60 T Straddle Carrier for Sale: Case Study on Efficiency & Safety

60 Ton Straddle Carrier for sale, showcasing efficiency & safety through a detailed case study on operational improvements. Get your custom straddle crane.

Category: Straddle Carrier

Your Trusted Industrial Straddle Carrier Crane Manufacturer & Supplier

60 Ton Straddle Carrier for Sale Good Price , Case Study: Efficiency & Safety

Overview of Straddle Carriers

A straddle carrier is a heavy-duty mobile crane specifically designed for lifting and transporting large, heavy loads. It features a distinctive structure where the carrier's four legs straddle the load, typically containers or other large cargo. This allows the machine to lift and move the load with great precision over short distances.

Why 60-ton capacity matters:

The 60-ton capacity of straddle carriers is a significant asset in heavy lifting operations. With this impressive weight limit, the machine can handle heavy cargo that would otherwise require multiple lifting operations or different machines. Whether it’s for containers in ports or steel coils in mills, a 60-ton straddle carrier provides the strength needed to manage large and bulky loads efficiently. This increased lifting capacity not only speeds up operations but also minimizes the need for multiple lifting equipment, saving both time and costs.

Purpose of Straddle Carriers in Various Industries

Where are straddle carriers used?

Straddle carriers are versatile machines that find applications in various industries, including:

- Steel mills: Handling steel coils and large metal products.

- Ports and terminals: Moving containers and cargo across loading docks.

- Other industries: Transporting bulky or heavy items that need precise, short-distance handling.

These machines are widely used in environments that require the safe and efficient movement of large, heavy items.

How straddle carriers improve productivity:

Straddle carriers are essential for improving efficiency in industries that deal with heavy lifting and container handling. Here's how they contribute:

- Speed and efficiency: With the 60-ton capacity, straddle carriers can lift and move large loads quickly, reducing time spent on each operation.

- Versatility: One machine can handle multiple tasks, from lifting containers to positioning heavy materials.

- Reduced equipment need: A straddle carrier's ability to perform several functions cuts down the need for multiple lifting machines, thus lowering operational costs and maintenance needs.

- Space optimization: In places like steel mills or ports, straddle carriers help optimize space by precisely placing loads where they're needed, reducing congestion and improving workflow.

In summary, straddle carriers are not just lifting machines; they are productivity boosters that ensure faster, safer, and more cost-effective operations in various heavy-duty industries.

Features and Specifications of 60-Ton Straddle Carriers

Technical Specifications

Load Capacity: 60 Tons

The 60-ton capacity ensures the straddle carrier can handle some of the heaviest loads encountered in various industries, from large containers to bulky steel products. This makes it an ideal choice for operations that require lifting heavy materials or equipment.

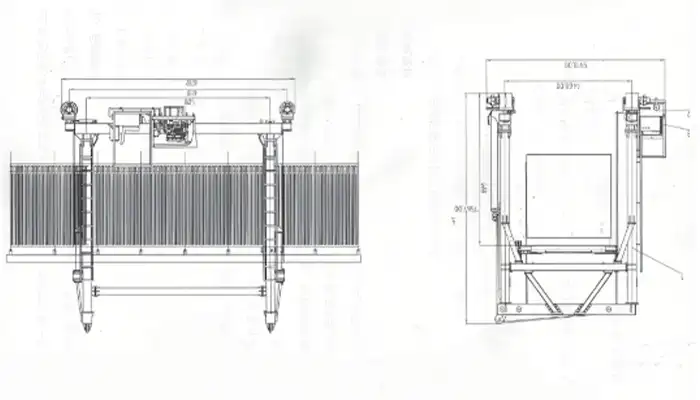

Dimensions

- Overall size: The machine's dimensions, typically around 6782mm x 5600mm x 6900mm, ensure it is compact enough to fit in tight spaces yet large enough to handle substantial loads.

- Wheelbase: The distance between the wheels is crucial for stability when lifting and moving heavy cargo. The dimensions are designed for balanced weight distribution to minimize risks during operations.

- Lifting height: The maximum lifting height is typically 4459mm (with the lowest at 2069mm), allowing for easy lifting and stacking of containers or materials, reducing the risk of damage during handling.

Engine and Powertrain Specifications

- Engine: Typically powered by a Weichai diesel engine, providing the necessary power to drive the hydraulic systems and move heavy loads efficiently.

- Hydraulic System: The hydraulic system is key to its lifting capabilities, powered by a CBQ-F571-F550CLP gear pump, allowing smooth and precise control over lifting and lowering operations.

Operational Capabilities

Lifting Height and Load Distribution

The straddle carrier is designed with advanced hydraulic lifting systems, which allow it to raise heavy loads to heights of up to 4459mm. The lifting speed for empty loads can reach 35mm/s, ensuring swift and efficient operation. Load distribution is evenly balanced, thanks to the carrier's structure and the hydraulic system, ensuring stability even during high lifts.

Travel Speeds (Forward and Backward)

- The maximum travel speed of the carrier is 3.5 km/h (with empty loads), which may vary depending on load weight and terrain. This speed allows operators to move loads across the worksite without compromising safety or precision.

- Backward movement is as essential as forward motion, ensuring versatility in tight spaces or when repositioning loads.

Mobility and Maneuverability Features

- Turning Radius: With the ability to rotate the wheels up to 110 degrees, the straddle carrier can maneuver easily within confined spaces, ideal for use in environments such as ports, terminals, or steel mills.

- The hydraulic steering system adds to its flexibility, allowing smooth adjustments in direction for greater operational ease.

Safety Features

Safety Systems to Avoid Overloading

The straddle carrier is equipped with systems designed to prevent overloading. Load sensors and pressure monitoring in the hydraulic system ensure that the carrier never exceeds its weight limit. These systems help to avoid unnecessary wear and tear and reduce the risk of accidents.

Hydraulic and Structural Safety Mechanisms

- Hydraulic Fail-Safes: The hydraulic system incorporates fail-safes that prevent any sudden pressure spikes that could damage the machine or cause injury. These systems maintain consistent pressure for safe lifting.

- Structural Integrity: The frame and critical components are designed for high stress, with high-quality steel used in critical areas such as the main girder and columns. This ensures that the machine remains durable and stable under heavy loads.

Emergency Stops and Load Balancing

Emergency stops are installed in accessible locations to ensure operators can quickly halt operations if needed. Additionally, load balancing systems automatically adjust the lifting arms to ensure even load distribution, which reduces the risk of tip-over or instability during lifting operations. This is crucial when working with heavy or uneven loads.

In conclusion, the 60-ton straddle carrier combines advanced engineering with a focus on safety and operational efficiency, making it a critical tool for industries that handle large, heavy cargo. Its robust technical specifications, operational capabilities, and safety features ensure it can tackle tough lifting and transport tasks while maintaining high levels of productivity and safety.

Key Components of 60-Ton Straddle Carriers

Hydraulics System

Hydraulic Pumps, Oil Tanks, and Valves

The hydraulic system is at the heart of the 60-ton straddle carrier's ability to lift and move heavy loads. It consists of hydraulic pumps that drive the lifting mechanisms, ensuring smooth and efficient movement of the lifting arms. The system also includes oil tanks to store hydraulic fluid and valves to control the flow of fluid to various components. These elements work together to manage the load and control the steering system.

Role in Lifting, Steering, and Load Management

- The hydraulic pumps provide the necessary force to raise and lower the lifting arms, allowing the carrier to move loads. The system ensures precise control over lifting height and speed, making it efficient for both empty and loaded operations.

- For steering, the hydraulic system controls the wheels' rotation, allowing the straddle carrier to navigate tight spaces with ease.

- Load management is critical, and the hydraulics help in distributing the weight evenly to ensure balance. This reduces the risk of accidents or damage to the load or equipment.

Maintenance and Troubleshooting

Proper maintenance is crucial to keep the hydraulic system functioning efficiently. Regular inspection of hoses, pumps, and filters ensures no leaks or clogs, preventing any operational failures. Common troubleshooting tasks include checking for fluid leaks, replacing worn-out seals, and ensuring the system is properly pressurized. Routine oil changes and cleaning of filters are essential for avoiding blockages and maintaining smooth operation.

Tires and Wheel Systems

Types of Tires (e.g., Solid, Pneumatic)

The tires on the straddle carrier play an essential role in ensuring stability and mobility. Common types of tires used are:

- Solid tires are more durable and resistant to punctures, providing better stability in environments where sharp objects are common.

- Pneumatic tires are air-filled and provide better shock absorption, which is beneficial when traveling over uneven surfaces. Both tire types are designed to handle heavy loads and tough conditions.

Maintenance and Inspection of Tires

Tires should be inspected regularly for any signs of damage, such as cuts, cracks, or punctures. Checking the tire pressure is also vital, especially for pneumatic tires, as low pressure can affect load-bearing capacity and fuel efficiency. Additionally, routine checks should include examining the tread wear to ensure even distribution and proper grip.

Handling Tire Wear and Load Stress

Excessive wear on tires can lead to decreased performance and safety. If tire wear is not evenly distributed, it may indicate issues with load balance or wheel alignment. Straddle carriers are subjected to high stress due to heavy loads and constant movement, so rotating the tires and replacing them when necessary is essential for maintaining stability and extending the life of the equipment.

Engine and Power Systems

- Diesel Engine Specifications: The 60-ton straddle carrier typically operates on a diesel engine, which provides the necessary power for lifting, moving, and overall performance. Engine specifications include the engine’s power output (usually around 81 kW), which ensures sufficient energy for demanding operations. The engine is designed to handle the rigorous requirements of lifting and hauling heavy loads across various terrain.

- Fuel Efficiency and Power Output: Fuel efficiency is an important consideration, especially for equipment used in high-demand environments. Diesel engines offer high power output without sacrificing fuel economy. A well-maintained engine ensures long operational hours while minimizing fuel consumption. Keeping the engine clean, checking for any leaks, and maintaining the right fuel levels are essential for optimizing fuel efficiency.

- Regular Engine Checks and Oil Changes: Regular engine checks are vital to ensure smooth operation and to prevent potential failures. Engine oil should be checked frequently, and oil changes should occur as specified in the user manual (usually every 200 hours or so). Oil filters should also be replaced periodically to ensure that the engine runs smoothly and to extend its life. Keeping the engine clean and ensuring the proper cooling system function is critical to avoiding overheating or performance issues.

In summary, the hydraulics system, tires and wheel systems, and engine power are the key components that ensure the 60-ton straddle carrier operates effectively and safely. By maintaining these critical systems, operators can keep the carrier running at peak performance, reducing downtime, improving safety, and extending the lifespan of the equipment.

Maintenance and Operation

Daily, Monthly, and Yearly Maintenance

- Regular Checks on Hydraulic, Engine, and Powertrain Systems: The core systems of the 60-ton straddle carrier—hydraulics, engine, and powertrain—must be checked regularly. Daily checks should focus on visual inspections for any leaks or irregularities in these systems. Monthly checks should involve more thorough assessments of oil levels, hydraulic fluid quality, and overall system performance. Yearly checks will involve deep inspections and potential replacements of components showing wear.

- Tire, Brake, and Lubrication Inspections: Tires, brakes, and lubrication systems must be closely monitored. Daily tire inspections help identify any visible damage or wear, such as cuts, punctures, or cracks. Brake systems should be tested for functionality, and lubrication points should be checked for adequate grease coverage. Lubrication maintenance is key for ensuring the smooth movement of parts like bearings and joints.

- Scheduled Replacement of Filters and Oils: Replacing filters and oils as per the maintenance schedule is essential to avoid system malfunctions. The engine oil and hydraulic oil should be replaced at regular intervals, typically after 200 hours for the engine and 500 hours for the hydraulics. Filters should be cleaned or replaced to maintain the system’s efficiency and prevent damage from contaminants.

Lubrication and Hydraulics Maintenance

- Importance of Lubricating Critical Components (e.g., Steel Ropes, Pulleys): Regular lubrication of critical components like steel ropes and pulleys ensures smooth operation and extends their lifespan. These parts are subjected to significant wear and tear, especially under heavy loads. Applying grease or oil to them helps reduce friction, minimizing the risk of damage and ensuring the straddle carrier's lifting operations remain efficient and reliable.

- Hydraulic Oil Checks and Replacements: Hydraulics are integral to the lifting mechanism, and the quality of hydraulic oil plays a significant role in ensuring its functionality. Oil should be checked regularly for contamination or degradation, as dirty or old oil can affect system performance. Replacing hydraulic oil and cleaning filters when necessary helps prevent clogs or pressure loss within the system.

- Ensuring Smooth Operation and Avoiding Leaks: Leaks in hydraulic systems can be costly and dangerous. Daily inspections should include checking for signs of leakage from hydraulic hoses, seals, and fittings. Immediate action should be taken if any leaks are found, including replacing faulty seals and tightening fittings. Proper lubrication and leak prevention measures ensure smooth operation and prevent unexpected downtimes.

Tire Maintenance

- Checking for Wear, Cracks, and Damage: Tires on a 60-ton straddle carrier carry a significant load, so it's important to check them daily for any visible signs of wear or damage. Cracks, punctures, and bulges can compromise safety, and excessive wear could affect load-bearing capacity. Inspections should be thorough, looking for signs of uneven wear or pressure loss.

- Correct Pressure Levels and Load Distribution: Maintaining correct tire pressure is essential to ensure optimal performance and safety. Tires that are under or over-inflated can wear unevenly and reduce traction. It’s crucial to follow the manufacturer’s recommendations for tire pressure, considering factors such as load distribution and travel conditions. Regularly checking tire pressure helps prevent damage and maintains the carrier’s stability.

- Tire Replacements and Preventive Measures: Tires that have reached the end of their lifespan should be replaced promptly to avoid operational issues. Preventive measures like rotating tires, inspecting for damage after long shifts, and ensuring proper load distribution can extend the lifespan of tires. Implementing a regular tire maintenance schedule will help catch small issues before they become big problems.

Engine and Fuel System Care

- Regular Engine Checks: Sounds, Exhaust Color, Oil Levels: Monitoring the engine for unusual sounds or signs of malfunction is important for detecting problems early. Pay attention to exhaust color—black smoke may indicate an issue with the engine, while white smoke could suggest coolant problems. Checking the engine oil level daily ensures that the engine runs smoothly and prevents overheating or potential damage due to insufficient lubrication.

- Fuel and Air Filter Replacements: Filters are responsible for keeping contaminants out of the engine and fuel system. Air filters should be replaced regularly to ensure that the engine gets the proper airflow. Similarly, fuel filters need to be checked and replaced to prevent clogging, which can affect fuel efficiency and engine performance.

- Fuel Tank and Pump Maintenance: Ensuring the fuel tank is clean and free of debris is vital for the engine’s long-term health. Fuel pumps should be regularly tested for any signs of malfunction, as an inefficient pump can lead to poor engine performance. Regularly inspecting fuel lines for leaks or cracks is also essential to prevent fuel loss and ensure safe operations.

By following a detailed and consistent maintenance routine, the 60-ton straddle carrier can maintain high performance, ensure operational safety, and extend its lifespan. Each of these maintenance tasks, while simple, plays a crucial role in keeping the machine running at optimal levels and avoiding costly repairs down the line.

Straddle Carrier Operations: Best Practices

Load Handling

Safe Loading Techniques and Weight Balancing: Safe and efficient load handling begins with proper loading techniques. Ensuring that the load is evenly distributed across the carrier's frame is critical for stability during transport. This means ensuring the center of gravity is kept low and centered, and that the load is distributed symmetrically to prevent tipping or swaying. Always make sure that the weight limit is not exceeded, as straddle carriers have a maximum capacity of 60 tons—overloading can cause system failures and safety hazards.

Preventing Overloading or Improper Load Distribution: Overloading or improper load distribution can lead to serious issues, such as tire damage, structural strain, and even failure of the hydraulic systems. It's vital to always adhere to the load specifications and conduct regular checks before and during operation. Operators should be trained to assess the weight and size of the load to ensure it fits within the safe operational limits.

Ensuring Proper Cargo Attachment and Handling: When moving cargo, the correct attachment methods are key. Cargo must be secured properly to avoid shifting during transit, which could destabilize the load. Use appropriate lifting attachments, such as spreader bars or lifting slings, and ensure they are in good condition. The cargo should be lifted slowly and steadily, with constant attention to any potential movement.

Safety Protocols

- Preventing Human Accidents Around the Straddle Carrier: Human safety around the straddle carrier is of utmost importance. Establish no-go zones around the carrier’s lifting area to keep workers clear of potential hazards. Operators must ensure that no one is underneath the load or near the tires while the carrier is in operation. Safety barriers, warning signs, and spotters should be used to direct and protect personnel.

- Training Operators for Safe Operations: Operator training is crucial in preventing accidents. Operators must be well-versed in all aspects of safe straddle carrier operation, especially during lifting and maneuvering. Training should focus on load balancing, emergency procedures, and proper use of the hydraulic system. Periodic retraining ensures that operators stay updated on best practices, machine upgrades, and safety regulations.

- Emergency Stop Features and Failure Response: Every straddle carrier should have easily accessible emergency stop buttons and clear emergency response protocols in case of equipment failure or an unexpected hazard. Operators should be trained on how to stop the machine safely in emergencies, and the carrier should have redundant safety mechanisms to minimize the risk of an accident. Additionally, emergency procedures should include proper reporting and troubleshooting of equipment failures.

Operating Conditions

- Proper Ground Conditions for Safe Operation: Straddle carriers are best operated on solid, level ground. Soft, uneven, or slippery terrain can cause instability and increase the risk of tipping or damage. It’s important to inspect the operating surface before deployment and ensure that it can handle the carrier's weight and size. Uneven surfaces can also put undue stress on tires and other components, reducing the carrier’s lifespan.

- Operating in Extreme Weather Conditions: Straddle carriers are often used in environments that can be harsh, such as steel mills, ports, or terminals. Extreme weather conditions, including cold, rain, snow, and heat, can affect the machine’s performance. In cold weather, the carrier may need to be winterized by ensuring that fluids do not freeze and that the battery is functioning properly. In hot weather, the engine cooling system must be closely monitored. Operators should take extra precautions when working in adverse conditions to ensure both the carrier and the personnel stay safe.

- Identifying Potential Environmental Risks: Environmental factors such as high winds, lightning, or poor visibility can pose risks to safe operation. Operators must be trained to recognize and respond to environmental risks, such as halting operations when winds exceed safe limits or lightning strikes occur. Regular environmental risk assessments should be conducted to identify specific dangers based on location and time of year.

Troubleshooting Common Issues

Hydraulic Failures

Signs of Hydraulic Failure: Leaks, Reduced Lifting Capacity

Hydraulic systems are essential for the operation of straddle carriers, and any failure in the hydraulic system can significantly affect performance. Common signs of hydraulic failure include:

- Leaks around hydraulic hoses, pumps, or cylinders.

- Reduced lifting capacity, meaning the carrier struggles to lift loads that are within the expected range.

- Sluggish or erratic movement during operation, indicating insufficient pressure or hydraulic fluid.

How to Troubleshoot and Resolve Hydraulic Issues

- Inspect the hydraulic lines for visible damage or leaks. If leaks are found, replace the affected hoses or seals immediately.

- Check hydraulic fluid levels and ensure the fluid is clean. Low or contaminated hydraulic oil can cause the system to perform poorly.

- If there’s a reduction in lifting capacity, assess the hydraulic pressure and ensure it meets the required specifications. You may need to adjust the pressure settings or replace damaged components like pumps or valves.

- Regular oil changes and keeping the hydraulic components free from contamination is key to avoiding system failures.

Engine Malfunctions

Common Engine Problems (e.g., Overheating, Poor Fuel Efficiency)

The engine is the heart of the straddle carrier, and malfunctioning engines can cause operational delays. Common engine problems include:

- Overheating, often caused by insufficient coolant or a clogged radiator.

- Poor fuel efficiency, which can be a sign of dirty fuel injectors, air filters, or problems in the fuel system.

- Struggling to start or stalling, which may be due to issues with the starter motor, fuel supply, or battery.

Diagnostics and Repair Protocols

- Check the coolant system for leaks or blockages and replace any damaged parts such as radiator hoses or the water pump.

- Inspect the fuel system, including the fuel filter and injectors. Replace clogged filters or clean the injectors to improve fuel efficiency.

- For starting issues, check the battery charge and ensure the starter motor is functioning properly. If the engine is stalling, inspect the fuel pump and ensure there’s adequate fuel pressure.

- Regular maintenance such as oil changes, fuel filter replacements, and air filter cleaning will help prevent these engine problems from developing.

Structural Problems

Identifying Structural Damage in the Frame or Lifting Mechanism

The frame and lifting mechanism are critical to the stability and safety of the straddle carrier. Over time, wear and tear or sudden impact can cause structural damage. Look for:

- Cracks or dents in the frame or lifting arms.

- Worn or damaged welds that may have weakened the structure.

- Misalignment in the lifting mechanism or wheels, which could indicate damage to the frame.

Preventive Measures and Timely Repairs

- Conduct regular visual inspections for cracks, dents, and other signs of wear. Pay special attention to areas that experience the most stress, such as the lifting arms and wheel axles.

- Preventive measures include avoiding overloading the straddle carrier and ensuring the carrier operates within safe limits.

- For damaged components, it is essential to conduct repairs or replacements as soon as possible to avoid compromising the carrier’s operational integrity.

- A professional assessment may be required for significant structural issues, as repairs to the frame and lifting system may involve welding or other specialized techniques.

Troubleshooting Common Issues

Hydraulic Failures

- Signs of Hydraulic Failure: Leaks, Reduced Lifting Capacity: One of the most common issues in straddle carriers is hydraulic failure, which can manifest as leaks or a significant reduction in lifting capacity. Signs to look out for include visible hydraulic fluid leaks around the cylinders, pumps, or hoses. Additionally, the carrier may struggle to lift loads or move heavy containers efficiently, indicating that the hydraulic system is not performing at full capacity.

- How to Troubleshoot and Resolve Hydraulic Issues: If a hydraulic issue is suspected, first check for visible leaks in the hydraulic lines and inspect the hydraulic fluid level to ensure it is at the recommended level. Low fluid can lead to poor system performance. If the fluid level is adequate, examine the hydraulic pump and valve systems for malfunctions. If any component is found to be faulty or worn, replace it immediately. Regularly scheduled hydraulic system maintenance and filter replacements can help prevent these issues from escalating.

Engine Malfunctions

- Common Engine Problems: Overheating, Poor Fuel Efficiency: Engine malfunctions can be a major hindrance to straddle carrier performance. Some common engine issues include overheating, especially in hot weather or under heavy load conditions, and poor fuel efficiency, which can indicate that the engine is not running optimally. Other issues could include abnormal exhaust smoke or strange engine noises during operation.

- Diagnostics and Repair Protocols: To diagnose engine issues, start by checking the coolant levels and engine oil. Overheating may be caused by a lack of coolant or clogged radiator. If fuel efficiency is poor, inspect the fuel system (including filters and injectors) for blockages or wear. Regular oil changes and air filter replacements are essential for maintaining engine performance. If the engine shows persistent issues, it may require professional diagnostics or part replacements.

Structural Problems

- Identifying Structural Damage in the Frame or Lifting Mechanism: Over time, the frame or lifting mechanism of a 60-ton straddle carrier may experience structural damage, such as cracks, bends, or wear due to the heavy loads it carries. Inspecting the frame regularly for visible cracks or deformations is important for maintaining the carrier's integrity. Pay special attention to areas where stress is most likely, such as the lifting arms and wheel axles. Structural failure can cause severe safety risks, so it’s crucial to address these issues promptly.

- Preventive Measures and Timely Repairs: Regularly inspect the structural integrity of the carrier and perform necessary repairs before any damage worsens. Welding and reinforcement may be required to fix cracks or bent parts. It's recommended to conduct a comprehensive inspection at regular intervals to identify any wear-and-tear early, especially after heavy use. Proper maintenance of suspension systems and lifting arms can help extend the lifespan of the carrier. Addressing these problems early can prevent costly repairs or accidents later on.

Conclusion

- Regular maintenance and inspections are essential for the safe and efficient operation of 60-ton straddle carriers. Ensuring that all systems—hydraulics, engine, tires, and structural components—are well-maintained can significantly reduce the risk of malfunctions, improve operational performance, and extend the lifespan of the carrier. Scheduling routine checks helps prevent costly repairs, enhances the safety of operators, and ensures that the carrier can handle heavy lifting tasks without failure.

- The 60-ton straddle carrier plays a critical role in improving operational efficiency in environments like steel mills, ports, and terminals. Its ability to handle large loads with precision and speed directly impacts productivity. Additionally, the inclusion of safety features like load balancing and emergency stops helps safeguard operators and reduce the likelihood of accidents, making it a valuable asset in both industrial and commercial settings.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch