How to Choose Right Wall Mounted Jib Crane Capacity 500kg to 5 Ton

How to choose right wall mounted jib crane capacity ( 500kg to 5 ton ) by evaluating load requirements, workspace limitations, & operational needs.

Category: Wall Crane

Your Trusted Overhead Crane Manufacturer & Supplier

How to Choose Right Wall Mounted Jib Crane Capacity 500kg to 5 Ton

How to choose right wall mounted jib crane capacity ( 500kg to 5 ton ) by evaluating load requirements, workspace limitations, & operational needs.

Overview of Wall Mounted Jib Cranes

Wall mounted jib cranes are versatile lifting devices that attach directly to a wall or a structural support, providing a cost-effective solution for handling materials and equipment in confined spaces. Unlike freestanding cranes, which require their own support structure, wall mounted jib cranes use the building's wall as a mounting point, allowing for efficient use of floor space.

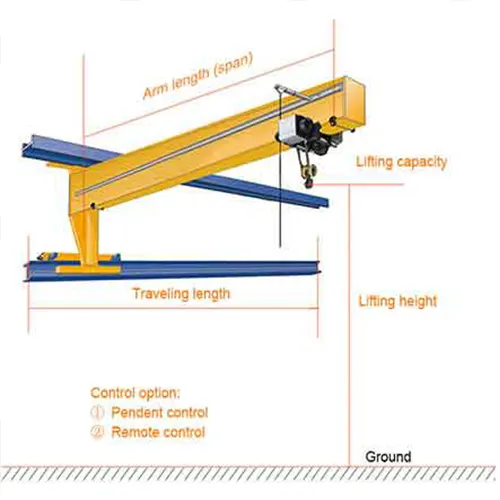

A wall mounted jib crane consists of a horizontal jib or arm that extends from a vertical mast or column, which is fixed to a wall. This configuration allows the crane to provide a range of motion within a specific area, making it ideal for tasks that require precision and accessibility. The primary purpose of these cranes is to assist with lifting and moving loads within a defined workspace, enhancing productivity and reducing manual handling efforts.

Common Applications in Various Industries

Wall mounted jib cranes are widely used across multiple industries due to their flexibility and space-saving design. Some common applications include:

- Manufacturing: In factories, these cranes facilitate the movement of parts and tools along assembly lines, helping to streamline production processes.

- Warehousing: In warehouses, they are used to lift and position inventory, improving the efficiency of storage and retrieval operations.

- Automotive: Within automotive workshops, wall mounted jib cranes assist with handling engine components, tools, and other heavy items, aiding in maintenance and repair tasks.

- Construction: They are employed on construction sites to move materials and equipment, especially in areas with limited space.

- Laboratories: In lab environments, these cranes handle delicate equipment and materials, providing precise control and reducing the risk of contamination or damage.

These applications highlight the crane's ability to adapt to various tasks and environments, making it a valuable asset for many operational settings.

Crane Capacity of Standard Wall Mounted Jib Cranes (0.5 Ton to 5 Ton)

Standard wall mounted jib cranes are versatile lifting solutions designed to handle a range of capacities from 0.5 ton to 5 tons. These cranes are ideal for applications where space is limited and precise load handling is required. Understanding the capacity options and their applications helps in selecting the right crane for specific operational needs.

Capacity Range Overview

- 0.5 Ton Wall Mounted Jib Cranes: These are typically used in light-duty applications where loads are relatively small and manageable. Ideal for tasks such as lifting small tools, components, or light materials in workshops and laboratories. Despite their lower capacity, these cranes offer precision and ease of use in confined spaces.

- 1 Ton Wall Mounted Jib Cranes: A step up from the 0.5 ton models, 1 ton wall mounted jib cranes are suitable for handling slightly heavier loads. Commonly used in small manufacturing setups, repair shops, and warehouses for lifting medium-sized parts, materials, and equipment.

- 2 Ton Wall Mounted JibCranes: These cranes handle a broader range of medium-duty tasks. They are often used in manufacturing plants, assembly lines, and distribution centers to lift and position heavier components or bulkier items. They provide a balance of capacity and maneuverability.

- 3 Ton Wall Mounted JibCranes: Designed for more demanding tasks, 3 ton wall mounted jib cranes are used in industrial environments where heavier loads are frequently handled. They are suitable for lifting large components, machinery, and substantial quantities of materials, making them ideal for automotive workshops and production facilities.

- 5 Ton Wall Mounted JibCranes: At the higher end of the standard range, 5 ton jib cranes offer robust lifting capabilities. These are commonly used in heavy-duty applications, such as large manufacturing plants, construction sites, and large-scale warehouses. They can handle significant weights and are often used for moving heavy machinery and large materials.

0.5 Ton Wall Mounted Jib Cranes

1 Ton Wall Mounted Jib Cranes

2 Ton Wall Mounted Jib Cranes1

2 Ton Wall Mounted Jib Cranes

3 Ton Wall Mounted Jib Cranes

5 Ton Wall Mounted Jib Cranes

Standard Jib Crane Specification for Your Reference

Technical Specifications of BX wall mounted cantilever Crane |

|||||||

Capacity |

t |

0.5 |

1 |

2 |

3 |

5 |

|

Valid radius |

R(m) |

3~8 |

3~8 |

3~8 |

3~8 |

3~8 |

|

Lifting height |

m |

6~30 |

6~30 |

6~30 |

6~30 |

6~30 |

|

Lifting speed |

m/min |

8(0.8/8) |

8(0.8/8) |

8(0.8/8) |

8(0.8/8) |

8(0.8/8) |

|

Trolley speed |

m/min |

10(20) |

10(20) |

10(20) |

10(20) |

10(20) |

|

Slewing speed |

r/min |

0.5~1 |

0.5~1 |

0.5~1 |

0.5~1 |

0.5~1 |

|

Slewing angle |

0°~180° |

0°~180° |

0°~180° |

0°~180° |

0°~180° |

||

Work duty |

A3~A4 |

A3~A4 |

A3~A4 |

A3~A4 |

A3~A4 |

||

Applications and Considerations

- Workspace Requirements: Ensure that the workspace is adequate for the crane's capacity and reach. Larger capacity cranes may require more space for operation and positioning.

- Load Handling: Consider the types of loads and how they will be handled. For example, a 5 ton crane might be used to lift large components or multiple items at once, whereas a 0.5 ton crane would be more appropriate for lighter, individual items.

- Safety and Maintenance: Regardless of capacity, ensure that safety features such as overload protection and regular maintenance are implemented. Proper maintenance is crucial for all capacity ranges to ensure safe and efficient operation.

- Customization Options: For specific needs, consider customizing features such as arm length and reach. Even within the standard capacity range, customization can enhance the crane's functionality to better suit particular tasks.

Choosing the right wall mounted jib crane capacity from 0.5 ton to 5 tons depends on the specific requirements of your operation. By understanding the capacity range and its applications, you can select a crane that offers the optimal balance of strength, precision, and functionality for your lifting needs.

How to Confirm Wall Jib Crane Capacity ?

Understanding Load Requirements

Assessing the Types of Loads

When selecting a wall mounted jib crane, understanding the types of loads it will handle is crucial. Loads can be categorized into two main types: static and dynamic.

- Static Loads: These are constant, unchanging loads that the crane will handle. They include items like stationary equipment or materials that are lifted and placed but not frequently moved or repositioned. For example, a wall mounted jib crane might lift and position a fixed set of tools or a pallet of materials in a warehouse.

- Dynamic Loads: These involve moving or shifting loads, which introduce additional stress on the crane. Dynamic loads can be caused by the movement of equipment or materials, such as when lifting and repositioning heavy components in a manufacturing setting. This type of load requires careful consideration of the crane's ability to handle both the weight and the forces generated during movement.

Specific Examples

To accurately assess load requirements, consider the specific items the crane will handle:

- Tools: Precision tools or heavy machinery components might require careful load assessment to ensure the crane can manage both the weight and any associated dynamic forces.

- Materials: Items like metal sheets, construction materials, or pallets must be evaluated for weight and distribution to avoid overloading the crane.

- Equipment: Heavy equipment or machinery, often found in manufacturing and automotive settings, needs to be assessed not only for weight but also for how the crane will handle the load during movement and positioning.

Determining Load Capacity Needs

Calculating the Maximum Load

To determine the appropriate crane capacity, you must calculate the maximum load the crane will need to handle. This involves:

- Weighing the Load: Accurately measure or estimate the weight of the heaviest item the crane will lift.

- Considering Additional Factors: Account for any additional factors that may affect the crane's performance, such as load weight fluctuations or the need to lift multiple items simultaneously.

Considerations for Load Distribution

Proper load distribution is essential for safe and efficient crane operation:

- Center of Gravity: Ensure that the load is evenly distributed relative to the crane's arm to avoid undue stress on the crane and wall mount.

- Load Stability: Use appropriate lifting accessories or attachments to stabilize the load and prevent tipping or swinging.

- Workspace Layout: Plan the crane's operation within the workspace to ensure that loads can be moved and positioned without excessive strain on the crane or the surrounding area.

By thoroughly assessing these factors, you can ensure that the wall mounted jib crane you select will meet your load handling needs effectively and safely.

Key Factors Influencing Crane Capacity

Frequency of Use

The frequency with which a wall mounted jib crane will be used plays a significant role in determining the appropriate crane capacity.

- High-Frequency Use: For environments where the crane will be in constant operation, such as in busy manufacturing facilities or warehouses, it's crucial to select a crane with a robust capacity to handle continuous use without strain. Frequent lifting and lowering of heavy loads can lead to wear and tear, so a crane with a higher capacity will be more durable and reliable.

- Low-Frequency Use: In settings where the crane will be used less frequently, such as in a workshop with occasional lifting tasks, the capacity requirements may be less stringent. However, the crane should still be capable of handling the maximum anticipated load safely.

Working Environment

The environment in which the crane operates impacts its capacity and overall performance:

- Indoor vs. Outdoor Usage: Indoor cranes are typically protected from the elements and can be designed with standard materials and components. Outdoor cranes, however, need to be built with additional considerations for weather resistance and durability. Rain, wind, and temperature fluctuations can affect the crane's performance and safety, so an outdoor crane may need a higher capacity or additional protective features.

- Temperature and Environmental Conditions: Extreme temperatures and environmental conditions can influence the crane's operation. For example, very high or low temperatures can affect the strength and flexibility of materials. Cranes operating in environments with high humidity, corrosive substances, or dust may require special coatings or treatments to prevent damage and maintain capacity.

Space Constraints

The available space within the operational area directly impacts the selection and placement of a wall mounted jib crane:

- Workspace Dimensions and Layout: Measure the dimensions of the workspace where the crane will be installed. The crane's arm length and the mounting height must be compatible with the space available to ensure that it can maneuver loads effectively without obstruction.

- Reach and Height Considerations: Evaluate the required reach and height of the crane. The reach is the distance from the wall to the end of the jib, and the height is the distance from the floor to the crane's lifting hook. Ensure that the crane can cover the necessary reach and lift loads to the required height while maintaining stability and safety.

By taking these factors into account, you can select a wall mounted jib crane that is well-suited to your specific operational needs, ensuring efficient performance and safety in your workspace.

Evaluating Safety Features

Importance of Safety in Crane Selection

When choosing a wall mounted jib crane, safety is a paramount consideration. The right safety features not only protect operators but also enhance the overall efficiency of operations. A crane equipped with adequate safety mechanisms reduces the risk of accidents and equipment failure, ensuring smooth and reliable performance in various working conditions.

- Impact on Operational Safety: Proper safety features help prevent accidents such as load drops, collisions, or mechanical failures, which can result in injury or damage. Implementing safety features minimizes risks and provides a safer working environment for personnel.

- Impact on Efficiency: Safety features such as overload protection and emergency stop functions contribute to operational efficiency by preventing downtime and minimizing disruptions caused by safety incidents. A well-maintained crane with reliable safety systems reduces the need for emergency repairs and ensures continuous, smooth operation.

Key Safety Features to Look For

When selecting a wall mounted jib crane, it is essential to ensure it is equipped with the following key safety features:

- Overload Protection: Overload protection systems are designed to prevent the crane from lifting loads that exceed its maximum capacity. This feature typically includes load sensors or indicators that alert operators if the load is approaching or exceeding the crane's safe working limit. By avoiding overloading, you protect the crane from potential damage and prevent accidents related to load failure.

- Emergency Stop Functions: Emergency stop functions allow for the immediate halting of crane operations in the event of an emergency. This feature can be activated by a button or switch located within easy reach of the operator or other personnel. It ensures that any sudden or unexpected issues can be addressed promptly, reducing the risk of injury and damage.

- Regular Maintenance and Inspections: Regular maintenance and inspections are crucial for keeping the crane in safe operating condition. Establish a routine maintenance schedule to check and service components such as the hoist, jib arm, and wall mount. Regular inspections help identify and address wear and tear, mechanical issues, or safety concerns before they become serious problems. This proactive approach helps maintain the crane's performance and safety over its operational life.

By carefully evaluating and ensuring these safety features are included, you can significantly enhance the safety and efficiency of your wall mounted jib crane, creating a safer and more productive work environment.

Customization and Additional Features

Custom Capacity Options

Tailoring the capacity of a wall mounted jib crane to specific needs is crucial for optimizing performance and ensuring safety. Custom capacity options allow you to adapt the crane to handle the unique demands of your operation:

- Tailoring Capacity to Specific Needs: Evaluate the maximum load and the nature of the loads your crane will handle. Customizing the crane's capacity involves selecting a model that meets or exceeds these requirements. This may include choosing a crane with a higher load rating or adjusting components to support particular weights and sizes. For example, if you frequently handle very heavy or unusually shaped items, you might need a crane with a specialized load-bearing capacity or reinforced structures to ensure safe and efficient lifting.

Wall mounted cantilever jib crane for sale, low headroom jib crane customized for you needs, hot sale capacity 0.5 ton, 1 ton, 2 ton, 3 ton, 4 ton, 5 ton

Wall mounted jib crane for sale , customized for you needs, hot sale capacity 0.5 ton, 1 ton, 2 ton, 3 ton, 4 ton, 5 ton

Optional Accessories and Enhancements

In addition to customizing capacity, various accessories and enhancements can further improve the functionality and versatility of a wall mounted jib crane:

- Rotating Heads: Rotating heads allow the jib arm to swivel, providing a wider range of motion and increased flexibility in positioning loads. This feature is particularly useful in environments where precise placement or multiple handling positions are required. It helps operators efficiently move and position loads without having to reposition the crane.

- Extended Arms: Extended arms increase the reach of the crane, allowing it to cover a larger working area. This is beneficial in spaces where the crane needs to access materials or equipment located at varying distances from the wall. Extended arms can improve workflow by reducing the need for manual handling and allowing the crane to reach further without requiring relocation.

- Additional Lifting Attachments: Consider incorporating additional lifting attachments such as hooks, clamps, or slings tailored to specific types of loads. These attachments can enhance the crane's versatility and efficiency by providing customized solutions for handling various materials.

- Auxiliary Equipment: Other enhancements, such as additional control panels or advanced safety features, can be integrated to further customize the crane's performance. For example, remote control systems can provide operators with greater flexibility and precision in controlling the crane from a distance.

By incorporating these customization options and accessories, you can optimize the performance of your wall mounted jib crane to better meet the specific requirements of your workspace, improving both efficiency and safety.

Case Studies and Examples

Real-World Applications

Examining real-world applications of wall mounted jib cranes across different industries provides valuable insights into their practical use and effectiveness. Here are some examples:

- Manufacturing Facility: In a high-volume automotive manufacturing plant, a wall mounted jib crane is used to lift and position engine components during assembly. The crane's customized capacity handles the heavy loads and its rotating head allows operators to easily maneuver parts into precise locations along the assembly line. This setup has significantly improved production speed and worker safety by reducing manual lifting and positioning efforts.

- Warehouse Operations: A large distribution warehouse utilizes wall mounted jib cranes to manage inventory. The cranes are equipped with extended arms to reach across wide shelving units and handle bulky packages. This setup has optimized storage efficiency and streamlined the process of retrieving and moving goods, reducing the time required for inventory management and minimizing physical strain on employees.

- Construction Site: On a construction site, a wall mounted jib crane is installed to lift and place building materials such as beams and concrete blocks. The crane's high reach and robust capacity enable it to handle the heavy, irregularly shaped materials. By integrating a rotating head, the crane provides flexibility in placing materials in various locations around the site, enhancing workflow and reducing the need for additional equipment.

Lessons Learned and Best Practices

The following lessons and best practices have emerged from these case studies:

- Customization is Key: Tailoring the crane's capacity and features to specific operational needs is crucial. For example, adding extended arms or rotating heads based on the workspace layout and load types can significantly enhance efficiency and flexibility.

- Regular Maintenance is Essential: Implementing a routine maintenance schedule is vital for ensuring the crane's reliability and longevity. Regular inspections and servicing help prevent unexpected breakdowns and maintain safety standards.

- Safety Features Must be Prioritized: Incorporating safety features such as overload protection and emergency stop functions is essential to prevent accidents and ensure safe operation. Adhering to safety protocols and providing training for operators helps minimize risks.

- Effective Space Utilization: Optimizing the crane's reach and positioning capabilities to fit within the available workspace enhances its effectiveness. Proper planning of crane placement and movement paths can improve overall efficiency and reduce operational constraints.

- Adaptability Enhances Performance: The ability to adapt the crane's functionality with additional accessories and custom features can address specific challenges and improve performance. For example, rotating heads and various lifting attachments can provide solutions for handling diverse load types and complex tasks.

By learning from these real-world applications and following best practices, businesses can make informed decisions when selecting and utilizing wall mounted jib cranes, leading to improved operational efficiency, safety, and productivity.

Conclusion

When selecting the ideal wall mounted jib crane, several crucial factors must be considered to ensure optimal performance, safety, and efficiency:

- Load Requirements: Assess both static and dynamic loads, and accurately determine the maximum load capacity needed for your specific applications. Consider how load distribution affects the crane's operation and stability.

- Key Influencing Factors: Evaluate the frequency of use, working environment, and space constraints. The crane's capacity must align with how often it will be used, the conditions it will operate under (indoor vs. outdoor, temperature extremes), and the physical space available (workspace dimensions, reach, and height).

- Safety Features: Prioritize safety by ensuring the crane has essential features such as overload protection, emergency stop functions, and a maintenance plan. These features protect operators and enhance the crane's reliability and performance.

- Customization and Accessories: Consider custom capacity options and additional features like rotating heads and extended arms to tailor the crane to your specific needs. These enhancements improve versatility and efficiency in various applications.

- Case Studies and Best Practices: Learn from real-world examples and implement best practices such as regular maintenance, prioritizing safety, and optimizing space utilization. These lessons help in making informed decisions and improving overall operational effectiveness.

Final Recommendations

To choose the ideal wall mounted jib crane capacity for your needs, follow these steps:

- Evaluate Your Load Requirements: Conduct a thorough assessment of the types of loads the crane will handle, including weight, frequency of movement, and dynamic forces. Calculate the maximum load capacity required and ensure the crane can accommodate these needs.

- Analyze Your Working Environment: Consider the operating conditions, such as whether the crane will be used indoors or outdoors, and any temperature or environmental factors that may affect performance. Choose a crane that is designed to withstand these conditions.

- Assess Space Constraints: Measure the available workspace and determine the required reach and height for the crane. Ensure that the crane can fit within the space while providing the necessary lifting capabilities.

- Check Safety Features: Ensure the crane includes critical safety features such as overload protection and emergency stop functions. Implement a regular maintenance and inspection schedule to keep the crane in optimal condition.

- Consider Customization Options: Explore custom capacity options and additional features that can enhance the crane's functionality. Select accessories like rotating heads or extended arms based on your specific operational requirements.

- Review Real-World Examples: Learn from case studies and best practices to understand how different configurations and features impact crane performance. Apply these insights to make an informed choice.

By carefully considering these factors and following these recommendations, you can select a wall mounted jib crane that meets your operational needs effectively, ensuring safe and efficient performance in your workspace.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch