Overhead Crane Choices: Overhead Cranes for Steelworks, Fabrication & Storage

Explore overhead crane options tailored for steelworks, fabrication, and storage, focusing on load capacity, crane type, and efficient handling.

Category: Steel

Your Trusted Steel Mill Overhead Crane Manufacturer & Supplier

Overhead Crane Choices: Overhead Cranes, Gantry Cranes for Steelworks, Fabrication & Storage

Explore overhead crane options tailored for steelworks, fabrication, and storage, focusing on load capacity, crane type, and efficient handling. Hot sale processed cranes for your steel mill and product handling. Check to get your customized overhead cranes, gantry cranes for your steel works, fabrication and storage.

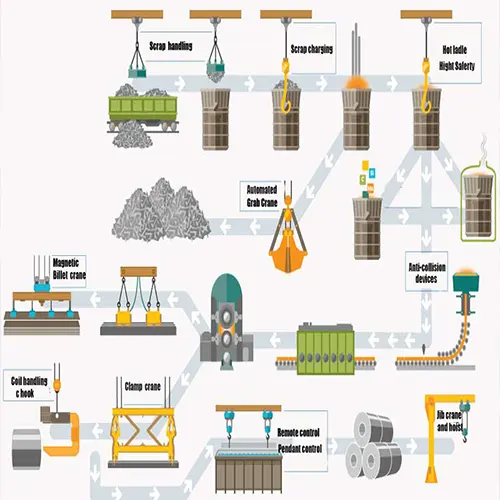

Overview of Overhead Cranes in the Steel Industry

When it comes to steelmaking, overhead cranes are like the unsung heroes of the operation. Think of them as the backbone of steelworks, fabrication, and storage—essential tools that make everything run smoothly. Whether you're handling scrap metal or molten steel, these cranes are designed to tackle the heavy lifting with precision and reliability.

Overhead cranes are crucial in steelworks because they manage the heavy loads and high temperatures that come with steel production. From the moment scrap metal arrives at the yard to the final product being stored or shipped out, these cranes are at work, ensuring every step is executed with accuracy. They help streamline processes, increase productivity, and improve safety in what can be a hazardous environment.

Benefits and Efficiencies Provided by Various Crane Types

Choosing the right overhead crane can make a world of difference. For example, double girder cranes are fantastic for handling heavy loads like molten steel, while single girder cranes are perfect for lighter tasks, such as handling cold-rolled sheets. Each type of crane offers specific benefits—some are built for speed, others for stability or precision.

Here's a little insider tip: a crane with the right features can transform how efficiently your workshop operates. For instance, using cranes with heat-resistant components in high-temperature areas can extend their lifespan and reduce maintenance costs. And let's not forget about automation—modern cranes can handle tasks with minimal human intervention, which boosts productivity and reduces the risk of accidents.

In short, overhead cranes are more than just equipment; they are a critical part of the steel industry's infrastructure. They bring benefits that go beyond just lifting—enhancing safety, efficiency, and overall productivity. So, whether you're in steelworks, fabrication, or storage, understanding the role and advantages of these cranes can help you make the best choices for your operation.

Overhead Cranes in Steelworks

Scrap Yard Handling

In the busy environment of a scrap yard, overhead cranes are the workhorses that keep everything running smoothly. For handling scrap metal and metal bales, single girder and gantry cranes are your go-to options. These cranes come with capacities ranging from 5 to 30 tons, which is just the right amount for managing hefty loads of scrap.

Crane Type: Single Girder Overhead Cranes and Gantry Cranes

Typical Capacity: 5 to 30 tons

Typical Objects Handled: Steel scrap, metal bales

Below Hook Devices: Clamshell buckets, magnetic grabs

Single Girder Overhead Cranes: Single girder cranes are favored in scrap yards for their simplicity and cost-effectiveness. They consist of one main girder that supports the crane, making them ideal for handling lighter to moderately heavy loads. Their design is compact, which helps in navigating the often-constrained spaces of a scrap yard. With capacities ranging from 5 to 30 tons, single girder cranes are well-suited for handling everyday scrap tasks, offering flexibility and reliability.

Gantry Cranes: Gantry cranes, which run on tracks mounted on the ground, are another excellent choice for scrap yards. They offer versatility and can be positioned to cover large areas, which is advantageous for the extensive and open layout of a scrap yard. Their robust design allows them to handle heavy and bulky loads, making them ideal for moving large bales and piles of scrap metal.

Typical Capacity: 5 to 30 Tons

The capacity range of 5 to 30 tons is well-suited for the types of loads typically encountered in scrap yards. This range allows for efficient handling of various scrap materials, including metal bales and other heavy scrap. It ensures that the cranes can manage the loads without compromising on performance or safety.

Typical Objects Handled: Steel Scrap, Metal Bales

In scrap yards, overhead cranes are primarily used to handle:

- Steel Scrap: This includes various types of metal scrap that are sorted and processed. The cranes need to efficiently lift, move, and place these materials for further processing or loading.

- Metal Bales: These are compressed bundles of scrap metal that need to be moved with precision. The cranes must handle these bales carefully to avoid damage and ensure efficient processing.

Below Hook Devices: Clamshell Buckets, Magnetic Grabs

Clamshell Buckets: Clamshell buckets are versatile attachments ideal for handling loose scrap metal. They are designed to scoop and hold metal scrap securely, allowing for efficient loading and unloading. Their ability to handle varying sizes and types of scrap makes them invaluable in a scrap yard setting.

Magnetic Grabs: Magnetic grabs are essential for handling ferrous materials. They use strong magnets to lift and move metal scrap, reducing manual handling and improving efficiency. They are particularly useful for quickly sorting and moving metal scrap, which is a common task in scrap yards.

Practical Tips for Selection:

Here's a little insider advice: when choosing a crane for your scrap yard, durability is key. These cranes are often subjected to frequent, heavy loads, so you'll want something built to last. Opt for models that can handle the rigors of constant use without breaking down.

For scrap handling, consider cranes equipped with magnetic grabs or clamshell buckets. Magnetic grabs are fantastic for lifting and moving metal scraps efficiently, while clamshell buckets excel in sorting and managing loose materials. This combination ensures that your crane is up to the task of dealing with different types of scrap material.

Remember, the right crane can make a significant difference in your scrap yard's efficiency and safety. Investing in robust, well-designed equipment will pay off in the long run by minimizing downtime and maintenance costs while boosting your overall productivity.

- Opt for Robust Cranes: Choose cranes that are built for heavy-duty use to withstand the harsh conditions of a scrap yard. Durability and reliability are key, as these cranes will be subject to frequent and heavy loads.

- Choose the Right Below-Hook Devices: Depending on the type of scrap you handle, select appropriate attachments. Clamshell buckets are great for general scrap handling, while magnetic grabs are ideal for lifting and moving ferrous materials efficiently.

By selecting the right overhead cranes and below-hook devices, you ensure that your scrap yard operates smoothly and efficiently, reducing downtime and increasing overall productivity.

Electric Arc Furnace (EAF) Charging

When it comes to feeding an Electric Arc Furnace (EAF), the demands are intense. Double girder overhead cranes for charging are the top choice for this task, boasting capacities between 20 to 50 tons. These cranes are specifically designed to handle the weight and precision required for charging scrap metal and additives into the furnace.

Crane Type: Double Girder Overhead Cranes

Typical Capacity: 20 to 50 tons

Typical Objects Handled: Scrap metal, additives

Below Hook Devices: Heavy-duty buckets, charging baskets

Double Girder Overhead Cranes: Double girder cranes are preferred for EAF charging because of their superior strength and stability. With two main girders supporting the crane, they provide greater lifting capacity and structural integrity. This is essential when handling the hefty loads of scrap metal and additives needed for the EAF. They can easily support weights ranging from 20 to 50 tons, ensuring that your operation can handle the most demanding tasks without compromising safety or efficiency.

Typical Capacity: 20 to 50 Tons

The capacity range of 20 to 50 tons is specifically suited for EAF charging operations. This range ensures that the crane can manage the substantial weight of scrap metal and additives required to charge the furnace effectively. It also allows for safe and efficient operation, reducing the risk of overloading and ensuring the crane can handle the high demands of the process.

Typical Objects Handled: Scrap Metal, Additives

In EAF charging, the overhead crane is responsible for handling:

- Scrap Metal: This is the primary material fed into the furnace. The crane must be capable of lifting and moving large quantities of metal with precision.

- Additives: Various materials are added to the furnace to aid the steelmaking process. These additives must be handled carefully to ensure accurate dosing and effective operation.

Below Hook Devices: Heavy-Duty Buckets, Charging Baskets

Heavy-Duty Buckets: Heavy-duty buckets are designed to handle large volumes of scrap metal. They are built to withstand the rigors of frequent use and heavy loads, making them ideal for EAF charging. The buckets should be robust enough to manage the high weight and potential abrasiveness of the materials.

Charging Baskets: Charging baskets are used to transport additives into the EAF. They need to be sturdy and capable of withstanding the harsh conditions inside the furnace. Their design should facilitate easy loading and unloading, ensuring a smooth and efficient charging process.

Practical Tips for Selection:

Here's some practical advice from the field: for EAF charging, you'll need a crane with a high load capacity and precise control. Why? Because you're dealing with heavy, potentially hazardous materials, and every move must be accurate to avoid costly mistakes or accidents.

Additionally, don't skimp on heat resistance. EAFs operate at extremely high temperatures, so your crane should be equipped with features that can withstand the heat. This means looking for models with heat-resistant coatings or components designed to handle the harsh conditions typical of steelmaking.

By choosing a crane with these specifications, you'll ensure efficient, safe, and reliable operation in your steel mill's charging process. Properly equipped cranes not only enhance productivity but also contribute to a safer working environment.

- High Load Capacity and Precision Control: Opt for a crane with a high load capacity to handle the heavy materials involved in EAF charging. Precision control is crucial to avoid missteps that could lead to accidents or inefficiencies. Accurate movement is essential for placing scrap metal and additives precisely where needed.

- Heat Resistance: EAFs operate at extremely high temperatures, which means your crane must be equipped to handle such conditions. Look for cranes with heat-resistant features, such as specialized coatings or components designed to withstand high temperatures. This will ensure the crane remains operational and reliable even under the intense heat of steelmaking.

By investing in a double girder overhead crane with these features, you ensure a safe, efficient, and productive EAF charging process. Properly selected and equipped cranes not only enhance operational performance but also contribute to a safer and more reliable steelmaking environment.

Ladle Handling

Handling ladles filled with molten steel is one of the most critical and demanding tasks in a steel mill. For this, heavy-duty double girder overhead cranes for ladle handling are your go-to equipment. These cranes typically handle loads ranging from 30 to 100 tons, making them perfect for the massive weights of ladles brimming with molten steel.

Crane Type: Heavy Duty Double Girder Overhead Cranes

Typical Capacity: 30 to 100 tons

Typical Objects Handled: Ladles with molten steel

Below Hook Devices: Ladle hooks, specialized molten steel handling attachments

Heavy Duty Double Girder Overhead Cranes: Heavy-duty double girder overhead cranes are specifically designed for the heavy lifting required in ladle handling. Their robust structure, with two main girders providing additional support, allows them to lift and move loads ranging from 30 to 100 tons with ease. This capacity is crucial for managing the massive weight of ladles brimming with molten steel, ensuring both safety and operational efficiency.

Typical Capacity: 30 to 100 Tons

The capacity range of 30 to 100 tons is ideal for handling ladles of molten steel. This range ensures that the crane can manage the substantial weight of the ladles and their contents, maintaining stability and control during operation. Adequate capacity also reduces the risk of overloading, which is critical in preventing accidents and ensuring smooth operations.

Typical Objects Handled: Ladles with Molten Steel

In ladle handling, the overhead crane is responsible for moving:

- Ladles with Molten Steel: These ladles are used to transport molten steel from the furnace to the casting area. The casting crane must be capable of lifting and positioning these heavy and extremely hot ladles with precision to avoid spills and accidents.

Below Hook Devices: Ladle Hooks, Specialized Molten Steel Handling Attachments

Ladle Hooks: Ladle hooks are designed to securely lift and support ladles filled with molten steel. They must be strong and durable to handle the intense weight and heat of the ladles. Additionally, they should be equipped with features that ensure a secure grip on the ladle, preventing any accidental drops.

Specialized Molten Steel Handling Attachments: These attachments are tailored for handling molten steel, designed to withstand extreme temperatures and harsh conditions. They include features such as heat-resistant coatings and robust construction to ensure safe and effective handling of molten steel. Their specialized design helps in maneuvering ladles precisely and safely.

Practical Tips for Selection:

Here's a tip from the pros: for ladle handling, your crane needs to excel in heat resistance. Molten steel is extremely hot, and your crane must withstand these high temperatures without faltering. Look for models with advanced heat-resistant features and materials designed for such intense conditions.

Precision is also key. You need a crane that offers exceptional control to avoid spills and accidents. Cranes designed with precise handling mechanisms and safety features will help you manage the molten steel safely and effectively, reducing risks and improving overall operational efficiency.

- Heat Resistance: When selecting a crane for ladle handling, ensure it has advanced heat-resistant features. Molten steel operates at extremely high temperatures, and the crane must be built with materials and coatings that can withstand such intense conditions. This ensures the crane remains operational and safe throughout its use.

- Precision Control: Precision is critical when handling molten steel to avoid spills and accidents. Choose a crane with exceptional control mechanisms that allow for accurate positioning of the ladles. Cranes equipped with fine control systems and safety features will enhance operational efficiency and reduce risks associated with ladle handling.

Investing in a heavy-duty double girder overhead crane with these specifications ensures that ladle handling is performed safely and efficiently. Properly equipped cranes not only improve operational performance but also contribute to a safer and more reliable steelmaking environment.

Continuous Casting

In the continuous casting process, precision and automation are your best friends. This stage involves handling mold sections and steel billets, which require a crane that can manage these tasks with high accuracy and reliability.

Crane Type: Semi-Gantry Cranes, Cantilever Cranes

Typical Capacity: 20 to 50 tons

Typical Objects Handled: Mold sections, steel billets

Below Hook Devices: Mold handlers, billet clamps

Semi-Gantry Cranes: Semi-gantry cranes are well-suited for continuous casting due to their ability to operate with great precision and flexibility. They typically feature one set of wheels on a fixed rail and another set on the ground, which provides excellent maneuverability and stability. This type of crane is particularly useful in environments where space is limited but precision is paramount.

Cantilever Cranes: Cantilever cranes, with their unique design that allows for extended reach and flexibility, are another excellent choice. These cranes extend out over the casting area, providing easy access to mold sections and billets without the need for extensive maneuvering space. Their design supports precise handling and positioning, crucial for effective continuous casting.

Typical Capacity: 20 to 50 Tons

Crane capacities in the range of 20 to 50 tons are ideal for handling the weight of mold sections and steel billets during continuous casting. This capacity ensures that the crane can manage the substantial weight of these components without compromising stability or control.

Typical Objects Handled: Mold Sections, Steel Billets

Mold Sections: In continuous casting, mold sections are critical components used to shape the steel as it solidifies. Handling these molds requires a crane that can operate with precise control to ensure that the molds are positioned correctly for optimal casting results.

Steel Billets: Steel billets are semi-finished products that need to be transported and positioned with high accuracy. A crane equipped to handle billets effectively will ensure that they are moved smoothly through the casting process, maintaining the flow and quality of production.

Below Hook Devices: Mold Handlers, Billet Clamps

Mold Handlers: Mold handlers are specialized attachments designed to lift, transport, and position mold sections accurately. They ensure that the molds are placed correctly in the casting area, which is crucial for maintaining the quality of the steel being produced.

Billet Clamps: Billet clamps are used to securely grip and transport steel billets. These clamps must be robust and reliable, capable of handling the weight and dimensions of the billets while ensuring they remain securely in place during movement.

Practical Tips for Selection:

For this operation, go for cranes that shine in precision and automation. Semi-gantry and cantilever cranes are ideal choices because they offer excellent maneuverability and control. Precision is critical here—mold sections and billets need to be handled with exacting accuracy to ensure a smooth casting process.

Also, make sure your crane is compatible with your existing casting equipment. Seamless integration between your crane and other machinery can significantly enhance operational efficiency and reduce downtime. A crane that fits perfectly with your setup will help maintain a steady workflow and support optimal performance in your casting operations.

- Precision and Automation: Opt for cranes that excel in precision and automation to handle mold sections and billets accurately. The ability to make fine adjustments and maintain control over the positioning of these components is essential for a smooth and efficient casting process.

- Compatibility with Existing Equipment: Ensure that your crane is compatible with your current casting setup. Seamless integration between the crane and other machinery will enhance operational efficiency, minimize downtime, and support a consistent workflow. A crane that fits well with your existing equipment will contribute to a more streamlined and effective casting operation.

By selecting a crane that meets these criteria, you'll ensure that your continuous casting operations are carried out with the highest level of precision and efficiency, ultimately leading to improved production quality and reduced operational challenges.

Overhead Cranes in Steel Fabrication

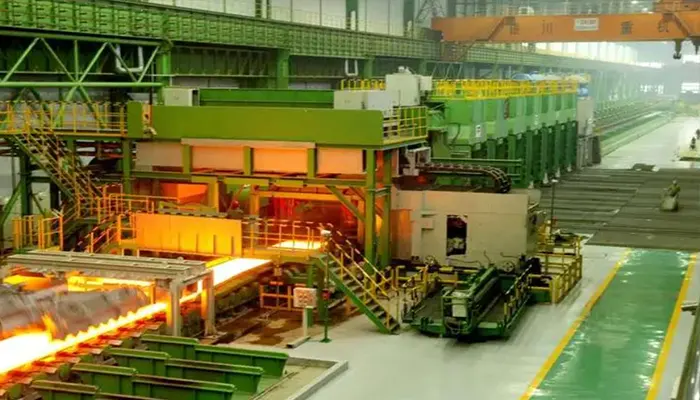

When it comes to steel fabrication, particularly in hot rolling mills, the right crane can make all the difference. These cranes need to handle hot, heavy materials with precision and speed.

Hot Rolling Mills

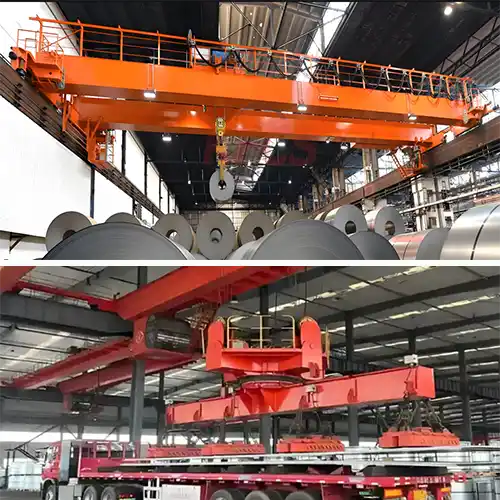

In hot rolling mills, you're dealing with some seriously heavy and hot loads, so your crane needs to be up to the task. Hot rolled coils and plates are the primary materials here, and they require robust handling solutions.

Crane Type: Double Girder Overhead Cranes

Typical Capacity: 20 to 80 tons

Typical Objects Handled: Hot rolled coils, plates

Below Hook Devices: Coil grabs, plate lifting devices

Crane Type: Double Girder Overhead Cranes

Double Girder Overhead Cranes: Double girder overhead cranes are the go-to choice for hot rolling mills due to their robust design and high load capacity. The double girder setup provides enhanced stability and strength, making it well-suited for handling the heavy and hot loads typical of this environment. With their ability to handle weights ranging from 20 to 80 tons, these cranes ensure that you can move large quantities of hot rolled coils and plates efficiently.

Typical Capacity: 20 to 80 Tons

Capacity Range: In hot rolling mills, cranes need to manage substantial weights. The typical capacity range of 20 to 80 tons for these cranes ensures that they can handle the bulk of hot rolled coils and plates without compromising on performance or safety.

Typical Objects Handled: Hot Rolled Coils, Plates

Hot Rolled Coils and Plates: These are the primary materials handled in hot rolling mills. Hot rolled coils are often very heavy and can reach high temperatures, making it crucial for cranes to have the capability to manage them effectively. Similarly, plates, which can be large and heavy, require robust handling solutions.

Below Hook Devices: Coil Grabs, Plate Lifting Devices

Coil Grabs: Coil grabs are essential for securely lifting and transporting hot rolled coils. These devices must be designed to handle the extreme heat and weight of the coils, providing a firm grip to prevent any slippage during movement.

Plate Lifting Devices: Plate lifting devices are used to handle large steel plates, allowing for safe and efficient movement. These devices should be capable of withstanding high temperatures and handling heavy loads with precision.

Practical Tips for Selection:

For these applications, double girder overhead cranes are a solid choice. They offer the speed and stability necessary to manage the fast-moving, heavy loads typically found in hot rolling mills. Look for cranes that can maintain high-speed operations without sacrificing stability. This is crucial for ensuring both efficiency and safety in handling hot coils and plates.

Additionally, ensure that the cranes are specifically designed to handle the intense heat generated by hot coils. Features that protect against high temperatures and provide effective cooling can prevent equipment wear and ensure a longer operational life. Investing in a crane with these capabilities will help you keep operations smooth and efficient, even under the toughest conditions.

- Speed and Stability: Opt for double girder overhead cranes that offer both high-speed operation and excellent stability. Hot rolling mills often involve fast-moving loads, so your crane must be able to keep up without sacrificing control or safety. Look for cranes with advanced drive systems that enhance speed while maintaining stability.

- Heat Resistance: Ensure the crane is designed to handle the high temperatures associated with hot coils and plates. Features such as heat-resistant coatings, cooling systems, and thermal protection can prevent premature wear and extend the life of your crane. Investing in these features will help maintain smooth operations and reduce the risk of equipment failure.

By selecting a double girder overhead crane that meets these criteria, you'll ensure that your hot rolling mill operations are efficient, safe, and capable of handling the demanding conditions of steel fabrication.

Cold Rolling Mills

Cold rolling mills deal with more delicate materials compared to hot rolling mills, requiring cranes that offer precision and gentle handling. The goal here is to process cold rolled coils and sheets with minimal disturbance.

Crane Type: Single Girder Overhead Cranes

Typical Capacity: 10 to 50 tons

Typical Objects Handled: Cold rolled coils, sheets

Below Hook Devices: Coil lifters, sheet grabs

Single Girder Overhead Cranes

Single Girder Overhead Cranes: Single girder overhead cranes are typically preferred for cold rolling mills due to their precision and ability to handle lighter loads compared to their double girder counterparts. These cranes, with their streamlined design, offer the necessary control and flexibility needed to manage cold rolled coils and sheets effectively. Check more on steel mill coil handling cranes or leave us a message down below now.

Typical Capacity: 10 to 50 Tons

Capacity Range: The capacity range of 10 to 50 tons is suitable for the weights of cold rolled coils and sheets. These cranes can manage the required loads without compromising on the delicate nature of the materials.

Typical Objects Handled: Cold Rolled Coils, Sheets

Cold Rolled Coils and Sheets: Cold rolled coils and sheets are often thinner and more sensitive to handling than hot rolled materials. Proper handling is crucial to avoid defects and ensure the quality of the finished products.

Below Hook Devices: Coil Lifters, Sheet Grabs

Coil Lifters: Coil lifters are designed to handle the delicate nature of cold rolled coils. They provide a secure grip while minimizing the risk of damage during lifting and transportation.

Sheet Grabs: Sheet grabs are used to handle cold rolled sheets with precision. These devices should be equipped to lift sheets gently, ensuring that the integrity of the material is maintained throughout the handling process.

Practical Tips for Selection:

They provide the precise control needed to handle cold rolled coils and sheets delicately. Look for cranes designed with low vibration features to avoid any damage to these sensitive materials. Adjustable lifting mechanisms are also a must, as they allow for versatility in handling various sheet sizes and weights.

Choosing a crane that excels in precision and stability will help maintain the quality of your cold rolled products and ensure smooth, efficient operations in your cold rolling mill.

- Precision and Stability: Choose single girder overhead cranes that offer precise control and minimal vibration. In cold rolling mills, the ability to handle materials gently and accurately is crucial to maintaining product quality. Cranes with advanced control systems and low-vibration features help achieve the desired handling precision.

- Adjustable Lifting Mechanisms: Look for cranes with adjustable lifting mechanisms to accommodate various sheet sizes and weights. Flexibility in handling different dimensions and weights ensures that the crane can adapt to changing operational needs, improving overall efficiency.

- Maintenance and Reliability: Ensure that the crane is reliable and easy to maintain. Regular maintenance is essential to keep the crane operating smoothly and prevent issues that could impact the handling of sensitive materials. Select models known for their durability and ease of service to reduce downtime and maintain high operational standards.

By selecting a single girder overhead crane that excels in precision and stability, you'll be well-equipped to handle the delicate materials in cold rolling mills effectively. This choice will help maintain the quality of your cold rolled products and support efficient, smooth operations in your facility.

Overhead Cranes for Steel Storage

When it comes to steel storage and warehousing, the primary objective is to manage and organize a variety of steel products efficiently. Cranes in this sector need to be versatile, capable of handling different types of steel products with ease.

Steel Storage and Warehousing

Crane Type: Overhead Bridge Cranes, Storage Cranes

Typical Capacity: 10 to 30 tons

Typical Objects Handled: Steel coils, plates, sections

Below Hook Devices: Magnetic lifts, coil spinners

Overhead Bridge Cranes, Storage Cranes

Overhead Bridge Cranes: These cranes are a popular choice for steel storage due to their versatility and ability to cover large areas. They are well-suited for handling various types of steel products, including coils, plates, and sections. Their design allows them to move smoothly across the width of a warehouse, providing efficient access to different storage areas.

Storage Cranes: Specialized storage cranes are designed specifically for the efficient management of steel in warehousing environments. They often feature advanced controls and high maneuverability, which are crucial for navigating tight spaces and handling diverse steel products.

Typical Capacity: 10 to 30 Tons

Capacity Range: A capacity range of 10 to 30 tons is generally adequate for handling steel coils, plates, and sections commonly found in storage environments. This range ensures that the crane can manage the weight of these products without compromising performance or safety.

Typical Objects Handled: Steel Coils, Plates, Sections

Steel Coils: Coils are often stored in large quantities and require careful handling to prevent damage. Cranes must be able to lift and maneuver these heavy, unwieldy items with precision.

Steel Plates: Plates, which can be both large and heavy, need cranes that provide stable lifting and positioning to avoid accidents or product damage.

Steel Sections: Steel sections come in various shapes and sizes, requiring cranes with versatile handling capabilities to manage them effectively.

Below Hook Devices: Magnetic Lifts, Coil Spinners

Magnetic Lifts: Magnetic lifts are ideal for handling steel products with a high degree of efficiency. They can securely lift and transport steel coils and plates without physical contact, reducing the risk of damage and increasing operational speed.

Coil Spinners: Coil spinners are useful for rotating steel coils to facilitate proper storage and easy access. They help in organizing steel products within the warehouse and make the handling process more efficient.

Practical Tips for Selection:

In steel storage and warehousing, overhead bridge cranes and storage cranes are ideal for their ability to navigate tight spaces and handle a range of steel products, from coils and plates to sections. These cranes should be chosen with an eye toward maximizing storage space and maneuverability within the warehouse.

For optimal performance, look for cranes equipped with magnetic lifts or coil spinners, which make it easier to handle various steel products efficiently. The right crane will help streamline your storage operations, ensuring that steel products are handled and stored safely and effectively.

- Maximize Storage Space: Choose cranes that are designed to make the most out of your warehouse space. Overhead bridge cranes with a wide span and storage cranes with high maneuverability can help optimize storage efficiency and ease access to different areas.

- Versatility and Maneuverability: Look for cranes that can handle various types of steel products and navigate tight spaces. Features such as adjustable lifting mechanisms and precise controls enhance versatility, making it easier to manage a diverse inventory.

- Efficiency and Safety: Ensure that the crane is equipped with devices like magnetic lifts and coil spinners to handle steel products efficiently and safely. These devices streamline operations and reduce the risk of product damage or accidents.

- Durability and Maintenance: Select cranes that are built to withstand the demands of a busy storage environment. Durability and ease of maintenance are essential to minimize downtime and keep operations running smoothly.

By choosing the right overhead crane for steel storage and warehousing, you'll enhance the efficiency of your operations and ensure the safe handling of various steel products. The right equipment will not only streamline your storage processes but also contribute to a safer and more organized warehouse environment.

Key Considerations for Selecting Overhead Cranes

Selecting the right overhead crane involves a mix of practical considerations and specific requirements tailored to your operations. Here's a guide to help you make the best choice for your steelworks, fabrication, and storage needs.

Determine the Specific Needs of Your Application

When choosing an overhead crane, the first step is to thoroughly assess the demands of your application. Start by identifying the types of loads and objects that the crane will handle. Are you dealing with heavy steel coils, delicate sheets, or bulky molds? Understanding this will guide you in selecting a crane that can handle these materials effectively.

Assess Types of Loads and Objects

Identify the Materials:

- Heavy Steel Coils: If your application involves handling heavy steel coils, you'll need a crane with a high load capacity and robust design. Consider cranes with features that accommodate the weight and size of these coils without compromising performance.

- Delicate Sheets: For handling sensitive materials like cold-rolled sheets, precision is key. Choose cranes with features that ensure gentle handling to avoid damaging the sheets, such as low vibration and adjustable lifting mechanisms.

- Bulky Molds: When dealing with large molds, the crane must be capable of precise positioning and maneuvering. Cranes with extended reach and stability features will be essential to handle these large items effectively.

Next, evaluate the required lifting capacity and crane reach. The lifting capacity should match or exceed the maximum weight of the items you need to move.

Evaluate Lifting Capacity

Match or Exceed Maximum Weight:

- Determine the maximum weight of the heaviest item you will handle. Your crane should be capable of lifting this weight safely and efficiently. Opt for a crane with a lifting capacity that not only meets but slightly exceeds the maximum load to ensure safe operation under all conditions.

Capacity Considerations:

- 5 to 30 Tons: Suitable for lighter tasks, such as handling scrap metal or smaller steel coils.

- 20 to 50 Tons: Ideal for heavier tasks, including electric arc furnace charging and handling large molds.

- 30 to 100 Tons: Necessary for extremely heavy loads, such as ladles filled with molten steel.

Similarly, ensure the crane's reach aligns with the dimensions of your workspace to allow for efficient operation and placement of materials.

Evaluate Crane Reach

Workspace Dimensions:

- Crane Span and Height: Ensure the crane's span and lifting height align with the dimensions of your workspace. The crane should be able to reach all areas where materials need to be placed or retrieved.

- Operational Space: Consider the layout of your facility. The crane should fit within the operational space without obstructing other equipment or workflow.

Efficient Operation:

- Choose a crane with an appropriate reach to minimize the need for repositioning. This enhances operational efficiency and reduces cycle times.

Taking these factors into account will help you select a crane that not only meets your operational needs but also enhances efficiency and safety in your workspace.

By thoroughly assessing the types of loads and objects you handle, evaluating the required lifting capacity, and ensuring the crane's reach aligns with your workspace dimensions, you will be better equipped to select a crane that meets your operational needs. This careful consideration will lead to improved efficiency, safety, and performance in your operations.

Consider Crane Type and Design

Choosing the right type and design of overhead crane is crucial for optimizing performance and ensuring seamless operation in your facility. Here's how to approach this decision:

By matching the crane type and design to your specific application and layout, you'll ensure that your overhead crane enhances efficiency, safety, and productivity in your operations.

Consider Crane Type and Design

Selecting the appropriate type and design of an overhead crane is fundamental to optimizing performance and ensuring it meets the operational demands of your facility. Here's a detailed guide to help you make an informed decision:

Match the Crane Type to Your Application and Layout: Different types of cranes are suited to specific tasks and environments. For instance, single girder cranes are often ideal for lighter loads and simpler tasks, while double girder cranes are better for heavier loads and more complex operations. Gantry cranes are a good choice for outdoor or large-scale applications where space and flexibility are key. Evaluate your specific needs—whether you need a crane for high-speed operations, heavy-duty lifting, or precise positioning—and select a crane type that aligns with these requirements.

Types of Cranes and Their Uses:

Single Girder Cranes:

- Ideal For: Lighter loads and simpler tasks.

- Advantages: Cost-effective, space-saving, and suitable for facilities with lower headroom.

- Applications: Cold rolling mills, light-duty fabrication.

Double Girder Cranes:

- Ideal For: Heavier loads and complex operations.

- Advantages: Greater lifting capacity, higher stability, and better suited for high-speed and heavy-duty applications.

- Applications: Hot rolling mills, EAF charging, ladle handling.

Gantry Cranes:

- Ideal For: Outdoor or large-scale applications where flexibility and space are key.

- Advantages: Can be used on a variety of surfaces, including outdoor environments, and allows for movement across different areas.

- Applications: Scrap yard handling, large-scale steel storage.

Semi-Gantry and Cantilever Cranes:

- Ideal For: Specific applications requiring precision and maneuverability.

- Advantages: Suitable for tasks where full gantry or bridge clearance isn't possible or required.

- Applications: Continuous casting, specific industrial setups with spatial constraints.

Ensure the Crane Design Meets Operational Requirements and Space Constraints: The crane's design should fit the operational demands of your facility and the physical space available. Consider factors such as the crane's height, span, and reach to ensure it integrates smoothly with your existing equipment and layout. The design should accommodate any space constraints, such as low headroom or narrow aisles, and support the required operational flow without obstructing other processes.

- High-Speed Operations: For tasks that require fast movement and handling, such as in hot rolling mills, double girder cranes with high-speed capabilities are essential.

- Heavy-Duty Lifting: For lifting extremely heavy materials, like ladles with molten steel, double girder cranes with high load capacities are necessary.

- Precise Positioning: For applications requiring precise control, such as cold rolling mills, cranes with advanced positioning and control features are crucial.

Ensure the Crane Design Meets Operational Requirements and Space Constraints

Design Considerations:

Crane Height and Span:

- Ensure the crane's height and span fit the physical dimensions of your facility. The crane should be able to cover the required area and reach all necessary locations without obstructing other equipment or workflow.

Headroom and Aisle Width:

- Low Headroom: For facilities with limited vertical space, select cranes designed to maximize headroom while maintaining lifting capabilities.

- Narrow Aisles: For facilities with tight spaces, choose cranes with compact designs and maneuverability features to navigate narrow aisles effectively.

Integration with Existing Equipment:

- The crane should integrate seamlessly with existing machinery and processes. Consider how the crane's movement and functionality will align with other operations to ensure a smooth workflow.

Space Optimization:

- Operational Flow: Ensure the crane design supports the desired operational flow, allowing for efficient material handling and minimizing downtime or interference with other processes.

By carefully matching the crane type to your specific application and ensuring the design accommodates operational needs and space constraints, you will enhance the efficiency, safety, and productivity of your facility. The right crane not only improves operational performance but also integrates smoothly into your existing layout, contributing to overall effectiveness in your operations.

Focus on Load Capacity and Hook Devices

Choose Cranes with Adequate Capacity for Your Heaviest Loads: The crane's load capacity is one of the most critical factors to consider. It's essential to select a crane that can comfortably handle the heaviest loads you'll be lifting. Overestimating the capacity needed can result in unnecessary costs, while underestimating can lead to safety issues and equipment failure. Consider not just the maximum weight but also the frequency and type of loads to ensure the crane operates efficiently and safely under all conditions.

Understanding Load Capacity:

- Capacity Range: Ensure that the crane's maximum load capacity exceeds the heaviest material you need to lift. This provides a safety margin and ensures that the crane can handle unexpected load variations.

- Frequency of Use: Consider not just the maximum weight but also how frequently the crane will be lifting these loads. Frequent lifting of heavy loads requires a crane designed for continuous, high-load operations to avoid wear and tear.

Types of Loads:

- Dynamic vs. Static Loads: Dynamic loads involve movement and require cranes with higher stability and capacity. Static loads are stationary and may allow for cranes with lower capacities, but the crane still needs to handle the load without strain.

- Load Variability: Different materials and objects vary in weight and handling requirements. A crane with adjustable capacity or one that can be equipped with various below-hook devices can handle a wider range of materials.

Safety Considerations:

- Overhead Safety: Ensure that the crane's design and capacity include safety features like overload protection systems to prevent accidents and equipment damage.

- Regular Inspections: Regularly inspect the crane to ensure it maintains its rated capacity and operational safety. Check for signs of wear and tear that could impact its lifting ability.

Operational Efficiency:

- Reduced Downtime: A crane with the right capacity will reduce downtime associated with overloading and equipment malfunctions, contributing to smoother operations and increased productivity.

- Cost-Efficiency: Avoid both over-specifying and under-specifying the crane capacity to balance between cost and operational efficiency. Over-specification leads to higher costs, while under-specification can result in safety risks and reduced crane lifespan.

Select Below-Hook Devices Tailored to the Types of Objects Handled: Below-hook devices are crucial for the effective handling of materials and should be chosen based on the specific objects your crane will lift. Common devices include clamshell buckets for scrap metal, coil grabs for hot rolled coils, and magnets for steel plates. Each device is designed for particular types of loads and tasks. For example, magnetic lifts are excellent for handling ferrous materials, while coil spinners are specialized for rotating and lifting steel coils. Choosing the right below-hook device enhances operational efficiency and reduces handling time, ensuring that your crane meets the precise needs of your operations.

Types of Below-Hook Devices:

Clamshell Buckets:

- Use: Ideal for handling scrap metal, loose materials, and bulk loads.

- Features: Equipped with a clamshell mechanism that can scoop, grab, and release materials efficiently.

Coil Grabs:

- Use: Specifically designed for lifting and handling steel coils.

- Features: Equipped with gripping mechanisms that securely hold and maneuver coils without causing damage.

Magnets:

- Use: Perfect for handling ferrous materials such as steel plates and scrap metal.

- Features: Electromagnets or permanent magnets can lift and move heavy steel items with ease.

Coil Spinners:

- Use: Specialized for rotating and lifting steel coils.

- Features: Allows for the easy handling and positioning of coils, particularly useful in processing and storage applications.

Device Selection Criteria:

- Compatibility: Ensure the below-hook devices are compatible with the crane's hook and lifting mechanism. Proper fit and alignment are essential for effective operation.

- Material Handling Needs: Choose devices based on the specific handling requirements of the materials, such as the need for secure gripping, gentle lifting, or rotational capabilities.

- Ease of Use: Select devices that enhance operator efficiency and safety. Devices with user-friendly controls and features will streamline operations and minimize handling time.

Performance and Maintenance:

- Efficiency: Well-chosen below-hook devices enhance the crane's performance by providing the right handling solutions for various materials, thereby increasing operational efficiency.

- Maintenance: Regularly inspect and maintain below-hook devices to ensure they function correctly and do not pose safety risks. Proper maintenance will extend the lifespan of both the crane and the devices.

Choosing the right crane capacity and below-hook devices is crucial for safe and efficient material handling. By selecting cranes with appropriate capacities and devices tailored to your specific needs, you enhance operational efficiency, improve safety, and ensure that your lifting operations run smoothly.

Evaluate Safety and Maintenance Features

Ensure Cranes Have Safety Features Like Overload Protection and Emergency Stops: Safety is paramount when selecting an overhead crane. Look for cranes equipped with safety features such as overload protection systems, which prevent the crane from lifting loads beyond its capacity, and emergency stop mechanisms that allow for immediate shutdown in case of a malfunction or hazard. These features help prevent accidents, protect both personnel and equipment, and ensure compliance with industry safety standards. Additionally, cranes should have clear and accessible controls, and operators should be trained to use these safety features effectively.

Overload Protection:

- Purpose: Overload protection systems prevent the crane from lifting loads that exceed its rated capacity. This feature is essential to avoid structural damage to the crane and to prevent accidents that could harm personnel or damage equipment.

- Types of Systems: Look for cranes equipped with load limiters or overload sensors that automatically detect and halt operations if the load exceeds safe limits. These systems can provide audible and visual warnings to operators as well.

- Compliance: Ensure that the overload protection systems comply with relevant industry standards and regulations, such as those outlined by the Occupational Safety and Health Administration (OSHA) or the European Standards (EN).

Emergency Stops:

- Purpose: Emergency stop mechanisms are critical for stopping the crane immediately in case of a malfunction, hazard, or emergency situation. This feature helps prevent accidents and ensures quick response to any unsafe conditions.

- Types of Stops: Cranes should have clearly marked and easily accessible emergency stop buttons or switches located at multiple points, including the operator's control station and remote locations if applicable.

- Testing and Training: Regularly test emergency stop systems to ensure they function correctly. Additionally, train operators on the proper use of emergency stops and the procedures to follow in case of an emergency.

Clear and Accessible Controls:

- Design: Ensure that crane controls are user-friendly and clearly labeled to minimize the risk of operational errors. Controls should be accessible to the operator from the normal operating position.

- Training: Provide comprehensive training for operators on the use of crane controls and safety features. Regularly review safety protocols and procedures to keep the team updated.

Consider Ease of Maintenance and Accessibility for Routine Checks: Regular maintenance is crucial for the longevity and reliable performance of overhead cranes. Choose cranes designed with maintenance in mind, such as those with easily accessible components for routine inspections and repairs. Features like lubrication points that are easy to reach and diagnostic systems that provide real-time information about crane performance can significantly simplify maintenance tasks. Ensuring that your crane is easy to maintain helps avoid unexpected downtime, prolongs the equipment's lifespan, and ensures ongoing operational efficiency.

Design for Maintenance:

- Accessibility: Choose cranes designed with maintenance in mind. This includes features such as easily accessible components, service panels, and lubrication points. Components should be arranged to facilitate straightforward inspection and servicing.

- Maintenance Stations: Some cranes are equipped with built-in maintenance stations or platforms that allow technicians to perform checks and repairs safely and efficiently.

Lubrication and Diagnostics:

- Lubrication Points: Ensure that lubrication points are easily reachable without requiring extensive disassembly. Regular lubrication is vital for reducing friction and wear on moving parts, which extends the crane's lifespan.

- Diagnostic Systems: Advanced cranes may include diagnostic systems that monitor performance and provide real-time feedback on equipment health. These systems can alert operators and maintenance personnel to potential issues before they lead to significant problems.

Regular Inspections and Maintenance:

- Inspection Schedule: Develop and adhere to a regular inspection and maintenance schedule to keep the crane in optimal condition. This should include routine checks of mechanical components, safety features, and control systems.

- Record Keeping: Maintain detailed records of all maintenance activities, including inspections, repairs, and part replacements. This documentation helps track the crane's performance and can be useful for identifying recurring issues.

Minimize Downtime:

- Preventive Maintenance: Implement a preventive maintenance program to address potential issues before they result in breakdowns. This can help reduce unplanned downtime and extend the life of the crane.

- Parts Availability: Ensure that replacement parts and maintenance supplies are readily available to minimize delays in repairs and maintenance.

By focusing on robust safety features, including overload protection and emergency stops, and ensuring that the crane is designed for easy maintenance, you enhance the safety, reliability, and efficiency of your overhead crane system. These considerations will help maintain safe operating conditions, extend the crane's lifespan, and ensure smooth, uninterrupted operations in your facility.

Conclusion

In the steel production, overhead cranes play a pivotal role across various stages, from initial steelmaking to final product handling and storage. Here's a quick recap of the essential crane types and their applications:

- Scrap Yard Handling: Single girder and gantry cranes with capacities ranging from 5 to 30 tons are ideal for managing steel scrap and metal bales. Equipped with clamshell buckets and magnetic grabs, these cranes are designed for durability and efficiency in heavy-load environments.

- Electric Arc Furnace (EAF) Charging: Double girder cranes, with capacities between 20 and 50 tons, handle scrap metal and additives. Heavy-duty buckets and charging baskets ensure safe and precise operation under high temperatures.

- Ladle Handling: Heavy-duty double girder cranes with capacities of 30 to 100 tons are critical for handling ladles filled with molten steel. Specialized ladle hooks and molten steel handling attachments are essential for safety and control.

- Continuous Casting: Semi-gantry and cantilever cranes, typically with capacities of 20 to 50 tons, manage mold sections and steel billets. Mold handlers and billet clamps provide high precision and integration with casting equipment.

- Hot Rolling Mills: Double girder cranes, with capacities from 20 to 80 tons, are used for moving hot rolled coils and plates. Coil grabs and plate lifting devices facilitate high-speed and stable handling.

- Cold Rolling Mills: Single girder cranes, with capacities ranging from 10 to 50 tons, handle cold rolled coils and sheets. Coil lifters and sheet grabs are selected for precise control and low vibration.

- Steel Storage and Warehousing: Overhead bridge and storage cranes with capacities of 10 to 30 tons are used for steel coils, plates, and sections. Magnetic lifts and coil spinners enhance maneuverability and efficiency in storage operations.

Future Trends and Innovations

The overhead crane industry is continually evolving, with new technologies and innovations pushing the boundaries of performance and efficiency. Emerging trends include:

- Smart Crane Systems: Integration of IoT and AI technologies allows for real-time monitoring, predictive maintenance, and enhanced automation. Smart cranes offer improved safety, efficiency, and operational insights.

- Enhanced Safety Features: Advances in safety technology include advanced collision avoidance systems, automated load monitoring, and improved ergonomic controls, all contributing to safer and more reliable crane operations.

- Energy-Efficient Designs: New crane designs focus on reducing energy consumption through more efficient motors, regenerative braking systems, and lightweight materials, helping to lower operational costs and environmental impact.

- Customizable Solutions: Increased demand for specialized and customizable crane solutions is leading to more flexible designs that can be tailored to unique industry requirements, improving overall functionality and adaptability.

By staying informed about these advancements and incorporating the latest technologies, businesses can ensure that their overhead crane systems continue to meet the demands of modern steel production and handling, driving greater efficiency and productivity in their operations.

Quick Reference List of Crane Capacities

For a quick and easy reference, here's a summary of the crane capacities suitable for different steel industry applications:

5 to 30 tons:

Scrap Yard Handling: For managing steel scrap and metal bales.

Steel Storage and Warehousing: Handling steel coils, plates, and sections.

Steel Fabrication Workshops: For fabricated steel parts and structural sections.

20 to 50 tons:

Electric Arc Furnace (EAF) Charging: Handling scrap metal and additives.

Continuous Casting: Managing mold sections and steel billets.

Hot Rolling Mills: Moving hot rolled coils and plates.

30 to 100 tons:

Ladle Handling: For handling ladles with molten steel.

10 to 50 tons:

Cold Rolling Mills: Handling cold rolled coils and sheets.

20 to 80 tons:

Hot Rolling Mills: Moving hot rolled coils and plates (specific capacities also fall under this range).

5 to 20 tons:

Steel Fabrication Workshops: For handling fabricated steel parts and structural sections.

This list helps you match the crane capacity with your specific steel handling and processing needs, ensuring you select the right equipment for optimal performance and efficiency.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch