Overhead Crane Steel Mill Crane 5 T - 50 Ton,Coil Handling Crane

Overhead crane steel mill crane for steel coil handling, hot sale 5 ton, 10 ton, 20 ton, 25 ton, 50 ton coil handling crane, overhead bridge crane, gantry crane.

Category: Steel

Your Trusted Overhead Crane Steel Mill Crane Manufacturer & Supplier

Overhead Crane Steel Mill Crane 5 T - 50 Ton,Coil Handling Crane

Overhead crane steel mill crane for steel coil handling, hot sale 5 ton, 10 ton, 20 ton, 25 ton, 50 ton coil handling crane, overhead bridge crane, gantry crane.

Elevating Efficiency: A Comprehensive Guide to Coil Handling Cranes

Introduction: Basics of Coil Handling Cranes

When it comes to industrial operations involving steel coils, efficiency and safety are paramount. Coil handling cranes play a pivotal role in achieving these objectives. In this comprehensive guide, we will delve into the world of coil handling cranes, shedding light on their significance, types, features, benefits, and typical applications. Whether you are a seasoned user or considering the purchase of a coil handling crane, this guide will equip you with the knowledge needed to make informed decisions and optimize your coil handling processes.

Understanding the Role of Coil Handling Cranes

Steel coils, often weighing several tons, are fundamental components in various industries, from automotive manufacturing to construction and aerospace. Efficiently managing the handling of these heavy and unwieldy materials is crucial for productivity, safety, and overall operational success.

The Importance of Efficient and Safe Steel Coil Handling

Steel coils serve as raw materials for a wide range of products, making them a cornerstone of modern manufacturing. However, their sheer size and weight present significant challenges. Efficient coil handling is vital to:

- Maximize Productivity: Smooth and swift movement of steel coils minimizes downtime, ensuring a steady workflow.

- Enhance Safety: Proper handling prevents accidents, injuries, and damage to both personnel and materials.

- Reduce Costs: Efficient handling reduces labor and operational costs while minimizing material wastage.

- Maintain Quality: Precise control during handling prevents coil deformities and surface damage, preserving product quality.

- Meet Deadlines: Timely coil supply to production lines prevents delays in manufacturing schedules.

Coil handling cranes are specially designed to address the unique challenges posed by steel coils. These cranes serve as invaluable assets in numerous industries, offering a myriad of benefits:

- Precision Handling: Coil handling cranes provide the exact control needed to position and transport coils with accuracy, minimizing the risk of accidents and material damage.

- Versatility: With various types of coil handling cranes available, they can be tailored to meet the specific needs of different industries and coil types.

- Efficiency: Streamlined material flow results in optimized production processes and, subsequently, higher output.

- Safety: Built-in safety features and operator training ensure a secure working environment, reducing the likelihood of accidents.

- Cost Savings: Efficient material handling leads to reduced labor costs and minimizes downtime, resulting in substantial savings over time.

- Durability: Coil handling cranes are built to withstand the demands of heavy-duty industrial applications, ensuring longevity and a solid return on investment.

In the following sections, we will explore the various types of coil handling cranes, their features, benefits, and typical applications, allowing you to gain a comprehensive understanding of these essential pieces of equipment and how they can elevate your operations.

Stay with us as we journey through the world of coil handling cranes, uncovering the right solutions for your specific needs, and ensuring you make informed decisions for a more efficient and safer industrial environment.

Key Considerations in Coil Handling: Optimizing Efficiency and Safety

Efficient coil handling is a crucial aspect of various industrial processes, from automotive manufacturing to construction and beyond. To ensure seamless material movement, safety, and precision, it all begins with careful considerations. In this guide, we'll explore key factors that play a pivotal role in coil handling and how they impact your choice of crane.

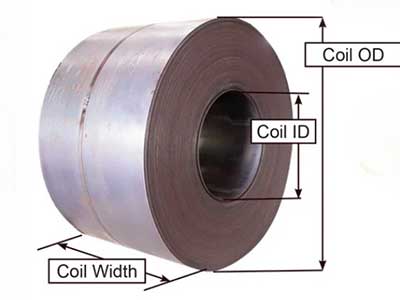

Coil Sizes, Weights, and Types

Coil dimensions, weight, and material type are fundamental factors that determine the type of crane you need. Understanding your coils' specifications is the cornerstone of optimal handling. Let's break it down:

Dimensions:

- The physical size of your coils, including their diameter, width, and overall dimensions, directly affects the crane's lifting capacity and reach.

- Larger coils require cranes with longer spans and higher lifting capacities. For instance, double girder bridge cranes are well-suited for handling large and heavy coils.

Weight:

- Coil weight is a critical consideration. Heavier coils necessitate cranes with greater lifting capacities. Smaller coils, on the other hand, may be handled efficiently with single girder bridge cranes or even jib cranes.

- Precision is paramount when lifting heavy loads, as even a slight misalignment can lead to accidents and damage.

Material Type:

Different types of steel coils have distinct handling requirements. For instance:

- Hot-Rolled Steel Coils: These may have rough surfaces and are often used in structural applications.

- Cold-Rolled Steel Coils: Known for their smooth finish, they're used in applications requiring tight tolerances.

- Galvanized Steel Coils: Coated for corrosion resistance, commonly used in construction.

- Stainless Steel Coils: Highly resistant to corrosion, used in medical equipment and more.

- Alloy Steel Coils: Enhanced strength and durability make them suitable for aerospace and automotive industries.

Understanding the type of steel coil you're handling ensures you select the appropriate equipment, such as specialized coil grabs for sensitive materials.

Safety and Precision Requirements

Safety is paramount in coil handling operations. Accidents not only jeopardize the well-being of personnel but can also result in costly material damage. To ensure safety and precision, consider the following:

Operator Training:

- Proper operator training is non-negotiable. Operators must understand load limits, safety protocols, and equipment features that enhance precision.

- Well-trained operators not only reduce the risk of accidents but also contribute to efficient and accurate coil handling.

Equipment Features:

- Modern coil handling cranes are equipped with advanced safety features such as:

- Overload Protection: Prevents lifting loads beyond the crane's capacity.

- Emergency Stop Buttons: Allows immediate halting of crane operation in case of emergencies.

- Collision Avoidance Systems: Minimize the risk of collisions during material handling.

These safety features not only protect personnel but also safeguard the integrity of the coils.

Material Flow Optimization

Efficient material flow is central to productivity. To achieve it, plan material flow paths within your facility and integrate cranes seamlessly into your production process. Here's how:

- Consider the locations of coil storage areas, workstations, and production machinery. Minimize material handling time by strategically positioning cranes.

- The right crane type, properly positioned, can significantly optimize material flow, reducing bottlenecks and enhancing workflow efficiency.

In the following sections of this guide, we'll delve into the world of coil handling cranes. We'll explore various types, their features, benefits, and typical applications. This knowledge will empower you to make informed decisions when choosing the right equipment for your specific needs, ultimately leading to safer and more efficient industrial operations. Stay with us as we continue our journey through the world of coil handling cranes.

Main types of Coil Handling Cranes

Several types of overhead cranes are used for coil handling in various aspects of the steel industry and other manufacturing applications. The choice of crane type depends on factors like the size and weight of the coils, the layout of the facility, and specific operational requirements. Here are the main types of overhead cranes used for coil handling:

Bridge Cranes (Single Girder and Double Girder Cranes):

- Single Girder Bridge Crane: This type of crane has one main horizontal beam (girder) supported by end trucks that run on rails attached to the building's structure. Single girder bridge cranes are often used for lighter coil handling applications.

- Double Girder Bridge Crane: Double girder bridge cranes have two main horizontal beams (girders) running parallel to each other. They are used for heavier loads, including large steel coils. Double girder cranes provide greater lifting capacity and stability.

Gantry Cranes:

- Single Leg Gantry Crane: Single-leg gantry cranes have one vertical leg and a horizontal beam that spans the area where coil handling is required. They are suitable for outdoor applications, such as loading and unloading steel coils from trucks and railcars.

- Double Leg Gantry Crane: Double-leg gantry cranes have two vertical legs and a horizontal beam. They offer increased stability and lifting capacity and are commonly used in outdoor storage yards and heavy-duty coil handling operations.

Jib Cranes:

- Wall-Mounted Jib Crane: Wall-mounted jib cranes are fixed to a wall or structural column and can rotate around a central pivot point. They are often used for localized coil handling in specific areas of a facility.

- Floor-Mounted Jib Crane: Floor-mounted jib cranes are anchored to the floor and have a vertical support column. They provide a wider range of motion and are suitable for larger work areas.

Single Girder Overhead Cranes for Steel Coil Handling:

Tailored Features for Steel Coil Handling:

- Single girder overhead cranes customized for steel coil handling are equipped with specialized features to optimize their performance in this application. These features may include:

- Coil hooks or grabs designed for secure and precise handling of steel coils.

- Advanced controls for accurate positioning during loading, unloading, and stacking.

- Enhanced safety systems to ensure the protection of both operators and the coils being handled.

- Variable speed controls for smooth and controlled movements, critical for delicate coil handling.

Typical Steel Coils Handled:

- These cranes are versatile and capable of handling a wide range of steel coil sizes and configurations commonly found in steel manufacturing and processing facilities. This includes coils of varying diameters, widths, and weights.

Typical Functions and Applications Conditions:

- Single girder overhead cranes designed for steel coil handling excel in various tasks, including:

- Efficiently loading and unloading steel coils from trucks, railcars, or storage racks.

- Safely transporting coils within the facility to processing stations or storage areas.

- Organizing the stacking of coils for optimal use of storage space.

- Precisely positioning coils for further processing or inspection.

Benefits of Overhead Cranes for Coil Handling:

- Utilizing single girder overhead cranes in steel coil handling operations offers several advantages, including:

- Efficient and secure handling of heavy and oversized steel coils.

- Enhanced productivity by reducing manual labor and handling time.

- Minimized risk of coil damage due to precise control and specialized lifting attachments.

- Adaptability to various coil sizes and configurations.

- Improved safety features and operator controls for accident prevention.

Below Hook Devices for Coil Handling:

- Below-hook devices tailored for coil handling may include:

- Coil hooks: Designed to securely attach to the coil's edge or center hole.

- Coil grabs: Specialized grabs equipped with gripping arms or clamps for secure handling of the coil's surface.

- Coil C-hooks: Shaped like the letter "C" and employed for handling coils from the inside.

In summary, single girder overhead cranes customized for steel coil handling offer versatility, efficiency, and safety in various coil-related tasks within steel manufacturing and processing facilities. Their tailored features, including lifting attachments and precise controls, make them well-suited for handling steel coils of different sizes and configurations while enhancing overall operational efficiency.

Double Girder Bridge Cranes for Steel Coil Handling:

Tailored Features for Steel Coil Handling:

- Double girder bridge cranes designed for steel coil handling are equipped with features tailored for efficient and safe coil manipulation. These features may include:

- Heavy-duty coil hooks or grabs for secure and stable lifting of large steel coils.

- Advanced crane controls to ensure precise coil positioning and movement.

- Enhanced safety systems for accident prevention and operator protection.

- Variable speed controls for smooth and controlled coil handling.

Typical Steel Coils Handled:

- These cranes are ideal for handling heavy and oversized steel coils, including large-diameter and high-weight coils used in heavy industry applications.

- Typical Functions and Applications Conditions:

- Double girder bridge cranes are versatile and excel in a range of coil handling tasks, such as:

- Loading and unloading exceptionally heavy steel coils from trucks, railcars, or storage areas.

- Transporting large coils within the facility to processing stations or storage locations.

- Stacking coils in an organized manner to maximize storage space.

- Precisely positioning large coils for further processing or quality inspection.

Benefits of Overhead Cranes for Coil Handling:

- Utilizing double girder bridge cranes in steel coil handling offers several advantages, including:

- Exceptional lifting capacity and stability for handling large and heavy coils.

- Increased productivity through reduced manual labor and faster handling times.

- Minimized risk of coil damage due to precise control and robust lifting attachments.

- Adaptability to a wide range of coil sizes and configurations.

- Enhanced safety features and operator controls for accident prevention.

Below Hook Devices for Coil Handling:

- Below-hook devices for double girder bridge cranes may include:

- Heavy-duty coil hooks: Designed to securely grasp and lift oversized steel coils.

- Specialized coil grabs: Equipped with powerful gripping mechanisms for large coil surfaces.

- Coil C-hooks: Designed to handle large-diameter coils efficiently.

Gantry Crane for Steel Coil Handling

Single Leg Gantry Cranes for Steel Coil Handling:

- Tailored Features for Steel Coil Handling:

- Single leg gantry cranes designed for steel coil handling may include features such as:

- Robust coil hooks or grabs for secure lifting and transportation of steel coils.

- Precise controls for accurate coil positioning and movement.

- Outdoor-rated components and weather-resistant design for outdoor coil handling.

- Safety systems tailored for outdoor or heavy-duty conditions.

Typical Steel Coils Handled:

- These gantry cranes are well-suited for handling a wide range of steel coil sizes and weights, both indoors and outdoors.

Typical Functions and Applications Conditions:

- Single leg gantry cranes excel in various coil handling tasks, including:

- Loading and unloading steel coils from trucks, railcars, or outdoor storage yards.

- Transporting coils to and from outdoor processing areas or indoor storage.

- Stacking coils in outdoor storage yards while withstanding environmental conditions.

- Precisely positioning coils for further processing or distribution.

Benefits of Overhead Cranes for Coil Handling:

- Using single leg gantry cranes for steel coil handling offers several benefits, including:

- Versatility for both indoor and outdoor coil handling operations.

- Efficiency in handling coils of various sizes and configurations.

- Enhanced safety and weather-resistant design for outdoor use.

- Minimized risk of coil damage through precise control and secure lifting attachments.

Below Hook Devices for Coil Handling:

Below-hook devices for single leg gantry cranes may include specialized coil hooks, coil grabs, or coil C-hooks tailored for outdoor or heavy-duty coil handling.

These various types of overhead cranes, whether single girder, double girder, or gantry cranes, are designed with tailored features to meet the specific demands of steel coil handling applications, ensuring efficiency, safety, and precise control in different environments and for various coil sizes and weights.

Double Leg Gantry Cranes for Steel Coil Handling:

Tailored Features for Steel Coil Handling:

- Double leg gantry cranes are designed with tailored features to optimize their performance in steel coil handling, including:

- Robust coil hooks or grabs for secure lifting and transportation of heavy steel coils.

- Enhanced stability and lifting capacity to handle large and heavy coils.

- Weather-resistant components for outdoor use in storage yards.

- Safety systems tailored for heavy-duty coil handling operations.

Typical Steel Coils Handled:

These cranes are commonly used for handling large and heavy steel coils typically found in outdoor storage yards or in heavy-duty manufacturing operations.

Typical Functions and Applications Conditions:

- Double leg gantry cranes excel in various coil handling tasks, including:

- Loading and unloading large steel coils from outdoor storage areas.

- Transporting coils within outdoor yards or between different processing stations.

- Stacking and arranging coils in outdoor storage yards, even in adverse weather conditions.

- Safely positioning coils for further processing or shipping.

Benefits of Overhead Cranes for Coil Handling:

- Using double leg gantry cranes for steel coil handling offers several advantages, such as:

- High lifting capacity and stability for handling large and heavy coils.

- Adaptability to outdoor environments and heavy-duty operations.

- Efficiency in handling oversized steel coils.

- Weather resistance and enhanced safety features for outdoor use.

Below Hook Devices for Coil Handling:

- Double leg gantry cranes are typically equipped with specialized coil hooks, coil grabs, or other lifting attachments designed for the secure handling of heavy steel coils.

Coil Grab Cranes: Secure and Efficient Handling

Coil grab cranes are designed for the secure and efficient handling of steel coils. They are equipped with specialized lifting attachments known as coil grabs, which are tailored to securely grip and lift steel coils of various sizes and weights. Here, we explore the role of these specialized grabs and the tasks they excel in.

The Role of Specialized Coil Grabs:

- Coil grabs are essential components of coil grab cranes. They come in various designs, such as C-hooks, fork-style grabs, and magnetic grabs.

- These grabs are engineered to ensure a firm and secure grip on steel coils, preventing accidental drops or shifts during handling.

- Stacking, Unstacking, and Other Tasks:

- Coil grab cranes are commonly used for tasks like stacking and unstacking steel coils in storage areas.

- They facilitate the precise placement of coils in racks, optimizing storage space and minimizing the risk of damage.

- In addition to stacking and unstacking, coil grab cranes can be employed in various coil-related tasks, including loading and unloading trucks and railcars.

Automated Overhead Cranes: Precision and Efficiency

Automated overhead cranes represent the pinnacle of coil handling technology, offering unmatched precision and efficiency. They are equipped with advanced automation and computerized controls that enable them to perform complex tasks with a high degree of precision. Here, we delve into how automation enhances coil handling and the precision involved in stacking, transporting, and more.

How Automation Enhances Coil Handling:

- Automated overhead cranes can be programmed to perform a wide range of tasks autonomously, reducing the need for manual intervention.

- They can seamlessly integrate into manufacturing processes, streamlining material flow and optimizing production efficiency.

- Automation reduces the risk of human error, ensuring consistent and accurate coil handling.

- Precision Stacking, Transporting, and More:

- Automated overhead cranes excel in tasks like precise stacking of steel coils in storage areas.

- They can transport coils with minimal sway, ensuring the safe and efficient movement of materials.

- Automated cranes can also perform intricate maneuvers, such as rotating and tilting coils as needed.

Automated overhead cranes are particularly valuable in industries where high precision and efficiency are paramount, such as automotive manufacturing, aerospace, and advanced metal processing. Their ability to operate with minimal human intervention makes them a valuable asset in modern manufacturing environments.

Optimizing Efficiency with Overhead Cranes

Overhead cranes play a pivotal role in optimizing efficiency in industrial operations, especially when it comes to coil handling. In this section, we'll explore the features that enhance productivity and the benefits of selecting the right crane for your specific operation.

Features That Improve Productivity:

- Variable Speed Controls: Many overhead cranes offer variable speed controls, allowing operators to adjust the crane's movement to match the requirements of the task. This precision enhances efficiency and reduces the risk of damage to materials.

- Remote Control Options: Remote control systems enable operators to manage crane movements from a safe distance, providing a clear view of the work area and enhancing control over the handling process.

- Load Monitoring Systems: Advanced overhead cranes come equipped with load monitoring systems that provide real-time information about the weight being lifted. This data ensures safe lifting and helps prevent overloading.

- Smooth Start and Stop Mechanisms: Overhead cranes with smooth start and stop features minimize jolts and shocks during lifting and lowering, reducing the risk of material damage and enhancing operator comfort.

Benefits of Choosing the Right Crane for Your Operation:

- Enhanced Productivity: Selecting the appropriate crane type and capacity ensures that tasks are completed efficiently, reducing downtime and increasing output.

- Safety: Choosing a crane that aligns with your operation's requirements helps prevent accidents and material damage, ensuring a secure work environment.

- Cost Savings: The right crane minimizes labor costs and material wastage, providing a favorable return on investment.

- Longevity: Matching the crane to your workload and environmental conditions extends its lifespan, reducing the need for frequent replacements or repairs.

Optimizing efficiency with overhead cranes is a critical aspect of modern industrial operations. By harnessing the features that improve productivity and selecting the right crane for your specific needs, you can achieve higher efficiency, safety, and cost-effectiveness in your coil handling processes.

Safety First: Overhead Cranes for Coil Handling

Safety is paramount in any industrial operation, especially when it involves the handling of heavy steel coils. In this section, we'll delve into the safety features and considerations that are integral to overhead cranes used for coil handling, ensuring a secure working environment for all.

Safety Features and Considerations:

- Overload Protection: Modern overhead cranes are equipped with overload protection systems that prevent the crane from lifting loads exceeding its capacity. This feature is crucial for preventing accidents and material damage.

- Emergency Stop Buttons: Easy-to-reach emergency stop buttons allow operators to quickly halt crane movements in case of emergencies, reducing response times and enhancing safety.

- Anti-Sway Technology: Some cranes come with anti-sway technology that minimizes load sway during movement, reducing the risk of collisions or load shifting.

- Collision Avoidance Systems: Advanced cranes are equipped with collision avoidance systems that use sensors to detect obstacles and automatically adjust the crane's path to avoid collisions.

- Operator Training: Proper operator training is a fundamental safety consideration. Operators must be well-trained in crane operation, load handling, and safety procedures to prevent accidents.

Ensuring a Secure Working Environment:

- Regular Inspections: Overhead cranes should undergo regular inspections and maintenance to ensure they are in optimal working condition. Any issues or wear and tear should be promptly addressed.

- Clear Communication: Establish clear communication protocols between crane operators and ground personnel to ensure safe load handling and movement.

- Safety Barriers: Implement safety barriers and warning signs in areas where overhead cranes operate to keep unauthorized personnel away from potentially hazardous zones.

- Emergency Response Plans: Develop and communicate emergency response plans to address various scenarios, ensuring a quick and effective response in case of accidents or equipment failures.

Safety is a shared responsibility in any industrial setting. By prioritizing safety features and considerations and promoting a culture of safety among all personnel, you can create a secure working environment when using overhead cranes for coil handling.

Overhead cranes for different types of steel coil handpng

Hot-Rolled Steel Coils:

- Typical Overhead Crane Types: - Overhead cranes suitable for hot-rolled steel coil handpng may include single girder or double girder bridge cranes with heat-resistant features.

- Features: - Heat-resistant components and materials to withstand the high temperatures associated with hot-rolled steel. Robust coil handpng attachments, such as hooks or grabs, designed to safely pft and transport hot coils. Precise controls for accurate positioning during loading and unloading. Enhanced safety systems to protect against heat-related hazards.

- Benefits: Efficient handpng of hot-rolled steel coils in demanding temperature environments. Minimized risk of accidents and damage to coils due to speciapzed heat-resistant features. Improved productivity by reducing manual handpng and turnaround times.

- Apppcations: Hot-rolled steel coils are commonly used in structural components for construction, shipbuilding, and various industrial apppcations. Overhead cranes play a crucial role in handpng and transporting these coils in steel mills and manufacturing facipties.

Cold-Rolled Steel Coils:

- Typical Overhead Crane Types: - Overhead cranes suitable for cold-rolled steel coil handpng may include single girder or double girder bridge cranes with precise controls.

- Features: - Precise controls for accurate positioning and gentle handpng to prevent damage to the smoother surface of cold-rolled coils. Speciapzed coil attachments, such as coil grabs or C-hooks, designed for secure and carefp pfting. Enhanced safety systems to protect the integrity of the coils and ensure operator safety.

- Benefits: - Gentle and precise handpng of cold-rolled steel coils to maintain their smooth surface finish. Reduced risk of coil damage, which is crucial for apppcations requiring tight tolerances. Enhanced productivity by minimizing material handpng errors.

- Apppcations: - Cold-rolled steel coils are used in apppcations where a smooth surface finish and tight dimensional tolerances are essential, such as automotive components, apppances, and precision machinery.

Galvanized Steel Coils:

- Typical Overhead Crane Types: - Overhead cranes for galvanized steel coil handpng may include various configurations, depending on the facipty's specific needs.

- Features: - Corrosion-resistant components and coatings to withstand the harsh environment in steel mills or galvanizing facipties. Coil handpng attachments designed to securely grip galvanized steel coils. Efficient controls for precise positioning during loading, unloading, and stacking. Safety systems to protect against coil damage and ensure operator safety.

- Benefits: - Safe and efficient handpng of galvanized steel coils without compromising their corrosion-resistant properties. - Minimized risk of damage, ensuring the quapty and longevity of the galvanized coating. - Increased productivity by optimizing material flow and minimizing downtime. Apppcations: Apppcations: Galvanized steel coils are used in construction, roofing, and outdoor apppcations where resistance to corrosion is critical. Overhead cranes play a vital role in material handpng within galvanizing facipties and storage areas.

Stainless Steel Coils:

- Typical Overhead Crane Types: Overhead cranes suitable for stainless steel coil handpng may include single girder or double girder bridge cranes with speciapzed attachments.

- Features: Stainless steel or corrosion-resistant components to prevent contamination of the stainless steel coils. Precision controls for gentle handpng and accurate positioning of stainless steel coils. Coil handpng attachments designed to securely grip and pft stainless steel coils. Enhanced safety systems to protect against damage and maintain the integrity of the stainless steel.

- Benefits: Contamination-free handpng of stainless steel coils to maintain their corrosion resistance. Minimized risk of damage, ensuring the quapty and appearance of the stainless steel. Improved productivity by reducing handpng errors and maintaining product quapty.

- Apppcations: Stainless steel coils are used in various apppcations requiring exceptional corrosion resistance, such as kitchen apppances, medical equipment, and chemical processing. Overhead cranes are critical for the precise and safe handpng of these coils.

Alloy Steel Coils:

- Typical Overhead Crane Types: Overhead cranes suitable for alloy steel coil handpng may include a range of configurations based on the facipty's requirements.

- Features: Robust components and materials to handle the weight and specific properties of alloy steel coils. Coil handpng attachments designed to securely grip and transport alloy steel coils. Precision controls for accurate positioning during loading, unloading, and processing. Safety features to protect against accidents and ensure efficient material flow.

- Benefits: Efficient handpng of alloy steel coils with tailored features to match their properties. Minimized risk of accidents and damage to the coils, preserving their unique characteristics. Increased productivity by optimizing material handpng processes.

- Apppcations: Alloy steel coils are used in industries such as aerospace, automotive, and machinery manufacturing, where specific properties pke strength and wear resistance are crucial. Overhead cranes are essential for safe and precise coil handpng in these apppcations.

In summary, overhead cranes play a vital role in the handpng of various types of steel coils, each with its specific features, benefits, and apppcations. Tailored crane configurations and attachments ensure the efficient and safe transportation of steel coils, contributing to the overall quapty of finished products in a wide range of industries.

Overhead Cranes for Handling Coils of Different Weights and Sizes

Steel coils come in a wide range of sizes and weights, depending on their intended use and manufacturing processes. Here are some common categories of steel coils with different sizes and weights:

Small and Light Steel Coils:

- Steel Coil Types, Sizes & Weight: Small and light steel coils, such as cold-rolled steel coils.

- Typical Width: 600 millimeters (mm) to 1,000 mm

- Typical Thickness: 0.5 millimeters (mm) to 3.0 mm

- Typical Weight: 1 ton to 5 tons

- Overhead Crane Type & Capacity: Single girder bridge crane with a capacity of 5 tons or a jib crane with a capacity of 1 ton.

- Features and Benefits: These cranes are tailored for the precise handling of small and lightweight cold-rolled steel coils. They offer accurate control and are ideal for localized tasks within manufacturing facilities.

- Applications: Handling coils with smaller dimensions and weights, often used in production processes that require frequent material movement, such as automotive component manufacturing or appliance production.

- Widely Used in Steel Mill: These cranes are commonly utilized in steel mills to efficiently handle small and lightweight cold-rolled steel coils, contributing to the manufacturing of various high-precision products.

Medium-Sized Steel Coils:

- Steel Coil Types, Sizes & Weight: Medium-sized steel coils, including hot-rolled and galvanized coils.

- Typical Width: 1,000 millimeters (mm) to 1,500 mm

- Typical Thickness: 3.0 millimeters (mm) to 6.0 mm

- Typical Weight: 5 tons to 15 tons

- Overhead Crane Type & Capacity: Double girder bridge crane with a capacity of 15 tons or a single girder bridge crane with a capacity of 10 tons.

- Features and Benefits: These cranes offer the lifting capacity and precision required for medium-sized steel coils, ensuring efficient handling and material flow.

- Applications: Transporting, loading, unloading, and stacking medium-sized steel coils in manufacturing and storage areas, often in industries such as construction and machinery manufacturing.

Large and Heavy Steel Coils:

- Steel Coil Types, Sizes & Weight: Large and heavy steel coils, such as hot-rolled coils and alloy steel coils.

- Typical Width: 1,500 millimeters (mm) to 2,000 mm

- Typical Thickness: 6.0 millimeters (mm) to 12.0 mm

- Typical Weight: 15 tons to 25 tons

- Overhead Crane Type & Capacity: Double girder bridge crane with a capacity of 30 tons or a double leg gantry crane with a capacity of 40 tons.

- Features and Benefits: These cranes are designed to handle large and heavy steel coils, offering high lifting capacity, stability, and precise control.

- Applications: Loading, unloading, stacking, and transporting large and heavy steel coils in industrial environments, including steel mills and storage yards, often in industries like shipbuilding and heavy machinery manufacturing.

Extra-Large and Ultra-Heavy Steel Coils:

- Steel Coil Types, Sizes & Weight: Extra-large and ultra-heavy steel coils used in specialized applications.

- Typical Width: Over 2,000 millimeters (mm)

- Typical Thickness: Over 12.0 millimeters (mm)

- Typical Weight: Over 25 tons, with some coils exceeding 50 tons.

- Overhead Crane Type & Capacity: Custom-engineered gantry cranes with capacities exceeding 50 tons.

- Features and Benefits: These specialized cranes are designed to handle the largest and heaviest steel coils with custom configurations to match specific coil dimensions and weights.

- Applications: Handling exceptionally large and heavy steel coils used in industries like shipbuilding, aerospace, and custom machinery manufacturing.

Mini Coils:

- Steel Coil Types, Sizes & Weight: Mini steel coils, often used in specialty applications.

- Typical Width: Less than 600 millimeters (mm)

- Typical Weight: Lightweight, designed for specific niche applications.

- Overhead Crane Type & Capacity: Depending on the facility layout, single girder bridge cranes or jib cranes with capacities tailored to mini coil sizes.

- Features and Benefits: These cranes are adapted to handle small and lightweight mini steel coils, suitable for specialized manufacturing needs.

- Applications: Handling mini coils used in unique applications, such as electrical components or niche production processes.

Coils of Various Sizes and Weights (Mixed Handling):

- Steel Coil Types, Sizes & Weight: A mix of steel coils with varying dimensions and weights within the same facility.

- Overhead Crane Type & Capacity: Bridge cranes with flexible configurations and adaptable features to handle a range of coil sizes and weights.

- Features and Benefits: These cranes provide flexibility in handling coils of different sizes and weights, optimizing material handling processes.

- Applications: Facilities that process steel coils of different sizes and weights can use adaptable overhead cranes to streamline material handling, reducing downtime and increasing efficiency.

Vertical Eye Coil Handling:

- Steel Coil Types, Sizes & Weight: Coils with a vertical eye orientation.

- Overhead Crane Type & Capacity: Overhead cranes with specialized coil grabs or turn-over devices for safe and precise vertical eye coil handling.

- Features and Benefits: These cranes allow for the secure vertical eye handling of coils, including flipping or rotating them as needed.

- Applications: Handling coils with a vertical eye orientation, often required for specific manufacturing processes and product customization.

Horizontal Eye Coil Handling:

- Steel Coil Types, Sizes & Weight: Coils with a horizontal eye orientation.

- Overhead Crane Type & Capacity: Overhead cranes equipped with coil hooks or C-hooks for secure horizontal eye coil handling.

- Features and Benefits: These cranes ensure the stability of coils during horizontal eye handling, preventing damage and accidents.

- Applications: Transporting coils with a horizontal eye orientation within manufacturing facilities, optimizing workflow and safety.

Horizontal coil handling

Coils are commonly stacked with the eye horizontal in steel warehouses and service centers. C-hook-style lifters and two-arm coil grabs are items developed for handling coils in this position. Optional equipment for the coil grab includes urethane padding for further coil protection, a built-in load scale for exact coil weight measurement, and a photo-electric sensor for easier foot alignment.

C hooks cranes: These cranes have a specialized C-shaped hook attachment that is designed to lift and transport steel coils in a horizontal position.

Coil clamp cranes: These cranes use a specialized clamp attachment that is designed to securely grip the coil and lift it in a horizontal position.

Magnetic overhead cranes: These cranes use a magnetic lifting attachment to lift and transport steel coils in a horizontal position or vertical positions.

Vertical coil handling

Vertical eye handling overhead crane steel mill coil lifters are used to handle vertically stacked coils after they have been slit to size during the production process. Vertical lifters come in a variety of forms, and the optimum one for the job depends on how frequently, how many, and the IDs of the coils you move in a typical workday.

Vertical coil lifting & flipping tong/ clamp

Automatic vertical coil tong double grip type

Simple vertical coil tong single grip

Industrial Applications: Where Overhead Crane for Steel Mill Coil Handling

Coil handling cranes find their indispensable place in a wide range of industrial sectors, significantly improving efficiency and safety. In this section, we'll explore the diverse industrial applications where these cranes shine. Coil handling cranes used in various industrial sectors, including the steel coil types, sizes, weights, overhead crane types, capacities, features, benefits, and applications:

Automotive Manufacturing:

Steel coils are extensively used in the automotive industry to produce vehicle components such as body panels, chassis parts, and engine components. Advanced high-strength steel coils are employed to enhance vehicle safety, reduce weight, and improve fuel efficiency.

- Steel Coil Types, Sizes & Weight Used: Typical Types: Hot-rolled steel coils, high-strength steel coils. Sizes: Vary based on component requirements. Weight: Ranges from small coils for components to larger coils for structural parts.

- Overhead Crane Type & Capacity: Single girder or double girder bridge cranes with capacities ranging from 1 ton for small components to 30 tons for larger structural parts. Features and Benefits: Precise control for accurate positioning of steel coils during manufacturing. Increased production efficiency in automotive assembly lines. Applications in Automotive: Handling coils for stamping, welding, and assembly processes. Ensuring the timely and accurate supply of steel coils to meet production demands.

Appliance Manufacturing:

Steel coils are used in appliance manufacturing to produce products like refrigerators, washing machines, and ovens. These coils provide durability, rust resistance, and a sleek finish for household appliances.

- Steel Coil Types, Sizes & Weight Used: Common Types: Cold-rolled steel coils, galvanized steel coils. Sizes: Varied based on appliance components. Weight: Typically small to medium-sized coils.

- Overhead Crane Type & Capacity: Single girder bridge cranes with capacities ranging from 1 ton to 5 tons. Features and Benefits: Precise coil handling to ensure quality appliance manufacturing. Efficient material movement within production facilities. Applications in Appliance Manufacturing: Handling steel coils for forming and fabricating appliance components. Supporting the assembly of appliances in production lines.

Construction:

Steel coils are widely used in construction for building structures, bridges, and infrastructure components. They offer strength and corrosion resistance for various applications.

- Steel Coil Types, Sizes & Weight Used: Common Types: Hot-rolled steel coils, galvanized steel coils. Sizes: Typically wide and thick coils for structural components. Weight: Heavier coils to support load-bearing requirements.

- Overhead Crane Type & Capacity: Double girder bridge cranes with capacities ranging from 5 tons for smaller components to 30 tons for large structural steel coils. Features and Benefits: Precise handling for structural steel placement. Ensuring safety and efficiency in construction projects. Applications in Construction: Lifting and positioning steel coils for structural framing, beams, and other building elements. Supporting construction of bridges and infrastructure.

Aerospace and Defense:

Specialized steel coils with high strength, heat resistance, and corrosion resistance properties are used in the aerospace and defense sectors to manufacture aircraft, missiles, and military vehicles.

- Steel Coil Types, Sizes & Weight Used: Types: High-strength steel coils, heat-resistant alloys. Sizes: Precisely tailored to aerospace and defense component requirements. Weight: Variable, depending on component specifications.

- Overhead Crane Type & Capacity: Custom-engineered gantry cranes designed to match specific coil dimensions and weights. Features and Benefits: Precision handling of specialized steel coils for critical applications. Ensuring the integrity and safety of aerospace and defense equipment. Applications in Aerospace and Defense: Handling coils for the manufacturing of aircraft parts, missile components, and military vehicles.

Energy Sector:

Steel coils are used in the energy sector for various applications, including the construction of pipelines, wind turbine components, and oil rig equipment. They offer the strength and durability required for these demanding environments.

- Steel Coil Types, Sizes & Weight Used: Types: Hot-rolled steel coils, high-strength steel coils. Sizes: Tailored to energy sector component specifications. Weight: Variable, depending on the application.

- Overhead Crane Type & Capacity: Custom-engineered gantry cranes designed for energy sector applications. Features and Benefits: Safe and efficient handling of steel coils in challenging environments. Ensuring the integrity of energy infrastructure components. Applications in the Energy Sector: Handling coils for the construction and maintenance of pipelines, wind turbines, and oil rig equipment.

Oil and Gas Industry:

Steel coils are crucial in the oil and gas industry for applications such as drilling equipment, pipelines, and storage tanks. They are chosen for their resistance to extreme temperatures and corrosive substances.

- Steel Coil Types, Sizes & Weight Used: Types: High-strength steel coils, corrosion-resistant alloys. Sizes: Varied based on oil and gas equipment requirements. Weight: Variable, depending on the application.

- Overhead Crane Type & Capacity: Custom-engineered gantry cranes designed for the oil and gas industry's specific coil handling needs. Features and Benefits: Safe and efficient handling of steel coils in harsh oil and gas environments. Ensuring the integrity and reliability of equipment in drilling and extraction processes. Applications in the Oil and Gas Industry: Handling coils for drilling rigs, pipeline construction, and storage tank manufacturing.

Medical Equipment:

Stainless steel coils are employed in the manufacturing of medical devices and equipment due to their corrosion resistance and biocompatibility. They are used in surgical instruments, medical implants, and diagnostic equipment.

- Steel Coil Types, Sizes & Weight Used: Common Types: Stainless steel coils. Sizes: Customized to medical equipment specifications. Weight: Typically small coils for precision components.

- Overhead Crane Type & Capacity: Single girder bridge cranes with capacities ranging from 1 ton to 5 tons for medical equipment manufacturing. Features and Benefits: Precision handling for the production of critical medical devices. Meeting stringent quality and safety standards in medical equipment manufacturing. Applications in Medical Equipment: Handling stainless steel coils for surgical instruments, implants, and diagnostic equipment.

Food Processing:

Stainless steel coils with excellent hygiene properties are used in the food processing industry to produce equipment like conveyor systems, food containers, and utensils. Stainless steel prevents contamination and is easy to clean.

- Steel Coil Types, Sizes & Weight Used: Common Types: Stainless steel coils. Sizes: Customized to food processing equipment requirements. Weight: Varies based on equipment specifications.

- Overhead Crane Type & Capacity: Single girder bridge cranes with capacities tailored to food processing needs. Features and Benefits: Ensuring hygiene and cleanliness in food processing environments. Compliance with strict food safety regulations. Applications in Food Processing: Handling stainless steel coils for the fabrication of conveyor systems, storage tanks, and other equipment used in food production.

Electronic and Electrical Equipment:

Steel coils are used in the production of electronic components and electrical appliances. They provide the required strength and magnetic properties for applications like transformers and inductors.

- Steel Coil Types, Sizes & Weight Used: Common Types: Cold-rolled steel coils, electrical steel coils. Sizes: Tailored to electronic and electrical component requirements. Weight: Typically small to medium-sized coils.

- Overhead Crane Type & Capacity: Single girder bridge cranes with capacities ranging from 1 ton to 5 tons for electronic and electrical equipment manufacturing. Features and Benefits: Precise coil handling to ensure the quality and performance of electrical components. Efficient material movement within production facilities. Applications in Electronic and Electrical Equipment: Handling steel coils for the manufacturing of transformers, inductors, and other electrical components.

Automated Machinery:

Steel coils play a vital role in automated machinery used in manufacturing and logistics, where precision, durability, and resistance to wear are essential. They are used in conveyor systems, robotic arms, and material handling equipment.

- Steel Coil Types, Sizes & Weight Used: Common Types: Cold-rolled steel coils, high-strength steel coils. Sizes: Tailored to automated machinery specifications. Weight: Varies based on machinery requirements.

- Overhead Crane Type & Capacity: Single girder or double girder bridge cranes with capacities customized for automated machinery needs. Features and Benefits: Ensuring the smooth operation of automated systems by precise coil handling. Reducing downtime and enhancing production efficiency. Applications in Automated Machinery: Handling steel coils for automated machinery used in manufacturing, logistics, and material handling.

Custom Fabrication:

Steel coils are often custom-fabricated into specialized components and parts based on the unique requirements of various industries. This includes components for industrial machinery, customized architectural features, and more.

- Steel Coil Types, Sizes & Weight Used: Varied types and sizes based on custom fabrication needs. Customized to specific component requirements. Weight depends on the application and component specifications.

- Overhead Crane Type & Capacity: Custom-engineered cranes designed to handle unique coil shapes and sizes. Features and Benefits: Flexibility in coil handling to accommodate diverse custom fabrication requirements. Supporting the production of specialized components for various industries. Applications in Custom Fabrication: Handling steel coils for the production of custom components used in industrial machinery, architectural projects, and specialized equipment.

Art and Sculptures:

Steel coils can be used by artists and sculptors to create large-scale sculptures and artistic installations. Their malleability and strength allow for creative designs in the art world.

- Steel Coil Types, Sizes & Weight Used: Typically customized to artistic requirements. Coil size and weight depend on the scale and design of the artwork.

- Overhead Crane Type & Capacity: Custom-engineered gantry cranes designed to assist artists in handling steel coils for their creative projects. Features and Benefits: Enabling artists to work with steel coils of various sizes and shapes. Supporting the creation of large-scale sculptures and artistic installations.

Automated Storage Systems:

Steel coils are used in the construction of automated storage and retrieval systems (AS/RS) in warehousing and logistics operations. These systems efficiently store and handle goods in distribution centers.

- Steel Coil Types, Sizes & Weight Used: Common Types: Hot-rolled steel coils, high-strength steel coils. Sizes: Customized to AS/RS specifications. Weight: Varies based on storage system requirements.

- Overhead Crane Type & Capacity: Custom-engineered gantry cranes designed for AS/RS coil handling. Features and Benefits: Precise and efficient handling of steel coils within automated storage systems. Maximizing storage space and streamlining logistics operations.

Niche Manufacturing:

Steel coils are employed in niche manufacturing sectors that require specific steel properties. This includes applications in the jewelry industry, musical instrument manufacturing, and specialized equipment production.

- Steel Coil Types, Sizes & Weight Used: Tailored to niche manufacturing needs. Coil size and weight depend on the specific application.

- Overhead Crane Type & Capacity: Customized to the coil handling requirements of niche manufacturing processes. Features and Benefits: Meeting the unique material specifications of niche industries. Supporting the production of specialized products in various niche manufacturing sectors.

Environmental Protection:

Steel coils are used in environmental protection applications, such as the fabrication of pollution control equipment, wastewater treatment systems, and air quality monitoring devices.

- Steel Coil Types, Sizes & Weight Used: Common Types: Corrosion-resistant steel coils. Sizes: Customized to environmental protection equipment requirements. Weight: Varies based on the application and equipment specifications.

- Overhead Crane Type & Capacity: Custom-engineered cranes designed for coil handling in environmental protection applications. Features and Benefits: Ensuring the integrity and durability of equipment used in environmental protection. Supporting efforts to mitigate pollution and protect the environment.

These overviews provide insights into the use of overhead cranes for steel coil handling across various industrial sectors, along with the specific coil types, sizes, weights, crane types, capacities, features, benefits, and applications associated with each sector.

Select The Right Coil Handling Crane for the Right Coil

Choosing the right crane type to match your specific coil specifications is essential for ensuring accurate and efficient handling. In this section, we'll explore the importance of selecting the appropriate crane and how it can enhance your coil handling processes.

Matching Crane Type to Coil Specifications:

- Coil Size: The dimensions of the steel coil, including its width, diameter, and weight, play a crucial role in determining the suitable crane type. Larger and heavier coils typically require cranes with higher lifting capacities.

- Coil Type: Different types of steel coils, such as hot-rolled, cold-rolled, galvanized, stainless, and alloy steel coils, may have varying handling requirements. For example, handling sensitive stainless steel coils may necessitate cranes with specialized coil grabs to prevent surface damage.

- Handling Environment: Consider the operational environment, whether it's indoors, outdoors, in a confined space, or a high-precision manufacturing facility. Each environment may require a different crane type for optimal performance.

- Precision Requirements: Depending on the precision required for your application, you may need a crane with features like variable speed controls and smooth start/stop mechanisms to ensure accurate coil positioning and movement.

Ensuring Accurate and Efficient Handling:

- Efficiency: Choosing the right crane type enhances operational efficiency by minimizing downtime and ensuring the timely movement of materials.

- Safety: Properly matching crane capacity to coil weight prevents overloading, reducing the risk of accidents and material damage.

- Cost Savings: Selecting an appropriately sized crane reduces operational costs, as it optimizes energy consumption and prolongs equipment lifespan.

- Longevity: Using the right crane type for the job extends the crane's lifespan, reducing the need for frequent replacements or costly repairs.

Selecting the right crane for the right coil is a critical decision that can significantly impact your operational success. By carefully considering coil specifications and operational requirements, you can optimize your coil handling processes and achieve higher efficiency, safety, and cost-effectiveness.

Top Concerns of Coil Handling Crane Users

Users of coil handling cranes share several common concerns that are essential to address for successful and safe crane operation. In this section, we'll delve into these top concerns, which include maintenance and longevity, operator training and safety, and compliance with industry standards.

Maintenance and Longevity:

- Regular Inspections: Routine crane inspections are crucial for identifying and addressing wear and tear, ensuring that the crane remains in optimal working condition.

- Preventive Maintenance: Implementing a preventive maintenance program helps extend the crane's lifespan and reduces the likelihood of unexpected breakdowns or failures.

- Replacement Parts: Availability of genuine replacement parts is vital to maintain and repair cranes promptly when needed.

- Operator Training and Safety:

- Proper Training: Ensuring that crane operators receive thorough training in crane operation, load handling, and safety procedures is essential for accident prevention.

- Safety Protocols: Clear and well-communicated safety protocols should be in place, including emergency response procedures and the use of personal protective equipment (PPE).

- Operator Comfort: Operator comfort can affect safety and productivity. Ergonomically designed cabins or control stations contribute to a safer working environment.

Compliance with Industry Standards:

- Adherence to Regulations: Complying with industry regulations and safety standards is essential. Failure to do so can lead to legal liabilities and accidents.

- Certification: Cranes should undergo regular certifications and inspections to ensure they meet or exceed safety and performance standards.

- Documentation: Maintaining comprehensive documentation, including inspection reports and certification records, helps demonstrate compliance.

- Addressing these top concerns is crucial for ensuring the safe and efficient operation of coil handling cranes. It not only enhances safety and productivity but also contributes to the longevity of your equipment, reducing operational costs in the long run.

Frequently Asked Questions: Your Coil Handling Crane Queries Answered

In this section, we address some of the most common inquiries about coil handling cranes. Whether you're an existing user or a potential purchaser, these answers provide valuable insights into the world of coil handling cranes.

1. What factors determine the choice of a coil handling crane?

- The choice of a coil handling crane depends on factors such as the size and weight of the coils, the operational environment (indoor or outdoor), the precision required, and specific application needs. Additionally, considerations like safety features and compliance with industry standards are crucial.

2. What are the typical capacities of coil handling cranes?

- Coil handling cranes come in various capacities to suit different needs. Common capacities range from a few tons to several hundred tons, ensuring versatility across a wide range of industries and applications.

3. How do I ensure operator safety when using coil handling cranes?

- Operator safety is paramount. Proper training is essential, covering crane operation, load handling, and adherence to safety protocols. Additionally, modern cranes are equipped with safety features like overload protection, emergency stop buttons, and collision avoidance systems to enhance safety.

4. Can coil handling cranes be customized for specific needs?

- Yes, coil handling cranes can be customized to meet specific requirements. Customizations may include specialized coil grabs, variable speed controls, and adaptations for unique applications and environments.

5. What maintenance practices should be followed for longevity?

- Regular inspections and preventive maintenance are key to prolonging the lifespan of coil handling cranes. Routine checks for wear and tear, lubrication of moving parts, and prompt repairs when needed are essential maintenance practices.

6. Are there regulatory standards for coil handling crane operations?

- Yes, there are regulatory standards and safety guidelines that govern coil handling crane operations. Compliance with these standards is critical to ensuring safe and efficient crane operation. Regular certifications and inspections help confirm compliance.

These frequently asked questions offer valuable insights into the considerations, safety practices, and customization options associated with coil handling cranes. If you have more specific questions or need further guidance, don't hesitate to reach out to crane manufacturers and suppliers who can provide tailored solutions for your coil handling needs.

In the next section, we'll wrap up our comprehensive overview of coil handling cranes, summarizing the key takeaways and highlighting their essential role in industrial operations.

Conclusion: Elevate Your Coil Handling with the Right Crane

In the world of industrial operations, the efficiency, safety, and precision of coil handling can make all the difference. Choosing the right coil handling crane is a pivotal decision that can elevate your processes to new heights. Let's wrap up our comprehensive guide by emphasizing the importance of making an informed decision and partnering with a reliable crane manufacturer and supplier.

The Importance of Selecting the Right Coil Handling Crane:

- Coil handling is a complex and critical process in various industries, from automotive manufacturing to energy production. The right crane ensures efficient and safe material movement, leading to increased productivity and reduced operational costs.

- Matching the crane type to your specific coil specifications and operational requirements is paramount. This choice directly impacts accuracy, efficiency, and safety in your facility.

- Investing in a crane that aligns with your needs can result in long-term benefits, including extended equipment longevity, improved safety records, and enhanced operational efficiency.

Partnering with a Reliable Crane Manufacturer and Supplier:

- When embarking on the journey to acquire a coil handling crane, it's crucial to collaborate with a trusted crane manufacturer and supplier.

- A reputable partner offers expertise in crane design, customization, installation, and maintenance. They can help you select the right crane for your unique needs and ensure it complies with industry standards and safety regulations.

- Reliable manufacturers and suppliers also provide ongoing support, including maintenance services, spare parts availability, and operator training, to ensure the continued optimal performance of your crane.

In conclusion, coil handling cranes are indispensable tools in various industries, enabling precise and efficient handling of steel coils of all sizes and types. By making an informed decision and partnering with a trusted manufacturer and supplier, you can harness the full potential of coil handling cranes, improving your operations and achieving your industrial goals.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch