load Characteristics and Lifting Requirements

Both Low Headroom and Wire Rope Variable Speed Electric Hoists offer unique advantages catering to distinct load characteristics and lifting requirements:

- Low Headroom Hoists: Ideal for environments with limited vertical space, they provide optimal maneuverability in tight spaces without compromising lifting capacities.

- Wire Rope Hoists: Suited for handling heavier loads with precision, these hoists offer exceptional strength and control for applications demanding robust lifting solutions.

- Practical Aspects to Ponder Before Implementing These Hoists in Various Settings

Before deploying Low Headroom or Wire Rope Variable Speed Electric Hoists in specific settings, certain practical aspects should be taken into account:

- Operational Compatibility: Ensure that the hoist type aligns with the operational demands and tasks expected within the intended working environment.

- Installation and Maintenance: Assess the installation requirements and maintenance protocols, considering the ease of installation and ongoing upkeep to optimize hoist performance.

These factors serve as guiding principles in determining the most suitable hoist type—Low Headroom or Wire Rope Variable Speed Electric—for different operational contexts and load handling needs.

Case Studies and Real-World Applications

Automotive Manufacturing Plant

An automotive manufacturing plant faced space constraints on its assembly lines, hindering the smooth flow of operations. By integrating Low Headroom Variable Speed Electric Hoists, the plant achieved remarkable improvements. These hoists efficiently handled vehicle components in confined spaces, enabling precise positioning while maintaining uninterrupted production flow. The implementation resulted in a significant reduction in downtime, enhancing overall productivity.

Mining Operations

A mining company utilized Wire Rope Variable Speed Electric Hoists for various tasks, including equipment installation and maintenance underground. These hoists effectively managed heavy loads while providing operators with fine control over lifting speeds, ensuring precise movements in challenging environments. The hoists' robust build and adjustable speed capabilities significantly contributed to operational efficiency and safety compliance.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch