Manual Powered Single Girder Overhead Suspended Crane for Safety

Eco-friendly, manual operation crane designed for hazardous and off-grid environments, offering safe, reliable, and cost-effective material handling solutions.

Category: Single Girder Overhead Crane

Your Trusted Single Girder Overhead Crane Manufacturer & Supplier

Manual Powered Single Girder Overhead Suspended Crane

A Reliable Solution for Hazardous and Off-Grid Environments

Introduction:Manual Powered Single Girder Overhead Suspended Crane

The Manual Powered Single Girder Suspended Crane is a type of manual bridge crane which offers a reliable and efficient lifting solution for environments where electricity is unavailable or where safety concerns are paramount. It is designed to provide safe, simple, and durable operation in hazardous areas or non-electric workshops.

Versatility for Non-Electric Environments

- Ideal for workshops without access to electrical power.

- Operates manually, making it perfect for off-grid facilities.

- Reduces the need for electric-powered systems, lowering energy costs.

This crane is an excellent choice for industries that need lifting equipment in areas without electrical connections. It ensures smooth operation and precise handling of loads without relying on power sources.

Suitability for Hazardous Environments

- Safe for use in explosive or flammable environments.

- Built to minimize electrical hazards, ensuring safer operations.

- Simple hand-pulled chain drive system for reliable performance.

In addition to its suitability for non-electric spaces, this crane is designed to perform safely in environments where electricity may pose a risk. Its manual operation helps reduce the chances of electrical accidents, making it ideal for chemical plants, warehouses, and similar hazardous environments.

Durability and Efficiency

- Sturdy and durable design for tough working conditions.

- Easy to install and maintain.

- Cost-effective solution with low operational costs.

This crane is built to withstand challenging conditions, offering long-lasting performance with minimal maintenance requirements. It's a cost-effective option for industries looking to maintain safety and productivity without relying on electricity.

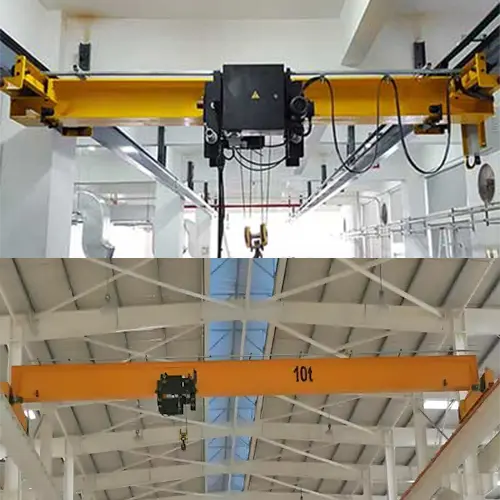

manual powered single girder overhead suspended crane

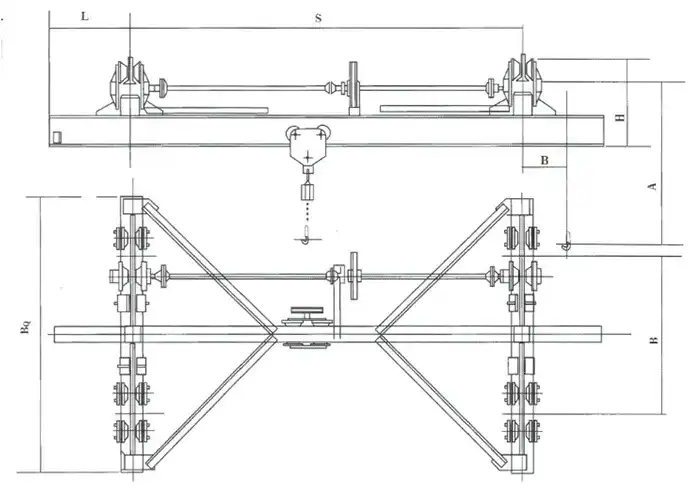

manual powered single girder overhead suspended crane drawing

Key Features

Lifting Capacities

The Manual Powered Single Girder Suspended Crane offers versatile lifting capabilities to suit various needs.- Available in lifting capacities of 1 ton, 2 tons, 3 tons, and more.

- Capable of handling a range of loads with ease, catering to different industrial applications.

This crane is designed to provide reliable performance in both light and heavy-duty lifting tasks, ensuring it meets the demands of your operations.

Manual Operation for Eco-Friendly and Cost-Effective Solutions

This crane operates manually, providing several advantages over electric-powered alternatives.

- Eliminates the need for electrical power, reducing energy consumption.

- Lowers operational costs by avoiding electricity-related expenses.

- An eco-friendly solution for industries looking to reduce their carbon footprint.

Ideal for facilities on a budget or without access to electricity, it offers a cost-effective, energy-efficient lifting option.

Designed for Flammable or Explosive Environments

Built to meet the needs of industries that require safe lifting equipment in hazardous environments.

- Specifically designed for use in environments where electrical systems could pose a risk, such as chemical plants or explosive areas.

- Provides safe, reliable operation in critical environments where safety standards must be strictly followed.

This crane is an ideal choice for industries that require specialized lifting solutions in risky or flammable areas.

Simple Yet Effective Hand-Pulled Chain Drive System

The crane features a straightforward hand-pulled chain system, ensuring ease of use and efficiency.

- The manual chain drive mechanism is simple and effective, providing reliable control.

- Easy to operate and maintain with minimal complexity.

- Smooth and controlled movement of loads, enhancing safety and efficiency.

This design ensures that the crane remains user-friendly while offering reliable lifting power.

Track-Mounted for Easy Movement Within the Workspace

Designed with a track-mounted system for easy and efficient maneuverability.

- Allows for smooth movement along the tracks, making it easier to navigate the workspace.

- Perfect for areas with limited space, improving workflow and productivity.

- Ideal for workshops or factories where space is tight and maneuverability is crucial.

This feature ensures the crane is adaptable to various workspace layouts, making it a versatile option for many industrial settings.

Components and Design

Main Components

The Manual Powered Single Girder Suspended Crane is made up of several key components that work together to provide reliable lifting performance.- Main Beam: The central support structure that bears the load during lifting operations.

- Trolley Running Mechanism: Ensures smooth movement of the manual trolley along the beam.

- Manual Trolley (Cat Head Hoist): Holds and moves the load across the beam with manual operation.

- Hand Chain Hoist: Provides the lifting power through a hand-pulled chain system.

Each component is carefully selected to provide the best performance for manual lifting tasks.

Quality Materials for Durability and Performance

The crane is constructed using high-quality, industrial-grade materials that ensure it can handle tough working conditions over time.

- Designed to resist wear, corrosion, and other environmental challenges.

- Materials chosen for their strength and durability under heavy loads.

- Minimizes the need for frequent maintenance, ensuring long-lasting reliability.

The use of superior materials guarantees the crane's performance in demanding environments, reducing downtime and increasing operational efficiency.

Structural Integrity for Safety and Reliability in Tough Environments

The crane's design is focused on safety and reliability, especially in challenging work environments.

- Reinforced structure to withstand heavy loads and maintain stability.

- Strong connections and joints to prevent failure during operation.

- Engineered for use in hazardous and tough environments, ensuring safety at all times.

This design ensures that the crane operates safely and reliably, even in tough or hazardous environments, making it a dependable choice for various industrial applications.

Applications

Ideal for Use in Non-Electric Workshops, Hazardous Areas, and Explosive Environments

The Manual Powered Single Girder Suspended Crane is designed for use in environments where electrical power is unavailable or where safety is a top priority.- Perfect for workshops and factories without electrical connections.

- Safe for use in hazardous areas where electrical systems could pose risks, such as chemical plants, oil refineries, and explosive environments.

This crane is a dependable solution for industries that operate in challenging conditions, offering safety and reliability without the need for electricity.

Suitable for Industries Such as Manufacturing, Chemical Processing, and Warehouses

The versatility of the Manual Powered Single Girder Suspended Crane makes it suitable for a wide range of industries, including:

- Manufacturing: Efficiently handles assembly line tasks and material movement.

- Chemical Processing: Safe for use in environments where chemicals and flammable materials are present.

- Warehouses: Ideal for lifting and transporting goods in storage areas, improving overall productivity.

Its adaptability makes it a valuable asset across various sectors, ensuring safe and efficient lifting in diverse applications.

Benefits

Cost-Effective and Energy-Efficient Manual Operation

The manual hand chain operation offers significant cost and energy savings.

- No electricity required: Operates without the need for electrical power, reducing energy consumption.

- Lower operational costs: Eliminates the need for expensive energy sources, making it ideal for budget-conscious businesses.

This cost-effective feature makes the crane an ideal solution for industries looking to minimize their energy expenses.

Safe and Reliable Operation in Hazardous and Off-Grid Environments

Designed to provide safe and reliable lifting in challenging environments.

- Safe for hazardous areas: Ideal for environments where electrical equipment could pose risks, such as chemical plants or explosive zones.

- Perfect for off-grid facilities: Works efficiently in locations without electrical power, providing a safe lifting solution in remote areas.

This crane ensures that lifting operations are conducted safely, even in the most difficult conditions.

Easy Installation and Minimal Maintenance

The crane is designed for straightforward installation and requires minimal ongoing maintenance.

- Quick installation: Setup is simple, and professional assistance is available if needed.

- Low maintenance: Regular inspections and lubrication are enough to keep the crane functioning smoothly.

These features make the crane an excellent choice for businesses looking for low-maintenance equipment.

Long-Lasting Durability and Low Operational Costs

Built to last, the Manual Powered Single Girder Suspended Crane offers durability and low ongoing costs.

- Durable construction: Made with high-quality materials to withstand the rigors of daily use.

- Low operational costs: Manual operation and minimal maintenance reduce the overall cost of ownership.

This crane provides excellent value, with long-term durability and minimal maintenance requirements.

Why Choose This Single Girder Manual Overhead Bridge Crane?

Advantages Over Electric Cranes in Certain Environments

The Manual Powered Single Girder Suspended Crane offers several advantages over electric cranes, especially in specific environments:- No electrical hazards: Ideal for use in hazardous or explosive environments where electrical equipment could pose safety risks.

- Works in off-grid locations: Does not require an external power source, making it perfect for facilities without access to electricity.

- Lower operational costs: Eliminates energy consumption associated with electric cranes, reducing long-term expenses.

These features make this crane a practical and safe choice for challenging workspaces.

Built for Specific Industrial Applications, Offering High Value

This crane is designed with specific industrial needs in mind, offering exceptional value to businesses:

- Tailored for diverse industries: From manufacturing to chemical processing, it's adaptable to a variety of environments.

- Efficient material handling: Perfect for small to medium-sized lifting tasks, enhancing workflow and productivity in industrial settings.

- Long-lasting performance: Designed for durability, ensuring reliable operation in harsh environments.

Its versatility and reliable performance make it a great investment for businesses looking for a durable and effective lifting solution.

Expert Manufacturing and Adherence to National Standards

Manufactured with precision and care, this crane adheres to national standards for safety and quality.

- Quality materials ensure the crane meets high-performance and safety standards.

- Expert craftsmanship guarantees reliability and durability throughout its operational life.

- Strict adherence to standards ensures that the crane complies with regulations, providing peace of mind for businesses.

With expert manufacturing and compliance with national standards, you can trust this crane for dependable performance.

Technical Specifications of SDXQ Type Manual Powered Single Girder Suspended Overhead Crane

| Lifting Capacity(T) | 0.5 Ton | 1 Ton | 2 Ton | 3 Ton | ||||||||||||

| Span(M) | 3~5 | 5.5~8 | 9~10 | 11~12 | 3~5 | 5.5~8 | 9~10 | 11~12 | 3~5 | 6~8 | 9~10 | 11~12 | 3~5 | 6~8 | 9~10 | 11~12 |

| Lifting Height(M) | 2.5-12 | 2.5-12 | 3-12 | 3-12 | ||||||||||||

| Rail | 120a-130c | 120a-130c | 124a-136c | 124a-136c | ||||||||||||

| Hoist Trolley | SDX-3.WA1/2 | SDX-3.WA1 | SDX-3.WA2 | DX-3.WA3 | ||||||||||||

| Manual Hoist | HS1/2 | HS1 | HS2 | HS3 | ||||||||||||

SDXQ Model Manual Single-Girder Suspension Crane Technical Parameters and Dimensional Chart

| Lifting Capacity (t) | Span (m) | Crane Weight (Kg) | Max. Wheel Presure (Kn) | Basic Dimensions(mm) | Traction force | |||||||

| H | B | BQ | A | S1 | L | Lifitng (kg) | Crane (kg) | Hoist (kg) | ||||

| 0.5 Ton | 3 | 451 | 1.98 | 525 | 1000 | 1516 | 746 | 805 | 1000 | 19.5 | 6 | 3 |

| 3.5 | 466 | 2.00 | ||||||||||

| 4 | 478 | 2.01 | ||||||||||

| 4.5 | 490 | 2.02 | ||||||||||

| 5 | 501 | 2.04 | ||||||||||

| 5.5 | 602 | 2.20 | 585 | 1200 | 1716 | 800 | 1005 | 1200 | ||||

| 6 | 642 | 2.21 | ||||||||||

| 7 | 678 | 2.26 | ||||||||||

| 8 | 714 | 2.32 | ||||||||||

| 9 | 872 | 2.54 | 605 | 1500 | 2016 | 820 | 1205 | 1400 | ||||

| 10 | 913 | 2.59 | ||||||||||

| 11 | 1078 | 2.76 | 635 | 1700 | 2216 | 850 | ||||||

| 12 | 1127 | 2.81 | ||||||||||

| 3 | 470 | 3.40 | 545 | 1000 | 1516 | 816 | 852 | 1000 | 21 | 9 | 5 | |

| 3.5 | 500 | 3.50 | ||||||||||

| 4 | 514 | 3.52 | ||||||||||

| 4.5 | 527 | 3.54 | ||||||||||

| 5 | 541 | 3.55 | ||||||||||

| 5.5 | 677 | 3.73 | 605 | 1200 | 1716 | 870 | 1052 | 1200 | ||||

| 6 | 698 | 3.75 | ||||||||||

| 7 | 740 | 3.85 | ||||||||||

| 8 | 780 | 3.86 | ||||||||||

| 9 | 1012 | 4.03 | 665 | 1500 | 2016 | 903 | 1252 | 1400 | ||||

| 10 | 1063 | 4.21 | ||||||||||

| 11 | 1393 | 4.80 | 745 | 1700 | 2216 | 1000 | ||||||

| 12 | 1551 | 4.90 | ||||||||||

| 2 Ton | 3 | 567 | 6.41 | 585 | 1200 | 1726 | 1150 | 560 | 800 | 32.5 | 12 | 11 |

| 3.5 | 586 | 6.44 | ||||||||||

| 4 | 605 | 6.46 | ||||||||||

| 4.5 | 622 | 6.48 | ||||||||||

| 5 | 639 | 6.50 | ||||||||||

| 5.5 | 824 | 6.76 | 665 | 1500 | 2026 | 1227 | 760 | 1000 | ||||

| 6 | 860 | 6.80 | ||||||||||

| 7 | 902 | 6.85 | ||||||||||

| 8 | 954 | 6.90 | ||||||||||

| 9 | 1186 | 7.21 | 745 | 1700 | 2226 | 1305 | 960 | 1200 | ||||

| 10 | 1250 | 7.26 | ||||||||||

| 11 | 1605 | 8.88 | 780 | 1700 | 2426 | 1345 | ||||||

| 12 | 1674 | 8.90 | ||||||||||

| 3 Ton | 3 | 831 | 4.90 | 566 | 1200 | 2126 | 1284 | 340 | 600 | 34.5 | 15 | 13 |

| 3.5 | 864 | 4.92 | ||||||||||

| 4 | 884 | 4.94 | ||||||||||

| 4.5 | 901 | 4.96 | ||||||||||

| 5 | 928 | 4.98 | ||||||||||

| 5.5 | 1244 | 5.58 | 706 | 1500 | 2426 | 1422 | 540 | 800 | ||||

| 6 | 1279 | 5.60 | ||||||||||

| 7 | 1347 | 5.64 | ||||||||||

| 8 | 1416 | 5.66 | ||||||||||

| 9 | 1637 | 6.23 | 746 | 1700 | 2626 | 1460 | 740 | 1000 | ||||

| 10 | 1712 | 6.30 | ||||||||||

| 11 | 1966 | 6.42 | 796 | 1508 | ||||||||

| 12 | 2047 | 6.50 | ||||||||||

Available Models: The Manual Powered Single Girder Suspended Crane comes in the following models, each designed to meet specific operational needs:SDXQ-3 Model. These models offer different features and configurations to cater to various lifting requirements.

Lifting Capacity Range: The crane is available in a range of lifting capacities to handle various load sizes:

- Lifting capacities from 1 ton to 3 tons, ensuring suitability for light to medium-duty lifting tasks.

- Offers flexibility to accommodate different types of loads, from small components to heavier items.

Power System: This crane operates through a manual hand chain drive system, providing an eco-friendly and cost-effective lifting solution:

- No need for electricity, reducing energy costs and ensuring safe operation in hazardous environments.

- Simple and effective hand-pulled chain mechanism for smooth load movement.

Track-Mounted Design for Ease of Movement: The crane features a track-mounted design, allowing it to move smoothly along the tracks:

- Enhances mobility within the workspace, making it ideal for facilities with limited space.

- Allows for precise handling of loads across the workspace with minimal effort.

Production Standards: The crane is manufactured according to National Standard production guidelines:

- Built to meet high safety and quality standards for industrial equipment.

- Ensures reliability and durability in various environments, from manufacturing to hazardous areas.

Customization Options

Non-Standard Customizations Available

The Manual Powered Single Girder Suspended Crane offers a range of customization options to suit unique operational requirements.

- Non-standard designs can be created to meet specific needs, ensuring the crane fits perfectly within your facility.

- Tailor the crane's features, such as lifting capacities, beam lengths, and track configurations, to meet specific industry demands.

Tailored to Meet Specific Operational Needs and Facility Requirements

Customization ensures that the crane operates efficiently and effectively in your particular workspace:

- Customized lifting capacity options available to handle loads beyond standard models.

- Track systems and beam designs can be adjusted for unique facility layouts, optimizing space and movement.

- Additional safety features can be integrated to meet specific safety standards or environmental conditions.

With these customizations, you can ensure that your crane is designed for maximum efficiency and safety, no matter the complexity of your operational environment.

Installation and Maintenance

Installation Options and Additional Charges

The Manual Powered Single Girder Suspended Crane offers various installation options to suit your needs.

- Installation services can be arranged for an additional charge to ensure proper setup and functionality.

- Installation is typically straightforward but may require adjustments depending on your facility's layout and crane configuration.

- Additional charges for installation depend on the complexity of the crane setup and location.

Professional installation guarantees the crane is correctly set up to perform at its best.

Maintenance Requirements for Optimal Performance and Longevity

To maintain optimal performance and extend the lifespan of the crane, regular maintenance is recommended.

- Routine inspections: Check the hand chain drive system, trolley, and tracks regularly for wear and tear.

- Lubrication: Moving parts should be lubricated to prevent friction and maintain smooth operation.

- Structural checks: Inspect all structural components for any damage or signs of wear to ensure safety and reliability.

Regular maintenance minimizes downtime and ensures that the crane operates efficiently over time.

One-Year Warranty for Peace of Mind

The crane comes with a one-year warranty to provide assurance of its quality and performance.

- Covers defects in materials and workmanship during the warranty period.

- Includes troubleshooting, repairs, and replacement of defective parts.

The warranty ensures that your investment is protected and that the crane remains operational for years to come.

Ordering Information

Contact Details for Inquiries and Orders

To inquire about the Manual Powered Single Girder Suspended Crane or place an order, you can reach us by leaving a message down below. Our sales team is available to assist with inquiries, provide quotes, and guide you through the ordering process.

Delivery Timelines and Customized Production Options

We offer customized production options to meet your unique requirements.

- Delivery timelines typically range from [insert time period] based on the specifics of your order.

- Customized production is available for specific configurations, lifting capacities, and additional features, ensuring the crane suits your exact needs.

For exact delivery schedules, please contact us directly.

After-Sales Service

One-Year Warranty

To ensure the ongoing performance of your crane, it comes with a one-year warranty, covering:

- Defects in materials or workmanship during the warranty period.

- Free repairs or replacements for any issues covered under the warranty.

This warranty ensures that you have support and peace of mind after your purchase.

Ongoing Support and Maintenance Guidance

We offer continued support even after the warranty period:

- Maintenance guidance: Our team provides useful tips and advice for keeping your crane in top working condition.

- Customer support: Our customer service team is available to assist with any technical issues or operational concerns.

With our ongoing support, you can ensure the crane's longevity and continued optimal performance.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch