Explosion-Proof Wireless Remote Controllers for Safe Hoisting

Explosion proof hoist crane remote control. Enhance safety & precision in hazardous environments with advanced explosion-proof wireless remote controllers.

Category: Crane Kit Parts

Your Trusted Explosion Proof Overhead Crane Manufacturer & Supplier

Explosion-Proof Wireless Remote Controllers for Sale

Safe Wireless Remote Controllers for Hoists and Cranes in Hazardous Environments

Enhance safety and precision in hazardous environments with advanced explosion-proof wireless remote controllers for cranes and hoists.

Explosion proof Wireless Remote Controllers

What Are Explosion-Proof Wireless Remote Controllers? Explosion-proof wireless remote controllers are specially designed devices or crane controllers that allow operators to safely and efficiently control electric hoists and cranes in hazardous environments. These controllers are built to prevent sparks or other ignition sources that could trigger fires or explosions in areas with flammable gases, vapors, or dust.

Why Are They Important in Hazardous Environments?

- Safety First: Traditional control methods, like wired systems or manual operation, expose workers to unnecessary risks in dangerous areas. Wireless remote controllers provide a safer alternative by enabling control from a distance.

- Enhanced Efficiency: Operators can manage equipment quickly and precisely, reducing downtime and increasing productivity.

- Compliance: These systems meet strict safety standards required for operations in hazardous locations, ensuring regulatory compliance.

Key Industries That Rely on These Systems

Explosion-proof wireless remote controllers are essential in industries where safety is critical:

- Oil and Gas: Used on offshore rigs, refineries, and storage facilities where flammable gases are common.

- Chemical Processing: Ideal for plants handling volatile chemicals and materials.

- Mining: Safeguard operations in environments with explosive dust or gases.

- Paint and Coating Factories: Prevent ignition in areas with flammable vapors.

- Other Hazardous Environments: Coal mines, flour mills, and aircraft maintenance facilities.

With their ability to combine safety, efficiency, and compliance, explosion-proof wireless remote controllers are indispensable for industries operating in hazardous environments.

Why Choose Explosion-Proof Wireless Remote Controllers?

Enhanced Safety Standards for Hazardous Environments

Explosion-proof wireless remote controllers are specifically designed to meet the safety demands of flammable and explosive environments. Their advanced engineering minimizes the risk of sparks or ignition, making them ideal for handling equipment in areas with volatile gases, vapors, or dust. These systems act as a crucial line of defense in protecting workers and equipment.

Eliminating Physical Proximity Hazards

With wireless technology, operators can control electric hoists and cranes from a safe distance. This eliminates the need for workers to be physically close to hazardous zones, reducing the risk of exposure to harmful substances, sudden equipment failures, or environmental dangers like gas leaks or explosions.

Compliance with Global Safety Standards

Explosion-proof controllers adhere to stringent international safety certifications, including:

- GB3638.1 and GB3836.4: Standards for explosion-proof equipment in flammable and explosive atmospheres.

- EXiBII BT4 Certification: Ensures intrinsic safety for use in highly volatile environments.

These certifications guarantee that the devices are rigorously tested and reliable, giving businesses peace of mind when operating in hazardous areas.

By prioritizing safety, reducing physical risks, and ensuring compliance with global standards, explosion-proof wireless remote controllers are a vital choice for industries requiring both precision and protection.

EF-24 Explosion-Proof Crane Radio Remote Control System Transmitter

Models Available: EF24-6S/D, EF24-8S/D, EF24-10S/D, EF24-12S/D

Model Code: EF24-TX

Item Code: 924-400-001

Dimensions: 186 x 61 x 51 mm

Weight: 280g (without batteries)

Transmitter Specifications: EF24-TX

- Material: Glass-fiber reinforced PA

- Enclosure Protection Rating: IP65

- Frequency Range:VHF: 310-331 MHz, UHF: 425-446 MHz

- Transmission Power: ≤ 10 dBm

- Power Source: 4 AA batteries

- Safety Code: 32 bits (4.3 billion unique codes)

- Operating Temperature Range: -40℃ to 85℃

- Control Range:Standard: 100 meters, Customizable up to 200 meters

Key Features:

- 10 double-step pushbuttons, Emergency Stop, Start Key, and spare buttons

- 20 control contactors for versatile operation

- Low battery warning system that cuts off power during low voltage

- Safety key switch to prevent unauthorized access

- Programmable button functions via computer interface

- Configurable interlock settings for Up/Down, East/West, and North/South directions

- Programmable start key for customized functions such as start, toggle switch, or normal

- Spare buttons can be programmed for various functions like start, toggle, or interlock

This transmitter ensures reliable and safe control in demanding environments, providing flexibility for custom functionality and operation.

Standard Configuration Details:

- Transmitter (with hanging belt): The transmitter is designed for easy handling, equipped with a durable hanging belt to ensure operators can securely hold and operate it during tasks. This feature adds convenience and prevents accidental drops in challenging environments.

- Dust Protection Bag: A dust bag is included to safeguard the transmitter from dust and environmental debris. This helps maintain the functionality and longevity of the equipment, especially in industries with high levels of airborne particles.

- Receiver: The receiver is a robust component responsible for receiving signals from the transmitter. It is designed to be durable, offering reliable performance even in hazardous conditions.

- Receiver Cable (1.6 meters): The receiver comes with a 1.6-meter cable, offering flexibility for positioning and easy integration into existing crane systems or hoist setups. The length of the cable allows for efficient setup in most operational environments.

- Batteries (One pair): A pair of batteries is included to power the transmitter. The batteries are designed for extended usage, providing consistent operation in critical environments. Their energy-efficient design helps to extend the operational time between charges or replacements.

- Receiving Antenna: The system includes a receiving antenna, which ensures stable and uninterrupted wireless communication between the transmitter and receiver, even in areas with high interference.

- Operation and Maintenance Manual: A detailed manual is provided, offering clear instructions for both operation and routine maintenance. This ensures that users can quickly familiarize themselves with the system and take necessary steps to keep it functioning at its best.

This complete set-up ensures that the explosion-proof crane radio remote control system is fully equipped for optimal use in hazardous environments, providing safety, durability, and long-term reliability.

EF-24 Explosion-Proof Crane Radio Remote Control System Receiver

- Model: EF24-RXC

- Item Code: 924-100-103

- Dimensions: 210 x 162 x 107 mm

- Weight: 1220 g

Receiver Specifications: EF24-RXC

- Material: Glass-fiber reinforced PA

- Protection Rating: IP65 enclosure for dust and water resistance

- Frequency Range:VHF: 310-331 MHz, UHF: 425-446 MHz

- Sensitivity: -110 dBm

- Power Supply Options:Standard: 18-65V AC/DC, Optional: 65-440V AC/DC

- Contactor Capacity:8A sealed relay output, AC 250V/10A relays with a 10A fuse

- Control Range:Approx. 100 meters (upgradable to 200 meters upon request)

- Safety Code: 32 bits, providing over 4.3 billion unique combinations

- Temperature Range: Operates efficiently between -40℃ and 85℃

Safety of Receiver Operation

The EF24-RXC receiver is designed to provide the highest level of safety in hazardous environments, following stringent international standards and safety protocols:

- Explosion-Proof Design: The receiver is housed in an explosion-proof casing that ensures protection against potential sparks or other ignition sources, effectively safeguarding the internal electronics. The design is fully compliant with ATEX (ATmosphères EXplosibles) regulations, making it suitable for use in explosive atmospheres.

- Inner Circuit Safety: The internal electronic circuitry of the receiver is optimized for safety. With a robust safety solution, it is engineered to prevent any failures or malfunctions that could lead to hazardous situations. The system uses advanced safety measures to ensure stable and secure operation in environments where risk factors are heightened.

- Compliance with Explosion-Proof Standards: The receiver strictly adheres to global explosion-proof standards, providing a reliable solution for industrial applications in hazardous locations. The casing and electronic design comply with both ATEX and IECEx safety standards, ensuring safe operation in flammable environments.

- Emergency Stop Circuit: In case of an emergency, the receiver is equipped with a dedicated emergency stop (E-stop) circuit. The emergency stop function is supported by redundant safety relays that are mechanically linked (forcibly guided). This ensures that if one relay fails, the system can still stop safely, meeting the E-stop class Gat.3 in the European mechanical equipment standard. This feature provides peace of mind by ensuring the system will perform its emergency function even if part of the relay system fails.

- Redundant Communication: Continuous, uninterrupted wireless communication is essential for safety. The receiver is equipped with built-in fail-safes to automatically stop operation if the radio signal is lost or if there is interference. This passive stop mechanism ensures that the equipment ceases operation as soon as any disruption in communication is detected, avoiding potential accidents caused by loss of control.

- Programmable Interlock Functionality: To further enhance safety, the receiver allows for the programming of button functions to create interlocks. This feature ensures that certain operations cannot be performed simultaneously or in opposing modes (such as lifting and lowering at the same time). By programming these interlocks, the system reduces the risk of operator errors and prevents potentially dangerous conflicting operations from occurring.

These safety features combine to provide a robust and reliable solution for crane and hoist control in hazardous environments, making the EF24-RXC receiver one of the safest options available on the market.

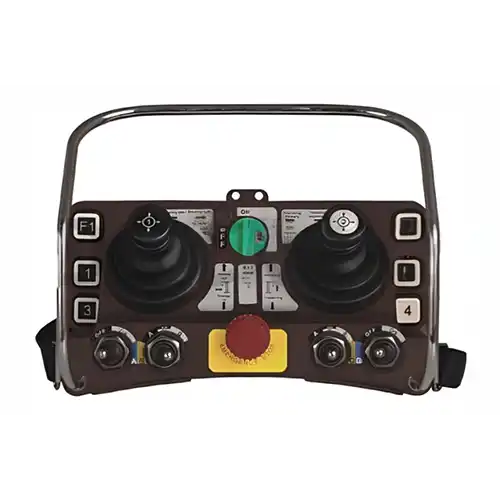

Explosion-Proof Crane Joystick Radio Remote Control System - EF24-60 Transmitter

Model: EF24-60-TX

Item Code: 924-600-002

Dimensions: 210 x 152 x 128 mm

Weight: 980g (without batteries)

Transmitter Specifications: EF24-TX

- Material: Glass-Fiber Reinforced PA

- Enclosure Protection: IP65, ensuring dust and water resistance for reliable outdoor operation.

- Frequency Range:VHF: 310-331 MHz,UHF: 425-446 MHz,

- Transmitter Power: ≤ 10 dBm

- Power Supply: 4 AA batteries

- Safety Code: 32-bit (over 4.3 billion codes), ensuring secure communication.

- Temperature Range: Operates effectively between -40℃ and 85℃

- Control Distance: Approx. 300 meters (with an option for 200 meters customized range)

Key Features:

- Control Buttons: 6 pushbuttons, 4 rotating switches (3-position or 2-position), emergency stop, start, and spare buttons for emergency situations.

- Joystick Control: Dual 5-step joysticks with a mechanical lifespan of 10 million cycles, providing proportional control for smooth and precise adjustments.

- Control Contacts: Supports up to 40 control contacts, offering flexibility for complex operations.

- Battery Voltage Warning: Alerts when battery power is low, automatically cutting off the power supply to prevent unsafe operation.

- Safety Key Switch: Prevents unauthorized access, ensuring only approved personnel can operate the system.

- Programmable Buttons: Buttons can be customized via a computer interface to assign different functions, such as interlocking or toggling.

- Versatile Start Key: The start key can be programmed for multiple operations such as toggling or normal starting.

- Spare Buttons: Additional buttons can be programmed for functions like start, toggle, interlock, or normal operations.

- Optional Proportional Module: Equipped with an optional proportional module for analog signal output, enhancing control for specific applications.

Standard Package Contents:

- 1 Transmitter (with Waist Belt): A lightweight and ergonomically designed transmitter for comfortable operation, even during extended use. It comes with a waist belt for hands-free convenience, ensuring the operator can easily carry it while managing crane operations in hazardous environments.

- 1 Receiver with 2.5-Meter Cable: The receiver is built to withstand tough industrial conditions, featuring a durable construction and a 2.5-meter cable for flexible installation. This allows easy placement of the receiver within the designated operational area.

- 2 Pairs of Batteries: Two sets of high-capacity batteries are included, ensuring that the transmitter operates for an extended period without the need for frequent replacements. The batteries are designed for reliability, even in harsh conditions, and can be easily swapped when needed.

- 1 Receiver Antenna: A robust antenna is provided for optimal signal reception, ensuring a stable and reliable connection between the transmitter and receiver. It enhances the communication range and ensures uninterrupted control even in challenging environments.

- 1 Battery Box: The package includes a durable battery box designed to securely hold the transmitter's batteries, providing easy access for battery replacement or maintenance. It ensures that the power supply remains reliable and consistent.

- Operation and Maintenance Manual: A comprehensive manual is included to guide the user through the operation, setup, and maintenance procedures. This ensures that operators can efficiently manage the system and address any potential issues, maximizing the lifespan and performance of the transmitter and receiver.

This explosion-proof crane joystick radio remote control system is engineered to provide reliable and secure operation in hazardous environments. The system is equipped with advanced safety features, including redundant communication protocols, and is constructed for high durability, ensuring that it can withstand the rigors of industrial operations. Whether used in offshore oil fields, chemical plants, or other hazardous settings, the EF24-60 transmitter offers precise control for crane operations, helping to improve safety and efficiency.

EF24-60 Explosion-Proof Crane Radio Remote Control System Receiver

Model: EF24-60-RXC

Item Code: 924-100-103

Dimensions: 210 x 162 x 107 mm

Weight: 1220 g

Receiver Specifications: EF24-RXC

- Material: Glass-fiber reinforced PA for strength and durability.

- Enclosure Protection: IP65 rating, providing dust and water resistance for reliable outdoor use.

- Frequency Range:VHF: 310-331 MHz,UHF: 425-446 MHz

- Receiver Sensitivity: -110 dBm

- Power Supply:18-65V AC/DC, 65-440V AC/DC (optional)

- Output Contactor Capacity: 8A sealed relay output (AC 250V/10A relays, 10A fuse).

- Control Distance: Approximately 300 meters (customizable range of 200 meters available).

- Safety Code: 32-bit (over 4.3 billion possible codes) to ensure secure communication.

- Temperature Range: -40℃ to 85℃, ensuring reliable operation in extreme conditions.

- Antistatic Shell: Constructed with an antistatic material, incorporating an agent to maximize anti-static protection for safer operations in sensitive environments.

Safety Features

- Continuous Wireless Communication: The system ensures uninterrupted wireless communication between the transmitter and receiver, allowing operators to manage lifting equipment with precision and maintain a safe distance from hazardous areas.

- Reliable System Decoding: Utilizes a non-repeating 4.3 billion code system for secure decoding between transmitter and receiver, enhancing safety.

- Digital Communication Hamming Code: Incorporates a Hamming code for error correction, ensuring reliable signal transmission with a minimal information difference of 4, thereby ensuring secure and accurate control.

Safety Features of the Receiver

The EF24-RXC receiver is designed to meet the highest standards of safety, with a durable explosion-proof casing and internal electronic circuits that comply with ATEX regulations. This ensures the system operates safely in hazardous environments, reducing the risk of ignition.

Key safety elements include:

- Explosion-Proof Design: The receiver's casing and electronics are built to prevent any internal sparks or explosions from affecting the surrounding environment.

- Emergency Stop (E-stop): Equipped with a redundant safety relay and duplex control, ensuring the system meets the European mechanical equipment standard for emergency stop circuits (Class Gat.3).

- Wireless Communication: In case of signal loss or interference, the receiver automatically ceases operation, ensuring that no unintended movements occur during communication disruptions.

- Programmable Interlock: Buttons can be programmed to interlock, preventing contradictory actions and reducing the chance of operational errors.

These features make the EF24-RXC a reliable and safe choice for crane operation in explosive and hazardous environments.

Product Highlights

Safety Features

- Explosion-Proof Casing and Anti-Static Materials: Designed to withstand flammable and explosive environments, the casing minimizes ignition risks while the anti-static materials prevent static discharge.

- Emergency Stop Function with Redundant Safety Relays: Features a fail-safe design that includes duplex redundant circuits, ensuring a quick and reliable emergency stop.

- Continuous Wireless Communication: Ensures uninterrupted operation, with a passive stop feature that halts operations if signals are interfered with or disconnected, prioritizing safety at all times.

Durability and Environmental Adaptability

- Wide Temperature Range: Operates reliably between -40℃ to 85℃, making it suitable for extreme industrial environments.

- IP65 Enclosure Protection: Both transmitters and receivers are shielded against dust, water, and harsh weather conditions, ensuring long-lasting performance.

- Built to Last: Constructed with high-quality materials and robust components to endure the demands of challenging industrial applications.

Precision Control and Customization

- Programmable Buttons: Offers flexibility with options for interlocking, toggling, or standard functions, tailored to specific operational needs.

- Advanced Proportional Modules: Optional analog output modules allow for precise control over lifting and movement, enhancing performance.

- Extended Control Distance: Operates efficiently up to 300 meters, providing operators with safe and convenient remote access to equipment.

By combining safety, durability, and precision, these controllers offer unmatched reliability for industries operating in hazardous environments.

Applications

Versatile Integration with Lifting Equipment

Explosion-proof wireless remote controllers are designed to seamlessly integrate with various types of lifting equipment, including:

- Electric Hoists: Ideal for precise and safe material handling in hazardous environments.

- Overhead Cranes: Enhances safety and efficiency in large-scale lifting operations.

- Gantry and Jib Cranes: Provides remote operation for confined or high-risk industrial areas.

Industries Benefiting from These Systems

These controllers are indispensable in environments where safety is paramount due to flammable or explosive risks. Typical industries include:

- Offshore and Onshore Oil Fields: Ensures safe operation of lifting equipment during oil extraction and processing.

- Chemical and Petrochemical Plants: Handles materials and machinery with reduced risk in volatile environments.

- Coal Mines: Operates in areas prone to explosive gases and dust.

- Paint Factories: Safeguards against ignition risks in flammable vapor-laden atmospheres.

- Aircraft Maintenance Facilities: Allows safe handling of heavy parts and components in sensitive zones.

These systems provide unmatched safety, control, and adaptability across industries where traditional operation methods might pose significant risks.

Benefits of Explosion-Proof Wireless Remote Controllers

Increased Operator Safety

By enabling remote operation, these controllers keep operators at a safe distance from hazardous zones. This reduces exposure to risks such as flammable gases, explosive dust, or dangerous machinery, creating a safer work environment.

Improved Operational Efficiency and Precision

The controllers enhance efficiency by:

- Allowing operators to manage equipment from optimal vantage points.

- Supporting precise control with customizable functions, interlocking features, and proportional modules for analog signals.

This leads to smoother workflows and minimized human error during operations.

Regulatory Compliance and Reliability

With adherence to global safety standards like GB3638.1, GB3836.4, and EXiBII BT4, these controllers ensure compliance with industry regulations. Their robust design also delivers long-term reliability, even in the harshest environments, giving operators and businesses peace of mind.

Cost Savings

Explosion-proof wireless remote controllers help reduce costs in multiple ways:

- Minimizing equipment downtime through safer and more efficient operation.

- Lowering maintenance expenses with durable components and reduced wear and tear.

- Enhancing productivity, which leads to better utilization of resources.

These benefits make them an essential investment for businesses operating in hazardous environments.

How to Select the Right Model?

Choosing the ideal explosion-proof wireless remote controller involves understanding your specific operational needs. Here are the key factors to consider:

Number of Control Points

Evaluate the number of control points or contacts required for your application. Some models can accommodate up to 40 control contacts, making them suitable for complex equipment with multiple functions.

Environmental Challenges

Consider the specific environmental conditions in which the controller will operate, such as:

- Extreme Temperatures: Ensure the device supports a wide operating range, like -40°C to 85°C.

- Humidity Levels: Choose a controller with appropriate sealing, such as IP65-rated enclosures, to protect against moisture and dust.

- Corrosive or Explosive Atmospheres: Select models designed with anti-corrosion coatings and explosion-proof casings to withstand these environments.

Distance and Frequency Requirements

Determine the required range of operation:

- For large facilities, opt for models with control distances of up to 300 meters.

- Ensure compatibility with your equipment's operating frequency to prevent interference and maintain seamless communication.

By carefully evaluating these factors, you can ensure that the selected model aligns with your operational demands and safety requirements.

Installation and Maintenance Guidelines

Proper installation and maintenance of explosion-proof wireless remote controllers are essential for ensuring long-term reliability and safe operation in hazardous environments.

Key Steps for Safe Installation

- Read the Manual: Always begin by thoroughly reading the product manual for specific installation guidelines and safety precautions.

- Ensure Proper Grounding: Confirm that the transmitter and receiver are correctly grounded to prevent electrical hazards.

- Install in Suitable Locations: Position the transmitter and receiver in locations that avoid exposure to harsh weather or physical damage while maintaining good signal range.

- Use Explosion-Proof Housing: Always verify that the equipment is housed in explosion-proof enclosures, as specified by the product's safety certifications (e.g., EXiBII BT4).

- Verify Compliance with Standards: Ensure installation adheres to safety standards like GB3638.1, GB3836.4, and other applicable regulations for hazardous locations.

- Safety Checks: Conduct pre-operation safety checks to verify proper wiring, functionality, and signal integrity.

Routine Maintenance Tips

- Inspect for Wear: Regularly check the transmitter and receiver for any signs of wear or damage, especially in high-stress areas like buttons or antennae.

- Clean the Equipment: Use a clean, dry cloth to wipe down the surfaces of the controllers. Avoid using harsh chemicals or solvents that might damage the explosion-proof casing or anti-static properties.

- Battery Checks: Ensure the batteries are replaced as needed. Always use approved battery types to maintain safe and efficient operation.

- Test Emergency Stop Function: Periodically test the emergency stop button and safety relays to ensure they are functioning properly.

- Environmental Condition Monitoring: Regularly assess the operating environment (temperature, humidity, and dust levels) to ensure they are within the operational range for the equipment.

Troubleshooting Common Issues

- Loss of Signal: If communication is lost between the transmitter and receiver, check for physical obstructions or sources of interference (e.g., large metal structures or electronic devices).

- Non-Responsive Buttons: Ensure that the buttons are not physically obstructed or damaged. Check the transmitter's battery level and replace if necessary.

- Interference or Erratic Behavior: If the signal becomes unstable, verify that the transmitter and receiver are operating on the correct frequencies and that there is no nearby equipment causing interference.

- Reduced Range: If the effective range is reduced, inspect the antenna for any physical damage and ensure it is properly aligned.

Typical Applications of Explosion proof Controllers

Applications in Hazardous Industries

Offshore Oil Fields:

- An offshore oil drilling company required reliable, safe, and efficient control of overhead cranes to handle heavy loads and ensure safe operations in explosive environments.

- The EF24 Explosion-Proof Wireless Remote Control System was integrated with the cranes to enable operators to control equipment from a safe distance, minimizing exposure to potential hazards such as gas leaks or fires.

- The remote control systems allowed operators to work from safer positions, drastically reducing the risk of accidents. The explosion-proof design ensured compliance with industry safety standards, and the equipment continued to perform reliably under extreme weather and operational conditions.

Chemical Plants:

- A chemical processing plant faced challenges in controlling hoists and cranes while minimizing risks of exposure to hazardous chemicals and explosive gases.

- Explosion-proof wireless remote controllers were used to operate cranes handling chemical containers, with the added benefit of programmable buttons to prevent accidental operations.

- The system enhanced operational safety by keeping workers at a safe distance from potentially dangerous processes, while the emergency stop function provided an added layer of security in case of equipment malfunction. The explosion-proof features ensured that the system met the strict requirements of the chemical industry.

Coal Mines:

- A coal mining company needed a robust crane control system to handle heavy materials in an environment filled with dust and volatile gases.

- The EF24 explosion-proof system was adapted to the mine's overhead and gantry cranes, offering remote control of hoisting operations without risking operator safety in such a hazardous setting.

- Increased operational efficiency and operator safety were achieved as workers were able to manage crane functions from a safe distance, minimizing exposure to the dangers of the mining environment.

Conclusion

The explosion-proof wireless remote controllers for electric hoists and cranes are designed to provide unmatched safety, durability, and efficiency in hazardous environments. These wireless remote control systems are specifically engineered to meet the demands of the most challenging and hazardous industries. Whether in offshore oil fields, chemical plants, coal mines, or aircraft maintenance facilities, the systems ensure that operations are carried out safely, efficiently, and in full compliance with stringent safety regulations. The rugged, explosion-proof design minimizes downtime and maintenance costs while providing enhanced control and precision for operators.

Ready to upgrade your explosion proof hoist and crane operations with the safest and most reliable explosion-proof wireless remote controllers? Contact us today to learn more about how our solutions can enhance your operations. Request a detailed quote and discover the perfect system for your unique material handling requirement.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch