5 Ton Top Running Single Girder Crane | Bridge Crane Zambia Case

5 ton top running single girder overhead crane, good price. Custom top running bridge crane design, 5 ton capacity, 12m span, 380V electric crane in Zambia.

| Crane type | Top running single girder crane |

| Crane specifications | 5 ton -12.3 m span - 6.5 m lifting height |

| Power supply | 220V60HZ3P |

| Crane runway | Provided |

| Project location | Zambia |

Category: Top Running Crane

Your Trusted Top Running Crane Manufacturer & Supplier

5 ton Top Running Single Girder Crane & Bridge Crane Zambia

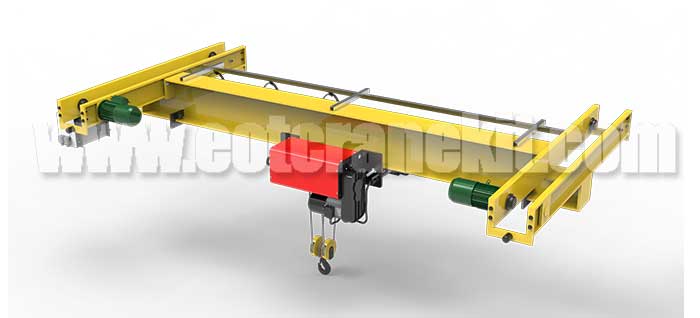

Custom Top Running Bridge Crane Design, 5 Ton, 12m Span, 380V Electric Crane

5 ton top running single girder overhead crane, good price. Custom top running bridge crane design, 5 ton capacity, 12m span, 380V electric crane in Zambia.

5 ton single girder top running cranes

- Overview of 5 ton overhead crane for sale Zambia

- Crane type: LD series of top running single girder overhead crane

- Crane capacity: 5 ton

- Crane span: 12 m

- Crane lifting height: 3.5m

- Crane power supply:380V50HZ3P

- Crane parts and components : 2x25m P24 track. 190 pressing plates, 7 pairs of clamping plates, 25m of seamless slide wire (6mm2), 1 collector.

Case Study: Enhancing Productivity with a 5 Ton Top Running Single Girder Crane in Zambia

In the competitive landscape of modern industries, optimizing operational efficiency and cost-effectiveness has become paramount. When a prominent player in Zambia's manufacturing sector sought to streamline their material handling processes, they turned to an innovative solution - a 5-ton top running single girder crane. This case study outlines how this investment led to improved productivity, cost savings, and an elevated competitive edge.

The client, a well-established manufacturing company in Zambia, specializes in the production of heavy machinery components. With a commitment to excellence, they were on the lookout for a reliable, high-capacity material handling solution that would seamlessly integrate into their existing operations.

Requirements of 5 ton top running single girder crane for sale Zambia

The client faced several challenges in their material handling processes:

- 1. Inefficient Manual Handling: Manual lifting and transporting of heavy components led to delays and increased the risk of workplace injuries.

- 2. Space Constraints: The client's facility had limited space for material movement, necessitating a compact yet powerful lifting solution.

- 3. Operational Costs: The costs associated with manual labor and potential equipment damage were cutting into the company's profitability.

Solution of 5 ton top running single girder cranes

The answer to these challenges came in the form of a custom-designed 5-ton top running single girder overhead crane. The crane boasted the following specifications:

- Crane Type: LD series of top running single girder overhead crane

- Crane Capacity: 5 tons

- Crane Span: 12 meters

- Crane Lifting Height: 3.5 meters

- Crane Power Supply: 380V, 50Hz, 3-phase

- Crane Components: 2x25m P24 track, 190 pressing plates, 7 pairs of clamping plates, 25m of seamless slide wire (6mm2), 1 collector

Benefits of top running single girder crane 5 ton

- 1. Enhanced Productivity: The 5-ton crane drastically improved material handling efficiency. It effortlessly lifted heavy components, reducing manual labor and minimizing production delays.

- 2. Space Optimization: The top running design saved valuable floor space while ensuring optimal vertical lifting capabilities. This was particularly advantageous in the client's space-constrained facility.

- 3. Cost Savings: The reduction in manual labor not only increased operational speed but also curtailed labor-related expenses. Additionally, the crane's precision minimized the risk of costly equipment damage.

- 4. Customization: The crane was tailored to the client's requirements, ensuring seamless integration into their existing workflow and layout.

- 5. Safety Boost: The automation of lifting operations significantly reduced the risk of workplace injuries, promoting a safer working environment.

- Competitive Edge: The investment in advanced material handling technology positioned the client as an industry leader, showcasing their commitment to innovation and excellence.

Main parts and components of 5 ton top running single girder cranes

I beam and U shaped box girder of 5 ton top running single girder crane for sale

Main girder and beam of to running single girder overhead crane for sale

Painted of 5 ton overhead crane with top running crane design

End carriage of single girder top running bridge crane 5 ton

Electric wire rope hoist 5 ton of single girder top running bridge crane

Electric crane hoist 5 ton for single girder top running overhead crane

Parts and components of 5 ton single girder overhead crane with top running crane design

Main parts and components of single girder crane 5 ton for sale

The integration of a 5-ton top running single girder crane into the client's operations in Zambia brought forth a transformative change. By addressing challenges related to efficiency, space, and costs, the crane acted as a catalyst for increased productivity and profitability. This case study serves as a testament to the power of strategic equipment investments in fostering growth and competitiveness within the manufacturing sector.

Types of 5 ton overhead cranes for Your selection

In Zambia's industrial landscape, various key types of 5-ton overhead cranes are available for purchase, each catering to distinct operational demands. Here, we outline the primary categories of 5-ton overhead cranes accessible in Zambia's market:

1. Single Girder 5 Ton Overhead Crane:

- Description: The single girder variant features a solitary horizontal beam supporting the hoisting apparatus and trolley. Suited for light to moderate lifting tasks, it stands as a cost-effective choice.

- Advantages: Economical, apt for low to moderate operational cycles, demands less runway structure.

- Applications: Workshops, storage facilities, assembly lines, and maintenance setups.

2. Double Girder 5 Ton Overhead Crane:

- Description: The double girder option showcases two horizontal beams for hoist and trolley support. It boasts higher load-bearing capabilities, excelling in heavy-duty lifting.

- Advantages: Elevated load capacity, fitting for demanding cycles, grants more headroom.

- Applications: Manufacturing plants, steel mills, foundries, and industries dealing with substantial machinery.

3. Top Running 5 Ton Overhead Crane:

- Description: The top running configuration situates the crane rails atop the runway beams, optimizing vertical spatial utilization.

- Advantages: Maximizes vertical lifting scope, accommodates confined floor areas effectively.

- Applications: Warehouses, production lines, maintenance zones constrained by space.

4. Under Running 5 Ton Overhead Crane:

- Description: The under running model situates the crane rails beneath the runway beams, proving advantageous in limited headroom settings.

- Advantages: Well-suited for low-ceiling environments, offers additional headroom for lifting.

- Applications: Compact workshops, constrained spaces, locations with height constraints.

5. Freestanding 5 Ton Overhead Crane:

- Description: Freestanding cranes operate independently, circumventing the need for pre-existing building support. Ideal when building structures lack load-bearing capacity.

- Advantages: Absence of building dependency, flexible placement alternatives.

- Applications: Outdoor yards, open spaces, sites lacking adequate building reinforcement.

6. Floor-Mounted Jib Crane for 5 Tons:

- Description: This jib crane variant boasts a horizontal arm (jib) pivoting around a vertical column or pillar support.

- Advantages: Efficient space usage, localized lifting, versatile mobility.

- Applications: Workstations, assembly lines, loading/unloading points for materials.

Selecting the optimal 5-ton overhead crane variant in Zambia mandates consideration of load characteristics, frequency of usage, spatial availability, and budgetary considerations. Engaging with crane manufacturers or suppliers facilitates an informed decision based on these factors, ensuring the chosen crane aligns seamlessly with specific requirements.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch