Motorized Gantry Cranes /Bridge Cranes & Motorized Jib Cranes

Electric motorized travelling bridge cranes, motorized gantry crane with rail/ wheel / castor travelling, rotating motorized jib cranes for sale.

Category: Travelling Crane

Your Trusted Motorized Travelling Overhead Crane Manufacturer & Supplier

Motorized Gantry Cranes /Bridge Cranes & Motorized Jib Cranes

Electric motorized travelling bridge cranes, motorized gantry crane with rail/ wheel / castor travelling, rotating motorized jib cranes for sale.

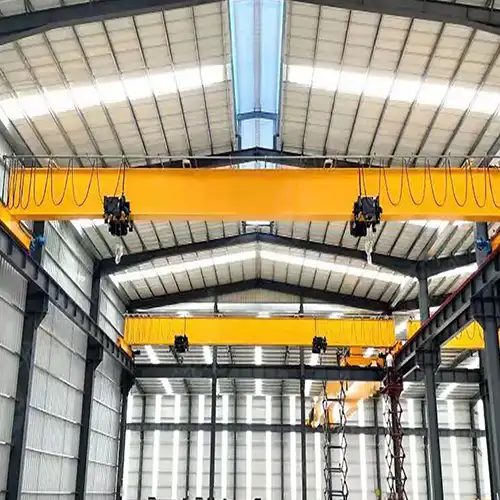

Overhead Motorized Cranes: Motorized Travelling Bridge Crane, Motorizied Gantry Crane, & Motorized Jib Cranes

Power of Motorized Travelling Overhead Cranes in Industry

In industrial operations, efficiency is paramount. Every movement counts, every task needs to be executed swiftly and securely. That's where motorized travelling overhead cranes step in, revolutionizing the way heavy loads are handled and transported within industrial settings. Let's embark on a journey to understand the significance of these powerful machines and explore the various types that make them indispensable assets in modern industries.

Motorized Travelling Bridge Cranes

Motorized travelling overhead cranes come in various configurations, each tailored to suit specific industrial needs. The most common types include:

- Single Girder Cranes: Featuring a single bridge beam, these cranes are ideal for light to moderate lifting tasks in smaller workspaces.

- Double Girder Cranes: With two bridge beams, double girder cranes offer increased lifting capacity and stability, making them suitable for heavyduty applications.

- Top Running Cranes: These cranes run on tracks installed on the top of the building structure, maximizing the available workspace below.

- Under Running Cranes: In contrast, under running cranes utilize tracks mounted on the underside of the building structure, making them ideal for facilities with limited overhead clearance.

Motorized Gantry Cranes:

Motorized gantry cranes stand as stalwarts in industrial settings, offering versatility and reliability in handling heavy loads across various work environments. Let's explore the different types of motorized gantry cranes and understand their functionalities:

- Single Leg Gantry Crane: With a single leg supporting the bridge, these cranes are ideal for areas where floor space is limited. They offer excellent maneuverability and can be customized to suit specific lifting requirements.

- Double Leg Gantry Crane: Featuring two legs on each side of the bridge, double leg gantry cranes provide enhanced stability and lifting capacity. They are commonly used in outdoor applications such as shipyards and construction sites.

- Adjustable Height Gantry Crane: These cranes come with adjustable legs, allowing operators to modify the crane's height based on the requirements of different lifting tasks. They offer flexibility and ease of operation in dynamic work environments.

- RailMounted Gantry Crane (RMG): Utilizing rails for movement, railmounted gantry cranes are commonly found in container terminals and logistics hubs. They offer highspeed operation and precise container handling capabilities.

Motorized gantry cranes play a crucial role in streamlining material handling processes, enhancing productivity, and ensuring workplace safety.

Motorized jib cranes are versatile lifting solutions that provide efficient material handling in confined spaces or areas with limited overhead clearance. Let's explore the various types of motorized jib cranes:

- Freestanding Jib Crane: Mounted on a vertical support column, freestanding jib cranes offer 360degree rotation and can cover a wide area within the workspace. They are suitable for lifting loads in workshops, warehouses, and assembly lines.

- WallMounted Jib Crane: Attached to a wall or existing structure, wallmounted jib cranes conserve floor space while providing efficient lifting capabilities. They are commonly used in areas with restricted floor space or obstacles.

- Articulating Jib Crane: Featuring a twopart arm design, articulating jib cranes offer greater flexibility and reach compared to traditional jib cranes. They are ideal for applications requiring precise load positioning and maneuverability.

- Portable Jib Crane: Designed for mobility, portable jib cranes can be easily moved to different locations within a facility. They offer quick setup and dismantling, making them suitable for temporary lifting tasks or job sites with changing requirements.

Motorized jib cranes are valued for their versatility, compact design, and ease of operation, making them indispensable tools in various industries.

Each type of motorized travelling overhead crane offers unique advantages and is chosen based on factors such as load capacity, span, and operational requirements.

Motorized Travelling Bridge Crane

Motorized travelling bridge cranes, also known as overhead bridge cranes, are vital assets in industrial environments, offering efficient and precise lifting capabilities. Let's delve deeper into the functionality, types, applications, benefits, and commonly asked questions about these versatile cranes:

Functionality and Components:

Motorized travelling bridge cranes consist of a horizontal bridge beam supported by end trucks that travel along elevated runways. The bridge beam can move horizontally across the length of the runway, while the hoist attached to the bridge provides vertical lifting and lowering of loads. The key components of a motorized travelling bridge crane include:

Bridge: The horizontal beam that spans the width of the workspace.

End Trucks: Wheeled assemblies that support and guide the bridge along the runway.

Hoist: The lifting mechanism mounted on the bridge, which can be electrically powered for efficient load handling.

Runway: Elevated tracks along which the bridge travels, providing support and guidance.

Types of Motorized Travelling Bridge Cranes:

Single Girder Motorized Travelling Bridge Crane

Single girder motorized travelling bridge cranes consist of a single horizontal girder supported by end trucks. The hoist and trolley run on the bottom flange of the girder. These cranes are suitable for moderate lifting tasks and provide an economical solution for various material handling needs.

Features:

Single Girder Design: Utilizes a single beam, making it lighter and less costly compared to double girder cranes.

Motorized Travel: Electric motors drive the movement of the crane along the runway.

Lower Load Capacity: Typically handles lighter loads compared to double girder cranes.

Simplified Structure: Easier installation and maintenance.

Safety Features: Includes limit switches, emergency stop buttons, and overload protection.

Typical Applications:

Manufacturing Plants: For lifting and moving parts and components.

Workshops: Assisting in tool and equipment handling.

Warehouses: Efficiently moving goods within the facility.

Maintenance Areas: Handling parts and tools during maintenance tasks.

Double Girder Motorized Travelling Bridge Crane

Double girder motorized travelling bridge cranes feature two parallel girders, providing enhanced strength and stability. The hoist and trolley run on rails mounted on top of the girders, allowing for higher lifting capacities and longer spans.

Features:

Double Girder Design: Provides increased strength and stability, suitable for heavyduty lifting tasks.

Higher Load Capacity: Capable of handling heavier loads compared to single girder cranes.

Motorized Travel: Electric motors drive the movement of the crane and the hoist/trolley.

Larger Span: Can cover larger work areas.

Safety Features: Includes advanced safety systems such as limit switches, emergency stop buttons, and overload protection.

Typical Applications:

Heavy Manufacturing: Lifting and moving large machinery and components.

Construction Sites: Handling heavy construction materials.

Shipyards: Loading and unloading heavy ship components.

Industrial Yards: Managing heavy equipment and materials.

Top Running Motorized Travelling Bridge Crane

Top running motorized travelling bridge cranes operate on rails mounted on top of the runway beams. They can be either single or double girder designs and are used in environments where maximum lifting height is required.

Features:

Top Running Design: The crane runs on rails mounted on top of runway beams, maximizing lifting height.

Flexible Configurations: Available in single or double girder designs.

High Load Capacity: Suitable for heavy lifting tasks.

Motorized Travel: Electric motors drive the crane along the runway and the hoist/trolley for lifting operations.

Larger Span: Can span larger work areas and handle heavy loads.

Safety Features: Includes limit switches, emergency stop buttons, anticollision devices, and overload protection.

Typical Applications:

Heavy Manufacturing: Lifting heavy machinery and components.

Warehouses: Handling large and bulky items.

Construction Sites: Moving heavy construction materials.

Shipyards: Managing heavy ship components and cargo.

Under Running Motorized Travelling Bridge Crane

Under running motorized travelling bridge cranes (also known as underhung cranes) are supported by the lower flange of the runway beams, which are typically suspended from the building's ceiling or roof structure. These cranes are ideal for applications where headroom is limited.

Features:

Under Running Design: The crane runs on the bottom flange of the runway beams, ideal for facilities with limited headroom.

Space Efficiency: Maximizes floor space by suspending the runway beams.

Flexible Installation: Can be installed in buildings without extensive modifications.

Motorized Travel: Electric motors drive the crane and hoist/trolley.

Lower Load Capacity: Typically handles lighter loads compared to top running cranes.

Safety Features: Includes limit switches, emergency stop buttons, and overload protection.

Typical Applications:

Light Manufacturing: Handling lighter components and machinery.

Workshops: Efficiently moving tools and materials.

Warehouses: Handling goods in facilities with limited headroom.

Maintenance Areas: Assisting in the lifting and positioning of parts and tools.

Conclusion

Each type of motorized travelling bridge crane offers distinct advantages suited to specific applications:

Single Girder Cranes: Economical and suitable for moderate lifting tasks.

Double Girder Cranes: Higher load capacity and ideal for heavyduty applications.

Top Running Cranes: Maximizes lifting height and suitable for heavy lifting in large spaces.

Under Running Cranes: Ideal for facilities with limited headroom and lighter lifting tasks.

Selecting the appropriate crane type depends on the specific requirements of the lifting task, the working environment, and the available space.

Specilized Motorized Travelling Bridge Cranes

Specialized motorized travelling bridge cranes are designed to meet unique requirements in specific industrial applications. These cranes incorporate advanced features and customizations to handle particular types of loads, environments, and operational demands.

ExplosionProof Motorized Travelling Bridge Cranes

Explosionproof motorized travelling bridge cranes are designed for use in hazardous environments where flammable gases, vapors, or dust are present. These cranes are built to prevent ignition sources and ensure safe operation.

Features:

ExplosionProof Components: Motors, controls, and electrical systems are designed to prevent sparks and contain explosions.

Safety Enclosures: Protective housings for electrical components.

CorrosionResistant Materials: Use of materials that resist corrosion in harsh environments.

Enhanced Safety Features: Includes limit switches, emergency stop buttons, and antisparking measures.

Typical Applications:

Chemical Plants: Handling chemicals and hazardous materials.

Oil and Gas Facilities: Operations in refineries and processing plants.

Pharmaceutical Industry: Manufacturing processes involving volatile substances.

Mining Operations: Environments with combustible dust.

Magnet Based Motorized Travelling Bridge Cranes

Magnetbased motorized travelling bridge cranes are equipped with electromagnets to lift and move ferrous materials. These cranes are ideal for handling metal products such as steel plates, pipes, and scrap.

Features:

Electromagnets: Strong magnets for lifting and transporting ferrous materials.

Variable Magnetic Force: Adjustable magnetic force for different load weights.

Safety Interlocks: Prevent accidental release of the load.

Durable Construction: Built to withstand heavy and continuous use.

Typical Applications:

Steel Mills: Handling steel products like beams, plates, and coils.

Scrap Yards: Moving and sorting scrap metal.

Manufacturing: Transporting metal parts and components.

Warehousing: Storing and retrieving metal goods.

Clean Room Motorized Travelling Bridge Cranes

Clean room motorized travelling bridge cranes are designed for use in environments that require stringent cleanliness standards, such as semiconductor manufacturing, pharmaceuticals, and biotechnology.

Features:

NonContaminating Materials: Construction using materials that do not release particles.

Sealed Bearings and Motors: Prevent contamination from lubricants.

Smooth Surfaces: Easy to clean and sterilize.

HEPA Filtration: Air filtration systems to maintain clean room standards.

Typical Applications:

Semiconductor Manufacturing: Handling sensitive electronic components.

Pharmaceutical Production: Moving materials in sterile environments.

Biotechnology Labs: Transporting biohazardous materials.

Food Processing: Ensuring contaminationfree handling of food products.

Specialized motorized travelling bridge cranes offer tailored solutions for unique industrial requirements. Whether operating in hazardous environments, handling hightemperature materials, ensuring contaminationfree operations, or integrating with automated systems, these cranes provide enhanced capabilities to meet specific challenges. Selecting the right specialized crane ensures safety, efficiency, and productivity in demanding applications.

Frequently Asked Questions:

What is the maximum lifting capacity of a motorized travelling bridge crane?

How do I determine the right type and size of bridge crane for my application?

What safety features are available on motorized travelling bridge cranes?

How often should bridge crane maintenance be performed, and what does it entail?

Are motorized travelling bridge cranes suitable for outdoor use?

The functionality, types, applications, and benefits of motorized travelling bridge cranes is essential for maximizing their efficiency and safety in industrial operations. In the next part of our comprehensive guide, we'll explore motorized gantry cranes, another integral component of material handling systems.

Electric Motorized Gantry Cranes

Motorized gantry cranes are a type of crane system that consists of a bridge supported by two or more rigid legs, which move on a rail or set of wheels. These cranes are powered by motors, enabling them to lift, lower, and move heavy loads with precision and ease.

Design and Operation:

Motorized gantry cranes are characterized by their gantry structure, consisting of two vertical legs and a horizontal bridge spanning the gap between them. The bridge houses the hoist mechanism, which is responsible for lifting and lowering loads. The entire crane is mounted on wheels or tracks, allowing for horizontal movement along the length of the gantry.

The operation of a motorized gantry crane involves the controlled movement of the bridge and hoist mechanism to position loads with precision. Operators can manipulate the crane using pendant controls or radio remote controls, ensuring safe and efficient material handling.

- Gantry Structure: The gantry structure forms the backbone of the crane, providing stability and support. It typically consists of two upright beams (legs) connected by a horizontal beam (bridge), with wheels or tracks mounted on the bottom for movement.

- Electric Motors: These are the powerhouse of the crane, providing the necessary energy for lifting and movement. Electric motors drive the hoisting mechanism, trolley, and travel motions, ensuring smooth and efficient operation.

- Hoisting Mechanism: The hoisting mechanism comprises a hoist, rope or chain, and hook or other lifting attachment. It is responsible for lifting and lowering loads with precision and control.

- Trolley: The trolley is mounted on the bridge and facilitates horizontal movement along the length of the crane. It carries the hoisting mechanism, allowing for precise positioning of the load.

- Controls: Electric motorized gantry cranes are equipped with userfriendly control systems that enable operators to maneuver the crane safely and efficiently. These controls may include pushbutton pendant stations, radio remote controls, or advanced automation features.

How Electric Motorized Gantry Cranes Work

The operation of electric motorized gantry cranes is relatively straightforward yet highly efficient. Here's a simplified overview:

- Lifting: When a load needs to be lifted, the electric motor drives the hoisting mechanism, causing the hoist to reel in the rope or chain attached to the load. As the load is lifted, the trolley may move along the bridge to position it accurately.

- Horizontal Movement: To move the load horizontally, the electric motor powers the trolley, allowing it to travel along the length of the crane bridge. This enables precise positioning of the load over the desired location.

- Travel Motion: For gantry cranes with wheeled legs, the electric motors drive the wheels, enabling the crane to move along the rails or tracks laid on the ground. This mobility is essential for transporting heavy loads across the worksite or facility.

Single Girder Rail Travelling Motorized Gantry Cranes

Single girder rail travelling motorized gantry cranes are a type of gantry crane that features a single girder or beam, supported by legs that run on rails. These cranes are designed for lifting and moving heavy loads with efficiency and precision. The "single girder" aspect means that there is one horizontal beam or girder, which the hoist travels along. These cranes are motorized, meaning they are powered by electric motors for both the movement along the rails and the lifting mechanism.

Detailed Features

- Single Girder Design: The crane consists of one horizontal girder, which reduces the overall weight and cost compared to double girder designs. This design also allows for a simpler and more compact structure.

- Motorized Movement: The crane is powered by electric motors for horizontal travel along the rails and vertical lifting of loads. Motors can be controlled via a pendant, remote control, or automated system.

- Rails: The crane runs on rails that are typically fixed to the ground, providing a stable and straight path for the crane's movement. The rails can be customized based on the length of the area the crane needs to cover.

- Hoist: Equipped with an electric hoist that moves along the girder. The hoist can lift, lower, and move loads with high precision.

- Controls: Can be operated via wired pendant controls, wireless remote controls, or automated systems. Some models include safety features such as overload protection and emergency stop functions.

- Adjustable Speed: Many models offer variable speed controls for both the hoist and the travel mechanism, allowing for precise positioning of loads.

- Durability and Safety: Constructed with robust materials to handle heavy loads and harsh environments. Includes safety features like limit switches, emergency brakes, and anticollision devices.

Full gantry motorized cranes are equipped with two legs that move along rails laid on the ground, allowing the crane to cover a large rectangular area. These cranes are typically used for outdoor applications where heavy loads need to be lifted and moved over significant distances.

Features:

Two Legs: Provides full support for the girder and hoist, ensuring stability.

Spanning Width: Can span large areas, making them ideal for extensive outdoor applications.

High Lifting Capacity: Designed to handle very heavy loads.

Motorized Travel: Equipped with motors for horizontal movement along the rails.

Customization: Can be customized in terms of span, height, and load capacity to suit specific requirements.

Safety Features: Includes limit switches, emergency stop buttons, anticollision devices, and overload protection.

Typical Applications:

Shipyards: For lifting and moving large ship components and containers.

Construction Sites: Handling heavy construction materials and precast concrete sections.

Industrial Yards: Moving heavy machinery and components in manufacturing or maintenance areas.

Rail Yards: Loading and unloading railcars.

Semigantry motorized cranes have one leg running on a rail at ground level and the other side supported by a structure at a higher elevation, such as a wall or a building column. This design is ideal for indoor or outdoor applications where space is constrained.

Features:

Single Leg Design: One side of the crane is supported by a groundlevel rail, while the other is supported by an elevated structure.

Space Efficiency: Takes up less floor space compared to full gantry cranes.

Versatility: Can be used in areas where a full gantry crane is impractical.

Motorized Travel: Equipped with motors for horizontal and vertical movements.

Customization: Can be tailored in terms of span, height, and load capacity.

Safety Features: Includes limit switches, emergency stop buttons, and overload protection.

Typical Applications:

Manufacturing Plants: Moving parts and equipment in constrained spaces.

Warehouses: Handling heavy goods while saving floor space.

Maintenance Areas: Facilitating repair and maintenance operations in confined spaces.

Construction: Useful in construction areas with limited ground space.

Truss Girder Motorized Gantry Crane

Truss girder motorized gantry cranes use a truss structure for the girder, making them lighter and suitable for long spans. The truss design is ideal for applications requiring a lighter crane with high strength and stability.

Features:

Truss Girder Design: Provides high strengthtoweight ratio.

Lightweight Structure: Easier to transport and install.

High Wind Resistance: The truss design offers better resistance to wind loads, making it suitable for outdoor use.

Motorized Travel: Equipped with motors for precise movement along rails.

Customization: Span, height, and capacity can be customized.

Safety Features: Includes limit switches, emergency stop buttons, and overload protection.

Typical Applications:

Construction Sites: For lifting and moving materials over long distances.

Shipyards: Suitable for handling ship components and containers with large spans.

Large Industrial Facilities: Moving heavy equipment and materials across wide areas.

Outdoor Yards: Used in environments where wind resistance is critical.

L leg motorized gantry cranes have legs that are shaped like an "L," providing a unique structural design that offers advantages in certain applications. This design can offer better stability and load distribution.

Features:

Lshaped Legs: Provides better load distribution and stability.

Versatile Design: Suitable for various indoor and outdoor applications.

High Lifting Capacity: Capable of handling heavy loads efficiently.

Motorized Travel: Equipped with motors for smooth and precise movement along rails.

Customization: Can be tailored to specific needs in terms of span, height, and load capacity.

Safety Features: Includes limit switches, emergency stop buttons, and overload protection.

Typical Applications:

Construction Sites: For handling heavy materials and equipment.

Industrial Yards: Moving heavy machinery and components.

Warehousing: Suitable for handling bulky items and pallets in warehouses.

Maintenance and Repair: Used in facilities requiring the lifting of large machinery parts.

Each type of motorized gantry crane offers unique advantages, making them suitable for various applications depending on the specific requirements of the task, space constraints, and load capacities.

Double Girder Rail Travelling Motorized Gantry Cranes

Double girder rail travelling motorized gantry cranes feature two horizontal girders for added strength and stability, allowing them to handle heavier loads and larger spans compared to single girder cranes. These cranes are ideal for demanding industrial applications that require precise and efficient handling of very heavy loads.

Double Girder Rail Travelling Motorized Gantry Cranes with Hoist Trolley

These cranes use a hoist trolley that moves along the double girders. The hoist is typically an electric hoist designed for high precision and efficiency.

Features:

Double Girder Design: Provides enhanced strength and stability for lifting heavier loads.

Hoist Trolley: Moves along the girders, allowing precise positioning of the load.

High Load Capacity: Capable of handling very heavy loads due to the double girder structure.

Motorized Travel: Motors for both horizontal and vertical movements.

Safety Features: Includes limit switches, emergency stop buttons, overload protection, and anticollision systems.

Typical Applications:

Heavy Manufacturing: Lifting and moving large parts and machinery.

Construction: Handling heavy materials and prefabricated components.

Shipyards: Loading and unloading ship components and containers.

Industrial Warehouses: Managing heavy and bulky items.

Double Girder Rail Travelling Motorized Gantry Cranes with Open Winch Trolley

These cranes feature an open winch trolley, which is a more robust lifting mechanism suitable for extremely heavy loads and critical applications.

Features:

Open Winch Trolley: Offers greater lifting capacity and durability compared to hoist trolleys.

High Precision: Capable of very precise lifting and positioning.

HeavyDuty Design: Designed for the most demanding industrial applications.

Motorized Travel: Motors for horizontal and vertical movements, often with variable speed controls.

Safety Features: Includes advanced safety systems such as overload protection, emergency stop, and anticollision devices.

Typical Applications:

Heavy Industry: For lifting extremely heavy machinery and equipment.

Steel Mills: Handling heavy steel products and materials.

Power Plants: Lifting large components such as turbines and generators.

Shipbuilding: Moving large ship sections and heavy shipbuilding materials.

Double Girder Rail Travelling Motorized Gantry Cranes with Grab, Magnet, and Beam Spreader

These cranes are equipped with specialized attachments such as grabs, magnets, and beam spreaders to handle specific types of loads like bulk materials, ferrous metals, and long loads.

Features:

Specialized Attachments:

Grab: For handling bulk materials such as sand, gravel, and grain.

Magnet: For lifting ferrous metal items like scrap metal and steel plates.

Beam Spreader: For handling long loads such as pipes, beams, and logs.

Double Girder Design: Provides the necessary strength for handling specialized attachments and heavy loads.

Motorized Travel: Equipped with motors for efficient movement.

Safety Features: Includes limit switches, emergency stops, and specialized safety systems for each attachment type.

Typical Applications:

Bulk Material Handling: Using grabs for loading and unloading bulk materials in ports and industrial facilities.

Scrap Yards: Using magnets to handle scrap metal efficiently.

Steel Mills: Moving steel products with magnets and beam spreaders.

Construction Sites: Using beam spreaders for handling long construction materials.

Double girder rail travelling motorized gantry cranes are versatile and powerful lifting solutions designed for a wide range of industrial applications. Their ability to handle heavy loads with precision and their adaptability to various attachments make them indispensable in sectors such as manufacturing, construction, shipbuilding, and material handling.

Rubber Tyred Wheel Travelling Motorized Gantry Cranes

Rubber tyred wheel travelling motorized gantry cranes (RTG cranes) are versatile, mobile cranes equipped with rubber tires instead of being fixed on rails. This design allows for greater flexibility in movement and positioning, making them ideal for various outdoor and indoor applications where rails are impractical or unavailable.

Single Girder A Frame Motorized Gantry Crane

Single girder A frame motorized gantry cranes feature a single horizontal girder supported by two Ashaped frames on either side, equipped with rubber tires for mobility. This type is suitable for lighter to moderate lifting tasks.

Features:

Single Girder Design: Simplifies the structure, reducing weight and cost.

A Frame Structure: Provides stable support and easy assembly.

Rubber Tires: Allows for movement on various surfaces, both indoor and outdoor.

Motorized Travel: Equipped with electric motors for horizontal movement and lifting.

Portability: Easily movable to different locations as needed.

Safety Features: Includes limit switches, emergency stop buttons, and overload protection.

Typical Applications:

Workshops and Warehouses: For moving moderate loads within the facility.

Construction Sites: Handling building materials and light equipment.

Maintenance Areas: Assisting in lifting and moving components for repair and maintenance tasks.

Double Girder A Frame Motorized Gantry Cranes

Double girder A frame motorized gantry cranes have two horizontal girders supported by Ashaped frames, providing greater lifting capacity and stability. This type is designed for heavier lifting tasks compared to the single girder variant.

Features:

Double Girder Design: Enhances strength and stability, allowing for higher load capacities.

A Frame Structure: Ensures stability and durability.

Rubber Tires: Provides flexibility to move across various surfaces.

Motorized Travel: Equipped with powerful electric motors for smooth movement and lifting operations.

Portability: Capable of being moved to different work areas as needed.

Safety Features: Includes advanced safety systems such as limit switches, emergency stop buttons, and overload protection.

Typical Applications:

Heavy Manufacturing: Lifting and moving large parts and machinery.

Construction Sites: Handling heavy materials and prefabricated components.

Shipyards and Ports: Loading and unloading heavy containers and ship components.

Industrial Yards: Managing heavy machinery and equipment.

Rubber Tyred Wheel Travelling Motorized Gantry Cranes U Frame

U frame rubber tyred wheel travelling motorized gantry cranes are designed with a Ushaped frame, providing a wide and clear passage underneath the crane. This design is particularly useful for handling wide and bulky loads.

Features:

U Frame Design: Offers a wide and unobstructed passage for large and wide loads.

Rubber Tires: Allows for flexible movement on various surfaces without the need for tracks.

Motorized Travel: Equipped with electric motors for precise movement and lifting.

High Load Capacity: Suitable for handling heavy and bulky items.

Portability: Easily moved to different locations as required.

Safety Features: Includes limit switches, emergency stop buttons, anticollision systems, and overload protection.

Typical Applications:

Container Handling: Ideal for moving large shipping containers in ports and storage areas.

Construction Sites: Useful for transporting large construction materials like beams and panels.

Heavy Manufacturing: For handling large and wide machinery and components.

Rail Yards: Moving large rail components and sections.

Rubber tyred wheel travelling motorized gantry cranes offer versatile and mobile solutions for various lifting and moving tasks. Their ability to operate on different surfaces without the need for fixed rails makes them highly adaptable for a wide range of industries, including construction, manufacturing, shipping, and more. Each type, whether single girder, double girder, or U frame, provides unique advantages tailored to specific applications and load requirements.

Motorized Roller or Castor Travelling Gantry Cranes

Motorized roller or castor travelling gantry cranes are mobile cranes that use rollers or castors for movement, allowing them to be easily repositioned within a facility. These cranes are typically used for lifting and moving loads in areas where flexibility and mobility are essential.

Motorized Roller Travelling Steel Gantry Cranes

Motorized roller travelling steel gantry cranes are constructed from steel, providing robust strength and durability. These cranes are suitable for heavyduty applications where lifting heavy loads is required.

Features:

Steel Construction: Offers high strength and durability, suitable for heavy loads.

Motorized Rollers: Equipped with electric motors to drive the rollers, allowing for easy movement.

High Load Capacity: Can handle heavier loads compared to aluminum gantry cranes.

Adjustable Height: Many models feature adjustable height for versatility in various applications.

Portability: Easily moved around the facility as needed.

Safety Features: Includes limit switches, emergency stop buttons, and overload protection.

Typical Applications:

Manufacturing Plants: For lifting and moving heavy machinery and components.

Construction Sites: Handling heavy construction materials and equipment.

Warehouses: Managing heavy and bulky items.

Maintenance Facilities: Assisting in the maintenance and repair of large equipment.

Motorized Roller Travelling Aluminum Gantry Cranes

Motorized roller travelling aluminum gantry cranes are constructed from aluminum, offering a lightweight and corrosionresistant alternative to steel. These cranes are ideal for applications where ease of movement and resistance to corrosion are important.

Features:

Aluminum Construction: Lightweight and corrosionresistant, making it easy to move and suitable for outdoor use.

Motorized Rollers: Electric motors drive the rollers for smooth and effortless movement.

Lower Load Capacity: Typically handle lighter loads compared to steel gantry cranes.

Adjustable Height: Many models have adjustable height to accommodate different lifting requirements.

Portability: Lightweight design makes them easy to transport and reposition.

Safety Features: Includes limit switches, emergency stop buttons, and overload protection.

Typical Applications:

Light Manufacturing: For handling lighter components and equipment.

Workshops: Moving tools and materials within a workshop environment.

Maintenance and Repair: Ideal for lifting smaller parts and equipment during maintenance tasks.

Outdoor Applications: Suitable for environments where corrosion resistance is essential, such as in marine or outdoor settings.

Motorized roller or castor travelling gantry cranes provide a versatile and mobile solution for lifting and moving loads within a facility. The choice between steel and aluminum construction depends on the specific needs of the application:

Steel Gantry Cranes: Offer high strength and are suitable for heavyduty applications.

Aluminum Gantry Cranes: Provide lightweight and corrosionresistant options for easier movement and outdoor use.

Both types of cranes enhance productivity by allowing for flexible and efficient handling of loads in various industrial environments.

Configurations based on Capacity, Span, and Lifting Height

- Capacity: Electric motorized gantry cranes are available in a wide range of lifting capacities, ranging from a few hundred kilograms to several hundred tons. The appropriate capacity depends on the weight of the loads to be lifted and the operational requirements of the facility.

- Span: The span of a gantry crane refers to the distance between the two legs of the gantry structure. Gantry cranes can be customized to accommodate varying spans, allowing them to cover specific work areas or accommodate different layouts within a facility.

- Lifting Height: The lifting height of a gantry crane is determined by the vertical distance between the ground and the maximum height to which the load can be lifted. Electric motorized gantry cranes can be equipped with different lifting mechanisms and height adjustments to suit the vertical clearance requirements of the facility.

When selecting an electric motorized gantry crane, it's essential to consider factors such as the nature of the loads to be lifted, the available space and infrastructure, and the operational requirements of the facility. By understanding the different types and configurations available, you can choose the crane that best meets your specific needs and maximizes efficiency and productivity in your operations.

Advantages of Electric Motorized Gantry Cranes

Electric motorized gantry cranes offer a host of advantages that make them a preferred choice for material handling and lifting operations in various industries. In this section, we'll explore some of the key benefits of these versatile machines.

Energy Efficiency

Electric motorized gantry cranes are highly energyefficient compared to other types of cranes, such as dieselpowered or hydraulic cranes. By utilizing electric motors for lifting and movement, these cranes minimize energy consumption and reduce operating costs over time. Additionally, electric motors produce fewer emissions, making them environmentally friendly and compliant with sustainability standards.

Flexibility in Operation and Movement

One of the significant advantages of electric motorized gantry cranes is their flexibility in operation and movement. Unlike fixedposition cranes, gantry cranes can be easily relocated to different areas within a facility or transported to remote job sites. This mobility allows for optimal use of space and resources, enabling operators to adapt quickly to changing work environments and project requirements. Moreover, electric motorized gantry cranes can navigate tight spaces and maneuver around obstacles with ease, maximizing efficiency and productivity in diverse applications.

Safety Features and Regulations Compliance

Safety is paramount in any industrial setting, and electric motorized gantry cranes are designed with this in mind. These cranes are equipped with a range of safety features, such as overload protection systems, emergency stop buttons, and safety interlocks, to ensure safe operation and protect personnel and equipment from accidents or injuries. Furthermore, electric motorized gantry cranes adhere to strict industry regulations and standards, such as OSHA (Occupational Safety and Health Administration) and CMAA (Crane Manufacturers Association of America) guidelines, to ensure compliance and minimize risk in the workplace.

The advantages of electric motorized gantry cranes are clear: they offer energy efficiency, flexibility in operation and movement, and robust safety features to enhance productivity and safety in industrial environments. Whether lifting heavy machinery in a manufacturing facility, loading cargo onto ships at a port, or stacking pallets in a warehouse, electric motorized gantry cranes prove to be indispensable tools for businesses looking to streamline their operations and maximize efficiency.

Each configuration of motorized gantry crane offers unique capabilities, allowing operators to tailor their lifting solutions to specific applications.

Advantages and Limitations:

The advantages of motorized gantry cranes include:

Versatility: Suitable for indoor and outdoor use, adaptable to a wide range of lifting tasks and environments.

Mobility: Can be easily moved to different locations within a facility or job site, providing flexibility in material handling operations.

CostEffectiveness: Offers a costeffective alternative to permanent overhead crane installations, especially in temporary or rented facilities.

Accessibility: Provides accessibility to loads in areas where overhead clearance is limited or obstructed.

However, motorized gantry cranes also have limitations, such as:

Lower Lifting Capacity: Generally have lower lifting capacities compared to overhead bridge cranes, limiting their suitability for heavyduty lifting tasks.

Floor Space Requirements: Require adequate floor space for maneuvering and operation, which may pose challenges in congested work areas.

Stability: Double leg gantry cranes offer better stability than single leg gantry cranes, but may still be affected by uneven terrain or environmental factors.

Addressing Common Concerns and Queries:

Common concerns and queries related to motorized gantry cranes include:

Safety: Ensuring proper training for operators, regular maintenance, and adherence to safety protocols to minimize the risk of accidents.

Load Capacity: Determining the maximum load capacity and ensuring compliance with safety regulations and manufacturer specifications.

Installation and Assembly: Seeking professional assistance for installation and assembly to ensure proper setup and operation of the crane.

Understanding the design, operation, configurations, advantages, limitations, and addressing common concerns and queries related to motorized gantry cranes is essential for optimizing their efficiency and safety in material handling applications. In the next part of our comprehensive guide, we'll explore motorized jib cranes, another vital component of industrial lifting solutions. Stay tuned for insights into their functionality, applications, and benefits!

Motorized Jib Crane

Motorized jib cranes might not be the most talkedabout piece of equipment in industrial settings, but they pack a punch when it comes to efficiency and versatility. Before we delve into the nittygritty details, let's break down what exactly motorized jib cranes are and why they matter.

At their core, motorized jib cranes are a type of lifting equipment used in various industries to handle loads with precision and ease. Unlike traditional jib cranes, which rely solely on manual operation, motorized jib cranes are equipped with electric motors that power their movement and lifting capabilities.

Importance and Benefits of Using Motorized Jib Cranes

Now, you might be wondering, "Why should I bother with a motorized jib crane when a manual one seems to do the job just fine?" Well, let's uncover the benefits:

- Enhanced Efficiency: Motorized jib cranes streamline lifting operations by reducing the need for manual effort. With the push of a button, operators can effortlessly maneuver loads with precision and speed.

- Increased Lifting Capacity: Thanks to their motorized mechanisms, these cranes can handle heavier loads compared to their manual counterparts. This means you can tackle larger tasks with ease, without sacrificing safety or risking overload.

- Versatility in Operation: Motorized jib cranes offer flexibility in operation, allowing for smooth movement and positioning of loads in confined spaces or challenging environments. Whether you're working in a tight warehouse or an expansive construction site, these cranes adapt to your needs.

- Improved Safety: With features like overload protection and emergency stop buttons, motorized jib cranes prioritize safety in the workplace. Operators can confidently handle loads without worrying about potential accidents or injuries.

Exploring the Types of Motorized Jib Cranes

Motorized jib cranes are versatile lifting devices with a rotating boom or arm, allowing for efficient handling of materials within a specific radius. These cranes are powered by electric motors, enabling smooth and precise movement. They can be mounted on walls, floors, or be portable for added flexibility.

Wall Mounted Jib Cranes with Motorized Rotating Cantilever Design

Wallmounted jib cranes with a motorized rotating cantilever are fixed to a wall or column, providing a compact lifting solution that maximizes floor space.

Features:

WallMounted Design: Saves floor space and provides a clean installation.

Motorized Cantilever Rotation: Allows for controlled and precise movement of the jib arm.

Adjustable Reach: The cantilever can often be adjusted to suit different working areas.

Compact Footprint: Ideal for small or congested workspaces.

Safety Features: Includes limit switches, emergency stop buttons, and overload protection.

Typical Applications:

Workstations: Providing localized lifting solutions in confined areas.

Machining Centers: Assisting with loading and unloading of workpieces.

Assembly Lines: Facilitating movement of parts and assemblies.

Maintenance Areas: Handling tools and equipment.

Freestanding Jib Cranes with Motorized Slewing Cantilever Design

Freestanding jib cranes with a motorized slewing cantilever are mounted on a floor or base plate, providing a versatile and flexible lifting solution that can be placed anywhere within a facility.

Features:

Freestanding Design: Can be installed in any suitable location within a facility.

Motorized Slewing: Allows for smooth and controlled rotation of the jib arm.

High Load Capacity: Suitable for handling heavier loads.

Versatility: Can be used in various industrial and commercial environments.

Safety Features: Includes limit switches, emergency stop buttons, and overload protection.

Typical Applications:

Industrial Facilities: Handling heavy machinery and components.

Warehouses: Moving large and bulky items.

Construction Sites: Facilitating material handling.

Manufacturing Plants: Assisting with heavy parts and equipment.

Motorized Rolling Jib Crane (Portable Jib Crane with Electric Motorized Travelling)

Motorized rolling jib cranes are portable cranes equipped with wheels or castors, allowing them to be moved easily around a facility. They feature an electric motor for powered travelling and lifting.

Features:

Portable Design: Equipped with wheels or castors for easy mobility.

Motorized Travel: Electric motor provides smooth and controlled movement.

Adjustable Height and Reach: Many models offer adjustable features for greater versatility.

Flexibility: Can be moved to different work areas as needed.

Safety Features: Includes limit switches, emergency stop buttons, and overload protection.

Typical Applications:

Maintenance and Repair: Providing flexible lifting solutions for maintenance tasks.

Workshops: Moving tools and materials within the workshop.

Construction Sites: Offering portable lifting capabilities.

Light Manufacturing: Assisting in handling small to mediumsized parts and components.

Motorized jib cranes offer versatile and efficient lifting solutions for a variety of industrial applications. The different types, including motorized rotating jib cranes, wallmounted designs, freestanding options, and portable rolling jib cranes, provide flexibility and adaptability to meet specific operational needs. These cranes enhance productivity and safety by facilitating precise and controlled handling of materials within a designated work area.

Components and Working Mechanism of Motorized Jib Cranes

The inner workings of motorized jib cranes is essential for harnessing their full potential. Let's dive into the key components that make up these powerful lifting machines, how they operate, and the types of motors that drive their functionality.

Components of Motorized Jib Cranes

- Mast: The mast is the vertical support structure of the jib crane, providing stability and rigidity to the crane assembly.

- Boom: The boom is the horizontal arm of the crane that extends outward from the mast. It supports the hoist and trolley and provides reach for lifting and maneuvering loads.

- Hoist: The hoist is the lifting mechanism that raises and lowers loads. It typically consists of a motorized winch or drum, a lifting hook or attachment, and a control system for operation.

- Trolley: The trolley is a movable carriage that travels along the length of the boom, allowing for horizontal movement of the load. It is powered by a motor and can be controlled remotely or manually.

- Motor: The motor powers the movement and lifting operations of the jib crane. It provides the necessary torque and horsepower to operate the hoist, trolley, and rotation mechanisms.

Working Mechanism of Motorized Jib Cranes

Motorized jib cranes operate on a simple yet efficient mechanism that enables precise control and movement of loads. Here's how it works:

- Lifting Operation: When a load needs to be lifted, the hoist motor engages, winding the hoist cable or chain around the drum or winch. As the cable is pulled in, the load is lifted vertically along the boom.

- Horizontal Movement: The trolley motor controls the horizontal movement of the load along the length of the boom. By powering the trolley carriage, the motorized jib crane can position the load precisely where needed within the workspace.

- Rotation: Depending on the crane's design, it may feature a motorized rotation mechanism that allows the entire crane assembly to swivel or rotate. This rotation function enables the crane to cover a wider area and reach multiple workstations without repositioning the base.

In essence, motorized jib cranes are sophisticated lifting machines that rely on a combination of components and motors to achieve precise control and movement of loads. By understanding their components and working mechanism, operators can harness the full potential of these cranes to optimize lifting operations and enhance productivity in industrial settings.

Answering Common Questions Regarding Motorized Jib Cranes:

Common questions regarding motorized jib cranes include:

What is the maximum lifting capacity of a motorized jib crane?

How do I determine the right type and size of jib crane for my application?

What safety features are available on motorized jib cranes?

How often should jib crane maintenance be performed, and what does it entail?

Are motorized jib cranes suitable for outdoor use?

The overview, types, key components, features, and common questions regarding motorized jib cranes is essential for selecting and operating these versatile lifting solutions effectively. In the next part of our comprehensive guide, we'll explore the operation, maintenance, and safety considerations of motorized travelling overhead cranes. Stay tuned for valuable insights into maximizing the efficiency and safety of your material handling operations!

Main Motorized Hoists

Motorized hoists are essential tools in material handling operations, providing efficient lifting and lowering of heavy loads. Let's delve into the details of motorized hoists, including their types, classifications, components, operating principles, and maintenance guidelines:

Detailed Examination of Various Types of Motorized Hoists:

Motorized hoists offer versatility in lifting solutions tailored to diverse needs and environments. Key types include:

Electric Chain Hoists:

Utilize electric motors to power a chain mechanism for vertical lifting.

Ideal for applications requiring precise and controlled lifting of loads.

Commonly used in workshops, warehouses, and manufacturing facilities.

Wire Rope Hoists:

Employ an electric motordriven drum to wind wire ropes for lifting and lowering heavy loads.

Suited for heavyduty lifting operations with higher load capacities.

Often utilized in construction, shipyards, and industrial settings.

European Style Motorized Chain Hoists:

Embrace the design principles of European standards for robustness and precision.

Offer enhanced safety features and durability for demanding lifting tasks.

Widely used in automotive, aerospace, and hightech industries.

European Style Motorized Rope Hoists:

Built according to European standards, ensuring reliability and performance.

Feature advanced control systems for precise load handling and positioning.

Commonly found in theatres, concert halls, and entertainment venues for stage rigging.

Each type of motorized hoist caters to specific lifting requirements, ensuring efficient and safe material handling across various industries and applications.

Troubleshooting and Maintenance Tips for Motorized Hoists:

Effective maintenance is essential for ensuring the reliability and longevity of motorized hoists. Some troubleshooting and maintenance tips include:

Regular Inspection: Check for signs of wear, damage, or malfunction in the motor, gearbox, hoist mechanism, and control system.

Lubrication: Keep moving parts welllubricated to reduce friction and prevent premature wear.

Calibration: Ensure proper alignment and calibration of the hoist components to maintain optimal performance.

Safety Checks: Test safety features such as overload protection and emergency stop functions regularly to ensure proper operation.

Addressing issues promptly and conducting routine maintenance can help prevent downtime and prolong the lifespan of motorized hoists, ensuring safe and efficient material handling operations.

The types, classifications, components, operating principles, and maintenance guidelines for motorized hoists is essential for selecting, operating, and maintaining these critical lifting tools effectively. In the next part of our comprehensive guide, we'll explore the types of overhead crane motors and their suitability for different applications. Stay tuned for valuable insights into optimizing your material handling operations!

Types of Overhead Crane Motors

Electric motors play a pivotal role in the operation of overhead cranes, providing the necessary power for lifting, traversing, and hoisting heavy loads. Let's explore the different aspects of overhead crane motors, including their introduction, differentiation, varieties, and factors influencing their selection:

Electric motors are the primary power source for overhead cranes, converting electrical energy into mechanical motion to facilitate lifting, traversing, and hoisting operations. These motors are designed to deliver the required torque and speed for efficient material handling in various industrial applications.

Differentiating Between Gantry Crane Motors, Overhead Crane Motors, and Electric Motor Cranes:

While the terms may sometimes be used interchangeably, there are distinctions between gantry crane motors, overhead crane motors, and electric motor cranes:

Gantry Crane Motors: Refer to the motors specifically used in gantry cranes, which are mobile lifting devices that operate on tracks or wheels.

Overhead Crane Motors: Pertains to the motors employed in overhead cranes, which are stationary lifting devices mounted on beams or runways.

Electric Motor Cranes: Encompasses overhead cranes and gantry cranes powered by electric motors, emphasizing their reliance on electricity for operation.

Varieties of Overhead Crane Motor Types and Their Suitability for Different Applications:

Overhead crane motors come in various types, each offering unique features and suitability for specific applications:

AC Induction Motors: Commonly used in overhead cranes due to their reliability, durability, and ability to provide high starting torque.

DC Motors: Known for their precise speed control and ability to generate high torque at low speeds, making them suitable for applications requiring precise positioning.

Servo Motors: Offer excellent speed and position control, making them ideal for highprecision lifting and handling tasks.

Synchronous Motors: Provide constant speed operation and are often used in applications where synchronous speed is critical, such as inverterduty crane systems.

The selection of overhead crane motors depends on factors such as load capacity, operating environment, duty cycle, and desired performance characteristics.

Factors Influencing the Selection of Overhead Crane Motors:

Several factors influence the selection of overhead crane motors:

Load Capacity: The motor's power rating should match or exceed the maximum load capacity of the crane to ensure efficient lifting operations.

Operating Environment: Considerations such as temperature, humidity, and hazardous conditions may dictate the type of motor suitable for the application.

Duty Cycle: Determine the frequency and duration of crane operation to select a motor capable of handling the required duty cycle without overheating or premature wear.

Performance Requirements: Evaluate factors such as speed, acceleration, and braking requirements to choose a motor that meets the desired performance criteria.

Safety Considerations and Regulations

Safety is paramount when operating motorized travelling overhead cranes to ensure the wellbeing of workers and the integrity of the workplace. Let's explore safety protocols, compliance with regulations, training requirements, and strategies for addressing safety concerns associated with motorized overhead cranes:

Comprehensive Overview of Safety Protocols:

Operating motorized travelling overhead cranes requires adherence to stringent safety protocols to prevent accidents and injuries. Some essential safety measures include:

Conducting preoperational checks to ensure equipment integrity and functionality.

Following proper load handling procedures, including weight limits, rigging techniques, and load securement.

Maintaining clear communication between crane operators and ground personnel using hand signals or radio communication.

Avoiding overloading the crane and maintaining a safe distance from overhead obstructions or electrical hazards.

Implementing lockout/tagout procedures during maintenance or repair activities to prevent accidental activation of the crane.

Compliance with Industry Standards and Regulations:

Motorized travelling overhead cranes must comply with industry standards and regulations to ensure safe operation. These standards may include:

Occupational Safety and Health Administration (OSHA) regulations in the United States, such as 29 CFR 1910.179 for overhead and gantry cranes.

European Machinery Directive (2006/42/EC) and relevant national standards in the European Union.

International standards such as ISO 124821:2014 for crane safety and ISO 43011:2016 for crane classifications and design.

Training Requirements for Crane Operators:

Proper training is essential for crane operators to operate motorized travelling overhead cranes safely and effectively. Training programs should cover:

Crane operation principles and procedures.

Load handling techniques and safe lifting practices.

Identification and mitigation of hazards associated with crane operation.

Emergency procedures and response protocols.

Operators should receive both theoretical instruction and practical handson training under the supervision of experienced personnel. Certification or licensing may be required depending on local regulations and industry standards.

Addressing Safety Concerns and Mitigating Risks:

Safety concerns associated with motorized overhead cranes may include:

Overloading: Implement load monitoring systems and conduct regular inspections to prevent overloading of the crane.

Collisions: Install collision avoidance systems and designate clear travel paths to minimize the risk of collisions with other equipment or structures.

Electrical Hazards: Ensure proper grounding and insulation of electrical components to prevent electrical shocks or fires.

Structural Integrity: Conduct periodic inspections and structural assessments to detect signs of wear, corrosion, or fatigue in crane components.

Regular safety audits, hazard assessments, and employee feedback mechanisms can help identify potential risks and implement corrective measures to mitigate them effectively.

By prioritizing safety protocols, complying with regulations, providing comprehensive training, and addressing safety concerns proactively, organizations can create a safe and productive work environment for operating motorized travelling overhead cranes. In the next part of our comprehensive guide, we'll conclude with a summary of key points and final thoughts on mastering motorized travelling overhead cranes. Stay tuned for a recap of valuable insights and recommendations for optimizing crane operations!

Conclusion

As we reach the conclusion of our comprehensive guide, let's recap the key points covered and reflect on the importance of mastering motorized travelling overhead cranes in industrial settings:

Key takeaway for your reference:

Throughout this guide, we've explored various aspects of motorized travelling overhead cranes, including:

Understanding the significance of motorized travelling overhead cranes in industrial applications.

Exploring different types of motorized travelling overhead cranes, such as bridge cranes, gantry cranes, and jib cranes.

Examining the components, functionalities, and classifications of motorized hoists used in crane systems.

Discussing the types of overhead crane motors and their suitability for different applications.

Exploring safety considerations, regulations, and training requirements for operating motorized overhead cranes.

Motorized travelling overhead cranes play a vital role in modern industrial operations, offering efficiency, precision, and safety in material handling tasks. Mastering the operation, maintenance, and safety protocols associated with these cranes is essential for maximizing productivity, minimizing downtime, and ensuring the wellbeing of workers.

As technology evolves and industries continue to innovate, there is always room for further exploration and learning in the field of motorized travelling overhead cranes. Whether it's staying updated on the latest advancements in crane technology, honing skills through continued training and certification programs, or sharing knowledge and experiences with peers in the industry, there are countless opportunities for growth and development.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch