4 Main Types of European-Style Electric Wire Rope Hoists

4 Types of European-Style Electric Wire Rope Hoists: Monorail, Double Rail, Foot Mounted, Standard Headroom – Choose Right Electric hoist 1 ton to 80 Ton!

| Electric Hoist | European Style Electric Wire Rope Hoist |

| Monorail Hoist | 1-20 ton |

| Double Rail Trolley | 3 to 80 ton |

| Lifting Height | As your request |

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

4 Main Types of European-Style Electric Wire Rope Hoist Configurations

Selecting the Right Hoist for Your Crane

Hot Sale 4 Types of Electric Hoists European Style

European-style electric wire rope hoists are widely used in industries for lifting and moving heavy loads. They are known for their durability, precision, and efficiency. However, not all hoists are the same, and choosing the right one is essential for smooth operations.4 Types of European-Style Electric Wire Rope Hoist Configurations: Monorail Low Headroom, Double Rail Trolley, Foot-Mounted, and Standard Headroom – Selecting the Right Hoist for Your European Style Adanced Overhead Cranes and Gantry Cfranes.

Why Choosing the Right Hoist Matters

Picking the right hoist configuration ensures:

- Maximum efficiency – Proper hoist selection helps optimize space and lifting height.

- Safety – Using the right hoist reduces the risk of mechanical failures and accidents.

- Cost-effectiveness – The right choice prevents unnecessary wear and tear, reducing maintenance costs.

What You'll Learn

This guide covers:

- The four main types of European-style electric wire rope hoists.

- How each configuration works and where it's best suited.

- Key factors to consider when selecting a hoist for your crane.

Overview of the 4 Main Hoist Configurations

Different crane setups require different hoist configurations. The right choice depends on factors like available space, lifting height, and operational needs.

Each hoist type is designed for specific applications:

Low-Headroom Monorail Hoist (NR)

Normal Headroom Monorail Hoist (NRS)

Foot-Mounted Hoist (NRT)

Double-Rail Trolley Hoist (NRT)

- Low-Headroom Monorail Hoist (NR) – Best for spaces with height restrictions, allowing maximum lifting height.

- Normal Headroom Monorail Hoist (NRS) – A standard option for general-purpose lifting.

- Foot-Mounted Hoist (NRT) – A stationary hoist used in fixed positions, ideal for maintenance or production setups.

- Double-Rail Trolley Hoist (NRT) – Designed for double-girder cranes, offering high stability for heavy loads.

Choosing the right configuration ensures smooth operations, prevents unnecessary wear, and maximizes efficiency. In the next sections, we'll take a closer look at each hoist type and its best applications.

Low-Headroom Monorail Electric Hoist (NR)

The low-headroom monorail hoist is designed for spaces with limited overhead clearance. Unlike standard hoists, it is mounted directly on the bottom flange of the main beam, allowing it to maximize lifting height. This makes it an ideal solution for workshops, warehouses, and production areas where space is restricted but efficient lifting is essential.

Why Choose This Hoist?

- Maximizes lifting height – Ideal for low-ceiling environments.

- Compact design – Saves space while maintaining lifting capacity.

- Smooth and stable operation – Ensures precise load handling.

Best Applications:

- Factories and workshops with height constraints.

- Warehouses needing efficient vertical lifting.

- Facilities where every inch of lifting height matters.

Key Components:

- Hoisting mechanism – Controls the lifting and lowering of loads.

- Rope anchorage – Secures the wire rope for safe operation.

- Hook – Attaches securely to the load.

- Standing pulley system – Guides the wire rope for smooth movement.

- Traveling mechanism – Moves the hoist along the beam.

- Conductive frame – Provides proper electrical connectivity.

- Electrical box – Houses the controls for safe operation.

This hoist is an excellent choice when you need to lift efficiently in tight spaces. It provides reliability, smooth movement, and optimal use of available height.

Normal Headroom Monorail Electric Hoist (NRS)

The normal headroom monorail hoist is a standard design used for general-purpose lifting. It is mounted on a single beam and provides a balanced combination of lifting height and versatility. Unlike the low-headroom hoist, it does not maximize hook travel but offers smoother operation and easy installation in various industrial settings.

Why Choose This Hoist?

- Reliable for general lifting tasks – A common choice for many industries.

- Moderate lifting height – Works well in spaces where height is not a major constraint.

- Simple and efficient design – Ensures easy maintenance and long-term durability.

Best Applications:

- Factories and warehouses with standard ceiling height.

- Production lines where loads need to be moved along a fixed path.

- Workshops requiring a durable and versatile lifting solution.

Key Components:

- Traveling mechanism – Moves the hoist along the beam for smooth operation.

- Hoisting mechanism – Lifts and lowers loads with precision.

- Electrical box – Houses control systems for safe and efficient operation.

- Rope wedge device – Secures the wire rope in place for stable lifting.

- Standing pulley system – Helps guide the rope and control movement.

- Hook assembly – Provides a secure connection to the load.

This hoist is ideal for general lifting needs, offering a balance between height, capacity, and ease of use. It is a cost-effective and reliable choice for many industrial applications.

Foot-Mounted Electric Hoist (NRT)

The foot-mounted electric hoist is a fixed-position lifting solution designed for stationary applications. Unlike traveling hoists, it remains securely mounted in one place, making it ideal for lifting tasks that do not require horizontal movement. This hoist is commonly used in maintenance areas and factory setups where loads need to be lifted but not transported along a beam.

Why Choose This Hoist?

- Ideal for fixed lifting operations – No need for rail or beam travel.

- Stable and reliable – Mounted securely for heavy-duty applications.

- Lower maintenance needs – Fewer moving parts reduce wear and tear.

Best Applications:

- Maintenance stations for lifting machinery or components in place.

- Factory setups where a fixed hoist is needed for assembly or repair.

- Heavy-duty lifting points where movement along a track is unnecessary.

Key Components:

- Lifting mechanism – Powers the hoist to raise and lower loads smoothly.

- Rope anchorage – Secures the wire rope for safe and stable operation.

- Standing pulley system – Guides the wire rope to ensure smooth lifting.

- Hook assembly – Provides a strong and secure connection to the load.

- Link beam – Supports the hoist and ensures structural stability.

This electric hoist is the perfect choice when horizontal movement is not required, offering stability, durability, and efficient lifting for fixed applications.

Double-Rail Trolley Electric Hoist (NRT)

The double-rail trolley electric hoist is designed for use with double-girder cranes, offering high stability and impressive load capacity. This type of hoist is perfect for heavy-duty lifting tasks in environments like workshops and factories where high performance and reliability are essential. The double-rail system provides superior stability and enables the hoist to handle larger, heavier loads with ease.

Why Choose This Hoist?

- High stability – The double-rail design ensures smooth movement and load control.

- Ideal for heavy-duty applications – Can handle larger and heavier loads without compromising performance.

- Efficient for large-scale operations – Suitable for workshops and factories with high lifting demands.

Best Applications:

- Factories requiring lifting of heavy machinery, materials, or equipment.

- Workshops where high stability is needed for handling large, bulky loads.

- Industrial environments needing a hoist capable of handling demanding lifting tasks.

Key Components:

- Lifting mechanism – Powers the hoist to lift and lower heavy loads.

- Rope anchorage – Secures the wire rope for smooth, stable operation.

- Standing pulley system – Guides the rope for precise lifting and lowering.

- Hook – Connects securely to the load for safe handling.

- Trolley frame – Supports the hoist and ensures smooth movement along the rails.

- Traveling mechanism – Moves the hoist along the double-rail system.

- Conductive frame – Provides electrical power to the hoist for reliable operation.

This electric hoist is ideal for heavy-duty, high-stability lifting needs, providing efficient performance for demanding industrial applications.

How to Select the Right Electric Hoist for Your Crane

Selecting the right hoist configuration for your crane involves considering multiple factors to ensure optimal performance, efficiency, and safety. Here's how to approach the decision-making process:

Crane Type: Single-Girder vs. Double-Girder

- Single-Girder Cranes: These are typically paired with low-headroom or normal headroom monorail hoists. They're great for spaces with moderate lifting needs and are ideal for lighter loads.

- Double-Girder Cranes: For heavy-duty applications, a double-rail trolley hoist is more suitable. These provide superior stability and support larger loads, making them ideal for workshops and factories that handle heavy lifting.

low headroom electric hoist single girder overhead crane

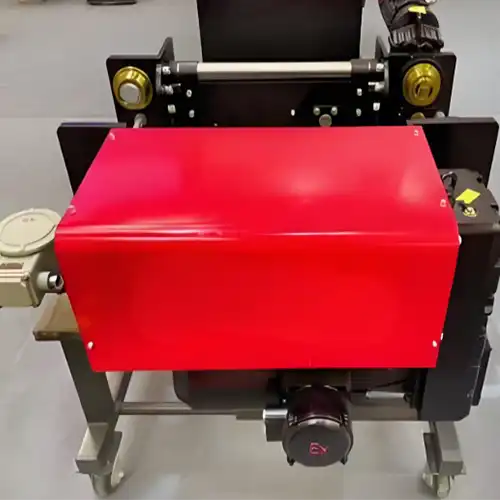

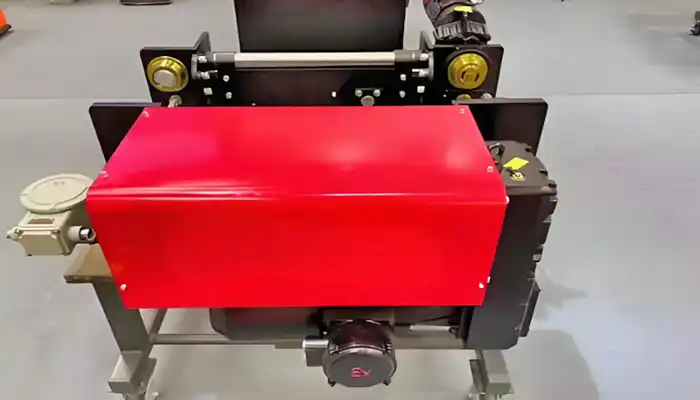

double rail electric hoist trolley for European style double girder overhead crane

Lifting Height Requirements: Low-Headroom vs. Normal Headroom

- Low-Headroom Solutions: If your space has limited ceiling height, opt for a low-headroom monorail hoist. This configuration maximizes the available lifting height, making it perfect for tighter spaces.

- Normal Headroom Solutions: In environments with standard ceiling height, a normal headroom monorail hoist offers a practical solution for general-purpose lifting without compromising on performance.

Space Constraints and Installation Flexibility

- Limited Space: If you have restricted space, the low-headroom monorail hoist is ideal for maximizing vertical lifting height while minimizing the footprint.

- Larger Workspaces: For larger spaces, consider normal headroom or double-rail trolley hoists, which provide more flexibility in terms of load movement and stability. These options are easier to install in expansive areas and require less maintenance.

Load Capacity and Duty Cycle

- Light-Duty Applications: For occasional lifting or lighter loads, consider a foot-mounted hoist or normal headroom hoist. These are cost-effective and provide adequate capacity for moderate use.

- Heavy-Duty Applications: For continuous, heavy lifting, choose a double-rail trolley hoist. This type of hoist is designed for high capacity and extended duty cycles, offering durability and strength for demanding operations.

Monorail electric hoist for light duty crane

Double rail trolley hoist for heavy duty crane

Environmental Conditions

- Cold Environments: For operations in cold storage or outdoor areas, select a hoist with specialized lubrication and motor protection. These features ensure that the hoist operates efficiently even in harsh, low-temperature conditions, preventing mechanical failures caused by freezing.

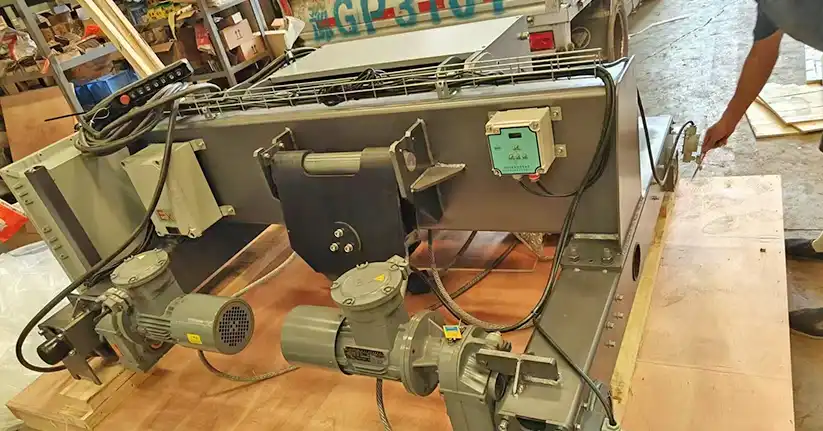

Explosion proof electric hoist

By evaluating these factors, you'll be able to choose the perfect hoist configuration for your crane, ensuring that it meets the specific demands of your operation while maintaining efficiency and safety.

Conclusion

In summary, choosing the right electric wire rope hoist configuration is crucial for ensuring optimal performance, safety, and efficiency in your lifting operations. Here are the key takeaways:

- Crane Type: Match your hoist to the crane type—single-girder cranes work well with low-headroom or normal headroom monorail hoists, while double-girder cranes are best paired with double-rail trolley hoists for heavy-duty tasks.

- Lifting Height: Consider your space limitations. Low-headroom hoists maximize lifting height in confined spaces, while normal headroom hoists are suited for standard height environments.

- Load Capacity and Duty Cycle: Ensure your hoist can handle the expected load and frequency of use. For lighter tasks, a foot-mounted hoist or normal headroom hoist suffices, while double-rail trolley hoists are necessary for heavy-duty, continuous operations.

- Space and Installation: Choose a hoist configuration that fits your space. Low-headroom hoists are ideal for tight spaces, while normal headroom and double-rail trolley hoists offer more flexibility in larger areas.

- Environmental Conditions: In cold environments, opt for hoists with specialized lubrication and motor protection to ensure reliable performance in harsh weather.

Final Recommendations

- For spaces with limited height, go for a low-headroom monorail hoist to maximize available lifting space.

- For general-purpose, moderate-duty applications, choose a normal headroom monorail hoist.

- For heavy-duty lifting, especially in large factories or workshops, a double-rail trolley hoist is the best option due to its high load capacity and stability.

- Consider environmental factors like temperature and space constraints to ensure the hoist is tailored to your specific operational needs.

By carefully evaluating these factors, you can confidently select the most suitable electric wire rope hoist configuration that will maximize performance, safety, and efficiency for your lifting operations.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch