Monorail Electric Hoists Designed for Curved Rails or Tracks

Curved track hoist for sale. Monorail electric hoists for curved rails enhance maneuverability, optimize space& improve material handling efficiency.

Category: Hoist

Your Trusted Electric Hoist Manufacturer & Supplier

Monorail Electric Hoists Designed for Curved Rails or Tracks

Curved track hoist for sale. Monorail electric hoists for curved rails enhance maneuverability, optimize space& improve material handling efficiency.

Monorail Electric Hoists Designed for Curved Rails or Tracks

Electric hoists are essential lifting devices used in various industries for handling heavy materials and equipment. Designed to operate smoothly on monorail systems, they play a crucial role in streamlining workflows and increasing productivity in industrial environments. However, when it comes to curved rail systems, electric hoists require specific configurations to maintain performance and ensure safe operation.

Curved rail systems are common in many modern industrial settings, particularly where space is limited or when the production process demands non-linear movement. These systems allow hoists to follow customized paths, enabling more versatile and efficient material handling. In such cases, choosing the right electric hoist—capable of handling curves without compromising on performance—is vital to achieving smooth and precise operations.

Selecting an electric hoist for a curved rail system involves more than just lifting capacity. The ability of the hoist to navigate bends and maintain balance during turns is critical. Improper selection could result in unstable movements, increased wear on the equipment, and even safety risks. For industries like manufacturing, warehousing, and assembly lines, where curved tracks are often used to optimize space or maneuver around obstacles, ensuring the hoist's compatibility with the curve radius and rail design is essential for consistent and safe operations.

Benefits of Using Electric Hoists on Curved Rails

Optimizing Material Handling Efficiency in Confined Spaces Curved rail systems allow electric hoists to operate in confined or irregularly shaped spaces, offering an effective solution where traditional straight rail systems may not fit. By following customized paths, these hoists can bypass obstacles, transport materials efficiently, and eliminate the need for additional equipment, reducing operational complexity.

Flexibility in Non-linear Workflows In environments where the production process isn't confined to straight-line movement, such as in certain assembly lines or workshops with multiple workstations, curved rails enable the hoist to seamlessly follow the workflow. This flexibility enhances overall productivity, as materials can be transported directly along the most efficient route without unnecessary detours, saving time and labor.

By integrating electric hoists with curved rail systems, businesses can enhance the adaptability of their material handling processes, optimizing both space and workflow flexibility.

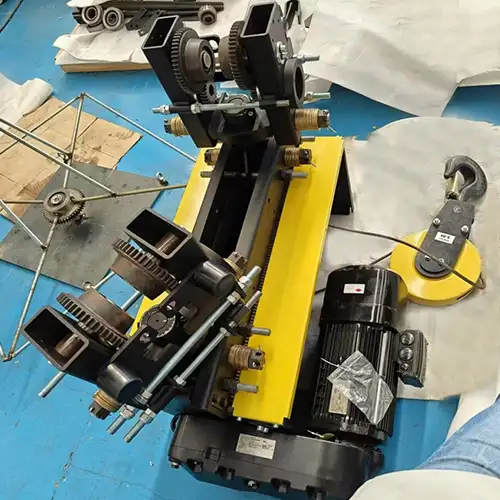

Types of Electric Hoists Used on Curved Rails

European Style Curved Track Monorail Electric Hoists

CD/MD Curved Track Monorail Electric Hoists

European Style Curved Track Monorail Electric Hoists

- Advanced Design for Curved Rail Compatibility European-style electric hoists are engineered with a more advanced design, making them ideal for navigating curved rail systems. Unlike traditional CD hoists, they are specifically built with features that improve their ability to operate smoothly on non-linear tracks. Their compact design and enhanced control systems allow for greater adaptability in more complex rail configurations, such as tight curves and varying track layouts.

- Compact and Low-Headroom Design One of the key benefits of European-style electric hoists is their compact and low-headroom design. This makes them particularly suitable for spaces with limited vertical clearance, such as warehouses or workshops with overhead constraints. The low-headroom feature enables them to move freely even in confined spaces, reducing the likelihood of collisions or operational limitations when navigating curves.

- Enhanced Control Features: Variable Frequency Drives, Precision Handling European-style hoists are often equipped with advanced control features such as variable frequency drives (VFDs) and precision handling systems. VFDs allow for smoother acceleration and deceleration, ensuring a more stable transition through curved sections of the rail. The ability to adjust the hoist's speed according to the curve's radius helps minimize mechanical strain and improve overall safety. Precision handling systems provide operators with greater control over the hoist's movements, reducing the risk of sudden jerks or instability during curved rail operation.

- Special Customization for Curved Rail Applications In addition to their advanced features, European-style electric hoists can be customized for specific curved rail applications. This includes tailoring the hoist's suspension and trolley system to suit the track's unique curvature, as well as integrating sensors and control systems that enhance performance on curves. This customization ensures that the hoist can navigate even the most complex rail layouts without sacrificing safety, efficiency, or precision. These features make European-style hoists a superior choice for industries that require reliable material handling solutions in environments with curved rail systems.

CD1/MD1 Curved Track Monorail Electric Hoists (Traditional)

- Basic Features and Design CD electric hoists are among the most commonly used types of hoists in industrial settings. Known for their simplicity and durability, these hoists feature a single-speed motor, which makes them reliable for general lifting tasks. They are typically mounted on monorail systems and can handle loads ranging from 0.5 to 32 tons. Their straightforward design and cost-effective nature have made them popular for a wide range of material handling needs.

- Common Applications and Limitations on Curved Rails While CD hoists perform well on straight rail systems, their design is not optimized for curved rails. On curved tracks, these hoists often face challenges related to maintaining smooth operation during turns. The lack of advanced control systems means that sudden movements or jerky transitions can occur when navigating curves, which can lead to mechanical wear or even safety risks over time. Additionally, their higher headroom requirements may limit their use in spaces with low clearance or where precision movement is essential.

- Performance on Curved Tracks: Strengths and Challenges CD hoists offer reliable lifting for basic applications, but on curved rails, their performance may be less efficient. The fixed-speed operation makes it difficult to control speed and adjust to the specific demands of curved paths, especially in tight radii. This limitation can result in higher wear on the hoist components and increased maintenance costs. For industries where smooth, precise movement on curved rails is critical, traditional CD hoists may not offer the best solution.

Key Features of Electric Hoists on Curved Rails

Smooth Cornering and Stability

- Importance of Specialized Trolley Systems for Curved Tracks The stability and performance of electric hoists on curved rails heavily depend on the design of the trolley system. Unlike straight rail operations, curved rails require a trolley that can navigate turns without causing instability or disruptions. These specialized trolley systems are designed to distribute the load evenly and provide smooth movement, even when the rail path changes direction. The design includes features like pivoting mechanisms and enhanced bearings to allow seamless transitions along curves.

- How the Trolley Design Affects Movement on Curves The geometry and flexibility of the trolley play a critical role in ensuring smooth cornering. A well-designed trolley reduces friction and minimizes wear on both the rail and the hoist itself. By allowing the wheels to adapt to the curvature of the track, the hoist moves with greater precision, reducing the risk of misalignment or jerky movements. This is particularly important in industrial environments where stability is critical to prevent damage to the load or nearby equipment.

- Ensuring Smooth Transitions Without Load Swings One of the primary challenges in curved rail operations is preventing load swings during transitions. Load swings can occur when the hoist moves through a curve at an inconsistent speed or when there is a sudden change in direction. To counter this, advanced hoists incorporate systems that balance the load and maintain a steady motion throughout the curve. This ensures not only safer operations but also protects the integrity of the materials being transported. Systems like variable speed controls and precise hoist-trolley synchronization are essential for achieving smooth transitions and eliminating load swings.

Load Capacities and Safety Considerations

- Load Ranges and the Impact of Load on Curved Rail Performance The load capacity of an electric hoist is a key factor in its performance on curved rails. Heavier loads exert more force on the trolley and rail system, making smooth navigation through curves more challenging. Hoists operating on curved rails need to be carefully selected based on their load capacity and the rail's specifications. Overloading the system can lead to performance issues, such as increased friction, slower operation, or in extreme cases, derailment of the trolley. Therefore, understanding the load ranges and adjusting the hoist's operation accordingly is crucial for ensuring optimal performance and safety.

- Overload Protection and Safety Mechanisms in Curved Rail Applications Safety mechanisms, such as overload protection, are critical when operating electric hoists on curved rails. These systems automatically detect when the load exceeds the hoist's capacity and stop the operation to prevent damage or accidents. In curved rail environments, these safety measures are even more important, as navigating turns can put additional stress on the equipment. Some hoists are equipped with advanced sensors that monitor both the load and the rail's condition, providing real-time feedback to prevent overload and ensure smooth operation. These systems significantly reduce the risk of accidents, protecting both the equipment and the operators.

- Addressing the Complexities of Load Movement on Curved Paths The movement of loads along curved rails introduces complexities that don't exist in straight-line operations. In addition to the risk of load swings, the centrifugal force generated during turns can affect the load's stability. To mitigate these effects, electric hoists on curved rails are often equipped with anti-sway technology that minimizes pendulum-like movements. This is particularly important for industries handling delicate or hazardous materials, where precise control over the load is essential for safety and efficiency.

Control Systems

- Role of Variable Frequency Drives (VFD) for Precision on Curved Rails Variable Frequency Drives (VFDs) play a pivotal role in controlling the speed and precision of electric hoists on curved rails. VFDs allow for smooth acceleration and deceleration, ensuring that the hoist can adjust its speed as it approaches and navigates curves. This precision is crucial for avoiding abrupt movements that could destabilize the load or cause unnecessary wear on the equipment. By providing operators with fine control over the hoist's movement, VFDs ensure a stable, predictable operation that improves both efficiency and safety.

- Differences in Speed Control for Straight vs. Curved Rail Movements Operating an electric hoist on a straight rail system allows for consistent speed control, but curved rail systems require more dynamic adjustments. On straight rails, the hoist can operate at higher speeds, whereas navigating curves demands slower, more controlled movements to prevent abrupt transitions. VFDs are essential in managing these speed differences, as they allow the hoist to decelerate smoothly when approaching a curve and then resume normal speed once the hoist is back on a straight path. This seamless transition is vital for maintaining control over the load and ensuring smooth, uninterrupted operations.

- Preventing Abrupt Stops or Jerks During Curved Transitions Curved rail systems often present the challenge of maintaining smooth movement without sudden stops or jerks, which can disrupt operations and pose safety risks. Advanced control systems, including VFDs and programmable logic controllers (PLCs), are designed to eliminate these issues by ensuring that the hoist maintains a consistent speed throughout the curve. These systems prevent abrupt changes in speed or direction, allowing the hoist to glide through turns with minimal friction and maximum stability. This not only improves the safety and longevity of the hoist but also enhances the overall efficiency of the material handling process.

Comparing CD Electric Hoists and European Style Electric Hoists on Curved Rails

CD Electric Monorail Hoists on Curved Monorail and Track

European Style Curved Rail Monorail Electric Hoists

CD Electric Monorail Hoists on Curved Monorail and Track

- Advantages: Cost-Effectiveness, Simplicity CD electric hoists are known for their cost-effectiveness and straightforward design, making them an attractive option for many businesses. Their simpler construction allows for lower initial investment, which is particularly appealing for smaller operations or those with limited budgets. Additionally, the ease of use and maintenance associated with CD hoists means less downtime and lower operating costs. This simplicity makes them suitable for applications where advanced features are not a necessity.

- Disadvantages: Limited Compatibility with Tight Curves, Less Precision Despite their advantages, CD electric hoists have limitations when it comes to navigating tight curves. Their design is more suited for straight or gradually curved tracks, making them less effective in environments requiring intricate maneuvers. The lack of precision in handling loads during cornering can lead to inefficiencies and safety concerns, particularly when operating in spaces with tight turns or complex layouts. This makes CD hoists less ideal for operations that demand high levels of accuracy and stability.

- Ideal for Straight or Gradually Curved Tracks CD electric hoists excel in applications where the track layout is predominantly straight or features gentle curves. Industries that require basic lifting capabilities without the need for extensive maneuverability can benefit from the simplicity and cost-effectiveness of CD hoists. They are commonly used in warehouses, assembly lines, and other environments where load handling does not involve significant lateral movement or sharp turns.

European Style Curved Rail Monorail Electric Hoists

- Advantages: Better Precision, Flexibility, and Adaptability for Complex Curved Tracks European style electric hoists are engineered with advanced features that enable better precision and adaptability, making them ideal for complex curved rail systems. Their design incorporates features such as compact configurations, variable frequency drives, and precision handling systems, allowing for smooth transitions through curves. This flexibility is especially beneficial in industries that require frequent changes in direction and load positioning, such as manufacturing and logistics.

- Disadvantages: Higher Cost, More Complex Installation One of the primary drawbacks of European style electric hoists is their higher upfront cost compared to CD hoists. The advanced technology and features included in their design contribute to this increased price. Additionally, the installation of European style hoists can be more complex, often requiring specialized knowledge and skills to ensure proper setup. This complexity can lead to longer installation times and increased labor costs, which may deter some businesses from choosing these hoists for their operations.

- Ideal for Applications Needing Smooth, Precise Movements and Complex Curved Paths European style electric hoists are best suited for applications that demand high levels of precision and smooth movements along complex curved paths. Industries such as automotive assembly, aerospace manufacturing, and heavy equipment handling often benefit from the enhanced control and adaptability these hoists provide. When the smooth handling of loads through tight curves is crucial, European style hoists offer a distinct advantage over their CD counterparts.

Performance Metrics Comparison

- Load Capacity Handling When comparing load capacity handling, both CD electric hoists and European style electric hoists can accommodate a range of weights, but the efficiency with which they handle loads on curved rails varies significantly. CD hoists typically have a set load capacity, which may be limited by their design when navigating curves. In contrast, European style hoists are engineered for dynamic load handling, allowing for more consistent performance even under varying conditions.

- Speed and Precision in Curved Rail Operations Speed and precision are critical performance metrics in curved rail operations. CD electric hoists generally operate at lower speeds due to their limitations in navigating tight curves, which can affect overall productivity. European style hoists, equipped with advanced control systems, can maintain higher speeds while ensuring precise movements along curves. This makes them more suitable for fast-paced environments where quick load handling is essential.

- Safety Features and Customization Options Safety is a paramount concern in industrial operations, and both hoist types offer safety features, but the scope of these features varies. CD electric hoists typically have basic safety mechanisms, while European style hoists come with advanced safety features, including overload protection, anti-sway technology, and customizable options tailored to specific operational needs. This adaptability allows businesses to configure their hoisting systems to meet unique safety requirements, enhancing the overall safety of their operations. Click to check

Monorail Overhead Crane for sale : Straight Rail vs Curved Monorail Hoist Crane.

Choosing the Right Electric Hoist for Curved Rail Systems

Factors to Consider

Selecting the appropriate electric hoist for curved rail systems is a crucial decision that can significantly impact operational efficiency and safety. Various factors should be taken into account to ensure the best fit for your specific needs.

Track Layout and Minimum Turning Radius

The design of the track layout is one of the most important factors when choosing an electric hoist. You must consider the minimum turning radius required for the specific hoist type you are evaluating. Different electric hoists, particularly CD and European styles, have varying capabilities when navigating curves. If your operations involve tight turns, a hoist designed for high adaptability and smooth cornering, like the European style, would be more suitable. Additionally, a thorough understanding of the entire rail system layout can help in determining the most effective hoist configuration, ensuring seamless integration into the existing infrastructure.

The design of the track layout is a critical factor when selecting an electric hoist for curved rail systems. Understanding the minimum turning radius required for the specific type of hoist you are evaluating is essential for ensuring optimal performance and efficiency in your operations.

Different electric hoists, particularly CD and European styles, possess distinct capabilities regarding curve navigation.

- CD Electric Hoists: These traditional hoists are typically more straightforward in design, making them less adaptable to tight curves. They may struggle with maneuverability in situations that require sharp turns, limiting their effectiveness in complex rail layouts. Their ideal application lies in environments where the rail system features gradual curves or predominantly straight sections.

- European Style Electric Hoists: In contrast, European-style hoists are engineered for high adaptability and smooth cornering. Their advanced design accommodates tighter turning radii, allowing them to navigate curves more efficiently. This makes them particularly suitable for operations that involve intricate track layouts and frequent changes in direction.

When designing the track layout, it's essential to consider not only the minimum turning radius but also the overall dimensions and characteristics of the hoist. By thoroughly understanding the entire rail system layout, you can determine the most effective hoist configuration. This will ensure seamless integration into your existing infrastructure, optimizing workflow and material handling efficiency.

Moreover, collaborating with experts in electric hoist systems can provide valuable insights into the best practices for track design. They can assist in evaluating the specific needs of your operation, helping you select a hoist that not only meets your requirements but also enhances productivity while ensuring safety and reliability in curved rail applications.

Load Size, Weight, and Nature

The nature of the loads being handled is another critical consideration. This includes evaluating not just the weight, but also the size and shape of the loads. Heavy, bulky items may require hoists with higher load capacities and stronger structural integrity. Furthermore, specific load characteristics, such as fragility or irregular shapes, may necessitate specialized hoists equipped with advanced control features to prevent damage during movement. By assessing these factors, you can select a hoist that effectively meets your handling requirements while ensuring the safety of both the loads and the surrounding personnel.

When selecting an electric hoist for curved rail systems, the nature of the loads being handled is a critical consideration. This assessment goes beyond merely evaluating the weight; it also involves understanding the size, shape, and characteristics of the loads to ensure safe and efficient operation.

- Weight: The weight of the loads directly impacts the choice of hoist. Heavy items necessitate hoists with higher load capacities to safely lift and transport them without risk of failure. It's essential to match the hoist's specifications with the maximum load weight to maintain operational safety and efficiency.

- Size and Shape: The dimensions of the loads also play a significant role. Bulky items may require hoists with a wider lifting span or specialized attachments to ensure proper handling. For instance, oversized loads may necessitate hoists that can navigate larger turning radii or operate effectively in confined spaces.

- Load Characteristics: Beyond weight and size, specific load characteristics must be considered. Fragile items, such as glass or delicate machinery components, require hoists equipped with advanced control features that allow for precise handling and minimal impact during movement. These features can include variable speed controls and soft start mechanisms that prevent sudden jerks, reducing the risk of damage.

- Irregular Shapes: Loads with irregular shapes may necessitate custom lifting attachments or hoists specifically designed for unique handling requirements. This ensures stability during transportation and minimizes the risk of tipping or dropping.

By thoroughly assessing these factors, you can select an electric hoist that effectively meets your handling requirements while ensuring the safety of both the loads and the surrounding personnel. Proper load management not only enhances efficiency but also safeguards against accidents and damage, creating a safer work environment for all involved.

Environmental and Space Constraints

The environment in which the electric hoist will operate can greatly influence the decision-making process. Factors such as temperature, humidity, and exposure to corrosive substances can dictate the type of hoist material and design you need. For example, operations in harsh environments may require hoists with enhanced anti-corrosion features or weather-resistant materials. Additionally, spatial constraints play a crucial role. Limited headroom or narrow aisles may restrict your choices, making compact designs like European style hoists more appealing. Understanding the specific environmental conditions and spatial limitations is essential for selecting a hoist that will perform optimally and have a long lifespan.

When selecting an electric hoist for curved rail systems, it's crucial to consider both environmental and spatial constraints, as these factors significantly influence the hoist's performance and longevity.

Environmental Factors

Temperature:

- Impact: Extreme temperatures, whether hot or cold, can affect hoist performance.

- Considerations: Some materials may become brittle in cold conditions, while others can warp under high heat. Ensure that the hoist is rated for the specific temperature range of your operational environment.

Humidity:

- Impact: High humidity levels can lead to moisture accumulation, increasing the risk of corrosion and electrical failure.

- Considerations: Choose electric hoists with enhanced anti-corrosion features, such as stainless steel components or specialized coatings, to withstand prolonged exposure to moisture.

Corrosive Substances:

- Impact: Exposure to chemicals can compromise hoist integrity.

- Considerations: Opt for hoists made from weather-resistant materials or those designed with specialized coatings to provide protection against corrosion and chemical damage.

Space Constraints

Limited Headroom:

- Impact: Low ceilings can restrict lifting operations.

- Considerations: Compact hoist designs, particularly European-style electric hoists, often feature low-headroom configurations that allow for safe and efficient operations without compromising space.

Narrow Aisles:

- Impact: Tight spaces can limit hoist maneuverability.

- Considerations: Select compact hoist designs that can navigate tight corners and curves effectively. European-style hoists are often more adaptable in such conditions, providing flexibility for diverse operational layouts.

By thoroughly evaluating environmental and spatial constraints, you can choose an electric hoist that performs optimally in your specific setting. This careful consideration ensures not only efficient operation but also extends the lifespan of the hoist, making it a smart investment for your facility. Understanding these factors allows you to align your lifting equipment with the operational demands and safety requirements essential for your success.

Budget and Long-term Operational Needs

While initial costs are an important consideration, it's vital to evaluate the long-term operational needs and total cost of ownership associated with each hoist type. CD electric hoists might offer lower upfront costs, but their limitations in navigating curves can lead to decreased efficiency and higher operational costs over time. On the other hand, European style hoists, while more expensive initially, may provide better long-term value through increased efficiency, reduced maintenance, and enhanced safety features. Therefore, a comprehensive analysis of both immediate budget constraints and anticipated future needs is essential to make an informed decision that aligns with your operational goals and financial resources.

When selecting an electric hoist for curved rail systems, the budget is just one aspect of the decision-making process. A thorough evaluation of long-term operational needs and the total cost of ownership (TCO) is crucial for ensuring that your investment aligns with both current and future operational goals.

Initial Costs vs. Total Cost of Ownership

Initial Costs:

- Consideration: The upfront price of electric hoists can vary significantly between different types. CD electric hoists typically have lower initial costs, making them appealing for businesses with limited budgets.

- Implication: While it might be tempting to go for the most affordable option, a lower purchase price does not always translate to long-term savings. Understanding the upfront cost is important, but it should not be the sole factor in your decision.

Long-term Costs:

- Operational Efficiency: CD electric hoists may struggle with tight curves, leading to inefficiencies in material handling. These limitations can result in increased cycle times, more frequent downtime, and ultimately higher labor costs as operators work to navigate challenging layouts.

- Maintenance Expenses: While CD hoists may have lower upfront costs, they often require more maintenance due to wear and tear from navigating curves poorly. Frequent repairs and component replacements can accumulate over time, leading to increased total operational costs.

Evaluating Long-term Value

Efficiency Gains:

- European Style Hoists: Though these hoists come with a higher initial price tag, they are designed for enhanced performance on curved tracks. Their ability to navigate complex rail systems with precision can lead to significant efficiency gains in material handling.

- Impact: Increased efficiency translates to faster operations, reduced cycle times, and potentially lower labor costs, offering substantial long-term savings.

Reduced Maintenance:

- Durability and Reliability: European-style electric hoists often come equipped with advanced engineering features that contribute to their longevity and reliability. This means fewer breakdowns and less frequent maintenance, which can drastically reduce costs over the hoist's lifespan.

- Safety Features: Enhanced safety features not only protect your workforce but also minimize the likelihood of costly accidents that can arise from equipment failures.

Alignment with Operational Goals:

- Future Needs: It's essential to consider how your operational needs may evolve. If you anticipate growth or changes in the type of materials being handled, investing in a hoist that can adapt to future requirements may be wise.

- Scalability: A hoist system that integrates well with existing infrastructure and can handle increased demands will ultimately save costs associated with additional purchases or system overhauls.

In summary, while budgetary constraints are a crucial consideration when selecting an electric hoist, it's vital to take a holistic view of the long-term operational needs and total cost of ownership. Balancing initial costs with future savings from efficiency, reduced maintenance, and safety features will lead to more informed decision-making. A comprehensive analysis will help ensure that you select the right hoist that meets both current and anticipated operational demands, ultimately aligning with your organization's financial resources and operational goals. By investing wisely, you can optimize productivity, enhance safety, and achieve significant long-term value.

By carefully considering these factors, you can ensure that your selection of an electric hoist for curved rail systems aligns with both your current operational requirements and future growth. A well-chosen hoist can lead to improved efficiency, enhanced safety, and a smoother workflow within your facility.

Installation and Maintenance of Electric Hoists on Curved Rails

Key Installation Considerations

Installing electric hoists on curved rails requires careful planning and execution to ensure safe and efficient operation. Several key considerations should be addressed during the installation process:

Importance of Proper Track Alignment

Achieving precise alignment of the curved track is crucial for the optimal performance of electric hoists. Misalignment can lead to issues such as increased wear on the trolley wheels, uneven load distribution, and decreased operational efficiency. It is essential to utilize accurate measuring tools and techniques during installation to ensure that the track is installed correctly according to the manufacturer's specifications. Additionally, regular checks and adjustments may be necessary to maintain proper alignment over time, especially in high-usage environments.

Ensuring Stability in Curved Path Installations

Stability is vital when installing curved rail systems. The design and support structure must accommodate the forces exerted during hoist operations, especially on curves where loads can shift more readily. Using robust mounting solutions, such as properly anchored supports and brackets, can help maintain stability and prevent any potential hazards during operation. Furthermore, ensuring that the curved rails are installed with the appropriate angle and curvature will allow for smooth transitions and reduce the risk of operational disruptions.

Common Challenges in Installing Curved Rail Systems

Installing curved rail systems can present unique challenges, including navigating existing infrastructure, limited space, and the need for specialized equipment. These challenges may require customized solutions, such as bespoke mounting hardware or tailored rail sections to accommodate specific operational requirements. It's also important to have a skilled installation team familiar with the nuances of curved rail systems to mitigate risks and ensure a successful installation process.

Maintenance Tips for Longevity

Regular maintenance is essential for the longevity and reliable performance of electric hoists on curved rails. Implementing the following tips can help ensure optimal operation:

Routine Inspections for Trolley Systems

Regular inspections of trolley systems are vital for identifying wear and potential issues before they escalate. Key areas to focus on include the wheels, bearings, and connections. Any signs of damage or excessive wear should be addressed promptly to prevent costly repairs and downtime. Creating a routine maintenance schedule can help ensure that inspections are performed consistently and systematically.

Maintaining the Integrity of Curved Rails and Electric Hoist Motors

The integrity of both the curved rails and the electric hoist motors must be maintained to ensure smooth operations. Regularly checking the rails for signs of wear, deformation, or corrosion is critical, especially in environments where moisture or corrosive materials are present. Additionally, the electric motor should be serviced according to manufacturer recommendations, including lubrication and cleaning to prevent overheating and operational failures.

Preventative Measures to Avoid Wear on Curved Rail Systems

Taking preventative measures can significantly extend the lifespan of your curved rail systems. This includes applying appropriate lubricants to reduce friction between moving parts, ensuring that the rails are clean and free of debris, and monitoring load capacities to prevent overloading. Implementing a training program for operators to ensure they understand the specific requirements of working with curved rails can also help minimize wear and damage. By emphasizing proactive maintenance practices, you can ensure that your electric hoist systems remain reliable and efficient over time.

In summary, proper installation and ongoing maintenance are essential for the effective operation of electric hoists on curved rails. By addressing key considerations during installation and implementing a robust maintenance program, you can enhance the safety, efficiency, and longevity of your hoist systems.

Applications and Case Studies

Electric hoists on curved rails have found widespread application across various industries, demonstrating their versatility and effectiveness in enhancing material handling processes. This section highlights notable applications and case studies, showcasing how these systems optimize efficiency and precision in different environments.

Monorail hoist crane system for sale

Automotive Industry

Case Study: Efficient Use of Curved Rails in Automotive Assembly Lines

In the automotive industry, the need for efficient assembly processes is paramount. A major automobile manufacturer implemented electric hoists on curved rails within their assembly line to improve workflow and maximize space. The curved rail system allowed the hoists to navigate around workstations seamlessly, enabling the transportation of heavy components like engines and chassis while reducing the footprint of the machinery.

By utilizing this system, the manufacturer experienced significant improvements in production efficiency, as the hoists could easily maneuver through tight corners without compromising load stability. The integration of variable frequency drives (VFD) also allowed for precise speed control, minimizing the risk of jolts that could disrupt assembly tasks. Overall, the introduction of electric hoists on curved rails led to faster assembly times and enhanced worker safety, as operators could focus on their tasks without the constant concern of navigating cumbersome equipment.

Shipbuilding and Aerospace

Case Study: Precision Handling on Curved Tracks for Large Components

In the shipbuilding and aerospace sectors, the handling of large, heavy components is a common challenge. A leading shipyard adopted electric hoists on curved rails to facilitate the movement of oversized sections of ships during the construction process. The curved rail system allowed hoists to transition smoothly between different areas of the workshop, optimizing space utilization and reducing the need for extensive ground support equipment.

The flexibility provided by the curved rail system enabled the shipyard to position hoists closer to the assembly points, improving turnaround times for moving large components like hull sections and propulsion systems. The electric hoists equipped with advanced control features ensured precision handling, which was crucial for aligning components accurately. This application resulted in improved production rates and significant reductions in operational delays, proving the value of electric hoists on curved rails in demanding industrial environments.

Warehousing and Manufacturing

Case Study: Maximizing Space with Curved Rails in Tight Workspaces

In warehousing and manufacturing facilities, maximizing usable space is often a critical concern. A medium-sized manufacturing plant faced space constraints that limited their ability to efficiently store and retrieve materials. To address this challenge, the facility implemented electric hoists on curved rails, which allowed for dynamic movement of materials within the warehouse.

The design of the curved rail system enabled the hoists to navigate around obstacles and access various storage areas without requiring extensive floor space. This innovative approach not only increased the facility's operational efficiency but also improved safety, as it reduced the need for manual material handling in tight spaces. The flexibility of the system allowed for quick adjustments based on changing workflows, demonstrating how electric hoists on curved rails can adapt to the unique needs of any warehouse or manufacturing operation.

The applications and case studies highlighted in this section illustrate the significant benefits of using electric hoists on curved rails across various industries. From enhancing efficiency in automotive assembly lines to enabling precision handling in shipbuilding and optimizing space in warehousing, these systems are proving to be invaluable assets in modern industrial operations. By integrating curved rail technology, companies can improve their productivity, safety, and overall operational effectiveness.

Conclusion: Get Your Customized Monorail Electric Hoist

The integration of electric hoists on curved rails presents a transformative approach to material handling across various industries. This article has explored the different types of electric hoists, their key features, and their applications, highlighting the significant benefits they offer in optimizing workflows, enhancing safety, and maximizing space.

Electric hoists on curved rails facilitate smoother operations in environments where traditional straight rail systems may fall short. The distinction between CD electric hoists and European-style electric hoists underscores the need to select the right equipment based on specific operational requirements. While CD electric hoists offer cost-effectiveness and simplicity, European-style hoists provide enhanced precision and adaptability for complex curved paths. Key features such as smooth cornering, load capacity considerations, and advanced control systems play a vital role in the performance of these hoists, ensuring efficient and safe operations.

The electric hoists on curved rails looks promising, driven by several emerging trends:

- Advances in Automation and AI-Driven Hoist Control: The integration of automation and artificial intelligence (AI) is set to revolutionize the operation of electric hoists. With the use of smart sensors and AI algorithms, hoists can be programmed to perform complex tasks autonomously, improving efficiency and minimizing human error. This trend is expected to enhance safety, as automated systems can continuously monitor load conditions and adjust operations in real-time.

- The Growing Need for Flexible Rail Systems in Modern Industries: As industries increasingly prioritize flexibility and adaptability, the demand for curved rail systems will continue to rise. These systems offer the versatility needed to accommodate changing production layouts and diverse material handling needs. The ongoing development of modular and customizable rail systems will further enhance the capabilities of electric hoists, allowing for seamless integration into various industrial environments.

In conclusion, electric hoists on curved rails are set to become integral to modern industrial operations, providing solutions that enhance efficiency, safety, and flexibility. As technology continues to advance, these systems will likely evolve, offering even more innovative features that meet the demands of today's dynamic manufacturing landscape. Embracing these advancements will be crucial for businesses seeking to maintain a competitive edge in their respective industries.

Main Projects

Related Products

22/5 Ton Overhead Crane Double Hook System: Robust double girder crane with 22-ton main and 5-ton auxiliary hooks for heavy lifting. Get double hook crane!

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch