10-Ton Overhead Crane for Automotive Mold Handling

Streamline automotive production with 10-ton overhead cranes for handling large injection molds, improving efficiency, safety, and mold lifespan.

Category: Auto

Overview of Injection Molding in the Automotive Industry

Injection molding plays a vital role in the automotive industry for producing essential car parts, including:Bumpers,Dashboards,Interior trim components, etc.

This process involves injecting molten material (such as plastic or metal) into molds to create car parts with precise shapes and dimensions. Injection molds in automotive manufacturing are often large, heavy, and complex, requiring specialized handling to maintain production efficiency and product quality.

Role of Overhead Cranes

Overhead die lifting cranes are essential for moving and positioning large molds in the automotive industry. These cranes help streamline the production process by:

- Lifting and transporting molds safely

- Reducing production delays

- Minimizing mold wear and tear

Efficient handling by overhead cranes ensures that molds are in the right place at the right time, contributing to smooth and continuous production.

Need for Specialized Equipment in Automotive Manufacturing

Handling large, heavy molds comes with specific challenges:

- Heavy weight: Molds can range from a few hundred kilograms to over two tons.

- Precise handling: Molds must be handled carefully to avoid damaging their intricate design, which can affect part quality.

Advantages of 10-Ton Overhead Cranes

A 10-ton overhead crane is well-suited for automotive manufacturing because it:

- Offers enough lifting capacity to handle large, heavy molds.

- Provides the precision needed to handle delicate molds without damaging them.

- Increases efficiency by safely moving molds across large factory spaces.

With the use of 10-ton overhead cranes, automotive manufacturers can improve production efficiency, minimize downtime, and ensure the high quality of molded parts.

Key Considerations for 10-Ton Overhead Crane in Automotive ManufacturingWeight and Size of Large Injection Molds

Injection molds used for automotive parts, such as bumpers, dashboards, and other components, vary in weight and size. Here are some key points:

- Weight Range: Automotive molds typically weigh between 500 kg to 2,500 kg (1,100 lbs to 5,500 lbs), depending on the complexity and size of the mold.

- Dimensions and Shape Variations: Molds can range from compact designs for small components to large, intricate shapes for complex car parts. Their size and shape can vary greatly, influencing the type of lifting equipment needed.

A 10-ton overhead crane is designed to handle these heavy molds, ensuring that they can be moved safely and efficiently without risk of damage or instability.

Precision Handling Needs

When dealing with large, delicate molds, precision is crucial. Here's why:

- Delicate Lifting and Lowering: Injection molds are often made from materials like steel or aluminum and feature complex, detailed surfaces. It's essential to handle them gently to avoid scratches, dents, or misalignment.

- Precise Load Positioning: During the production cycle, the molds must be positioned accurately in different stations, such as the injection machine, cooling areas, or storage. A 10-ton overhead crane offers precise control over lifting and lowering, ensuring that molds are correctly placed.

This precision is necessary for minimizing downtime, preventing mold damage, and maintaining the quality of the final car parts.

Factory Layout and Space Constraints

Factory layouts play a significant role in determining the right crane for mold handling:

Impact of Factory Design: In many automotive manufacturing facilities, space is limited, and molds need to be moved efficiently across large areas. Factory layouts with narrow aisles or low headroom may restrict the use of certain types of cranes.

Benefits of 10-Ton Overhead Cranes:

- Space Efficiency: Overhead cranes, like the 10-ton model, operate above the factory floor, allowing for optimal use of floor space.

- Flexibility: These cranes can navigate tight spaces and move molds across multiple production zones, improving workflow and minimizing the need for multiple handling steps.

In facilities with space constraints, a 10-ton overhead crane offers both flexibility and efficiency, ensuring that molds can be moved safely without crowding the production area.

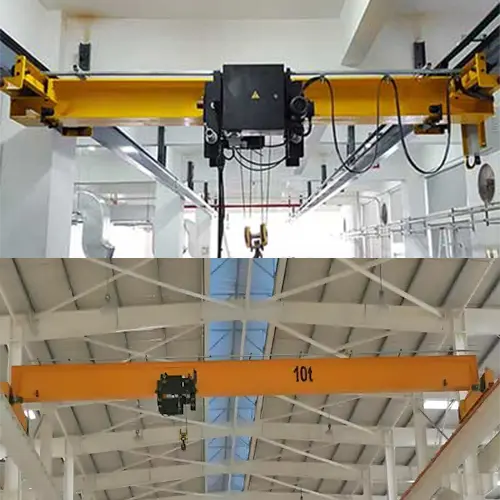

10 ton overhead cranes for sale, customized 10 ton crane for your needs

Types of Molds and Dies Handled by 10-Ton Overhead Cranes

Injection Molds for Car Parts

In the automotive industry, a variety of injection molds are used to produce parts like bumpers, dashboards, and interior components. A 10-ton overhead crane is ideal for handling these molds due to:

- Molds for Bumpers: Large and heavy, bumpers typically require careful handling to avoid damage to the mold's surface and internal components.

- Dashboards and Interior Components: These molds can be intricate, involving complex shapes and designs that need precise positioning and lifting.

A 10-ton crane can efficiently lift and position these molds, providing the necessary weight capacity and control to ensure smooth handling during production processes.

Handling Multiple Molds Simultaneously

In high-production environments, handling multiple molds simultaneously is a common requirement. A 10-ton overhead crane is capable of lifting and managing several smaller molds at once. Key points include:

- Increased Efficiency: With the ability to lift and move multiple molds, production time is reduced, leading to more streamlined operations.

- Flexible Lifting: The crane can be equipped with various attachments, like spreader beams or custom lifting hooks, allowing it to handle several molds simultaneously.

Using a 10-ton overhead crane for multiple mold handling boosts efficiency, especially in high-volume automotive production settings where time is critical.

Lifting and Transporting Heavy Molds

Transporting large and heavy molds across the factory floor can be challenging, but a 10-ton overhead crane simplifies this process. Some of the challenges addressed by this crane include:

- Moving Large Molds: Molds for large car parts, such as body panels or engine components, can weigh over a ton, and the crane must provide the capacity to safely lift and move them.

- Navigating the Factory Floor: Large molds often require movement across different areas, from molding machines to cooling stations or storage. A 10-ton overhead crane's flexibility allows for smooth, efficient transport of these heavy molds, reducing risk and downtime.

Overall, the 10-ton crane excels in moving heavy molds throughout the production facility, ensuring safety and efficiency while minimizing handling issues.

Recommended Features for 10-Ton Overhead Cranes

Load Capacity and Reach

A 10-ton overhead crane is perfectly suited for handling heavy automotive molds due to its balanced load capacity and reach. Key features include:

- Load Capacity: With a lifting capacity of 10 tons, this crane can easily handle the weight of large automotive molds, such as bumpers, dashboards, and body panels, which typically range from 500 kg to 2,500 kg (1,100 lbs to 5,500 lbs).

- Reach and Lifting Height: The crane's reach should be sufficient to cover the entire production area. It should be able to lift molds to varying heights, from the floor to the top of production equipment, depending on the factory layout. A longer reach ensures the crane can transport molds across the factory efficiently without obstruction.

Choosing a 10-ton overhead crane with proper load capacity and reach guarantees that large molds are safely and effectively lifted, transported, and positioned throughout the production facility.

Control Systems for Precision

Precision handling is critical in automotive mold production, where even the slightest misalignment can cause damage to expensive molds or slow down the production process. The crane's control systems should include:

- Load Positioning and Movement Control: Overhead cranes with advanced control systems enable precise load movement and positioning. This is especially important when handling delicate automotive molds that require careful maneuvering.

- Variable Frequency Drives (VFD): VFDs are commonly integrated into modern overhead cranes to provide smooth and gradual acceleration and deceleration during lifting operations. This ensures safe and controlled movements of heavy molds and minimizes the risk of damage during lifting and lowering cycles.

The ability to precisely control the crane's movement improves production efficiency, reduces the risk of mold damage, and supports seamless integration into the overall manufacturing process.

Safety Features

Safety is a primary concern in any industrial environment, especially when dealing with heavy molds in an automotive production setting. Essential safety features for a 10-ton overhead crane include:

- Load Limiters: These ensure that the crane does not exceed its rated capacity, preventing overloading and potential crane failure.

- Emergency Stop Functions: An easily accessible emergency stop button or system provides a safety mechanism to stop crane movement immediately in case of unexpected situations, preventing accidents or damage.

- Anti-Sway Systems: These systems are particularly important when transporting large, heavy molds across the factory floor. They reduce the swinging of loads, ensuring that molds are safely transported without collision or damage.

These safety features are critical in maintaining safe operations, reducing risks to workers, and ensuring that the mold handling process remains efficient and accident-free.

Benefits of Using a 10-Ton Overhead Crane in Automotive Manufacturing

Increased Efficiency

Using a 10-ton overhead crane significantly improves the speed of mold handling and movement within the automotive production line. Key benefits include:

- Faster Mold Handling: The crane's powerful lifting capacity allows molds to be moved quickly between stations, reducing the time spent on lifting and transporting. This results in faster production cycles.

- Streamlined Operations: With efficient mold transport, workers can focus on other tasks, further improving overall factory efficiency and throughput.

Faster mold handling directly translates into reduced cycle time, which is crucial in high-volume automotive manufacturing.

Reduced Mold Wear

Handling molds with care is essential to prolong their lifespan and ensure high-quality production. A 10-ton overhead crane offers the following benefits:

- Precise and Gentle Handling: With advanced control systems, the crane provides smooth and precise lifting, reducing the risk of mold damage during transport.

- Protection from Impacts: Anti-sway systems minimize mold movement, preventing collisions with other equipment or workers, which could cause wear or damage.

Reducing mold wear is vital for minimizing replacement costs and maintaining production efficiency.

Improved Production Reliability

A reliable crane system helps reduce downtime and ensures consistent mold handling throughout the production cycle. Benefits include:

- Reduced Equipment Failures: With regular maintenance and robust design, 10-ton overhead cranes reduce the likelihood of mechanical issues or breakdowns, ensuring reliable operation.

- Decreased Mold Handling Delays: With high lifting capacity and control, the crane minimizes delays in transporting molds between different stages of production, ensuring smooth operations.

Having a reliable crane reduces costly downtime and ensures the production line remains operational, improving overall production reliability.

Enhanced Flexibility

A 10-ton overhead crane offers exceptional versatility, making it ideal for handling a variety of molds in automotive manufacturing. Key points include:

- Ability to Handle Different Mold Sizes: The crane can easily accommodate molds of various sizes, from smaller, intricate components to large automotive parts like bumpers and dashboards.

- One Crane for Multiple Applications: Instead of needing multiple cranes, a single 10-ton overhead crane can handle different types of molds and production requirements, providing flexibility to adapt to changing manufacturing needs.

This flexibility allows manufacturers to maximize the crane's use, reducing the need for multiple lifting solutions and optimizing factory space.

Case Study Example

Real-World Example of 10-Ton Overhead Crane Use in Automotive Manufacturing

Company Background: An automotive parts manufacturer specializing in the production of bumpers, dashboards, and other essential car components. The company faced challenges with mold handling due to the large size and weight of the molds, which ranged from 500 kg to 2,500 kg. They were looking for a crane solution that could enhance their production efficiency, mold lifespan, and safety on the factory floor.

Challenge: The company struggled with inefficiencies in moving large molds between workstations. There were also concerns about mold damage during handling, particularly for the more intricate molds used for automotive interiors. Additionally, the factory layout, with space constraints, required a crane system that could operate in tight areas and still carry heavy loads.

Solution: The manufacturer decided to implement a 10-ton overhead crane system designed for heavy-duty lifting in confined spaces. The crane was equipped with advanced features, including:

- Variable Frequency Drives (VFD) for smooth control of the crane's movements.

- Anti-sway systems to minimize the potential for mold damage during transportation.

- Precision control to ensure exact positioning of molds during assembly and other critical processes.

Results:

- Increased Production Efficiency: The 10-ton overhead crane allowed the company to move molds quickly between production stations. This reduced mold handling time, leading to shorter production cycles and more efficient use of factory resources.

- Reduced Mold Wear: With smooth, controlled lifting and lowering, the company saw a significant reduction in mold damage. The precision control ensured that even delicate molds were handled without risk of impact or stress.

- Improved Safety: The crane's safety features, such as overload protection and emergency stop functions, helped reduce workplace accidents. The smooth operation and enhanced operator control minimized the risk of injuries.

- Enhanced Reliability: The robust crane system reduced maintenance downtime and improved the overall reliability of the production process, ensuring that operations could run without interruptions due to mold handling issues.

Key Benefits Observed:

- Increased Efficiency: Faster mold transport and handling led to shorter cycle times and more units produced daily.

- Extended Mold Lifespan: Reduced wear and tear on molds, which in turn, lowered mold replacement costs.

- Improved Workplace Safety: Fewer accidents and safer handling operations created a better working environment for employees.

- Greater Flexibility: The ability to handle multiple mold sizes and types with a single crane system improved production flexibility and cost-effectiveness.

This case study demonstrates the clear advantages of using a 10-ton overhead crane in automotive manufacturing, showing how the right lifting equipment can lead to enhanced productivity, better safety, and a longer lifespan for molds.

Conclusion

Final Thoughts on 10-Ton Overhead Cranes for the Automotive Sector

The 10-ton overhead crane has proven to be an invaluable tool in automotive manufacturing, especially when handling large and heavy injection molds. By providing precise control, reliability, and efficiency, these cranes significantly enhance the mold handling process, which is crucial in automotive production. Key benefits include:

- Enhanced Efficiency: Faster mold handling reduces production cycle times.

- Reduced Mold Wear: Protecting molds from damage increases their lifespan.

- Improved Safety: Safety features help ensure the protection of workers and equipment.

- Increased Flexibility: The crane system's adaptability allows for handling various mold sizes and types, making it suitable for diverse production needs.

How Investing in the Right Overhead Crane System Can Enhance Overall Manufacturing Performance

Investing in the right crane system, like the 10-ton overhead crane, can have a profound impact on manufacturing performance. By optimizing the handling of large molds, manufacturers can achieve:

- Greater Production Throughput: Faster and more efficient mold handling reduces bottlenecks, leading to higher output.

- Cost Savings: By minimizing mold damage and reducing downtime, manufacturers can lower repair and replacement costs.

- Improved Workplace Efficiency: With streamlined processes, employees can focus on higher-value tasks rather than dealing with mold handling issues.

The right crane system is not just a tool but an integral part of an automotive manufacturer's overall operational strategy.

Recommendations for Selecting and Implementing a 10-Ton Overhead Crane in Automotive Manufacturing

- Evaluate Mold Handling Needs: Assess the weight, size, and complexity of the molds to determine the crane's required capacity and features.

- Consider Factory Layout: Ensure the crane can operate efficiently in the available space, especially in areas with limited headroom or confined spaces.

- Prioritize Safety Features: Look for cranes with advanced safety systems such as overload protection, anti-sway systems, and emergency stops.

- Opt for Precision Control: Choose cranes with fine-tuned control for handling delicate and intricate molds with accuracy.

- Maintenance and Support: Select a crane system from a reliable supplier that offers strong after-sales support and maintenance services to minimize downtime.

By making informed decisions and selecting the right overhead crane, automotive manufacturers can optimize their mold handling process, improve production efficiency, and ensure the longevity of their equipment and molds.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch