Single Girder Ladle Hoist Specification 2 Ton, 3 Ton, 5 Ton, 10 Ton

Ladle hoist for single girder ladle crane for hot ladle handling for metallurgical use. Check ladle hoist specifications of 2 ton, 3 ton, 5 ton, 10 ton.

| Hoist type | Electric wire rope hoist for single girder ladle crane |

| Hoist capacity | 0.25 ton -10 ton, customized up to 16 ton, single girder hoist |

| Lifting Height | 6m - 20m |

| Working Class | M3 |

Category: Hoist and Crane Specifications

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Single Girder Ladle Hoist Specification 2 Ton, 3 Ton, 5 Ton, 10 Ton

Hot Ladle Handling for Metallurgical Use

The metallurgical use ladle hoist is a specially built high temperature electric wire rope hoist with high safety, adopting dual brake, double spacing, insulation boards, and other protection devices to ensure the high temperature material handling crane safety in the hazardous application conditions, such as the metallurgical casting workshop where hot molten metal ladles and solid hot metals required safety handling.

Electric hoist for a single girder ladle crane with a lifting capacity of 1–10 tons, a lifting height of 9–30 meters, a medium working duty M5, and the the non-standard ladle handling electric wire rope hoists are available designed based on your lifting requirements and application conditions.

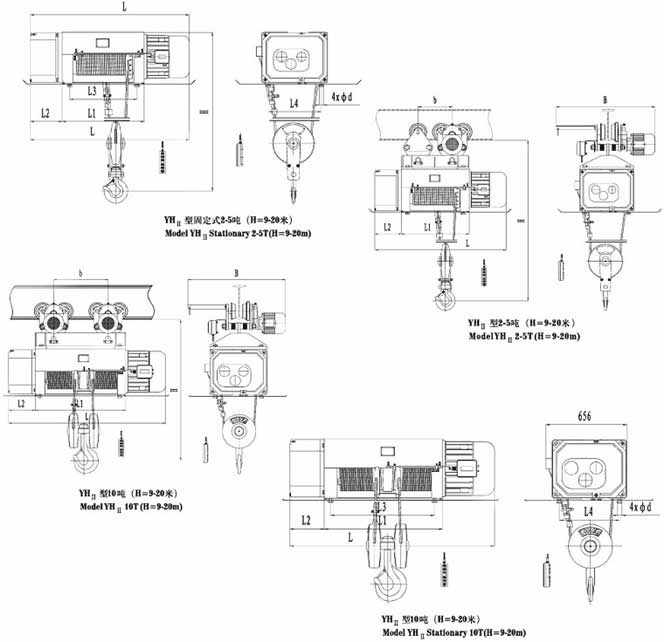

Light duty wire rope ladle hoist 2 ton -5 ton

Electric hoist trolley travelling electric wire rope ladle hoist

Heavy duty electric trolley travelling ladle hoist 10 ton

Application of ladle hoist

- General use ambient temperature of wire rope ladle hoist : -10℃~+60℃, moisture:≤85%. 380V, 50Hz, 3 phases is applied to the condition of 40℃, moisture ≤50%, altitude below 1000m. Beside, the ladle hoist also can be customize according to customers' requirements.

- The ladle hoist is applied to moving hot, solid objects, such as molten metal or other items.

- The ladle hoist can be used as the lifting mechanism of the single girder crane, single girder suspension crane and double girder with hoist crane. When set up on the fixed overhead track, the electric ladle hoist can also be used independently.

- The construction of electric wire rope hoist complies with the national standard (No. 2007 375 Document) set forth by AQSIQ. It is a specialized lifting equipment that is both safe and popular in small and medium-sized metallurgical workplaces for ladle handling with capacity from 0.25 ton to 10 ton.

Main Parts & Characteristics

Lifting Mechanism

Lifting Motor

- The motorized hoist for ladle handling adopts a conical brake asynchronous motor with a high starting torque, with a insulation class of H.

- The hoisting motor has an overheat protection device installed.

- Smooth operation, diminutive size, and light weight.

- ZDD type for double speed and ZD type for single speed motors. The ZDD motor's normal to low speed ratio is 4:1.

Reducer

- Long-lasting three-level dead axle with helical gear rotating body.

- Axle and gear are made of high intensity alloy steel after heat treatment.

- Box and cover are made of premium cast iron and are completely covered.

- lGreat speed ratio, high accuracy.

- Compact design, quiet operation, and high effectiveness.

- lEasily assemble and disassemble.

Drum

- Equipped with an emergency safety brake system,purely mechanical safety brake with no electrical influence.

- Others are the same as an general use cd/md electric wire rope hoist.

Hook

- Forged from special steel, the thrust ball bearing is connected to the casing via the hook and beam, allowing the hook to move freely.

- No more than 5 ton for a single pulley hook; no more than 10 ton for a double pulley hook.

- High security, safety buckle, and a mouse hook.

Wire Rope

- Metal core wire rope are used on the ladle hoist with high safety and dependability.

Travelling Mechanism

- The ladle hoist's traveling mechanism consists of an electric trolley, a traveling reducer, a traveling motor, a driven trolley, and other components. The mechanism moves in a reciprocating motion thanks to the main engine, which is powered by a side plate and a drum.

- When used with a box type girder or a H beam, the wheel tread is straight.

- When used with an I-beam, the wheel tread has a circular arc.

- Its travel speed is 20m/min, but 30m/min is possible; if 15 ton capacity with a lifting height of 12m or higher, a driven trolley is required.

Electrical Equipment

- Equipped with safety features such as double brakes, double limit, heat shield, and so on.

- Equipped with safety features such as double brakes, double limit, heat shield, and so on.

- contactor error protection.

- Others same as cd/md wire rope electric hoist

Electric Ladle Hoist Classification & Specification

Ladle hoist

Casting shop ladle handling hoist is used for hot metal & ladle handling in steel & metallurgic industries. 2 ton, 3 ton, 5 ton & 10 ton ladle hoist crane for sale.

- Hoist Type: YH metallurgic hot metal & ladle hoist

- Hoist Capacity of Ladle Hoist: Up to 10 ton

- Lifting Height of Ladle Hoist: 6~20m

- Working Class of Ladle Hoist: m3

Features of electric wire rope hoist for ladle handling, cost-effective ladle hoist

- Protection functions include double braking, double spacing, a heat insulation plate, and other features

- Install a collision prevention device as well as a sound and light alarm.

- Compact structure and rational design, simple installation, and high efficiency

Single speed metallurgical ladle hoist parameter

Single speed metallurgical ladle hoist parameter

Model | YH type ladle hadling electric wire rope hoist | |||||||||

Capacity | Tons | 0.25 | 0.5 | 1 | 2 | 3 | 5 | 10 | 16 | |

Hoisting height | M | 3,6,9 | 6,9,12 | 6,9,12,18,24,30 | 9,12,18,24,30 | |||||

Hoisting speed | M/MIN | 8 | 8 | 8 | 7 | 3.5 | ||||

Travel speed | M/MIN | 20 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 18 | |

Wirerope | Dia.(mm) | 3.6 | 4.8 | 7.4 | 11 | 13 | 15 | 15 | 17.5 | |

Spec. | 6×39 | 6×37+FC | 6×37+FC | 6×37+FC | 6×37+FC | |||||

Hoisting motor | Type | Type | ZD112-4 | ZD1 21-4 | ZD1 22-4 | ZD1 31-4 | ZD1 32-4 | ZD1 41-4 | ZD1 51-4 | ZD1 51-4 |

Power | Power(kW) | 0.4 | 0.8 | 1.5 | 3.0 | 4.5 | 7.5 | 13 | 13 | |

Rotation speed | Rotation speed(r/min) | 1380 | 1380 | 1380 | 1380 | 1380 | 1400 | 1400 | 1400 | |

Current | (A) | 1.25 | 2.2 | 4.3 | 7.6 | 11 | 18 | 30 | 30 | |

Travel motor | Type | Type | ZDY1 10-4 | ZDY1 11-4 | ZDY1 11-4 | ZDY1 12-4 | ZDY1 12-4 | ZDY1 21-4 | ZDY1 21-4 | ZDY1 21-4 |

Power | Power(kW) | 0.06 | 0.2 | 0.2 | 0.4 | 0.4 | 0.8 | 0.8x2 | 0.8×2 | |

Rotation speed | Rotation speed(r/min) | 1400 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | |

Current | Current(A) | 0.3 | 0.72 | 0.72 | 1.25 | 1.25 | 2.4 | 2.4 | 2.4 | |

Power | AC 380V,50HZ,3P | |||||||||

Double speed ladle hoist parameter

Double speed ladle hoist parameter

Model | YH type ladle hadling electric wire rope hoist | |||||||||

Capacity | Tons | 0.25 | 0.5 | 1 | 2 | 3 | 5 | 10 | 16 | |

Hoisting height | M | 3,6,9 | 6,9,12 | 6,9,12,18,24,30 | 9,12,18,24,30 | |||||

Hoisting speed | M/MIN | 0.8/8 | 0.8/8 | 0.8/8 | 0.7/7 | 0.35/3.5 | ||||

Travel speed | M/MIN | 20 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 20/30 | 18 | |

Wire rope | Dia.(mm) | 3.6 | 4.8 | 7.4 | 11 | 13 | 15 | 15 | 17.5 | |

Spec. | 6×39 | 6×37+FC | 6×37+FC | 6×37+FC | 6×37+FC | |||||

Hoisting motor | Type | Type | ZD112-4 | ZDS1 0.2/0.8 | ZDS1 0.2/1.5 | ZDS1 0.4/3.0 | ZDS1 0.4/4.5 | ZDS1 0.8/7.5 | ZDS1 1.5/13 | ZDS1 1.5/13 |

Power | Power(kW) | 0.4 | 0.2/0.8 | 0.2/1.5 | 0.4/3.0 | 0.4/4.5 | 0.8/7.5 | 1.5/13 | 1.5/13 | |

Rotation speed | Rotation speed(r/min) | 1380 | 1380 | 1380 | 1380 | 1380 | 1400 | 1400 | 1400 | |

Current | (A) | 1.25 | 0.72/2.4 | 0.72/4.3 | 1.25/7.6 | 2.4/11 | 2.4/18 | 5.2/30 | 5.2/30 | |

Travel motor | Type | Type | ZDY1 10-4 | ZDY1 11-4 | ZDY1 11-4 | ZDY1 12-4 | ZDY1 12-4 | ZDY1 21-4 | ZDY1 21-4 | ZDY1 21-4 |

Power | Power(kW) | 0.06 | 0.2 | 0.2 | 0.4 | 0.4 | 0.8 | 0.8x2 | 0.8×2 | |

Rotation speed | Rotation speed(r/min) | 1400 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | 1380 | |

Current | Current(A) | 0.3 | 0.72 | 0.72 | 1.25 | 1.25 | 2.4 | 2.4 | 2.4 | |

Power | AC 380V,50HZ,3P | |||||||||

YH Metallurgical electric ladle hoist 2 ton

YH Metallurgical electric ladle hoist 2 ton | ||||||

Lifting speed Normal(low) | m/min | 0.8/8(2) | ||||

Traveling speed | m/min | 20 | ||||

Lifting motor | kw | 3/0.75 | ||||

Traveling motor | kw | 0.4 | ||||

Traveling rail | 20a~30c | |||||

Lifting height | m | 9 | 12 | 18 | 24 | 30 |

Mini-turning Radius | m | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 |

Dead weight (Operating) | kg | 439 | 457 | 479 | 494 | 505 |

Dead weight | 409 | 427 | 449 | 464 | 475 | |

YH Metallurgical electric ladle hoist 3 ton

YH Metallurgical electric ladle hoist 3 ton | ||||||

Lifting speed Normal(low) | m/min | 8(2) | ||||

Traveling speed | m/min | 20 | ||||

Lifting motor | kw | 4.5/1.1 | ||||

Traveling motor | kw | 0.4 | ||||

Traveling rail | 20a~30c | |||||

Lifting height | m | 9 | 12 | 18 | 24 | 30 |

Mini-turning Radius | m | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 |

Dead weight (Operating) | kg | 475 | 495 | 515 | 530 | 540 |

Dead weight (Fixed) | 445 | 465 | 485 | 500 | 510 | |

YH Metallurgical electric ladle hoist 5 ton

YH Metallurgical electric ladle hoist 5 ton | ||||||

Lifting speed Normal(low) | m/min | 8(2) | ||||

Traveling speed | m/min | 20 | ||||

Lifting motor | kw | 7.5/2.0 | ||||

Traveling motor | kw | 0.8 | ||||

Traveling rail | 25a~50b | |||||

Lifting height | m | 9 | 12 | 18 | 24 | 30 |

Mini-turning Radius | m | 2.5 | 3.0 | 4.0 | 5.0 | 6.0 |

Dead weight (Operating) | kg | 680 | 750 | 780 | 795 | 810 |

Dead weight | 645 | 720 | 740 | 755 | 780 | |

YH Metallurgical electric ladle hoist 10 ton

YH Metallurgical electric ladle hoist 10 ton | ||||||

Lifting speed Normal(low) | m/min | 7(1.75) | ||||

Traveling speed | m/min | 20 | ||||

Lifting motor | kw | 13/3.25 | ||||

Traveling motor | kw | 0.8 | ||||

Traveling rail | 25a~50b | |||||

Lifting height | m | 9 | 12 | 18 | 24 | 30 |

Mini-turning Radius | m | 3.5 | 4.0 | 6.0 | 7.5 | 9.0 |

Dead weight (Operating) | kg | 1170 | 1120 | 1285 | 1325 | 1400 |

Dead weight | 1130 | 1180 | 1240 | 1290 | 1360 | |

Related production

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch